How to Identify and Measure Fittings

Pipe size is an industry designation, not the actual size. View information about how to measure threaded and unthreaded pipe and pipe fittings.

More

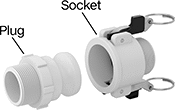

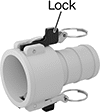

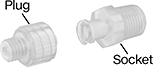

Plastic Cam-and-Groove Hose Couplings for Chemicals and Petroleum

Made of plastic, these couplings are lighter in weight than metal cam-and-groove hose couplings, yet have the chemical resistance to withstand gasoline and other harsh substances. A complete coupling consists of a plug and a socket (both sold separately) that allow you to quickly connect and disconnect medium-to large-diameter hose lines. To connect, insert the plug into the socket and press the levers down. The levers fit snugly into the groove on the plug’s body and force the plug against the gasket to form a tight seal. To disconnect, lift both levers and pull out the plug.

Plugs with barbed end are also known as E adapters. Insert the barbed end into rubber hose and secure with a clamp.

Sockets with locking levers prevent accidental disconnection. The locking pins engage automatically when the coupling is connected. Press the locking pins simultaneously to disengage.

Sockets with barbed end are also known as C couplers. Insert the barbed end into rubber hose and secure with a clamp.

PVDF plugs and sockets have better corrosion and chemical resistance than nylon plugs and sockets. Use them when your application involves harsh acids and solvents.

Note: To ensure a correct fit, make sure that the plug and socket have the same coupling size.

Warning: Relieve all pressure before disconnecting the couplings. Do not use cam-and-groove couplings with compressed air or gas.

- For Use With:

Nylon Plastic: Diesel Fuel, Gasoline, Varnish

PVDF Plastic: Diesel Fuel, Gasoline, Nitric Acid, Phosphoric Acid - Maximum Pressure: See table

- Temperature Range:

Nylon Plastic: -30° to 200° F

PVDF Plastic: -20° to 250° F - Attachment Type: Use Worm-Drive Clamps or Band-and-Buckle Clamps

- Specifications Met: Fed. Spec. A-A-59326

| Coupling Size | Plug OD | For Hose ID | Color | Max. Pressure | Each | |

PVDF Plastic | ||||||

|---|---|---|---|---|---|---|

| 3/4 | 1 1/4" | 1/2" | White | 125 psi @ 72° F | 00000000 | 000000 |

| 3/4 | 1 1/4" | 3/4" | White | 125 psi @ 72° F | 00000000 | 00000 |

| 1 | 1 7/16" | 1" | White | 125 psi @ 72° F | 00000000 | 00000 |

| 1 1/2 | 2 1/8" | 1 1/4" | White | 100 psi @ 72° F | 0000000 | 00000 |

| 1 1/2 | 2 1/8" | 1 1/2" | White | 100 psi @ 72° F | 0000000 | 00000 |

| 2 | 2 1/2" | 2" | White | 100 psi @ 72° F | 0000000 | 00000 |

| 3 | 3 5/8" | 3" | White | 50 psi @ 72° F | 0000000 | 00000 |

- For Use With:

Nylon Plastic: Diesel Fuel, Gasoline, Varnish

PVDF Plastic: Diesel Fuel, Gasoline, Nitric Acid, Phosphoric Acid - Maximum Pressure: See table

- Temperature Range:

Nylon Plastic: -30° to 200° F

PVDF Plastic: -20° to 250° F - Attachment Type: Use Worm-Drive Clamps or Band-and-Buckle Clamps

- Specifications Met: Fed. Spec. A-A-59326

Sockets | |||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|

Levers | Replacement Gaskets | ||||||||||

| Coupling Size | Socket ID | For Hose ID | Color | No. of | Material | Max. Pressure | Each | Pkg. Qty. | Pkg. | ||

PVDF Plastic | |||||||||||

| 1 1/2 | 2 1/8" | 1 1/4" | White | 2 | 304 Stainless Steel | 100 psi @ 72° F | 00000000 | 000000 | 10 | 0000000 | 000000 |

| 1 1/2 | 2 1/8" | 1 1/2" | White | 2 | 304 Stainless Steel | 100 psi @ 72° F | 00000000 | 00000 | 10 | 0000000 | 00000 |

| 2 | 2 1/2" | 2" | White | 2 | 304 Stainless Steel | 100 psi @ 72° F | 00000000 | 00000 | 10 | 0000000 | 00000 |

| 3 | 3 5/8" | 3" | White | 2 | 304 Stainless Steel | 50 psi @ 72° F | 00000000 | 000000 | 10 | 0000000 | 00000 |

- For Use With:

Nylon Plastic: Diesel Fuel, Gasoline, Varnish

PVDF Plastic: Diesel Fuel, Gasoline, Nitric Acid, Phosphoric Acid - Maximum Pressure: 125 psi @ 72° F

- Temperature Range:

Nylon Plastic: -30° to 200° F

PVDF Plastic: -20° to 250° F - Attachment Type: Use Worm-Drive Clamps or Band-and-Buckle Clamps

