Filter by

For Use With

Overall Length

Overall Width

Width

Length

Specifications Met

Export Control Classification Number (ECCN)

DFARS Specialty Metals

Height

Message

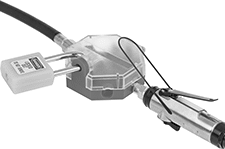

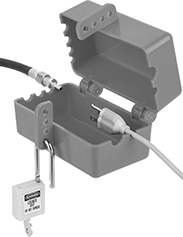

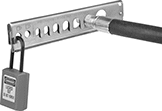

Air Hose Lockouts

|  |  |

Style A (Padlock Not Included) | Style B (Padlock Not Included) | C (Padlock Not Included) |

|  | |

Style D (Padlock Not Included) | Style E (Padlock Not Included) |

For Plug | Overall | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

Style | For Coupling Size | For Fitting Connection | For Quick-Disconnect Component | For Max. No. of Padlocks | For Max. Padlock Shackle Dia. | For Max. Cord Dia. | Max. Lg. | Wd. | Lg. | Wd. | Ht. | Temp. Range, ° F | Color | Label Included | Message | Each | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Lockout Cover | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Plastic | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| A | 1/4 | Quick Disconnect | Plug | 1 | 9/32" | — | — | — | 1 1/2" | 1" | 1" | -30 to 200 | Red | Yes | Pneumatic Tool Lockout | 0000000 | 000000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| B | 1/4, 3/8, 1/2 | Quick Disconnect | Plug | 2 | 1/4" | — | — | — | 3" | 3" | 7/8" | — | Red | No | — | 0000000 | 00000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| C | 1/8, 1/4, 3/8 | Quick Disconnect | Plug, Socket | 1 | 9/32" | — | — | — | 3 1/4" | 3 7/8" | 1 7/8" | -30 to 200 | Red | No | — | 0000000 | 00000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| D | 1/8 | Quick Disconnect | Plug | 4 | 1/4" | 1/4" | 5" | 2" to 3 1/2" | 6 1/4" | 4 1/2" | 3 3/4" | 0 to 175 | Red | Yes | Lockout Device—Do Not Plug In | 0000000 | 00000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Lockout Hasp | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Stainless Steel | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| E | 1/4, 5/16, 3/8, 7/16, 1/2, 9/16, 13/16 | Quick Disconnect | Plug | 2 | 9/32" | — | — | — | 7 3/4" | 1 3/8" | — | -30 to 183 | — | No | — | 0000000 | 00000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Lockout Bags

Overall | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

For Max. No. of Padlocks | For Max. Padlock Shackle Dia. | Lg. | Wd. | Color | Label Included | Language | Message | Specs. Met | Each | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Lockout Bag | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Canvas | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 1 | 9/32" | 18" | 9 3/4" | Yellow | Yes | English | Lock Out For Safety | OSHA Compliant 29 CFR 1910.147 | 00000000 | 000000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Nylon | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 6 | 9/32" | 17" | 7" | Red | Yes | English, Spanish, French | Locked Out—Do Not Remove Cerrado—No Lo Quite Verrouille—Ne Pas Enlever | OSHA Compliant 29 CFR 1910.147 | 0000000 | 00000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 6 | 9/32" | 26" | 10" | Red | Yes | English, Spanish, French | Locked Out—Do Not Remove Cerrado—No Lo Quite Verrouille—Ne Pas Enlever | OSHA Compliant 29 CFR 1910.147 | 0000000 | 00000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Polyester Plastic | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 1 | 5/16" | 5" | 5" | Red | Yes | English | Locked Out—Do Not Operate | OSHA Compliant 29 CFR 1910.147 | 00000000 | 00000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Electrical, Valve, and Air Hose Lockout Sets with Padlocks

