How to Identify and Measure Fittings

Pipe size is an industry designation, not the actual size. View information about how to measure threaded and unthreaded pipe and pipe fittings.

More

About Loc-Line and Snap-Loc Coolant Hose

Assemble and disassemble Loc-Line and Snap-Loc coolant hose by snapping components together or pulling them apart. Assembly and separation tools (sold separately) are recommended.

To ensure compatibility, select the color and trade size that match your current system. A system’s trade size is equal to the ID of its hose.

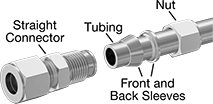

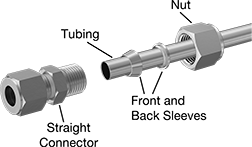

Yor-Lok Fittings for Stainless Steel Tubing

A nut with two sleeves (ferrules) gives these fittings extra gripping power. The sleeves bite into tubing as you tighten the nut, creating a strong seal. Also known as instrumentation fittings, they are made to tight tolerances for use in high-precision applications. They are compatible with Swagelok®, Let-Lok, and A-Lok fittings.

316 stainless steel fittings have excellent corrosion resistance.

- For Use With: Air, Cutting Oil, Fuel Oil, Gasoline, Hydraulic Fluid, Mineral Oil, Steam, Water

- Tubing: Use with welded or seamless 304/304L or 316/316L stainless steel that meets ASTM A213, ASTM A249, or ASTM A269

Fittings with standard barbed hose end connect to hose with a hose clamp (sold separately).

For Tube | |||||||

|---|---|---|---|---|---|---|---|

| OD, mm | Wall Thick., mm | For Hose ID | Material | Max. Pressure | Temp. Range, °F | Each | |

| 4 | 1 | 1/4" | 316 Stainless Steel | 300 psi @ 72° F | -40° to 200° | 00000000 | 000000 |

| 6 | 1 | 1/4" | 316 Stainless Steel | 300 psi @ 72° F | -40° to 200° | 00000000 | 00000 |

| 10 | 0.5 to 2 | 1/2" | 316 Stainless Steel | 300 psi @ 72° F | -40° to 200° | 00000000 | 00000 |

| 10 | 1 to 1.5 | 3/8" | 316 Stainless Steel | 300 psi @ 72° F | -40° to 200° | 00000000 | 00000 |

- For Use With: Air, Cutting Oil, Fuel Oil, Gasoline, Hydraulic Fluid, Mineral Oil, Water

- Tubing: Use with welded or seamless 304/304L or 316/316L stainless steel that meets ASTM A213, ASTM A249, or ASTM A269

Fittings with push-on barbed hose end have sharper barbs than standard barbed hose fittings to grip reinforced rubber push-on hose with no clamps required. The more you pull on the fittings, the tighter the hose will grip.

- For Use With: Air, Cutting Oil, Fuel Oil, Gasoline, Hydraulic Fluid, Mineral Oil, Water

- Tubing: Use with welded or seamless 304/304L or 316/316L stainless steel that meets ASTM A213, ASTM A249, or ASTM A269

Fittings with tube stem insert into the tube end of another fitting in place of a length of tubing.

Fittings with push-on barbed hose end have sharper barbs than standard barbed hose fittings to grip reinforced rubber push-on hose with no clamps required. The more you pull on the fittings, the tighter the hose will grip.

| Tube Stem OD | For Hose ID | Material | Max. Pressure | Temp. Range, °F | Each | |

| 1/4" | 1/4" | 316 Stainless Steel | 300 psi @ 72° F | -40° to 200° | 00000000 | 00000 |

| 3/8" | 1/4" | 316 Stainless Steel | 300 psi @ 72° F | -40° to 200° | 00000000 | 00000 |

| 3/8" | 3/8" | 316 Stainless Steel | 300 psi @ 72° F | -40° to 200° | 00000000 | 00000 |

| 1/2" | 1/4" | 316 Stainless Steel | 300 psi @ 72° F | -40° to 200° | 00000000 | 00000 |

| 1/2" | 3/8" | 316 Stainless Steel | 300 psi @ 72° F | -40° to 200° | 00000000 | 00000 |

| 1/2" | 1/2" | 316 Stainless Steel | 300 psi @ 72° F | -40° to 200° | 00000000 | 00000 |

| 3/4" | 3/4" | 316 Stainless Steel | 300 psi @ 72° F | -40° to 200° | 00000000 | 00000 |

Use these nuts with Yor-Lok sleeves and fittings to create an extra-strong seal on stainless steel tubing. They are 316 stainless steel for excellent corrosion resistance.