- Specifications Met: Fed. Spec. A-A-59326

Sockets | ||||||||||

|---|---|---|---|---|---|---|---|---|---|---|

Levers | Replacement Gaskets | |||||||||

| Coupling Size | Socket ID | For Hose ID | Color | No. of | Material | Each | Pkg. Qty. | Pkg. | ||

PVDF Plastic | ||||||||||

| 3/4 | 1 1/4" | 1/2" | White | 2 | 304 Stainless Steel | 00000000 | 000000 | 10 | 0000000 | 00000 |

| 3/4 | 1 1/4" | 3/4" | White | 2 | 304 Stainless Steel | 00000000 | 00000 | 10 | 0000000 | 0000 |

| 1 | 1 7/16" | 1" | White | 2 | 304 Stainless Steel | 00000000 | 00000 | 10 | 0000000 | 0000 |

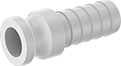

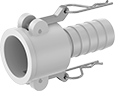

Plastic Barbed Hose Fittings for Chemicals and Petroleum

Made of plastic, these fittings are lighter in weight than metal barbed fittings, yet have the chemical and corrosion resistance to stand up to harsh substances. Slide the barbed end into plastic or rubber hose and secure with a clamp. Also known as hose nipples, they adapt a barbed end to a threaded end.

PVDF fittings have better chemical and corrosion resistance than nylon fittings. Use them when your application involves harsh acids.

- For Use With: Citric Acid, Mineral Oil, Nitric Acid, Phosphoric Acid

- Maximum Pressure: See table

- Temperature Range: -20° to 300° F

- Attachment Type: Use Worm-Drive Clamps or Bolt Clamps

| For Hose ID | Pipe Size | Color | Max. Pressure | Each | |

PVDF Plastic | |||||

|---|---|---|---|---|---|

| 1/2" | 1/2 | White | 125 psi @ 72° F | 0000000 | 000000 |

| 3/4" | 3/4 | White | 125 psi @ 72° F | 0000000 | 00000 |

| 1" | 1 | White | 125 psi @ 72° F | 0000000 | 00000 |

| 1 1/4" | 1 1/4 | White | 100 psi @ 72° F | 0000000 | 00000 |

| 1 1/2" | 1 1/2 | White | 100 psi @ 72° F | 0000000 | 00000 |

| 2" | 2 | White | 100 psi @ 72° F | 0000000 | 00000 |

| 3" | 3 | White | 50 psi @ 72° F | 0000000 | 00000 |

Cleaned and Bagged Metal Barbed Hose Fittings for Chemicals

Each of these metal fittings is double bagged to prevent contamination in areas that require a high level of cleanliness. They’re even clean enough to be used for oxygen service. Constructed from 316 stainless steel, they won’t corrode from repeat cleanings with harsh chemicals. They’re also called hose nipples. To connect them, slide the barbed end into plastic or rubber hose and secure it with a clamp.

- For Use With: Acetone, Butyl Alcohol, Citric Acid, Ethanol, Ethylene Glycol, Isopropyl Alcohol, Mineral Oil, Phosphoric Acid, Sodium Hydroxide

- Maximum Pressure: 400 psi @ 72° F

- Temperature Range: -100° to 450° F

- Attachment Type: Use Worm-Drive Clamps, Bolt Clamps, or Band-and-Buckle Clamps

| For Hose ID | Pipe Size | Each | |

316 Stainless Steel | |||

|---|---|---|---|

| 1/8" | 1/8 | 0000000 | 000000 |

| 1/8" | 1/4 | 0000000 | 00000 |

| 1/4" | 1/4 | 0000000 | 00000 |

| 1/4" | 3/8 | 0000000 | 00000 |

| 3/8" | 1/4 | 0000000 | 00000 |

| 3/8" | 3/8 | 0000000 | 00000 |

| 3/8" | 1/2 | 0000000 | 00000 |

| 1/2" | 1/4 | 0000000 | 00000 |

| 1/2" | 3/8 | 0000000 | 00000 |

| 1/2" | 1/2 | 0000000 | 00000 |

| 1/2" | 3/4 | 0000000 | 00000 |

| 5/8" | 1/2 | 0000000 | 00000 |

| 3/4" | 1/2 | 0000000 | 00000 |

| 3/4" | 3/4 | 0000000 | 00000 |

| 1" | 3/4 | 0000000 | 00000 |

| 1" | 1 | 0000000 | 000000 |

Chemical-Resistant PVDF Hose Fittings for Food and Beverage

- Maximum Pressure: 205 psi @ 72° F

- Temperature Range: 0° to 245° F

- Attachment Type: Use Worm-Drive Clamps or Bolt Clamps

- Specifications Met: NSF/ANSI 61, UL 94 V-0

To stand up to the harsh chemicals used to clean food-processing lines, these fittings are made of PVDF (polyvinylidene fluoride), also known as Kynar. They’ll resist degrading when exposed to strong alkali and highly acidic solutions, unlike other plastic fittings, such as those made from nylon and acetal. They are NSF/ANSI 61 certified for use in drinking water systems, and they won't impart any tastes or odors. Use them with both hot and cold substances. Since they're made of PVDF, these fittings can stand up to impact. Rated UL 94 V-0, they meet strict flammability standards.

