About Metal Tubing

More

About Conduit

More

Smooth-Bore Seamless Stainless Steel Tubing

Seamless construction with no weld bead gives this tubing an interior with unrestricted flow. It is stronger than welded tubing and can be flared without splitting.

304 stainless steel has very good corrosion resistance.

316 stainless steel offers excellent corrosion resistance.

Tubing that meets ASTM specifications adheres to international standards for dimensions and materials.

- Temperature Range: See Table

- Bending Method: Tube Bender

- For Use With: Natural Gas, Water, Oil, Air

- Compatible Tubing Fittings: Butt Weld, Compression, Flared, and Yor-Lok

- Temperature Range:

304 Stainless Steel: -425° to 1500° F

316 Stainless Steel: -325° to 1500° F - Bending Method: Tube Bender

- For Use With: Natural Gas, Water, Oil, Air

- Compatible Tubing Fittings: Butt Weld, Compression, Flared, and Yor-Lok

Welded Stainless Steel Tubing

When your application does not require a smooth interior, this tubing is an economical choice. It has a weld bead on the inside.

304 stainless steel has very good corrosion resistance.

316 stainless steel offers excellent corrosion resistance.

- Temperature Range: 304 Stainless Steel: -420° to 1500° F

316 Stainless Steel: -320° to 1500° F - Bending Method: Tube Bender

- Compatible Tube Fittings: See table

| OD | Wall Thickness | ID | Maximum Pressure | Temper Rating | Compatible Tube Fittings | 1 ft. | 3 ft. | 6 ft. | |

304 Stainless Steel—For Use With Air, Deionized Water, Hydraulic Fluid, Natural Gas, Oil, Water | |||||||||

|---|---|---|---|---|---|---|---|---|---|

| 3/4" | 0.065" | 0.62" | 2,900 psi @ 72° F | Soft | Butt Weld, Compression | 00000000 | |||

316 Stainless Steel—For Use With Air, Deionized Water, Hydraulic Fluid, Natural Gas, Oil, Water | |||||||||

| 3/4" | 0.065" | 0.62" | 2,900 psi @ 72° F | Soft | Butt Weld, Compression | 000000000 | |||

High-Polish Stainless Steel Tubing for Food, Beverage, and Dairy

The interior and exterior are polished to a high-luster finish to resist particle buildup and allow for easy cleaning. Tubing is welded with a smoothed weld bead on the inside.

304/304L stainless steel tubing has very good corrosion resistance. 316L stainless steel tubing has excellent corrosion resistance.

Note: Ra measures the smoothness of the tubing; the lower the Ra value, the smoother and more polished the surface.

For technical drawings and 3-D models, click on a part number.

- Temperature Range: -420° to 1500° F

- Bending Method: Tube Bender

- Compatible Tube Fittings: Butt Weld and High-Polish Quick Clamp

Smoothness, Ra | |||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|

| OD | Wall Thick. | ID | Max. Pressure | Temper Rating | Interior | Exterior | Specifications Met | 1 ft. | 3 ft. | 6 ft. | |

304L Stainless Steel | |||||||||||

| 3/4" | 0.065" | 0.62" | 2,300 psi @ 72° F | Soft | 20 | 30 | 3-A Certified 33-03, ASTM A269, ASTM A270 | 0000000 | |||

316L Stainless Steel | |||||||||||

| 3/4" | 0.065" | 0.62" | 2,300 psi @ 72° F | Soft | 20 | 30 | 3-A Certified 33-03, ASTM A269, ASTM A270 | 0000000 | |||

High-Polish Stainless Steel Tubing for Pharmaceuticals with Certification

- Temperature Range: -420° to 1500° F

- Bending Method: Tube Bender

- Compatible Tube Fittings: High-Polish Quick Clamp

This premium-grade tubing is polished to a high-luster finish to reduce particle buildup and allow for easy cleaning. It has excellent corrosion resistance. Tubing with interior smoothness of 20 Ra is capped, put in a plastic sleeve, then sealed in a cardboard tube. Tubing with interior smoothness of 15 Ra comes in a plastic sleeve. Tubing comes with a traceable lot number and material test report.

Seamless tubing is smoother and stronger than welded tubing and can be flared without splitting.

Note: Ra measures the smoothness of the tubing; the lower the Ra value, the smoother and more polished the surface.

For technical drawings and 3-D models, click on a part number.

