How to Identify and Measure Fittings

Pipe size is an industry designation, not the actual size. View information about how to measure threaded and unthreaded pipe and pipe fittings.

More

Barbed Hose Fittings for Food and Beverage

These fittings are FDA compliant, so they’re suitable for food and beverage applications and won’t impart tastes or odors to the product. Secure barbed ends into plastic or rubber hose with a clamp. These fittings are lightweight with good corrosion resistance.

Adapters are also known as hose nipples. They adapt a barbed end to a threaded end.

Polypropylene fittings meet NSF/ANSI 61 safety standards for use with drinking water systems.

For technical drawings and 3-D models, click on a part number.

- Maximum Pressure: See table

- Temperature Range:

Nylon Plastic: 0° to 230° F

Polypropylene Plastic: 10° to 180° F - Attachment Type: Use Worm-Drive Clamps or Bolt Clamps

- Specifications Met:

Nylon Plastic: FDA Compliant 21 CFR 177.1500

Polypropylene Plastic: FDA Compliant 21 CFR 176.170, FDA Compliant 21 CFR 178.3297, NSF/ANSI 61

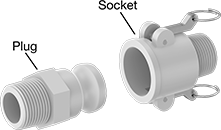

Cam-and-Groove Hose Couplings for Food and Beverage

Made of FDA listed materials, these couplings are suitable for food and beverage applications and won’t impart tastes or odors to the product. They also meet NSF/ANSI 61 safety standards for use with drinking water systems. A complete coupling consists of a plug and a socket (both sold separately) that allow you to quickly connect and disconnect medium-to large-diameter hose lines. To connect, insert the plug into the socket and press the levers down. The levers fit snugly into the groove on the plug’s body and force the plug against the gasket to form a tight seal. To disconnect, lift both levers and pull out the plug. Plugs and sockets are polypropylene, which is lightweight with good abrasion and corrosion resistance.

Plugs with male threaded end are also known as F adapters.

Plugs with female threaded end are also known as A adapters.

Plugs with barbed end are also known as E adapters. Insert the barbed end into rubber hose and secure with a clamp.

Sockets with male threaded end are also known as B couplers.

Sockets with female threaded end are also known as D couplers.

Sockets with barbed end are also known as C couplers. Insert the barbed end into hose and secure with a clamp.

Note: To ensure a correct fit, make sure that the plug and socket have the same coupling size.

Warning: Relieve all pressure before disconnecting the couplings. Do not use cam-and-groove couplings with compressed air or gas.

For technical drawings and 3-D models, click on a part number.

- Maximum Pressure: See table

- Temperature Range: 10° to 180° F

- Specifications Met: FDA Compliant 21 CFR 176.170

FDA Compliant 21 CFR 178.3297

NSF/ANSI 61

| Coupling Size | Plug OD | Pipe Size | Thread Type | Color | Max. Pressure | Each | |

Polypropylene Plastic | |||||||

|---|---|---|---|---|---|---|---|

| 3/4 | 1 1/4" | 1/2 | NPT | White | 125 psi @ 72° F | 000000000 | 00000 |

| 3/4 | 1 1/4" | 3/4 | NPT | White | 125 psi @ 72° F | 000000000 | 0000 |

| 1 | 1 7/16" | 1 | NPT | White | 125 psi @ 72° F | 000000000 | 0000 |

| 1 1/2 | 2 1/8" | 1 1/4 | NPT | White | 100 psi @ 72° F | 000000000 | 0000 |

| 1 1/2 | 2 1/8" | 1 1/2 | NPT | White | 100 psi @ 72° F | 00000000 | 0000 |

| 1 1/2 | 2 1/8" | 1 1/2 | BSPT | White | 100 psi @ 72° F | 000000000 | 00000 |

| 2 | 2 1/2" | 2 | NPT | White | 100 psi @ 72° F | 00000000 | 0000 |

| 2 | 2 1/2" | 2 | BSPT | White | 100 psi @ 72° F | 000000000 | 00000 |

| 3 | 3 5/8" | 3 | NPT | White | 50 psi @ 72° F | 00000000 | 00000 |

| 3 | 3 5/8" | 3 | BSPT | White | 50 psi @ 72° F | 000000000 | 00000 |

- Maximum Pressure: See table

- Temperature Range: 10° to 180° F

- Specifications Met: FDA Compliant 21 CFR 176.170

FDA Compliant 21 CFR 178.3297

NSF/ANSI 61

| Coupling Size | Plug OD | Pipe Size | Thread Type | Color | Max. Pressure | Each | |

