About Plastic and Rubber Tubing

More

Hard Plastic Tubing for Air and Water

This general purpose tubing has hard walls, yet is flexible enough for gradual bends. It has excellent strength and durability.

Nylon tubing can handle lower temperatures than polypropylene tubing and can withstand higher pressures. It has slightly softer walls than polypropylene tubing, making it more flexible and impact absorbent.

Opaque tubing doesn’t allow you to see what’s flowing through the line. Semi-clear tubing gives you a limited view inside the line.

- Semi-Flexible

- Compatible with Compression and Push to Connect Tube Fittings

- Hard (Rockwell R78)

- Temperature Range: -60° to 200° F

- Semi-Flexible

- Compatible with Compression and Push to Connect Tube Fittings

- Hard (Rockwell R78)

- Temperature Range: -60° to 200° F

High-Pressure Hard Plastic Tubing for Air and Water

Excellent strength and durability allow this tubing to handle high-pressure air and water applications.

Nylon tubing can handle higher pressures than polycarbonate tubing. It won’t crack even at low temperatures. Tubing is semi-flexible, so it is good for gradual bends. Semi-clear tubing gives you a limited view inside the line. Opaque tubing doesn’t allow you to see what’s flowing through the line.

- Semi-Flexible

- Compatible with Compression Fittings, Push to Connect Tube Fittings or both; see For Connection Style

- See table for hardness

- Temperature Range: See table

- Semi-Flexible

- Compatible with Compression Tube Fittings

- See table for hardness

- Temperature Range: See table

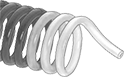

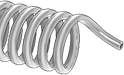

Self-Retracting Hard Plastic Tubing for Air and Water

- Semi-Flexible

- Compatible with Barbed and Push to Connect Tube Fittings

- Hardness:

Inch: Hard (Rockwell R80)

Metric: Hard (Rockwell R75) - Temperature Range: -40° to 180° F

Keep your work area tidy with this coiled tubing that extends when you need it and retracts out of the way when you don’t. Tubing is made of tough and abrasion-resistant nylon. It is semi-flexible, so it is good for gradual bends.

Semi-clear tubing gives you a limited view inside the line. Opaque tubing doesn’t allow you to see what’s flowing through the line.

Note: Length refers to the length you can extend the tubing. Overstretching can cause the tubing to lose its ability to fully retract back to its normal state. Retracted length refers to the length of the tubing when coiled.

| ID | OD | Wall Thick. | Coil OD | Lg. | Retracted Lg. | Max. Pressure | Max. Vacuum | Each | |

Nylon Plastic | |||||||||

|---|---|---|---|---|---|---|---|---|---|

Semi-Clear White | |||||||||

| 2.7mm | 4mm | 0.7mm | 34mm | 1 m | 40mm | 290 psi @ 72° F | 28 in. of Hg @ 72° F | 00000000 | 000000 |

| 2.7mm | 4mm | 0.7mm | 34mm | 3 m | 160mm | 290 psi @ 72° F | 28 in. of Hg @ 72° F | 00000000 | 00000 |

| 2.7mm | 4mm | 0.7mm | 34mm | 5 m | 276mm | 290 psi @ 72° F | 28 in. of Hg @ 72° F | 00000000 | 00000 |

| 2.7mm | 4mm | 0.7mm | 34mm | 10 m | 568mm | 290 psi @ 72° F | 28 in. of Hg @ 72° F | 00000000 | 00000 |

Opaque Black | |||||||||

| 2.7mm | 4mm | 0.7mm | 34mm | 1 m | 40mm | 290 psi @ 72° F | 28 in. of Hg @ 72° F | 00000000 | 00000 |

| 2.7mm | 4mm | 0.7mm | 34mm | 3 m | 160mm | 290 psi @ 72° F | 28 in. of Hg @ 72° F | 00000000 | 00000 |

| 2.7mm | 4mm | 0.7mm | 34mm | 10 m | 568mm | 290 psi @ 72° F | 28 in. of Hg @ 72° F | 00000000 | 00000 |

Opaque Blue | |||||||||

| 2.7mm | 4mm | 0.7mm | 34mm | 1 m | 40mm | 290 psi @ 72° F | 28 in. of Hg @ 72° F | 00000000 | 00000 |

| 2.7mm | 4mm | 0.7mm | 34mm | 3 m | 160mm | 290 psi @ 72° F | 28 in. of Hg @ 72° F | 00000000 | 00000 |

| 2.7mm | 4mm | 0.7mm | 34mm | 10 m | 568mm | 290 psi @ 72° F | 28 in. of Hg @ 72° F | 00000000 | 00000 |

Opaque Red | |||||||||

| 2.7mm | 4mm | 0.7mm | 34mm | 1 m | 40mm | 290 psi @ 72° F | 28 in. of Hg @ 72° F | 00000000 | 00000 |

| 2.7mm | 4mm | 0.7mm | 34mm | 3 m | 160mm | 290 psi @ 72° F | 28 in. of Hg @ 72° F | 00000000 | 00000 |

| 2.7mm | 4mm | 0.7mm | 34mm | 10 m | 568mm | 290 psi @ 72° F | 28 in. of Hg @ 72° F | 00000000 | 00000 |

Hard Plastic Tubing for Food and Beverage

Strong, hard walls give this tubing extra support in high-pressure and vacuum applications. It’s made of FDA listed materials, so it’s suitable for use with food and beverage. Free of plasticizers like DEHP, it won’t impart tastes or odors to the fluid passing through it.

Polyethylene tubing is semi-flexible and good for gradual bends, but it will crack if subjected to continual bending. Semi-clear tubing gives you a limited view inside the line. Opaque tubing doesn’t allow you to see inside the line.

- Semi-Flexible

- Compatible with Compression Tube Fittings and Push to Connect Tube Fittings

- Hard (Durometer 50D)

- Temperature Range:

Inch Tubing: -40° to 140° F

Metric Tubing: -40° to 150° F - Specifications Met: FDA Compliant 21 CFR 177.1520

- Semi-Flexible

- Compatible with Compression Tube Fittings and Push to Connect Tube Fittings

- Hard (Durometer 50D)

- Temperature Range:

Inch Tubing: -40° to 140° F

Metric Tubing: -40° to 150° F - Specifications Met: FDA Compliant 21 CFR 177.1520

Hard Plastic Tubing for Fuel

Hard walls give this tubing the strength to handle high-pressure fuel and gasoline applications. It is nylon, which has excellent abrasion resistance. This tubing can be brittle, so take care as you're handling it.

Clear tubing makes it easy to monitor flow. It is semi-flexible, so it is good for gradual bends.

- Semi-Flexible

- Compatible with Compression Tube Fittings

- Hard (Rockwell R127)

- Temperature Range: -40° to 212° F