Warning: Never use plastic hose fittings and pipe with compressed air or gas.

| For Hose ID | Pipe Size | Color | Each | |

PVDF Plastic | ||||

|---|---|---|---|---|

| 1/4" | 1/4 | White | 0000000 | 00000 |

| 1/4" | 1/2 | White | 0000000 | 0000 |

| 3/8" | 1/4 | White | 0000000 | 0000 |

| 3/8" | 3/8 | White | 0000000 | 0000 |

| 3/8" | 1/2 | White | 0000000 | 0000 |

| 1/2" | 1/4 | White | 0000000 | 0000 |

| 1/2" | 3/8 | White | 0000000 | 0000 |

| 1/2" | 1/2 | White | 0000000 | 0000 |

| 1/2" | 3/4 | White | 0000000 | 0000 |

| 5/8" | 1/2 | White | 0000000 | 0000 |

| 5/8" | 3/4 | White | 0000000 | 0000 |

| 3/4" | 1/2 | White | 0000000 | 0000 |

| 3/4" | 3/4 | White | 0000000 | 0000 |

Chemical Hose Nozzles

Adjust the flow while dispensing liquid chemicals. Nozzles are polypropylene, which is lightweight with excellent chemical resistance. They shut off manually.

Style B has a trigger to turn flow on and off. It has an angled design, which reduces hose kinking for efficient fueling. Nozzle has a barbed connection; twist hose onto the barbed end and secure with a clamp. Use to transfer citric acid, nitric acid, phosphoric acid, and sodium hydroxide from pumps and processing equipment.

Warning: Do not leave nozzles unattended when in use.

Spout | |||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|

| Style | Max. Flow Rate, gpm | For Hose ID | Connection | Max. Pressure | Temperature Range, °F | OD | Lg. | Material | Shut-Off Type | Each | |

For Use With Citric Acid, Nitric Acid, Phosphoric Acid, and Sodium Hydroxide | |||||||||||

| B | 40 | 1/2" | Barbed Male | 150 psi @ 72° F | 32° to 105° | 31/32" | 4 1/2" | Polypropylene Plastic | Manual | 00000000 | 0000000 |

| B | 40 | 3/4" | Barbed Male | 150 psi @ 72° F | 32° to 105° | 31/32" | 4 1/2" | Polypropylene Plastic | Manual | 00000000 | 000000 |

| B | 40 | 1" | Barbed Male | 150 psi @ 72° F | 32° to 105° | 31/32" | 4 1/2" | Polypropylene Plastic | Manual | 00000000 | 000000 |

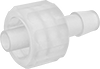

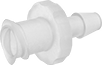

Luer Lock Tube Couplings for Plastic and Rubber Tubing—Chemicals

- For Use With: Acetic Acid, Bleach, Ethanol, Hydrochloric Acid, Nitric Acid, Phosphoric Acid, Sulfuric Acid

- Tubing: Use with soft (Durometer 40A-65A) PVC plastic or silicone rubber

A staple in labs, these couplings are highly versatile, fitting any luer lock plug, socket, syringe, or needle. They lock together with a push and turn, so they work well in lines that are frequently disconnected. Use them in low-pressure applications. They have a compact body for installation in tight spaces. Made of PVDF, they resist most acids, alcohols, and organic solvents. PVDF is also known as Kynar.

Note: For a complete coupling, order a plug and a socket.

| For Tube ID | Material | Color | Clarity | Max. Pressure | Locking Ring Included | Pkg. Qty. | Pkg. | |

| 1/16" | PVDF Plastic | White | Semi-Clear | Not Rated | With Locking Ring | 10 | 0000000 | 000000 |

| 3/32" | PVDF Plastic | White | Semi-Clear | Not Rated | With Locking Ring | 10 | 0000000 | 00000 |

| 1/8" | PVDF Plastic | White | Semi-Clear | Not Rated | With Locking Ring | 10 | 0000000 | 00000 |

| 5/32" | PVDF Plastic | White | Semi-Clear | Not Rated | With Locking Ring | 10 | 0000000 | 00000 |

| 1/4" | PVDF Plastic | White | Semi-Clear | Not Rated | With Locking Ring | 10 | 0000000 | 00000 |

| For Tube ID | Material | Color | Clarity | Max. Pressure | Pkg. Qty. | Pkg. | |

| 1/16" | PVDF Plastic | White | Semi-Clear | Not Rated | 10 | 0000000 | 00000 |

| 3/32" | PVDF Plastic | White | Semi-Clear | Not Rated | 10 | 0000000 | 0000 |

| 1/8" | PVDF Plastic | White | Semi-Clear | Not Rated | 10 | 0000000 | 0000 |

| 3/16" | PVDF Plastic | White | Semi-Clear | Not Rated | 10 | 0000000 | 0000 |

| 1/4" | PVDF Plastic | White | Semi-Clear | Not Rated | 10 | 0000000 | 0000 |