About Plastic and Rubber Tubing

More

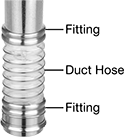

About Duct Hose

More

About Hose

More

Dry-Food Hose

- Temperature Range: 0° to 150° F

- Material: PVC

- Color: Clear

- Specifications Met: See table

- Compatible Hose Fittings: Cam-and-Groove

Move flour, grain, rice, sugar, and other dry food through your line. This hose meets strict FDA standards for food safety or 3-A standards for a sanitary design. Made of PVC, it won’t impart odors or tastes on the food. A smooth interior prevents the food from getting caught or building up inside this hose. It's also clear, so you can monitor the food as it passes through the hose. This hose is sturdy enough to be used as part of vacuum system—it won’t collapse when hooked up to a vacuum pump. The spiral reinforcement on the outside increases the hose's flexibility.

Hose with a static control wire creates an escape route for static buildup when used in a grounded system. The wire runs through the spiral, so it won't be exposed as the hose wears.

Per Ft. | |||||||||

|---|---|---|---|---|---|---|---|---|---|

| ID | OD | Bend Radius | Max. Pressure | Max. Vacuum | Specifications Met | Max. Continuous Lg., ft. | 1-99 | 100-Up | |

| 1" | 1 5/16" | 2" | 55 psi @ 72° F | 28" of Hg @ 72° F | 3-A Certified 62-02, FDA Compliant 21 CFR 177.1680, FDA Compliant 21 CFR 177.2600 | 100 | 5199K71 | 00000 | 00000 |

| 1 1/4" | 1 5/8" | 2" | 50 psi @ 72° F | 28" of Hg @ 72° F | 3-A Certified 62-02, FDA Compliant 21 CFR 177.1680, FDA Compliant 21 CFR 177.2600 | 100 | 5199K72 | 0000 | 0000 |

| 1 1/2" | 1 15/16" | 3" | 50 psi @ 72° F | 28" of Hg @ 72° F | 3-A Certified 62-02, FDA Compliant 21 CFR 177.1680, FDA Compliant 21 CFR 177.2600 | 100 | 5199K73 | 0000 | 0000 |

| 2" | 2 7/16" | 4" | 40 psi @ 72° F | 28" of Hg @ 72° F | 3-A Certified 62-02, FDA Compliant 21 CFR 177.1680, FDA Compliant 21 CFR 177.2600 | 100 | 5199K74 | 0000 | 0000 |

| 2 1/2" | 3" | 5" | 40 psi @ 72° F | 28" of Hg @ 72° F | 3-A Certified 62-02, FDA Compliant 21 CFR 177.1680, FDA Compliant 21 CFR 177.2600 | 100 | 5199K75 | 00000 | 00000 |

| 3" | 3 11/16" | 6" | 40 psi @ 72° F | 28" of Hg @ 72° F | 3-A Certified 62-02, FDA Compliant 21 CFR 177.1680, FDA Compliant 21 CFR 177.2600 | 100 | 5199K76 | 00000 | 00000 |

| 4" | 4 3/4" | 10" | 35 psi @ 72° F | 24" of Hg @ 72° F | 3-A Certified 62-02, FDA Compliant 21 CFR 177.1680, FDA Compliant 21 CFR 177.2600 | 100 | 5199K78 | 00000 | 00000 |

| 5" | 5 3/4" | 16" | 30 psi @ 72° F | 24" of Hg @ 72° F | 3-A Certified 62-02, FDA Compliant 21 CFR 177.1680, FDA Compliant 21 CFR 177.2600 | 20 | 5199K89 | 00000 | 00000 |

| 6" | 6 15/16" | 18" | 30 psi @ 72° F | 24" of Hg @ 72° F | 3-A Certified 62-02, FDA Compliant 21 CFR 177.1680, FDA Compliant 21 CFR 177.2600 | 20 | 5199K81 | 00000 | 00000 |

| 8" | 9" | 36" | 20 psi @ 72° F | 20" of Hg @ 72° F | 3-A Certified 62-02, FDA Compliant 21 CFR 177.1680, FDA Compliant 21 CFR 177.2600 | 20 | 5199K84 | 00000 | 00000 |