For Tube | ||||||

|---|---|---|---|---|---|---|

| OD | Wall Thick. | Nut Material | Max. Pressure | Temp. Range, °F | Each | |

| 1/4" | 0.035" | 316 Stainless Steel | 4,000 psi @ 72° F | -420° to 1200° | 00000000 | 00000 |

| 3/8" | 0.035" | 316 Stainless Steel | 2,500 psi @ 72° F | -420° to 1200° | 00000000 | 0000 |

| 1/2" | 0.035" | 316 Stainless Steel | 2,000 psi @ 72° F | -420° to 1200° | 00000000 | 00000 |

| 4mm | 1mm | 316 Stainless Steel | 3,500 psi @ 72° F | -420° to 1200° | 00000000 | 0000 |

| 6mm | 1mm | 316 Stainless Steel | 4,000 psi @ 72° F | -420° to 1200° | 00000000 | 0000 |

| 10mm | 0.5mm | 316 Stainless Steel | 2,500 psi @ 72° F | -420° to 1200° | 00000000 | 0000 |

Couple these sleeves with Yor-Lok nuts and fittings to create an extra-strong seal on stainless steel tubing. Sleeves are 316 stainless steel for excellent corrosion resistance. They are also known as ferrules.

For Tube | Front Sleeve | Back Sleeve | |||||||

|---|---|---|---|---|---|---|---|---|---|

| OD | Wall Thick. | Sleeve Material | Lg. | No. Included | Lg. | No. Included | Max. Pressure | Each | |

Sleeves | |||||||||

| 1/4" | 0.035" | 316 Stainless Steel | 3/16" | 1 | 3/32" | 1 | 4,000 psi @ 72° F | 00000000 | 00000 |

| 3/8" | 0.035" | 316 Stainless Steel | 3/16" | 1 | 3/32" | 1 | 2,500 psi @ 72° F | 00000000 | 0000 |

| 1/2" | 0.035" | 316 Stainless Steel | 19/64" | 1 | 5/32" | 1 | 2,000 psi @ 72° F | 00000000 | 0000 |

| 4mm | 1mm | 316 Stainless Steel | 5mm | 1 | 3mm | 1 | 3,500 psi @ 72° F | 00000000 | 0000 |

| 6mm | 1mm | 316 Stainless Steel | 5mm | 1 | 3mm | 1 | 4,000 psi @ 72° F | 00000000 | 0000 |

| 10mm | 0.5mm | 316 Stainless Steel | 5mm | 1 | 3mm | 1 | 2,500 psi @ 72° F | 00000000 | 0000 |

Sleeves with Dispenser | |||||||||

| 1/4" | 0.035" | 316 Stainless Steel | 3/16" | 10 | 7/64" | 10 | 4,000 psi @ 72° F | 00000000 | 00000 |

| 3/8" | 0.035" | 316 Stainless Steel | 3/16" | 10 | 7/64" | 10 | 2,500 psi @ 72° F | 00000000 | 00000 |

| 1/2" | 0.035" | 316 Stainless Steel | 9/32" | 10 | 5/32" | 10 | 2,000 psi @ 72° F | 00000000 | 00000 |

Save time installing sleeves and nuts—these sets come oriented in the correct direction and order on a dispenser. To install them, slide off a set and place it on your tubing. Each front sleeve, back sleeve, and nut is made of 316 stainless steel for excellent corrosion resistance. Five sets of sleeves and nuts come on each dispenser. Sleeves are also known as ferrules.