Polypropylene Plastic | |||||||

|---|---|---|---|---|---|---|---|

| 3/4 | 1 1/4" | 1/2 | NPT | White | 125 psi @ 72° F | 000000000 | 00000 |

| 3/4 | 1 1/4" | 3/4 | NPT | White | 125 psi @ 72° F | 000000000 | 0000 |

| 1 | 1 7/16" | 1 | NPT | White | 125 psi @ 72° F | 000000000 | 0000 |

| 1 1/2 | 2 1/8" | 1 1/4 | NPT | White | 100 psi @ 72° F | 000000000 | 0000 |

| 1 1/2 | 2 1/8" | 1 1/2 | NPT | White | 100 psi @ 72° F | 00000000 | 0000 |

| 1 1/2 | 2 1/8" | 1 1/2 | BSPP | White | 100 psi @ 72° F | 000000000 | 00000 |

| 2 | 2 1/2" | 2 | NPT | White | 100 psi @ 72° F | 00000000 | 0000 |

| 2 | 2 1/2" | 2 | BSPP | White | 100 psi @ 72° F | 000000000 | 00000 |

| 3 | 3 5/8" | 3 | NPT | White | 50 psi @ 72° F | 00000000 | 00000 |

| 3 | 3 5/8" | 3 | BSPP | White | 50 psi @ 72° F | 000000000 | 00000 |

- Maximum Pressure: See table

- Temperature Range: 10° to 180° F

- Attachment Type: Use Worm-Drive Clamps or Band-and-Buckle Clamps

- Specifications Met: FDA Compliant 21 CFR 176.170

FDA Compliant 21 CFR 178.3297

NSF/ANSI 61

| Coupling Size | Plug OD | For Hose ID | Color | Max. Pressure | Each | |

Polypropylene Plastic | ||||||

|---|---|---|---|---|---|---|

| 3/4 | 1 1/4" | 1/2" | White | 125 psi @ 72° F | 000000000 | 00000 |

| 3/4 | 1 1/4" | 3/4" | White | 125 psi @ 72° F | 000000000 | 0000 |

| 1 | 1 7/16" | 1" | White | 125 psi @ 72° F | 000000000 | 0000 |

| 1 1/2 | 2 1/8" | 1 1/4" | White | 100 psi @ 72° F | 000000000 | 0000 |

| 1 1/2 | 2 1/8" | 1 1/2" | White | 100 psi @ 72° F | 00000000 | 0000 |

| 2 | 2 1/2" | 2" | White | 100 psi @ 72° F | 00000000 | 0000 |

| 3 | 3 5/8" | 3" | White | 50 psi @ 72° F | 00000000 | 00000 |

- Maximum Pressure: See table

- Temperature Range: 10° to 180° F

- Specifications Met: FDA Compliant 21 CFR 176.170

FDA Compliant 21 CFR 178.3297

NSF/ANSI 61

- Maximum Pressure: See table

- Temperature Range: 10° to 180° F

- Specifications Met: FDA Compliant 21 CFR 176.170

FDA Compliant 21 CFR 178.3297

NSF/ANSI 61

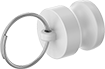

Sockets | |||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

Levers | Replacement Gaskets | Protective Plugs | |||||||||||||

| Coupling Size | Socket ID | Pipe Size | Thread Type | Color | No. of | Material | Pull Ring Material | Max. Pressure | Each | Pkg. Qty. | Pkg. | Each | |||