Per Ft. | ||||||||||

|---|---|---|---|---|---|---|---|---|---|---|

| ID | OD | Bend Radius | Max. Pressure | Max. Vacuum | Surface Resistance, ohms | Specifications Met | Max. Continuous Lg., ft. | 1-49 | 50-Up | |

| 1" | 1 5/16" | 2" | 55 psi @ 72° F | 28" of Hg @ 72° F | 1010 | FDA Compliant 21 CFR 177.1680, FDA Compliant 21 CFR 177.2600 | 50 | 5179K43 | 000000 | 00000 |

| 1 1/4" | 1 11/16" | 2" | 50 psi @ 72° F | 28" of Hg @ 72° F | 1010 | FDA Compliant 21 CFR 177.1680, FDA Compliant 21 CFR 177.2600 | 50 | 5179K23 | 00000 | 0000 |

| 1 1/2" | 1 15/16" | 3" | 50 psi @ 72° F | 28" of Hg @ 72° F | 1010 | FDA Compliant 21 CFR 177.1680, FDA Compliant 21 CFR 177.2600 | 50 | 5179K24 | 00000 | 00000 |

| 2" | 2 1/2" | 4" | 40 psi @ 72° F | 28" of Hg @ 72° F | 1010 | FDA Compliant 21 CFR 177.1680, FDA Compliant 21 CFR 177.2600 | 50 | 5179K25 | 00000 | 00000 |

| 2 1/2" | 3 1/16" | 5" | 40 psi @ 72° F | 28" of Hg @ 72° F | 1010 | FDA Compliant 21 CFR 177.1680, FDA Compliant 21 CFR 177.2600 | 50 | 5179K26 | 00000 | 00000 |

| 3" | 3 11/16" | 6" | 40 psi @ 72° F | 28" of Hg @ 72° F | 1010 | FDA Compliant 21 CFR 177.1680, FDA Compliant 21 CFR 177.2600 | 50 | 5179K27 | 00000 | 00000 |

| 4" | 4 3/4" | 10" | 35 psi @ 72° F | 24" of Hg @ 72° F | 1010 | FDA Compliant 21 CFR 177.1680, FDA Compliant 21 CFR 177.2600 | 50 | 5179K28 | 00000 | 00000 |

| 5" | 5 3/4" | 16" | 30 psi @ 72° F | 24" of Hg @ 72° F | 1010 | FDA Compliant 21 CFR 177.1680, FDA Compliant 21 CFR 177.2600 | 50 | 5179K45 | 00000 | 00000 |

| 6" | 6 13/16" | 18" | 30 psi @ 72° F | 24" of Hg @ 72° F | 1010 | FDA Compliant 21 CFR 177.1680, FDA Compliant 21 CFR 177.2600 | 50 | 5179K46 | 00000 | 00000 |

| 8" | 9" | 36" | 20 psi @ 72° F | 20" of Hg @ 72° F | 1010 | FDA Compliant 21 CFR 177.1680, FDA Compliant 21 CFR 177.2600 | 20 | 5179K44 | 000000 | 00000 |

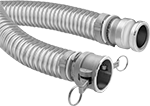

Dry-Food Hose with Cam-and-Groove Socket and Plug

- Temperature Range: 0° to 150° F

- Material: PVC

- Color: Clear

- Specifications Met: 3-A Certified 62-02, FDA Compliant 21 CFR 177.1680, FDA Compliant 21 CFR 177.2600

Transfer flour, grain, rice, sugar, and other dry food through lines connected by cam-and-groove fittings. This hose meets strict FDA standards for food safety and 3-A standards for a sanitary design. Made of PVC, it won’t impart tastes or odors on food products. Its interior is smooth, so food won't get caught or build up inside the hose. When vacuum is applied, this hose holds its shape and won't collapse. The spiral reinforcement on the outside increases its flexibility. To connect fittings, insert the plug into the socket and push the levers down.