For Use With | For Valve Control Type | Includes | Specs. Met | Each | ||

|---|---|---|---|---|---|---|

| Air Hose, Circuit Breakers, Electrical Panels, Electrical Plugs, Push Buttons, Valves, Wall Switches | Hand Wheel, Handle | 1 Each: Wall Switch Lockout 2 Each: Plug Lockouts 2 Valve Wheel Lockouts (1 Each that fits 1"-2 1/2" and 2 1/2"-5" Diameter Wheels) 3 Each: Circuit Breaker Lockouts 1 Each: Cable Lockout 2 Each: Lockout Hasps 1 Each: Air Hose Lockout 1 Each: Push Button Lockout 1 Each: Valve Handle Lockout (Fits 3/8 to 1 Pipe Size) 2 Each: 1/4" Shackle Diameter Keyed Differently Padlocks with Labels 5 Each: Cable Ties 5 Each: Tags Carrying Case | OSHA Compliant 29 CFR 1910.147 | 0000000 | 0000000 |

Wall-Mount Lockout Sets with Padlocks

Mounting Holes | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

Includes | Ht. | Wd. | Dp. | Fasteners Included | No. Of | Screw Size | Specs. Met | Each | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Board | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 10 Each: Tags 2 Each: Lockout Hasps 16 Each: 1/4" Shackle Diameter Keyed Differently Padlocks with Labels | 13 1/2" | 14 1/2" | 3" | No | 4 | No. 10 | OSHA Compliant 29 CFR 1910.147 | 00000000 | 0000000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 10 Each: Tags 10 Each: Cable Ties 2 Each: Lockout Hasps 8 Each: 1/4" Shackle Diameter Keyed Differently Padlocks with Labels | 15" | 15" | 2 1/2" | No | 4 | No. 10 | OSHA Compliant 29 CFR 1910.147, UL ECVP 2809-2 | 00000000 | 000000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 10 Each: Tags 10 Each: Cable Ties 2 Each: Lockout Hasps 12 Each: 1/4" Shackle Diameter Keyed Differently Padlocks with Labels | 23" | 15" | 2 1/2" | No | 4 | No. 10 | OSHA Compliant 29 CFR 1910.147, UL ECVP 2809-2 | 00000000 | 000000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 2 Each: Lockout Hasps 3 Each: Cable Ties 3 each: Tags 3 Each: 1/4" Shackle Diameter Keyed Differently Padlocks with Labels | 11" | 11" | 2 1/2" | No | 4 | No. 10 | OSHA Compliant 29 CFR 1910.147, UL ECVP 2809-2 | 00000000 | 000000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Case | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 4 Each: 1/4" Shackle Diameter Keyed Differently Padlocks with Labels 2 Each: Lockout Hasps 12 Each: Cable Ties 12 Each: Tags | 12 1/4" | 16" | 1 3/4" | No | 4 | No. 6 | OSHA Compliant 29 CFR 1910.147 | 0000000 | 000000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 2 Each: Lockout Hasps 24 Each: Tags 24 Each: Cable Ties 10 Each: 1/4" Shackle Diameter Keyed Differently Padlocks with Labels | 15 1/2" | 22" | 1 3/4" | No | 4 | No. 6 | OSHA Compliant 29 CFR 1910.147 | 0000000 | 000000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Threaded Flow-Adjustment Valves with Garden Hose Outlet

Brass Body

|  |

Female × Male | Male × Male |

Overall | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

Pipe Size | Flow Coefficient (Cv) | Hose Size | Max. Pressure @ Temp. | Ht. | Lg. | Temp. Range, ° F | Port-to-Port Lg. | Stem Type | For Use With | Valve Type | Each | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

NPT Female × GHT Male | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 1/2 | Not Rated | 3/4 | 125 psi @ 100° F | 3 1/8" | 3 3/8" | 40 to 180 | 1 1/2" | Nonrising | Water, Oil | Globe | 0000000 | 000000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 3/4 | Not Rated | 3/4 | 125 psi @ 100° F | 3 5/16" | 3 3/8" | 40 to 180 | 1 1/2" | Nonrising | Water, Oil | Globe | 0000000 | 00000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

NPT Male × GHT Male | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 1/2 | Not Rated | 3/4 | 125 psi @ 100° F | 3 3/8" | 3 11/16" | 40 to 180 | 1 9/16" | Nonrising | Water, Oil | Globe | 0000000 | 00000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 3/4 | Not Rated | 3/4 | 125 psi @ 100° F | 3 7/16" | 3 3/4" | 40 to 180 | 1 9/16" | Nonrising | Water, Oil | Globe | 0000000 | 00000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