Ultra-High-Polish Stainless Steel Tubing with Certification

- Temperature Range: -420° to 1500° F

- Bending Method: Tube Bender

- Compatible Tube Fittings: High-Polish Quick Clamp

Polished to a 10 Ra finish on the inside, this tubing has the smoothest interior of any tubing we offer. Tubing comes with a traceable lot number and material test report. It is welded with a smoothed weld bead on the inside to reduce particle buildup and allow for easy cleaning. Tubing is commonly used in semiconductor applications or anywhere surface contamination is a concern. It has excellent corrosion resistance. Tubing comes in a plastic sleeve.

Note: Ra measures the smoothness of the tubing; the lower the Ra value, the smoother and more polished the surface.

For technical drawings and 3-D models, click on a part number.

General Purpose Aluminum Tubing

- Temperature Range: -450° to 400° F

- Bending Method: Tube Bender

- Compatible Tube Fittings: Flared

This tubing is lightweight with good corrosion resistance and weldability. It has magnesium and silicon added for strength. Tubing is seamless, which provides a smooth interior for unrestricted flow. It can be flared without splitting.

Rigid Aluminum Tubing

Unlike other aluminum tubing, this tubing is rigid and will not bend. It contains manganese for good corrosion resistance, strength, and weldability. Tubing connects by welding.

- Temperature Range: See Table

- Temper: H14 (1/2 Hard)

- Bendable: No

6" | ||||||

|---|---|---|---|---|---|---|

| OD | Wall Thick. | ID | Max. Pressure | Temp. Range, °F | Each | |

For Use With Air, Hydraulic Fluid, Oil, Water | ||||||

| 3/4" | 0.065" | 0.62" | 1,820 psi @ 72° F | -110° to 300° | 00000000 | 00000 |

- Temperature Range: See Table

- Temper: H14 (1/2 Hard)

- Bendable: No

| OD | Wall Thick. | ID | Max. Pressure | Temp. Range, °F | Each | |

1 ft. | ||||||

|---|---|---|---|---|---|---|

For Use With Air, Hydraulic Fluid, Oil, Water | ||||||

| 3/4" | 0.065" | 0.62" | 360 psi @ 72° F | -110° to 300° | 00000000 | 000000 |

2 ft. | ||||||

For Use With Air, Hydraulic Fluid, Oil, Water | ||||||

| 3/4" | 0.065" | 0.62" | 1,820 psi @ 72° F | -110° to 300° | 00000000 | 00000 |

3 ft. | ||||||

For Use With Air, Hydraulic Fluid, Oil, Water | ||||||

| 3/4" | 0.065" | 0.62" | 360 psi @ 72° F | -110° to 300° | 00000000 | 00000 |

6 ft. | ||||||

For Use With Air, Hydraulic Fluid, Oil, Water | ||||||

| 3/4" | 0.065" | 0.62" | 360 psi @ 72° F | -110° to 300° | 00000000 | 00000 |

12 ft. | ||||||

For Use With Air, Hydraulic Fluid, Oil, Water | ||||||

| 3/4" | 0.065" | 0.62" | 1,820 psi @ 72° F | -110° to 300° | 00000000 | 00000 |

General Purpose Copper Tubing

This tubing has good corrosion resistance and excellent heat transfer qualities. It is seamless, which provides a smooth interior for unrestricted flow. It can be flared without splitting. All tubing meets international standards for copper tubing.

Note: Copper tube size is an accepted industry designation, not an actual size.

- Temperature Range: -420° to 400° F

- Bendable: No

- Specifications Met: ASTM B75

- Compatible Tube Fittings: Compression and Solder Connect

- Temperature Range: -420° to 400° F

- Bending Method: By Hand

- Specifications Met: ASTM B75

- Compatible Tube Fittings: Compression and Solder Connect

Brass Tubing

Frequently used in a wide range of plumbing applications, this tubing holds up well in mildly corrosive environments. Tubing is seamless, so it has a smooth interior for unrestricted flow.

Smooth-Bore Seamless Steel Tubing

Seamless construction with no weld bead gives this tubing a smooth interior for unrestricted flow. It is stronger than welded tubing and can be flared without splitting. Do not use in corrosive environments.

- Temperature Range: See Table

- Bending Method: Tube Bender

- For Use With: Hydraulic Fluid, Natural Gas

- Compatible Tubing Fittings: Compression and Flared

High-Temperature Nickel Tubing

- Temperature Range: -320° to 1200° F

- Bending Method: Tube Bender

Also known as Inconel, this tubing has the highest temperature rating of all the non-stainless steel tubing we offer. It has excellent corrosion and chemical resistance. It’s also seamless—the smooth interior won’t restrict flow. You can flare the ends without splitting the tubing, and weld to connect. All sizes meet ASTM B163, which is an international standard for tubing dimensions.