For Tube | Front Sleeve | Back Sleeve | Nut | ||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|

| OD | Wall Thick. | Material | Lg. | No. Included | Lg. | No. Included | Lg. | No. Included | Max. Pressure | Each | |

Sets with Dispenser | |||||||||||

| 1/4" | 0.035" | 316 Stainless Steel | 3/16" | 5 | 7/64" | 5 | 1/2" | 5 | 4,000 psi @ 72° F | 0000000 | 000000 |

| 3/8" | 0.035" | 316 Stainless Steel | 3/16" | 5 | 7/64" | 5 | 9/16" | 5 | 2,500 psi @ 72° F | 0000000 | 00000 |

| 1/2" | 0.035" | 316 Stainless Steel | 9/32" | 5 | 5/32" | 5 | 11/16" | 5 | 2,000 psi @ 72° F | 0000000 | 00000 |

| 4mm | 1mm | 316 Stainless Steel | 5mm | 5 | 3mm | 5 | 12mm | 5 | 3,500 psi @ 72° F | 0000000 | 00000 |

| 6mm | 1mm | 316 Stainless Steel | 5mm | 5 | 3mm | 5 | 13mm | 5 | 4,000 psi @ 72° F | 0000000 | 00000 |

| 10mm | 1mm | 316 Stainless Steel | 5mm | 5 | 3mm | 5 | 15mm | 5 | 2,500 psi @ 72° F | 0000000 | 00000 |

Tube supports are recommended for soft plastic tubing to prevent the tube from collapsing.

For Tube | ||||||

|---|---|---|---|---|---|---|

| OD | ID | Tube Support Material | Tube Support Style | Temp. Range, °F | Each | |

| 1/4" | 1/8" | 316 Stainless Steel | Smooth | -420° to 1200° | 00000000 | 00000 |

| 3/8" | 1/4" | 316 Stainless Steel | Smooth | -420° to 1200° | 00000000 | 0000 |

| 1/2" | 1/4" | 316 Stainless Steel | Smooth | -420° to 1200° | 00000000 | 00000 |

| 6mm | 4mm | 316 Stainless Steel | Barbed | -420° to 1200° | 00000000 | 0000 |

| 8mm | 6mm | 316 Stainless Steel | Barbed | -420° to 1200° | 00000000 | 0000 |

| 10mm | 8mm | 316 Stainless Steel | Barbed | -420° to 1200° | 00000000 | 0000 |

| 12mm | 10mm | 316 Stainless Steel | Barbed | -420° to 1200° | 00000000 | 00000 |

Yor-Lok Fittings for Copper Tubing

- For Use With: Air, Cutting Oil, Diesel Fuel, Fuel Oil, Gasoline, Hydraulic Fluid, Mineral Oil, Water

- Temperature Range: -40° to 400° F

- Tubing: Use with seamless copper

- Specifications Met: ASME B31.3

A nut with two sleeves (ferrules) gives these fittings extra gripping power. The sleeves bite into tubing as you tighten the nut, creating a strong seal. Also known as instrumentation fittings, they are made to tight tolerances for use in high-precision applications. Fittings are brass for good corrosion resistance. They are compatible with Swagelok®, Let-Lok, and A-Lok fittings.

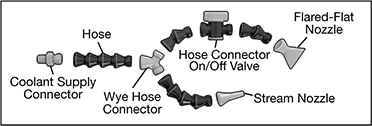

1/4" Loc-Line Coolant Hose

Build a custom system to deliver coolant, cutting oil, water, or air in any direction. Once in position, hose stays put—there's no spring back or movement caused by vibration or heavy flow.

Assemble and disassemble by snapping components together or pulling them apart. Assembly pliers (sold separately) are recommended. To ensure compatibility, select the color and trade size that match your current system. These components fit Loc-Line hose with a 1/4” ID.

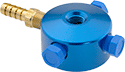

Manifolds can be joined with connectors.

For styles 34 and 35 manifolds, use a style 2 coolant supply connector to connect a style 12 wye-shaped hose connector.

Barbed Tube Inlet Connection | Threaded Pipe Outlet Connections | O'all | ||||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Style | No. of | For Tube ID | No. of | Size | Thread Type | Gender | Ht. | Wd. | Lg. | OD | Material | Fitting Material | Max. Flow Rate, gph | Max. Pressure, psi | Max. Temp., °F | Includes | Each | |

| 34 | 1 | 1/2" | 2 | 1/4 | NPT | Female | 2 9/16" | 1 3/16" | 1 7/16" | __ | Aluminum | Brass | 250 | 50 | 335° | One 1/4 NPT Plug | 000000000 | 000000 |

| 35 | 1 | 3/8" | 4 | 1/4 | NPT | Female | 1 3/16" | __ | __ | 2 1/8" | Aluminum | Brass | 250 | 50 | 170° | Three 1/4 NPT Plugs | 00000000 | 00000 |