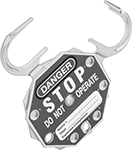

Choose-a-Color Lockout Hasps with Label

Hasp Clearance | Overall | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

Vertical | Horizontal | Hasp Thk. | For Max. No. of Padlocks | For Max. Padlock Shackle Dia. | Lg. | Wd. | Label Included | Language | Message | Specs. Met | Choose a Color | Each | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Lockout Hasp | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Anodized Aluminum | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 1 1/16" | 1 3/8" | 3/16" | 6 | 5/16" | 7 3/8" | 3" | Yes | English | Danger—Do Not Operate | OSHA Compliant 29 CFR 1910.147 | Blue , Green , Red | 00000000 | 000000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Low-Profile Lockout Hasps with Label

Hasp Clearance | Overall | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

Vertical | Horizontal | Hasp Thk. | For Max. No. of Padlocks | For Max. Padlock Shackle Dia. | Lg. | Wd. | Label Included | Language | Message | Specs. Met | Each | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Lockout Hasp | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Nickel-Plated Steel | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 1" | 1 1/4" | 1/4" | 7 | 3/8" | 3" | 3" | Yes | English | Danger—Do Not Operate | OSHA Compliant 29 CFR 1910.145, OSHA Compliant 29 CFR 1910.147 | 00000000 | 000000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Nonconductive Lockout Hasps with Tag Holder

Hasp Clearance | Overall | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

Vertical | Horizontal | Hasp Thk. | For Max. No. of Padlocks | For Max. Padlock Shackle Dia. | Lg. | Wd. | Color | Tag Included | Features | Specs. Met | Each | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Lockout Hasp | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Plastic | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 2 3/4" | 1 3/8" | 1/2" | 3 | 5/16" | 5 1/4" | 3" | Red | No | Tag Holder | OSHA Compliant 29 CFR 1910.147 | 00000000 | 000000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Trailer Brake Lockouts

Overall | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

For Max. No. of Padlocks | For Max. Padlock Shackle Dia. | Lg. | Wd. | Ht. | Color | Label Included | Specs. Met | Each | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Lockout Cover | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Plastic | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 1 | 9/32" | 4" | 3" | 2" | Red | No | OSHA Compliant 29 CFR 1910.147 | 0000000 | 000000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Dual-Jaw Lockout Hasps

Hasp Clearance | Overall | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

Vertical | Horizontal | Hasp Thickness | For Max. No. of Padlocks | For Max. Padlock Shackle Dia. | Lg. | Wd. | Label Included | Specs. Met | Each | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Lockout Hasp | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Zinc-Plated Steel | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 1/2" x 1" | 1/2" x 1" | 5/16" x 5/16" | 6 | 5/16" | 7 3/4" | 1 3/8" | No | OSHA Compliant 29 CFR 1910.147 | 00000000 | 000000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Aluminum | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 1" x 1 1/2" | 1" x 1 1/2" | 1/4" x 1/4" | 8 | 9/32" | 5 7/8" | 2" | No | OSHA Compliant 29 CFR 1910.147 | 00000000 | 0000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Lockout Hasps with Chain

Hasp Clearance | Overall | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

Vertical | Horizontal | Hasp Thk. | For Max. No. of Padlocks | For Max. Padlock Shackle Dia. | Lg. | Wd. | Color | Label Included | Specs. Met | Each | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Lockout Hasp | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Vinyl-Coated Aluminum | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 1" | 1" | 1/4" | 6 | 7/16" | 4 3/8" | 1 1/2" | Red | No | OSHA Compliant 29 CFR 1910.147 | 00000000 | 000000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 1 1/2" | 1 1/2" | 1/4" | 6 | 7/16" | 4 7/8" | 1 1/2" | Red | No | OSHA Compliant 29 CFR 1910.147 | 00000000 | 00000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Lockout Hasps with Label