Acid-Resistant Nickel Tubing

- Temperature Range: -320° to 900° F

- Bending Method: Tube Bender

This tubing won't degrade, even when used with harsh acids. It is also known as Monel. Tubing has excellent corrosion resistance. It is seamless, which provides a smooth interior for unrestricted flow. It can be flared without splitting and connects by welding.

For technical drawings and 3-D models, click on a part number.

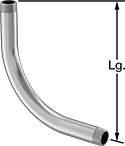

Rigid PVC Conduit

Also known as PVC Schedule 40 conduit, this conduit is corrosion resistant and UV light resistant for outdoor use. It is lightweight with strong walls to provide protection from damage. It can be buried or encased in concrete.

The female end is expanded so another piece of conduit can be pushed in to connect without a fitting. PVC cement is required (not included) when joining conduit and push-in ends on fittings and access ports.

8-ft. lengths can be shipped via small-parcel carrier.

8 ft. Lg. | ||||

|---|---|---|---|---|

| ID | OD | Environment | Each | |

| 0.62" | 0.84" | Outdoor, Underground | 0000000 | 000000 |

Attach PVC Schedule 40 or Schedule 80 conduit to a knockout in an outlet box or enclosure. These adapters are lightweight, corrosion resistant, and UV light resistant for outdoor use. They can be buried or encased in concrete. PVC cement is required (not included) to secure push-in connections.

Adapters with NPT threads connect unthreaded conduit to threaded fittings and knockouts. Push-in male × flanged end male adapters, also known as box adapters, install through a knockout from inside an electrical enclosure.

Conduit Connection | Electrical Box Connection | ||||||

|---|---|---|---|---|---|---|---|

| Conduit Trade Size | Gender | Pipe Size | Thread Type | For Knockout Trade Size | Gender | Each | |

Push-In Conduit Connection × Threaded Electrical Box Connection | |||||||

| 1/2 | Female | 1/2 | NPT | __ | Male | 0000000 | 00000 |

Push-In Conduit Connection × Flanged End Electrical Box Connection | |||||||

| 1/2 | Male | __ | __ | 1/2 | Male | 0000000 | 0000 |

Join pieces of PVC Schedule 40 or Schedule 80 conduit. These connectors are lightweight, corrosion resistant, and UV light resistant for outdoor use. They can be buried or encased in concrete. They have push-in ends that slide over conduit. PVC cement is required (not included) to secure the connection.

Conduit Connection | |||

|---|---|---|---|

| Conduit Trade Size | Gender | Each | |

Push-In Conduit Connection | |||

| 1/2 | Female | 0000000 | 00000 |

Join pieces of PVC Schedule 40 or Schedule 80 conduit. These connectors are lightweight, corrosion resistant, and UV light resistant for outdoor use. They can be buried or encased in concrete. They have push-in ends that slide over conduit. PVC cement is required (not included) to secure the connection.

Push-In Conduit Connection | Threaded Conduit Connection | ||||||||

|---|---|---|---|---|---|---|---|---|---|

| Conduit Trade Size | Gender | Pipe Size | Thread Type | Gender | Material | Color | Specifications Met | Each | |

Push-In Conduit Connection × Threaded Conduit Connection | |||||||||

| 1/2 | Female | 1/2 | NPT | Female | PVC | Gray | UL Listed | 0000000 | 00000 |

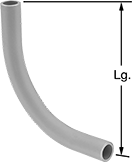

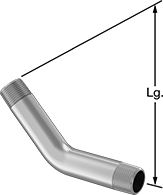

Join pieces of PVC Schedule 40 or Schedule 80 conduit. These connectors are lightweight, corrosion resistant, and UV light resistant for outdoor use. They can be buried or encased in concrete. PVC cement is required (not included) to secure the connection.

Conduit Connection | ||||

|---|---|---|---|---|

| Conduit Trade Size | Gender | Lg. | Each | |

Push-In Conduit Connection | ||||

| 1/2 | Male | 5 1/2" | 0000000 | 00000 |

Join pieces of PVC Schedule 40 or Schedule 80 conduit. These connectors are lightweight, corrosion resistant, and UV light resistant for outdoor use. They can be buried or encased in concrete. They have push-in ends that slide over conduit. PVC cement is required (not included) to secure the connection.