Hose with static control wire provides an escape route for static buildup when used in a grounded system. The wire runs through the hose’s spiral, so it won’t be exposed if the hose wears.

| Coupling Size | ID | OD | Bend Radius | Max. Pressure | Max. Vacuum | 5 ft. | 10 ft. | 15 ft. | 20 ft. | 25 ft. | 30 ft. | 50 ft. | |

Aluminum Cam-and-Groove Female Socket × Aluminum Cam-and-Groove Male Plug | |||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| 1 1/2 × 1 1/2 | 1 1/2" | 1 15/16" | 3" | 50 psi @ 72° F | 28" of Hg @ 72° F | 5199K53 | |||||||

| 2 × 2 | 2" | 2 7/16" | 4" | 40 psi @ 72° F | 28" of Hg @ 72° F | 5199K54 | |||||||

| 2 1/2 × 2 1/2 | 2 1/2" | 3" | 5" | 40 psi @ 72° F | 28" of Hg @ 72° F | 5199K55 | |||||||

| 3 × 3 | 3" | 3 11/16" | 6" | 40 psi @ 72° F | 28" of Hg @ 72° F | 5199K56 | |||||||

| 4 × 4 | 4" | 4 3/4" | 10" | 35 psi @ 72° F | 24" of Hg @ 72° F | 5199K58 | |||||||

| Coupling Size | ID | OD | Bend Radius | Max. Pressure | Max. Vacuum | Surface Resistivity, ohms-m | 5 ft. | 10 ft. | 15 ft. | 20 ft. | 25 ft. | 30 ft. | 50 ft. | |

Aluminum Cam-and-Groove Female Socket × Aluminum Cam-and-Groove Male Plug | ||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| 1 1/2 × 1 1/2 | 1 1/2" | 1 15/16" | 3" | 50 psi @ 72° F | 28" of Hg @ 72° F | 103 to 106 | 5179K12 | |||||||

| 2 × 2 | 2" | 2 1/2" | 4" | 40 psi @ 72° F | 28" of Hg @ 72° F | 103 to 106 | 5179K13 | |||||||

| 3 × 3 | 3" | 3 11/16" | 6" | 40 psi @ 72° F | 28" of Hg @ 72° F | 103 to 106 | 5179K15 | |||||||

| 4 × 4 | 4" | 4 3/4" | 10" | 35 psi @ 72° F | 24" of Hg @ 72° F | 103 to 106 | 5179K16 | |||||||

Large-Diameter Thin-Wall Firm Rubber Tubing for Food, Beverage, and Dairy

- Flexible

- Firm (Durometer 80A)

- Temperature Range: -40° to 190° F

Sized for vibrating sifters, screeners, hoppers, and packaging equipment, this tubing has a diameter of 4" or larger to handle a variety of bulk food processing applications. It is made of FDA listed materials. Free of plasticizers like DEHP, it won’t impart tastes or odors to the product passing through it. Tubing is polyurethane for excellent resistance to abrasion and tearing. The tubing material is ether based, so the tubing won’t degrade in humid environments. Tubing is clear, so you can see inside the line to monitor flow. It is flexible and bends easily around objects.

Tubing connects to fittings with a worm-drive clamp (sold separately).

| ID | OD | Wall Thick. | Specifications Met | Lengths, ft. | Per Ft. | |

Clear Polyurethane Rubber | ||||||

|---|---|---|---|---|---|---|

| 4 1/4" | 4 5/16" | 1/32" | FDA Compliant 21 CFR 177.1680 | 5971K13 | 000000 | |

| 5 1/4" | 5 5/16" | 1/32" | FDA Compliant 21 CFR 177.1680 | 5971K14 | 00000 | |

| 6 1/4" | 6 5/16" | 1/32" | FDA Compliant 21 CFR 177.1680 | 5971K15 | 00000 | |

| 7 1/8" | 7 3/16" | 1/32" | FDA Compliant 21 CFR 177.1680 | 5971K16 | 00000 | |

| 8 1/8" | 8 3/16" | 1/32" | FDA Compliant 21 CFR 177.1680 | 5971K17 | 00000 | |

| 9 1/8" | 9 3/16" | 1/32" | FDA Compliant 21 CFR 177.1680 | 5971K18 | 00000 | |

| 10 1/8" | 10 3/16" | 1/32" | FDA Compliant 21 CFR 177.1680 | 5971K19 | 00000 | |

| 12 1/8" | 12 3/16" | 1/32" | FDA Compliant 21 CFR 177.1680 | 5971K21 | 00000 | |