Hasp Clearance | Overall | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

Style | Vertical | Horizontal | Hasp Thk. | For Max. No. of Padlocks | For Max. Padlock Shackle Dia. | Lg. | Wd. | Color | Label Included | Language | Message | Specs. Met | Each | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Lockout Hasp | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Vinyl-Coated Steel | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| A | 1 1/8" | 2 1/16" | 3/16" | 6 | 5/16" | 5 7/16" | 3 7/16" | Red | Yes | English | Danger—Do Not Operate | OSHA Compliant 29 CFR 1910.147 | 0000000 | 000000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Anodized Aluminum | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| B | 1 1/2" | 1 1/2" | 3/16" | 6 | 9/32" | 7" | 2 3/4" | Red | Yes | English | Danger—Do Not Operate | OSHA Compliant 29 CFR 1910.147 | 0000000 | 00000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Low-Profile Lockout Hasps

Hasp Clearance | Overall | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

Vertical | Horizontal | Hasp Thk. | For Max. No. of Padlocks | For Max. Padlock Shackle Dia. | Lg. | Wd. | Label Included | Specs. Met | Each | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Lockout Hasp | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Nickel-Plated Steel | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 1" | 1 1/4" | 1/4" | 7 | 3/8" | 3" | 3" | No | OSHA Compliant 29 CFR 1910.147 | 00000000 | 000000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

304 Stainless Steel | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 1" | 1 1/4" | 1/4" | 7 | 3/8" | 3" | 3" | No | OSHA Compliant 29 CFR 1910.147 | 00000000 | 00000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

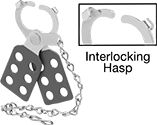

Pry-Resistant Interlocking-Hasp Lockouts with Chain

Hasp Clearance | Overall | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

Vertical | Horizontal | Hasp Thk. | For Max. No. of Padlocks | For Max. Padlock Shackle Dia. | Lg. | Wd. | Mounting Chain Lg. | Label Included | Specs. Met | Each | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Lockout Hasp | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Vinyl-Coated Steel | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 1" | 1" | 1/8" | 6 | 3/8" | 4 1/2" | 1 1/2" | 8" | No | OSHA Compliant 29 CFR 1910.147 | 00000000 | 00000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 1 1/2" | 1 1/2" | 1/8" | 6 | 3/8" | 5" | 1 1/2" | 8" | No | OSHA Compliant 29 CFR 1910.147 | 00000000 | 00000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Wall-Mount Group Lockout Boxes

Mounting Holes | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

For Max. No. of Padlocks | For Max. Padlock Shackle Dia. | Lg. | Wd. | Ht. | Color | No. of Key Hooks | Fasteners Included | No. Of | Screw Size | No. of Windows | Window Material | Includes | Features | Specs. Met | Each | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Lockout Box | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Plastic | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 12 (Outside of Box) | 9/32" | 2 3/4" | 4" | 5 3/4" | Red | 3 | No | 3 | No. 4 | 1 | Polycarbonate | Wall-Mount Bracket | Key Slot | OSHA Compliant 29 CFR 1910.147 | 00000000 | 000000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 26 (Outside of Box) | 15/32" | 4" | 13" | 11" | Red | 11 | No | 2 | No. 10 | 1 | Polycarbonate | — | Control-Lock Hole, Key Slot | OSHA Compliant 29 CFR 1910.147 | 000000000 | 000000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Pry-Resistant Lockout Hasps

Hasp Clearance | Overall | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

Vertical | Horizontal | Hasp Thk. | For Max. No. of Padlocks | For Max. Padlock Shackle Dia. | Lg. | Wd. | Color | Label Included | Specs. Met | Each | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Lockout Hasp | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Plastic | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 1 1/8" | 1" | 1/8" | 2 | 9/32" | 3 1/8" | 2 3/16" | Red | No | OSHA Compliant 29 CFR 1910.147 | 000000000 | 00000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Zinc-Plated Steel | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 3" | 1" | 1/4" | 6 | 3/8" | 6 3/4" | 2 1/4" | — | No | OSHA Compliant 29 CFR 1910.147 | 00000000 | 00000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Vinyl-Coated Zinc-Plated Steel | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 1 1/4" | 1" | 1/4" | 6 | 3/8" | 5" | 2 5/16" | Red | No | OSHA Compliant 29 CFR 1910.147 | 00000000 | 00000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Pry-Resistant Interlocking-Hasp Lockouts