Polypropylene Plastic | |||||||||||||||

| 3/4 | 1 1/4" | 1/2 | NPT | White | 2 | 304 Stainless Steel | Stainless Steel | 125 psi @ 72° F | 000000000 | 000000 | 10 | 0000000 | 000000 | 000000 | 00 |

| 3/4 | 1 1/4" | 3/4 | NPT | White | 2 | 304 Stainless Steel | Stainless Steel | 125 psi @ 72° F | 000000000 | 00000 | 10 | 0000000 | 00000 | 000000 | 00 |

| 1 | 1 7/16" | 1 | NPT | White | 2 | 304 Stainless Steel | Stainless Steel | 125 psi @ 72° F | 000000000 | 00000 | 10 | 0000000 | 00000 | 000000 | 00 |

| 1 1/2 | 2 1/8" | 1 1/4 | NPT | White | 2 | 304 Stainless Steel | Stainless Steel | 100 psi @ 72° F | 000000000 | 00000 | 10 | 0000000 | 00000 | 000000 | 00 |

| 1 1/2 | 2 1/8" | 1 1/2 | NPT | White | 2 | 304 Stainless Steel | Stainless Steel | 100 psi @ 72° F | 00000000 | 00000 | 10 | 0000000 | 00000 | 000000 | 00 |

| 1 1/2 | 2 1/8" | 1 1/2 | BSPT | White | 2 | 304 Stainless Steel | Stainless Steel | 100 psi @ 72° F | 000000000 | 00000 | __ | 000000 | 00 | 000000 | 00 |

| 2 | 2 1/2" | 2 | NPT | White | 2 | 304 Stainless Steel | Stainless Steel | 100 psi @ 72° F | 00000000 | 00000 | 10 | 0000000 | 00000 | 0000000 | 000000 |

| 2 | 2 1/2" | 2 | BSPT | White | 2 | 304 Stainless Steel | Stainless Steel | 100 psi @ 72° F | 000000000 | 00000 | __ | 000000 | 00 | 0000000 | 00000 |

| 3 | 3 5/8" | 3 | NPT | White | 2 | 304 Stainless Steel | Stainless Steel | 50 psi @ 72° F | 00000000 | 00000 | 10 | 0000000 | 00000 | 0000000 | 00000 |

| 3 | 3 5/8" | 3 | BSPT | White | 2 | 304 Stainless Steel | Stainless Steel | 50 psi @ 72° F | 000000000 | 00000 | __ | 000000 | 00 | 0000000 | 00000 |

- Maximum Pressure: See table

- Temperature Range: 10° to 180° F

- Specifications Met: FDA Compliant 21 CFR 176.170

FDA Compliant 21 CFR 178.3297

NSF/ANSI 61

Sockets | |||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

Levers | Replacement Gaskets | Protective Plugs | |||||||||||||

| Coupling Size | Socket ID | Pipe Size | Thread Type | Color | No. of | Material | Pull Ring Material | Max. Pressure | Each | Pkg. Qty. | Pkg. | Each | |||

Polypropylene Plastic | |||||||||||||||

| 3/4 | 1 1/4" | 1/2 | NPT | White | 2 | 304 Stainless Steel | Stainless Steel | 125 psi @ 72° F | 000000000 | 000000 | 10 | 0000000 | 000000 | 000000 | 00 |

| 3/4 | 1 1/4" | 3/4 | NPT | White | 2 | 304 Stainless Steel | Stainless Steel | 125 psi @ 72° F | 000000000 | 00000 | 10 | 0000000 | 00000 | 000000 | 00 |

| 1 | 1 7/16" | 1 | NPT | White | 2 | 304 Stainless Steel | Stainless Steel | 125 psi @ 72° F | 000000000 | 00000 | 10 | 0000000 | 00000 | 000000 | 00 |

| 1 1/2 | 2 1/8" | 1 1/4 | NPT | White | 2 | 304 Stainless Steel | Stainless Steel | 100 psi @ 72° F | 000000000 | 00000 | 10 | 0000000 | 00000 | 000000 | 00 |

| 1 1/2 | 2 1/8" | 1 1/2 | NPT | White | 2 | 304 Stainless Steel | Stainless Steel | 100 psi @ 72° F | 00000000 | 00000 | 10 | 0000000 | 00000 | 000000 | 00 |

| 1 1/2 | 2 1/8" | 1 1/2 | BSPP | White | 2 | 304 Stainless Steel | Stainless Steel | 100 psi @ 72° F | 000000000 | 00000 | __ | 000000 | 00 | 000000 | 00 |

