About Sleeving

More

About Plastic and Rubber Tubing

More

About Duct Hose

More

About Hose

More

High-Temperature Coolant Hose

- Temperature Range: -65° to 350° F

- Material: Silicone Rubber

- Color: Blue

- For Clamp Type: Worm Drive

Silicone rubber gives this hose, often called radiator hose, the ability to handle high-heat conditions. Hose with steel wire reinforcement resists kinking.

Coolant Hose

- Temperature Range: 0° to 210° F

- Material: Buna-N Rubber

- Color: Black with Green Stripe

- For Clamp Type: Worm Drive

Commonly known as radiator hose, this hose is for low-pressure coolant applications.

Per Ft. | ||||||

|---|---|---|---|---|---|---|

| ID | OD | Max. Pressure | Max. Continuous Lg., ft. | 1-24 | 25-Up | |

| 1 3/8" | 1 7/8" | 50 psi @ 72° F | 25 | 00000000 | 000000 | 000000 |

Flexible Coolant Hose

- Temperature Range: -20° to 210° F

- Maximum Vacuum: 28" of Hg @ 72° F

- Material: Buna-N Rubber with Neoprene Rubber Cover

- Color: Black with Yellow Stripe

- For Clamp Type: Worm Drive

With a tighter bend radius than other coolant hose, this hose can easily twist and turn around equipment.

Per Ft. | |||||||

|---|---|---|---|---|---|---|---|

| ID | OD | Bend Radius | Max. Pressure | Max. Continuous Lg., ft. | 1-24 | 25-Up | |

| 1 3/8" | 1 7/8" | 4 1/8" | 40 psi @ 72° F | 25 | 0000000 | 000000 | 000000 |

High-Temperature Soft Rubber Tubing for Air and Water

- Flexible

- Compatible with Barbed Tube Fittings

- Soft

- Temperature Range: -90° to 390° F

More resilient than latex rubber, this silicone rubber tubing can stand up to high-temperature applications. Commonly used with metering (peristaltic) pumps and robotics, it can handle continuous bending and flexing and maintains its flexibility over time.

Opaque tubing doesn’t allow you to see what’s flowing through the line. Semi-clear tubing gives you a limited view inside the line.

UV-Resistant Soft Plastic and Rubber Tubing for Air and Water

This tubing won’t degrade when exposed to the damaging effects of ultraviolet light. It is opaque, so you can’t see what’s flowing through the line.

EPDM rubber tubing is the most flexible option. It has better durability than PVC tubing to stand up to harsh outdoor environments. It has excellent resistance to ozone as well as UV light.

Crack-Resistant Firm Plastic Tubing for Food and Beverage

This tubing offers superior impact and crack resistance—even at low temperatures. Made of FDA listed materials, it is suitable for use with food and beverage. It is made without plasticizers like DEHP, so it won’t impart tastes or odors to the fluid passing through it. Tubing is semi-flexible, so it is good for gradual bends.

Polyethylene tubing can withstand lower temperatures and higher pressures than EVA tubing.

Semi-clear tubing gives you a limited view inside the line.

Hard Plastic Tubing for Food and Beverage

Strong, hard walls give this tubing extra support in high-pressure and vacuum applications. It’s made of FDA listed materials, so it’s suitable for use with food and beverage. Free of plasticizers like DEHP, it won’t impart tastes or odors to the fluid passing through it.

PVC tubing has harder walls than polyethylene tubing and can handle higher pressures. It meets NSF/ANSI Standard 51 for food contact. Tubing is rigid and will not bend. It is clear, so you can easily monitor flow.

- Rigid

- Compatible with Socket Connect Tube Fittings

- Hard (Durometer 80D)

- Temperature Range: -40° to 140° F

- Specifications Met: FDA Compliant 21 CFR 175.300, NSF/ANSI 51

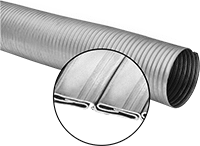

High-Temperature Rigid Metal Duct Hose for Fumes

- Rigid

- Compatible Clamps: U-Bolt Clamps

- Max. Temperature: Galvanized Steel: 750° F; Aluminum: 450° F; 304 Stainless Steel: 1500° F; 316 Stainless Steel: 1200° F

Metal interlocked strips create a rigid, durable hose that stays strong under high temperatures. Hose is for use with smoke, welding fumes, and oil fumes.

Galvanized steel offers fair corrosion resistance.

304 stainless steel has very good corrosion resistance.

Spark-Resistant Tube Sleeving

A specially formulated silicone rubber coating on this fiberglass sleeving sheds sparks, molten metal splash, hydraulic fuel, and lubricating oil. Exposure to a torch will char the coating, but will not scorch the fiberglass inner layer. It also resists fraying. Because this sleeving is non-expandable, it does not stretch, so it’s best for applications where you know the exact diameter of the items you need to protect.

Extra-Thick Spark-Resistant Tube Sleeving

Made from thicker and denser fiberglass than standard spark-resistant sleeving, this sleeving is more abrasion resistant and provides better insulation. The specially formulated silicone rubber coating sheds sparks, molten metal splash, hydraulic fuel, and lubricating oil. It also resists fraying. Exposure to a torch will char the coating, but will not scorch the fiberglass inner layer. It can withstand short-term flame exposure up to 2000° F, and is flame rated VW-1 to meet requirements for preventing the spread of flames based on a timed test of vertically suspended material. Because this sleeving is non-expandable, it does not stretch, so it’s best for applications where you know the exact diameter of the items you need to protect.

Spark-Resistant Hook-and-Loop Wrap-Around Sleeving

A specially formulated silicone rubber coats this fiberglass sleeving to shed sparks, molten metal splash, hydraulic fuel, and lubricating oil. Wrap it around wire, cable, and hose without disconnecting them. It has a slit along the entire length and a strip of hook-and-loop that keeps it securely closed but allows you to maintain access along the length of the sleeving.

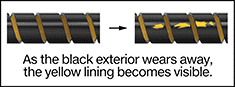

Wear-Indicating Spiral Sleeving

Identify wear and tear on your sleeving before its contents become exposed. This sleeving has a yellow inner layer that shows through when the black outer layer wears off. It’s a great choice for components such as sensitive hydraulic hoses, fluid lines, and cables that shouldn’t be installed without protection. Made of HDPE plastic, it stands up to wear and crushing forces better than standard spiral sleeving, so it’s great for high-traffic areas. It also blocks out dust and debris, thanks to its tight coil. Use it indoors and outdoors—it won’t become brittle in direct sunlight, and it won’t swell from moisture.

The spiral construction means you can access your wire, cable, or hose at any point for repairs. Plus, you can pull out individual components of your bundle to route them elsewhere. With smooth, rounded edges, this sleeving won’t scrape you or your components during installation. Unlike cable ties and tape, you can unwind and reuse it.