Adjustable-angle elbow connectors also attach conduit to a knockout when you take off the removable ends to access the threaded connections.

Conduit or Electrical Box Connection | |||||||

|---|---|---|---|---|---|---|---|

| Conduit Trade Size | Pipe Size | Thread Type | Gender | Lg. | Includes | Each | |

Push-In Conduit or Electrical Box Connection | |||||||

| 1/2 | 1/2 | NPT | Male | 12" | Two Locknuts | 0000000 | 000000 |

Connect two different sizes and genders of PVC Schedule 40 or Schedule 80 conduit. These reducing adapters are lightweight, corrosion resistant, and UV light resistant for outdoor use. They can be buried or encased in concrete. PVC cement is required (not included) to secure the connection.

Also known as conduit bodies, these ports provide access to wire and cable inside PVC Schedule 40 or Schedule 80 conduit for pulling, splicing, and maintenance. They are also used to change the direction of a run. These ports are lightweight, corrosion resistant, and UV light resistant for outdoor use. They can be buried or encased in concrete. PVC cement is required (not included) to secure the connection.

Conduit Connection | |||

|---|---|---|---|

| Conduit Trade Size | Gender | Each | |

Push-In Conduit Connection | |||

| 1/2 | Female | 0000000 | 000000 |

Also known as conduit bodies, these ports provide access to wire and cable inside PVC Schedule 40 or Schedule 80 conduit for pulling, splicing, and maintenance. They are also used to change the direction of a run. These ports are lightweight, corrosion resistant, and UV light resistant for outdoor use. They can be buried or encased in concrete. PVC cement is required (not included) to secure the connection.

Conduit Connection | |||

|---|---|---|---|

| Conduit Trade Size | Gender | Each | |

Push-In Conduit Connection | |||

| 1/2 | Female | 0000000 | 000000 |

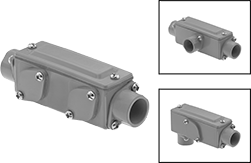

Also known as conduit bodies, these ports provide access to wire and cable inside PVC Schedule 40 or Schedule 80 conduit for pulling, splicing, and maintenance. They are also used to change the direction of a run. These ports are lightweight, corrosion resistant, and UV light resistant for outdoor use. They can be buried or encased in concrete. PVC cement is required (not included) to secure the connection.

Conduit Connection | |||

|---|---|---|---|

| Conduit Trade Size | Gender | Each | |

Push-In Conduit Connection | |||

| 1/2 | Female | 0000000 | 000000 |

Also known as conduit bodies, these ports provide access to wire and cable inside PVC Schedule 40 or Schedule 80 conduit for pulling, splicing, and maintenance. They are also used to change the direction of a run. These ports are lightweight, corrosion resistant, and UV light resistant for outdoor use. They can be buried or encased in concrete. PVC cement is required (not included) to secure the connection.

Conduit Connection | |||

|---|---|---|---|

| Conduit Trade Size | Gender | Each | |

Push-In Conduit Connection | |||

| 1/2 | Female | 0000000 | 00000 |

Rigid Stainless Steel Conduit

Use in food-processing and chemical plants—this is the most corrosion resistant thick-wall (rigid) conduit we offer. It is also crush and impact resistant. This conduit has one threaded male end; the other end has a threaded female connector.

5-ft. lengths can be shipped via small-parcel carrier.

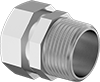

Also known as hubs, these adapters attach rigid stainless steel conduit to a knockout in an outlet box or enclosure. They are corrosion resistant, so you can use them in food-processing and chemical plants.

Conduit Connection | Electrical Box Connection | ||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|

| Conduit Trade Size | Pipe Size | Thread Type | Gender | Pipe Size | Thread Type | Gender | Material | Specifications Met | Electrical Connector Component | Each | |

Compression Conduit Connection | |||||||||||

| 1/2 | __ | __ | Female | 1/2 | NPT | Male | 316 Stainless Steel | __ | Adapter | 0000000 | 000000 |

Threaded Conduit Connection | |||||||||||

| 1/2 | 1/2 | NPT | Female | 1/2 | NPSM | Male | 316 Stainless Steel | UL Listed, C-UL Listed | Adapter | 0000000 | 000000 |

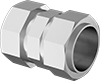

Join pieces of rigid stainless steel conduit. These connectors are corrosion resistant, so you can use them in food-processing and chemical plants.