Hasp Clearance | Overall | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

Vertical | Horizontal | Hasp Thk. | For Max. No. of Padlocks | For Max. Padlock Shackle Dia. | Lg. | Wd. | Color | Label Included | Specs. Met | Each | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Lockout Hasp | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Powder-Coated Steel | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 1" | 1" | 1/2" | 6 | 3/8" | 4 1/2" | 1 1/2" | Red | No | OSHA Compliant 29 CFR 1910.147, UL ECVP 2809-2 | 000000000 | 00000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 1 1/2" | 1 1/2" | 1/2" | 6 | 3/8" | 5" | 1 1/2" | Red | No | OSHA Compliant 29 CFR 1910.147, UL ECVP 2809-2 | 000000000 | 0000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Vinyl-Coated Steel | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 1" | 1" | 1/8" | 6 | 3/8" | 4 1/2" | 1 1/2" | Red | No | OSHA Compliant 29 CFR 1910.147 | 00000000 | 0000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 1 1/2" | 1 1/2" | 1/8" | 6 | 3/8" | 5" | 1 1/2" | Red | No | OSHA Compliant 29 CFR 1910.147 | 00000000 | 00000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Nonconductive Lockout Hasps

|  |  |  | |

Style A | Style B | Style C | Style D | Style E |

Hasp Clearance | Overall | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

Style | Vertical | Horizontal | Hasp Thk. | For Max. No. of Padlocks | For Max. Padlock Shackle Dia. | Lg. | Wd. | Color | Label Included | Specs. Met | Each | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Lockout Hasp | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Plastic | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| A | 1" | 1" | 3/8" | 6 | 3/8" | 5" | 1 1/2" | Red | No | OSHA Compliant 29 CFR 1910.147, UL ECVP 2809-2 | 000000000 | 000000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| A | 1 1/2" | 1 1/2" | 3/8" | 6 | 3/8" | 4 1/2" | 1 1/2" | Red | No | OSHA Compliant 29 CFR 1910.147, UL ECVP 2809-2 | 000000000 | 00000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| B | 1 3/4" | 3/4" | 1" | 2 | 1 1/2" | 4 3/4" | 2 1/2" | Red | No | OSHA Compliant 29 CFR 1910.147 | 000000000 | 00000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| C | 1 15/16" | 1" | 1/4" | 3 | 1/4" | 8" | 1 3/4" | Red | Yes | OSHA Compliant 29 CFR 1910.147, UL ECVP 2809-2 | 000000000 | 00000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| D | 3 1/2" | 1 1/4" | 3/8" | 6 | 3/8" | 7" | 1 3/4" | Orange | No | OSHA Compliant 29 CFR 1910.147 | 00000000 | 00000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| E | 3 1/2" | 1 1/4" | 1/2" | 12 | 1/4" | 7 1/4" | 3 1/4" | Red | No | OSHA Compliant 29 CFR 1910.147 | 000000000 | 00000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Portable/Wall-Mount Group Lockout Boxes