| 2 | 2 1/2" | 2 | NPT | White | 2 | 304 Stainless Steel | Stainless Steel | 100 psi @ 72° F | 00000000 | 00000 | 10 | 0000000 | 00000 | 0000000 | 000000 |

| 2 | 2 1/2" | 2 | BSPP | White | 2 | 304 Stainless Steel | Stainless Steel | 100 psi @ 72° F | 000000000 | 00000 | __ | 000000 | 00 | 0000000 | 00000 |

| 3 | 3 5/8" | 3 | NPT | White | 2 | 304 Stainless Steel | Stainless Steel | 50 psi @ 72° F | 00000000 | 00000 | 10 | 0000000 | 00000 | 0000000 | 00000 |

| 3 | 3 5/8" | 3 | BSPP | White | 2 | 304 Stainless Steel | Stainless Steel | 50 psi @ 72° F | 000000000 | 00000 | __ | 000000 | 00 | 0000000 | 00000 |

- Maximum Pressure: See table

- Temperature Range: 10° to 180° F

- Attachment Type: Use Worm-Drive Clamps or Band-and-Buckle Clamps

- Specifications Met: FDA Compliant 21 CFR 176.170

FDA Compliant 21 CFR 178.3297

NSF/ANSI 61

Sockets | ||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

Levers | Replacement Gaskets | Protective Plugs | ||||||||||||

| Coupling Size | Socket ID | For Hose ID | Color | No. of | Material | Pull Ring Material | Max. Pressure | Each | Pkg. Qty. | Pkg. | Each | |||

Polypropylene Plastic | ||||||||||||||

| 3/4 | 1 1/4" | 1/2" | White | 2 | 304 Stainless Steel | Stainless Steel | 125 psi @ 72° F | 000000000 | 000000 | 10 | 0000000 | 000000 | 000000 | 00 |

| 3/4 | 1 1/4" | 3/4" | White | 2 | 304 Stainless Steel | Stainless Steel | 125 psi @ 72° F | 000000000 | 00000 | 10 | 0000000 | 00000 | 000000 | 00 |

| 1 | 1 7/16" | 1" | White | 2 | 304 Stainless Steel | Stainless Steel | 125 psi @ 72° F | 000000000 | 00000 | 10 | 0000000 | 00000 | 000000 | 00 |

| 1 1/2 | 2 1/8" | 1 1/4" | White | 2 | 304 Stainless Steel | Stainless Steel | 100 psi @ 72° F | 000000000 | 00000 | 10 | 0000000 | 00000 | 000000 | 00 |

| 1 1/2 | 2 1/8" | 1 1/2" | White | 2 | 304 Stainless Steel | Stainless Steel | 100 psi @ 72° F | 00000000 | 00000 | 10 | 0000000 | 00000 | 000000 | 00 |

| 2 | 2 1/2" | 2" | White | 2 | 304 Stainless Steel | Stainless Steel | 100 psi @ 72° F | 00000000 | 00000 | 10 | 0000000 | 00000 | 0000000 | 000000 |

| 3 | 3 5/8" | 3" | White | 2 | 304 Stainless Steel | Stainless Steel | 50 psi @ 72° F | 00000000 | 00000 | 10 | 0000000 | 00000 | 0000000 | 00000 |

- Maximum Pressure: See table

- Temperature Range: 10° to 180° F

- Specifications Met: FDA Compliant 21 CFR 176.170

FDA Compliant 21 CFR 178.3297

NSF/ANSI 61

Sockets | |||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

Levers | Replacement Gaskets | 6" Retaining Chains | 12" Retaining Chains | ||||||||||||

| Coupling Size | Socket ID | Color | No. of | Material | Pull Ring Material | Max. Pressure | Each | Pkg. Qty. | Pkg. | Each | Each | ||||