Join pieces of rigid stainless steel conduit. These connectors are corrosion resistant, so you can use them in food-processing and chemical plants.

Thin-Wall (EMT) Stainless Steel Conduit

The most corrosion-resistant thin-wall conduit we offer, use this along walls and ceilings in food-processing and chemical plants. Also known as electrical metallic tubing (EMT), it has thin walls that are easy to bend with a conduit bender (not included) and cut with a hacksaw.

5-ft. lengths can be shipped via small-parcel carrier.

Conduit × Threaded

Electrical Box Adapter

Conduit × Threaded

Electrical Box Adapter

Attach thin-wall (EMT) stainless steel conduit to a knockout in an outlet box or enclosure. All of these adapters are corrosion resistant, so you can use them in food-processing and chemical plants.

A compression end offers a more reliable hold on conduit than a screw-clamp end. It pushes onto the conduit; tighten the compression ring to secure. The screw-clamp end tightens around conduit with a screw.

Conduit Connection | Electrical Box Connection | ||||||

|---|---|---|---|---|---|---|---|

| Conduit Trade Size | Gender | Pipe Size | Thread Type | Gender | Material | Each | |

Compression Conduit Connection × Threaded Electrical Box Connection | |||||||

| 1/2 | Female | 1/2 | NPT | Male | 316 Stainless Steel | 0000000 | 000000 |

Screw Clamp Conduit Connection × Threaded Electrical Box Connection | |||||||

| 1/2 | Female | 1/2 | NPT | Male | 316 Stainless Steel | 0000000 | 00000 |

Join pieces of thin-wall (EMT) stainless steel conduit. All of these connectors are corrosion resistant, so you can use them in food-processing and chemical plants.

Compression ends offer a more reliable hold than screw-clamp or push-in ends. Tighten the compression ring to secure. Screw-clamp ends tighten around conduit with screws.

Join pieces of thin-wall (EMT) stainless steel conduit. All of these connectors are corrosion resistant, so you can use them in food-processing and chemical plants.

Conduit Connection | |||||

|---|---|---|---|---|---|

| Conduit Trade Size | Gender | Lg. | Material | Each | |

Push-In Conduit Connection | |||||

| 1/2 | Male | 7" | 316 Stainless Steel | 0000000 | 000000 |

Choose-a-Color Thin-Wall (EMT) Steel Conduit

Visually identify different runs of wire and cable along walls and ceilings with this conduit that has a painted exterior. Also known as electrical metallic tubing (EMT), it has thin walls that are easy to bend with a conduit bender (not included) and cut with a hacksaw.

Use these adapters to attach choose-a-color thin-wall (EMT) steel conduit to a knockout in an outlet box or enclosure. The screw-clamp end tightens around conduit with a screw.

Thin-Wall (EMT) Steel Conduit

Also known as electrical metallic tubing (EMT), this conduit has thin walls that easily bend with a conduit bender (not included) and can be cut with a hacksaw. Run it along walls and ceilings, away from high-traffic areas.

5-ft. lengths can be shipped via small-parcel carrier.

Use these adapters to attach thin-wall (EMT) steel conduit to a knockout in an outlet box or enclosure. A compression end offers a more reliable hold on conduit than a screw-clamp end. It pushes onto the conduit; tighten the compression ring to secure. The screw-clamp end tightens around conduit with a screw.

Adapters with grommet protect wire and cable from abrasion when being pulled.

Adapters with O-ring prevent liquid from entering the conduit. They meet UL raintight standards when used with EMT conduit.

Conduit Connection | Electrical Box Connection | ||||||

|---|---|---|---|---|---|---|---|

| Conduit Trade Size | Gender | Pipe Size | Thread Type | Gender | Includes | Each | |

Compression Conduit Connection × Threaded Electrical Box Connection | |||||||

| 1/2 | Female | 1/2 | NPSM | Male | Grommet, Locknut | 0000000 | 00000 |

| 1/2 | Female | 1/2 | NPSM | Male | Grommet, Locknut, O-Ring | 0000000 | 0000 |

| 1/2 | Female | 1/2 | NPSM | Male | Locknut | 0000000 | 0000 |

| 1/2 | Female | 1/2 | NPSM | Male | Locknut, O-Ring | 0000000 | 0000 |

Screw-Clamp Conduit Connection × Threaded Electrical Box Connection | |||||||

| 1/2 | Female | 1/2 | NPSM | Male | Grommet, Locknut | 0000000 | 0000 |

| 1/2 | Female | 1/2 | NPSM | Male | Locknut | 0000000 | 000 |

Use these adapters to attach thin-wall (EMT) steel conduit to a knockout in an outlet box or enclosure. A compression end offers a more reliable hold on conduit than a screw-clamp end. It pushes onto the conduit; tighten the compression ring to secure. The screw-clamp end tightens around conduit with a screw.