Mounting Holes | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

Style | Color | Lg. | Wd. | Ht. | For Max. No. of Padlocks | For Max. Padlock Shackle Dia. | No. of Key Hooks | Fasteners Included | No. Of | Screw Size | Mounting Location | Mount Type | No. of Windows | Features | Enclosure Rating | Each | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Plastic Box with Polycarbonate Window | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| A | Red | 13" | 3 1/2" | 13" | 44 (Outside of Box) | 5/16" | 16 | No | 2 | 1/4" | Wall | Freestanding | 1 | Control-Lock Hole, Handle, Key Slot | — | 0000000 | 000000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Powder-Coated Steel Box | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| B | Red | 6 3/8" | 3 1/2" | 12 3/4" | 14 (Outside of Box) | 9/32" | 12 | No | 4 | No. 8 | Wall | Freestanding | — | Handle, Key Slot | — | 00000000 | 00000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| B | Yellow | 6 3/8" | 3 1/2" | 12 3/4" | 14 (Outside of Box) | 9/32" | 12 | No | 4 | No. 8 | Wall | Freestanding | — | Handle, Key Slot | — | 00000000 | 00000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Powder-Coated Steel Box with Polycarbonate Window | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| C | Red | 10 1/2" | 3 1/2" | 6 1/8" | 12 (Outside of Box) | 5/16" | 6 | No | 2 | No. 8 | Wall | Freestanding | 1 | Handle, Key Slot | — | 0000000 | 00000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Powder-Coated 430 Stainless Steel Box with Wall-Mount Bracket, Polycarbonate Window | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| D | Red | 8 3/8" | 4" | 6 7/8" | 8 (Outside of Box) | 3/8" | 4 | No | 3 | No. 10 | Wall | Freestanding | 1 | Dry Erase Label, Handle, Key Slot | — | 0000000 | 00000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Powder-Coated 430 Stainless Steel Box with Document Display, Polycarbonate Window | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| E | Red | 12 1/8" | 4 3/4" | 31" | 12 (Outside of Box), 12 (Removable Lock Caddy) | 9/32" | 12 | No | 8 | No. 8 | Wall | — | 2 | Control-Lock Hole, Dry Erase Label, Handle, Key Slot, Removable Key Cup | IP03 | 000000000 | 000000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Pry-Resistant Lockout Hasps with Padlock Slot

Hasp Clearance | Overall | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

Vertical | Horizontal | Hasp Thk. | For Max. No. of Padlocks | For Max. Padlock Shackle Dia. | Body Ht. | Lg. | Wd. | Label Included | Specs. Met | Each | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Lockout Hasp | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Zinc-Plated Steel | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 1" | 1" | 1/8" | 5 | 5/16" | 2" | 3 1/4" | 2 1/4" | No | OSHA Compliant 29 CFR 1910.147 | 00000000 | 00000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 1" | 1" | 1/4" | 5 | 5/16" | 2" | 3 1/4" | 2 1/4" | No | OSHA Compliant 29 CFR 1910.147 | 00000000 | 0000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 1 1/2" | 1" | 3/8" | 6 | 7/16" | 3 1/2" | 5 3/8" | 2 1/2" | No | OSHA Compliant 29 CFR 1910.147 | 000000000 | 00000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 3" | 1" | 1/8" | 9 | 5/16" | 3 1/2" | 6 5/8" | 2 1/4" | No | OSHA Compliant 29 CFR 1910.147 | 00000000 | 00000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 3" | 1" | 1/4" | 9 | 5/16" | 3 1/2" | 6 3/4" | 2 1/4" | No | OSHA Compliant 29 CFR 1910.147 | 00000000 | 00000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 4 3/4" | 1 1/2" | 1/4" | 3 | 3/8" | 2" | 7" | 3" | No | OSHA Compliant 29 CFR 1910.147 | 000000000 | 00000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

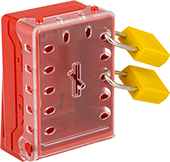

Portable Group Lockout Boxes

Style | Min. Padlock Vert. Shackle Clearance | For Max. No. of Padlocks | For Max. Padlock Shackle Dia. | Lg. | Wd. | Ht. | Color | No. of Windows | Window Material | Features | Specs. Met | Stackable | Each | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