Sanitary Snap-In Duct Hose and Fittings

- Flexible

- Color: Clear

- Temperature Range: See Table

Transfer material from sifters, feeders, and strainers to other parts of your sanitary line with these hose lengths and fittings. They’re 3-A and USDA certified to meet sanitary design standards, as well as FDA compliant for direct contact with food. Cuffs at each end of the hose have grooves that snap into matching grooves on fittings. These grooves form a seal that’s more sanitary than hose clamp connections, since there are no gaps where contaminants could gather. It’s also tighter and less likely to leak than hose clamps. When pressure increases, the hose presses against fittings, tightening the seal. You don’t need tools to install or remove this hose—squeeze the end cuff to slide it into or out of fittings.

Made from flexible, abrasion-resistant plastic, this hose won’t crack and rip from the movement of your machines. It’s also chemical-resistant, so it holds up to frequent washing during clean-in-place (CIP) cycles. The smooth seams won't trap food and other particles. It's clear, so you can monitor flow.

When choosing a hose length, consider the side-to-side, horizontal, and rotational movement of your machines. You’ll need hose that’s slightly longer than the gap between equipment to account for movement and vibration.

Hose with 1" coil is good for applications with up-and-down movement, such as bag feeders. The closely-spaced internal coil helps the hose maintain its shape while it’s compressed.

Hose without coil has thick, flexible walls that bend side-to-side to handle misalignment and rotation. It’s often used with sifters and strainers. This hose doesn’t handle up-and-down movement as well as hose with 1" coil, since the walls may crease when the hose is compressed. Creases in the hose wall restrict flow, increase wear, and create pockets that trap food and liquids. This hose is latex-free and doesn’t include Bisphenol A (BPA), which is a chemical that can contaminate your line.

Fittings are stainless steel, which won’t corrode from harsh cleaners and sanitizers. You can cut them to fit onto existing pipes. Weld them to the inlets and outlets on your equipment before attaching hose.

Spiral | ||||||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| ID | OD | Bend Radius | Compresses To | Max. Vacuum | Max. Pressure | Temperature Range, °F | Material Thickness | Direction | Material | Surface Resistivity, ohms/sq. | Specifications Met | 4" Lg. | 6" Lg. | 8" Lg. | 10" Lg. | 12" Lg. | 16" Lg. | |

Plastic | ||||||||||||||||||

1" Coil | ||||||||||||||||||

| 3 15/16" | 4" | Not Rated | 33% | Not Rated | Not Rated | 0° to 180° | 0.024" | Right Hand | Metal | Not Rated | 3-A Certified 20-27 3-A Certified 63-03 FDA Compliant 21 CFR 175.105 FDA Compliant 21 CFR 177.1680 FDA Compliant 21 CFR 177.2600 | 7133N6 | ||||||

Without Coil | ||||||||||||||||||

| 3 15/16" | 4" | Not Rated | 40% | Not Rated | Not Rated | -10° to 230° | 0.035" | __ | __ | 1010 | 3-A Certified 20-27 3-A Certified 63-03 FDA Compliant 21 CFR 177.1680 FDA Compliant 21 CFR 177.2600 | 7133N1 | ||||||

| 5 15/16" | 6" | Not Rated | 40% | Not Rated | Not Rated | -10° to 230° | 0.035" | __ | __ | 1010 | 3-A Certified 20-27 3-A Certified 63-03 FDA Compliant 21 CFR 177.1680 FDA Compliant 21 CFR 177.2600 | 7133N2 | ||||||

| 7 15/16" | 8" | Not Rated | 40% | Not Rated | Not Rated | -10° to 230° | 0.035" | __ | __ | 1010 | 3-A Certified 20-27 3-A Certified 63-03 FDA Compliant 21 CFR 177.1680 FDA Compliant 21 CFR 177.2600 | 7133N3 | ||||||