Adapters with grommet protect wire and cable from abrasion when being pulled.

Conduit Connection | Electrical Box Connection | ||||||

|---|---|---|---|---|---|---|---|

| Conduit Trade Size | Gender | Pipe Size | Thread Type | Gender | Includes | Each | |

Compression Conduit Connection × Threaded Electrical Box Connection | |||||||

| 1/2 | Female | 1/2 | NPSM | Male | Grommet, Locknut | 0000000 | 00000 |

| 1/2 | Female | 1/2 | NPSM | Male | Locknut | 0000000 | 0000 |

Screw-Clamp Conduit Connection × Threaded Electrical Box Connection | |||||||

| 1/2 | Female | 1/2 | NPSM | Male | Grommet, Locknut | 0000000 | 000 |

| 1/2 | Female | 1/2 | NPSM | Male | Locknut | 0000000 | 000 |

Use these adapters to attach thin-wall (EMT) steel conduit to a knockout in an outlet box or enclosure. A compression end offers a more reliable hold on conduit than a screw-clamp end. It pushes onto the conduit; tighten the compression ring to secure.

Conduit Connection | Electrical Box Connection | ||||||

|---|---|---|---|---|---|---|---|

| Conduit Trade Size | Gender | Pipe Size | Thread Type | Gender | Includes | Each | |

Compression Conduit Connection × Threaded Electrical Box Connection | |||||||

| 1/2 | Female | 1/2 | NPSM | Male | Locknut | 0000000 | 00000 |

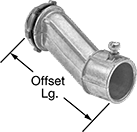

Use these adapters to attach thin-wall (EMT) steel conduit to a knockout in an outlet box or enclosure. The screw-clamp end tightens around conduit with a screw.

Conduit Connection | Electrical Box Connection | |||||||

|---|---|---|---|---|---|---|---|---|

| Conduit Trade Size | Gender | Pipe Size | Thread Type | Gender | Offset Lg. | Includes | Each | |

Screw-Clamp Conduit Connection × Threaded Electrical Box Connection | ||||||||

| 1/2 | Female | 1/2 | NPSM | Male | 3/8" | Locknut | 0000000 | 00000 |

Join pieces of thin-wall (EMT) steel conduit. Compression ends offer a more reliable hold than screw-clamp or push-in ends. Tighten the compression ring to secure. Screw-clamp ends tighten around conduit with screws.

Connectors with O-ring prevent liquid from entering the conduit. They meet UL raintight standards when used with EMT conduit.

Join pieces of thin-wall (EMT) steel conduit. Compression ends offer a more reliable hold than screw-clamp or push-in ends. Tighten the compression ring to secure. Screw-clamp ends tighten around conduit with screws.

Join pieces of thin-wall (EMT) steel conduit. Screw-clamp ends tighten around conduit with screws.

Screw-clamp 90° elbow with removable cover allows for quick access to pull wire and cable.

Join pieces of thin-wall (EMT) steel conduit.

Conduit Connection | ||||

|---|---|---|---|---|

| Conduit Trade Size | Gender | Lg. | Each | |

Push-In Conduit Connection | ||||

| 1/2 | Male | 6 1/8" | 0000000 | 00000 |

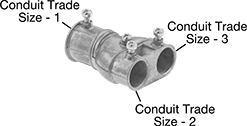

Connect different sizes of thin-wall (EMT) steel conduit. These reducers have screw-clamp ends that tighten around conduit with screws.

Conduit Connection | ||||

|---|---|---|---|---|

| Conduit Trade Size - 1 | Conduit Trade Size - 2 and - 3 | Gender | Each | |

Screw-Clamp Conduit Connection | ||||

| 3/4 | 1/2 | Female | 0000000 | 000000 |

Slide these grommets into thin-wall (EMT) steel conduit ends to protect wire and cable from abrasion when being pulled.

Conduit Connection | ||||

|---|---|---|---|---|

| Conduit Trade Size | Gender | Color | Each | |

Push-In Conduit Connection | ||||

| 1/2 | Male | White | 0000000 | 00000 |