How to Identify and Measure Fittings

Pipe size is an industry designation, not the actual size. View information about how to measure threaded and unthreaded pipe and pipe fittings.

More

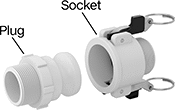

Plastic Cam-and-Groove Hose Couplings for Chemicals and Petroleum

Made of plastic, these couplings are lighter in weight than metal cam-and-groove hose couplings, yet have the chemical resistance to withstand gasoline and other harsh substances. A complete coupling consists of a plug and a socket (both sold separately) that allow you to quickly connect and disconnect medium-to large-diameter hose lines. To connect, insert the plug into the socket and press the levers down. The levers fit snugly into the groove on the plug’s body and force the plug against the gasket to form a tight seal. To disconnect, lift both levers and pull out the plug.

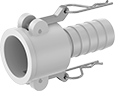

Plugs with barbed end are also known as E adapters. Insert the barbed end into rubber hose and secure with a clamp.

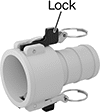

Sockets with locking levers prevent accidental disconnection. The locking pins engage automatically when the coupling is connected. Press the locking pins simultaneously to disengage.

Sockets with barbed end are also known as C couplers. Insert the barbed end into rubber hose and secure with a clamp.

Nylon plugs and sockets have better strength than PVDF plugs and sockets. They have good corrosion and chemical resistance to handle gasoline and fuel applications.

Note: To ensure a correct fit, make sure that the plug and socket have the same coupling size.

Warning: Relieve all pressure before disconnecting the couplings. Do not use cam-and-groove couplings with compressed air or gas.

- For Use With:

Nylon Plastic: Diesel Fuel, Gasoline, Varnish

PVDF Plastic: Diesel Fuel, Gasoline, Nitric Acid, Phosphoric Acid - Maximum Pressure: See table

- Temperature Range:

Nylon Plastic: -30° to 200° F

PVDF Plastic: -20° to 250° F - Attachment Type: Use Worm-Drive Clamps or Band-and-Buckle Clamps

- Specifications Met: Fed. Spec. A-A-59326

| Coupling Size | Plug OD | For Hose ID | Color | Max. Pressure | Each | |

Nylon Plastic | ||||||

|---|---|---|---|---|---|---|

| 3/4 | 1 1/4" | 1/2" | Yellow | 125 psi @ 72° F | 0000000 | 00000 |

| 3/4 | 1 1/4" | 3/4" | Yellow | 125 psi @ 72° F | 0000000 | 0000 |

| 1 | 1 7/16" | 1" | Yellow | 125 psi @ 72° F | 0000000 | 0000 |

| 1 1/2 | 2 1/8" | 1 1/4" | Yellow | 100 psi @ 72° F | 0000000 | 00000 |

| 1 1/2 | 2 1/8" | 1 1/2" | Yellow | 100 psi @ 72° F | 0000000 | 00000 |

| 2 | 2 1/2" | 2" | Yellow | 100 psi @ 72° F | 0000000 | 00000 |

| 3 | 3 5/8" | 3" | Yellow | 50 psi @ 72° F | 0000000 | 00000 |

| 4 | 4 3/4" | 4" | Yellow | 50 psi @ 72° F | 0000000 | 00000 |

- For Use With:

Nylon Plastic: Diesel Fuel, Gasoline, Varnish

PVDF Plastic: Diesel Fuel, Gasoline, Nitric Acid, Phosphoric Acid - Maximum Pressure: See table

- Temperature Range:

Nylon Plastic: -30° to 200° F

PVDF Plastic: -20° to 250° F - Attachment Type: Use Worm-Drive Clamps or Band-and-Buckle Clamps

- Specifications Met: Fed. Spec. A-A-59326

Sockets | ||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|

Levers | Replacement Gaskets | |||||||||||

| Coupling Size | Socket ID | For Hose ID | Color | No. of | Material | Pull Ring Material | Max. Pressure | Each | Pkg. Qty. | Pkg. | ||

Nylon Plastic | ||||||||||||

| 1 1/2 | 2 1/8" | 1 1/4" | Yellow | 2 | 304 Stainless Steel | 302 Stainless Steel | 100 psi @ 72° F | 00000000 | 000000 | 10 | 0000000 | 000000 |

| 1 1/2 | 2 1/8" | 1 1/2" | Yellow | 2 | 304 Stainless Steel | 302 Stainless Steel | 100 psi @ 72° F | 00000000 | 00000 | 10 | 0000000 | 00000 |

| 2 | 2 1/2" | 2" | Yellow | 2 | 304 Stainless Steel | 302 Stainless Steel | 100 psi @ 72° F | 00000000 | 00000 | 10 | 0000000 | 00000 |

| 3 | 3 5/8" | 3" | Yellow | 2 | 304 Stainless Steel | 302 Stainless Steel | 50 psi @ 72° F | 00000000 | 00000 | 10 | 0000000 | 00000 |

| 4 | 4 3/4" | 4" | Yellow | 2 | 304 Stainless Steel | 302 Stainless Steel | 50 psi @ 72° F | 00000000 | 00000 | 10 | 0000000 | 00000 |

- For Use With:

Nylon Plastic: Diesel Fuel, Gasoline, Varnish

PVDF Plastic: Diesel Fuel, Gasoline, Nitric Acid, Phosphoric Acid - Maximum Pressure: 125 psi @ 72° F

- Temperature Range:

Nylon Plastic: -30° to 200° F

PVDF Plastic: -20° to 250° F - Attachment Type: Use Worm-Drive Clamps or Band-and-Buckle Clamps

- Specifications Met: Fed. Spec. A-A-59326

Sockets | ||||||||||

|---|---|---|---|---|---|---|---|---|---|---|

Levers | Replacement Gaskets | |||||||||

| Coupling Size | Socket ID | For Hose ID | Color | No. of | Material | Each | Pkg. Qty. | Pkg. | ||

Nylon Plastic | ||||||||||

| 3/4 | 1 1/4" | 1/2" | Yellow | 2 | 304 Stainless Steel | 00000000 | 000000 | 10 | 0000000 | 00000 |

| 3/4 | 1 1/4" | 3/4" | Yellow | 2 | 304 Stainless Steel | 00000000 | 00000 | 10 | 0000000 | 0000 |

| 1 | 1 7/16" | 1" | Yellow | 2 | 304 Stainless Steel | 00000000 | 00000 | 10 | 0000000 | 0000 |

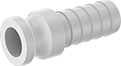

Plastic Barbed Hose Fittings for Chemicals and Petroleum

Made of plastic, these fittings are lighter in weight than metal barbed fittings, yet have the chemical and corrosion resistance to stand up to harsh substances. Slide the barbed end into plastic or rubber hose and secure with a clamp. Also known as hose nipples, they adapt a barbed end to a threaded end.

Nylon fittings are stronger than PVDF fittings. They have good corrosion and chemical resistance to handle gasoline and other fuel applications.

- For Use With: Citric Acid, Diesel Fuel, Gasoline, Mineral Oil, Varnish

- Maximum Pressure: 150 psi @ 72° F

- Temperature Range: -30° to 200° F

- Attachment Type: Use Worm-Drive Clamps or Bolt Clamps