Lockout Box | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Plastic | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| A | 1 1/2" | 17 (Outside of Box) | 1/4" | 7 3/4" | 4" | 7 3/4" | Red | 1 | Polycarbonate | Handle, Key Slot | OSHA Compliant 29 CFR 1910.147 | No | 00000000 | 000000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Powder-Coated Steel | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| B | 5/8" | 13 (Outside of Box) | 9/32" | 9" | 3 1/2" | 6" | Blue | — | — | Control-Lock Hole, Handle, Key Slot | OSHA Compliant 29 CFR 1910.147 | No | 00000000 | 00000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| B | 5/8" | 13 (Outside of Box) | 9/32" | 9" | 3 1/2" | 6" | Red | — | — | Control-Lock Hole, Handle, Key Slot | OSHA Compliant 29 CFR 1910.147 | No | 00000000 | 00000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| B | 3/4" | 13 (Outside of Box) | 5/16" | 10" | 4" | 6" | Yellow | — | — | Control-Lock Hole, Handle, Key Slot | OSHA Compliant 29 CFR 1910.147 | No | 000000000 | 00000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| B | 1" | 7 (Outside of Box) | 5/16" | 4 1/4" | 4 1/4" | 6 1/4" | Red | — | — | Control-Lock Hole, Handle, Key Slot | OSHA Compliant 29 CFR 1910.147 | No | 00000000 | 00000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| C | 1/2" | 21 (Outside of Box) | 5/16" | 12" | 8 1/4" | 9" | Red | 1 | Polycarbonate | Control-Lock Hole, Handle, Key Slot, Removable Key Cup | OSHA Compliant 29 CFR 1910.147 | Yes | 00000000 | 000000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| C | 3/4" | 20 (Outside of Box) | 1/4" | 8" | 4 1/2" | 4 3/4" | Red | 2 | Polycarbonate | Handle, Key Slot | OSHA Compliant 29 CFR 1910.147 | No | 00000000 | 00000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Powder-Coated Stainless Steel | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| C | 3/4" | 19 (Outside of Box) | 3/8" | 12" | 6 1/2" | 5 3/4" | Red | 1 | Polycarbonate | Control-Lock Hole, Drain Holes, Handle, Key Slot, Removable Key Cup | OSHA Compliant 29 CFR 1910.147 | Yes | 00000000 | 00000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Lockout Hasps

Hasp Clearance | Overall | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

Vertical | Horizontal | Hasp Thk. | For Max. No. of Padlocks | For Max. Padlock Shackle Dia. | Lg. | Wd. | Color | Specs. Met | Each | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Aluminum | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Powder Coated | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 1" | 1" | 1/2" | 6 | 3/8" | 4 7/16" | 1 1/2" | Red | OSHA Compliant 29 CFR 1910.147, UL ECVP 2809-2 | 000000000 | 000000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 1 1/2" | 1 1/2" | 1/2" | 6 | 3/8" | 5" | 2 1/16" | Red | OSHA Compliant 29 CFR 1910.147, UL ECVP 2809-2 | 000000000 | 00000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Vinyl Coated | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 1" | 1" | 1/4" | 6 | 7/16" | 4 3/8" | 1 1/2" | Red | OSHA Compliant 29 CFR 1910.147 | 00000000 | 00000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 1 1/2" | 1 1/2" | 1/4" | 6 | 7/16" | 4 7/8" | 1 1/2" | Red | OSHA Compliant 29 CFR 1910.147 | 00000000 | 00000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Steel | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Powder Coated | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 1" | 1" | 1/4" | 12 | 3/8" | 6 1/2" | 1 1/2" | Red | OSHA Compliant 29 CFR 1910.147 | 000000000 | 00000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 1" | 1" | 1/4" | 24 | 1/4" | 10 3/8" | 1 1/2" | Red | OSHA Compliant 29 CFR 1910.147 | 000000000 | 00000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Vinyl Coated | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 1" | 1" | 3/8" | 6 | 3/8" | 4 1/2" | 1 3/4" | Red | OSHA Compliant 29 CFR 1910.147 | 000000000 | 0000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 1 1/2" | 1 1/2" | 3/8" | 6 | 3/8" | 5" | 2 3/8" | Red | OSHA Compliant 29 CFR 1910.147 | 000000000 | 0000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Epoxy Coated | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 1" | 1" | 3/8" | 6 | 3/8" | 5 1/16" | 1 3/4" | Yellow | OSHA Compliant 29 CFR 1910.147 | 000000000 | 00000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 1 1/2" | 1 1/2" | 3/8" | 6 | 3/8" | 5 1/16" | 2 1/4" | Yellow | OSHA Compliant 29 CFR 1910.147 | 000000000 | 00000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

304 Stainless Steel | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Vinyl Coated | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 1" | 1" | 1/4" | 6 | 7/16" | 4 7/16" | 1 1/2" | Red | OSHA Compliant 29 CFR 1910.147 | 00000000 | 00000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 1 1/4" | 1 1/4" | 1/4" | 6 | 5/16" | 4 9/16" | 1 1/2" | Red | OSHA Compliant 29 CFR 1910.147 | 00000000 | 00000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||