Polypropylene Plastic | |||||||||||||||

| 3/4 | 1 1/4" | White | 2 | 304 Stainless Steel | Stainless Steel | 125 psi @ 72° F | 000000000 | 000000 | 10 | 0000000 | 000000 | 00000000 | 00000 | 00000000 | 00000 |

| 1 | 1 7/16" | White | 2 | 304 Stainless Steel | Stainless Steel | 125 psi @ 72° F | 000000000 | 00000 | 10 | 0000000 | 00000 | 00000000 | 0000 | 00000000 | 0000 |

| 1 1/2 | 2 1/8" | White | 2 | 304 Stainless Steel | Stainless Steel | 100 psi @ 72° F | 00000000 | 00000 | 10 | 0000000 | 00000 | 00000000 | 0000 | 00000000 | 0000 |

| 2 | 2 1/2" | White | 2 | 304 Stainless Steel | Stainless Steel | 100 psi @ 72° F | 00000000 | 00000 | 10 | 0000000 | 00000 | 00000000 | 0000 | 00000000 | 0000 |

| 3 | 3 5/8" | White | 2 | 304 Stainless Steel | Stainless Steel | 50 psi @ 72° F | 00000000 | 00000 | 10 | 0000000 | 00000 | 00000000 | 0000 | 00000000 | 0000 |

Wide-Airflow Air Nozzles

The flat nozzle tip distributes air over a wider area than focused-airflow nozzles. Volume (dBA) is measured 3 ft. from the nozzle at 80 psi.

Nozzles that are OSHA Compliant 29 CFR 1910.95 conform to requirements for noise.

For technical drawings and 3-D models, click on a part number.

Tip | ||||||||||

|---|---|---|---|---|---|---|---|---|---|---|

| Air Consumption | Max. Temp., °F | Volume | Wd. | Thick. | O'all Lg. | Max. Inlet Pressure, psi | Specifications Met | Each | ||

Barbed Male Inlet for 5/16" Hose ID | ||||||||||

Steel | ||||||||||

| F | 20 cfm @ 75 psi | 120° | 83 dBA @ 80 psi | 1 7/8" | 1/8" | 8" | 75 | FDA Compliant 21 CFR 177.2470, FDA Compliant 21 CFR 178.3297, OSHA Compliant 29 CFR 1910.95 | 0000000 | 000000 |

Food Industry Wide-Airflow Air Nozzles

These nozzles are made of FDA-listed materials. They have a flat shape that distributes air over a wider area than focused-airflow nozzles. All conform to OSHA 29 CFR 1910.95 requirements for noise.

For technical drawings and 3-D models, click on a part number.

Tip | ||||||||||

|---|---|---|---|---|---|---|---|---|---|---|

| Air Consumption | Max. Temp., °F | Volume | Wd. | Thick. | O'all Lg. | Max. Inlet Pressure, psi | Specifications Met | Each | ||

1/4 NPT Male | ||||||||||

Acetal Plastic | ||||||||||

| A | 13 cfm @ 75 psi | 120° | 80 dBA @ 80 psi | 1" | 1/16" | 3 9/16" | 85 | FDA Compliant 21 CFR 177.2470, FDA Compliant 21 CFR 178.3297, OSHA Compliant 29 CFR 1910.95 | 0000000 | 000000 |

| A | 18 cfm @ 75 psi | 120° | 86 dBA @ 80 psi | 1 7/8" | 1/4" | 3 1/2" | 85 | FDA Compliant 21 CFR 177.2470, FDA Compliant 21 CFR 178.3297, OSHA Compliant 29 CFR 1910.95 | 0000000 | 00000 |

| A | 20 cfm @ 75 psi | 120° | 83 dBA @ 80 psi | 1 7/8" | 1/8" | 3 9/16" | 85 | FDA Compliant 21 CFR 177.2470, FDA Compliant 21 CFR 178.3297, OSHA Compliant 29 CFR 1910.95 | 0000000 | 00000 |

1/4 BSPP Male | ||||||||||

Acetal Plastic | ||||||||||

| A | 13 cfm @ 75 psi | 120° | 80 dBA @ 80 psi | 1" | 1/16" | 3 9/16" | 85 | FDA Compliant 21 CFR 177.2470, FDA Compliant 21 CFR 178.3297, OSHA Compliant 29 CFR 1910.95 | 0000000 | 00000 |

| A | 18 cfm @ 75 psi | 120° | 84 dBA @ 80 psi | 1 7/8" | 1/4" | 3 5/8" | 85 | FDA Compliant 21 CFR 177.2470, FDA Compliant 21 CFR 178.3297, OSHA Compliant 29 CFR 1910.95 | 0000000 | 00000 |