About Plastic and Rubber Tubing

More

Cold-Weather Garden Hose

- Temperature Range: -30° to 180° F

- Material: TPE Rubber

- Color: Red

- For Use Outdoors: Yes

Bend and flex this hose in the coldest weather—down to -30° F. A TPE rubber cover conducts heat to prevent it from becoming stiff and cracking, even if water inside the hose freezes. The spigot end has a kink absorber to protect the connection point from the strain of pulling or harsh bends.

For technical drawings and 3-D models, click on a part number.

50-ft. Lengths | ||||||

|---|---|---|---|---|---|---|

| Hose Size | ID | OD | Max. Pressure | Features | Each | |

Anodized Aluminum Threaded GHT Male × Anodized Aluminum Threaded GHT Female | ||||||

| 3/4 × 3/4 | 5/8" | 7/8" | 100 psi @ 72° F | Kink Absorbers | 0000000 | 000000 |

Lightweight Soft Plastic Tubing for Food, Beverage, and Dairy

- Semi-Flexible

- Compatible with Barbed Tube Fittings

- Soft (Durometer 70A)

- Temperature Range: -60° to 180° F

Lighter than other plastic and rubber tubing, but extremely tough, this TPE plastic tubing stands up to the wear and tear of daily use. It’s made of FDA listed materials, so it’s suitable for use with food and beverage. Since it doesn’t contain plasticizers like DEHP, it won’t impart tastes or odors to the fluid passing through it. Tubing is opaque, so you cannot see inside the line to monitor flow. It is semi-flexible, so it is good for gradual bends.

For technical drawings and 3-D models, click on a part number.

| ID | OD | Wall Thick. | Bend Radius | Max. Pressure | Max. Vacuum | Color | Specifications Met | Lengths, ft. | Per Ft. | |

Opaque TPE Plastic | ||||||||||

|---|---|---|---|---|---|---|---|---|---|---|

| 1/4" | 1/2" | 1/8" | 1" | 120 psi @ 72° F | 27 in. of Hg @ 72° F | Blue | FDA Compliant 21 CFR 177.1810 | 000000 | 00000 | |

| 3/8" | 5/8" | 1/8" | 1 1/2" | 100 psi @ 72° F | 27 in. of Hg @ 72° F | Blue | FDA Compliant 21 CFR 177.1810 | 000000 | 0000 | |

| 1/2" | 3/4" | 1/8" | 2" | 60 psi @ 72° F | 27 in. of Hg @ 72° F | Blue | FDA Compliant 21 CFR 177.1810 | 000000 | 0000 | |

| 9/16" | 15/16" | 3/16" | 2" | 80 psi @ 72° F | 27 in. of Hg @ 72° F | Blue | FDA Compliant 21 CFR 177.1810 | 000000 | 0000 | |

| 5/8" | 1" | 3/16" | 2 1/2" | 75 psi @ 72° F | 27 in. of Hg @ 72° F | Blue | FDA Compliant 21 CFR 177.1810 | 000000 | 0000 | |

| 3/4" | 1 1/8" | 3/16" | 3" | 65 psi @ 72° F | Not Rated | Blue | FDA Compliant 21 CFR 177.1810 | 000000 | 0000 | |

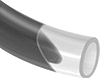

Chemical-Resistant Firm Plastic Tubing for Food and Beverage

Made from TPE plastic, this tubing doesn’t contain plasticizers like DEHP, so it won’t impart tastes or odors to the fluid passing through. The surface isn’t absorbent, making it easy to clean. Tubing is clear, so you can monitor flow.

Tubing with a PVDF liner is often used in pharmaceutical applications since it won’t bind to proteins or leach substances into the fluid moving through. It’s more flexible than tubing made entirely from PVDF.

Tygon tubing resists staining and won’t break down when exposed to alcohol and acids. It’s often used with wine, coffee, and other pigmented liquids.

For technical drawings and 3-D models, click on a part number.

- Flexible

- Compatible with Barbed Tube Fittings

- Firm (Durometer 85A)

- Temperature Range: -50° to 170° F

| ID | OD | Wall Thickness | Bend Radius | Maximum Pressure | Color | Specifications Met | Length, ft. | Each | |

| 1/32" | 3/32" | 1/32" | 1/16" | 330 psi @ 72° F | Clear | FDA Compliant 21 CFR 177.1520, FDA Compliant 21 CFR 177.2600, USP Class VI | 50 | 0000000 | 0000000 |

| 1/16" | 1/8" | 1/32" | 1/8" | 220 psi @ 72° F | Clear | FDA Compliant 21 CFR 177.1520, FDA Compliant 21 CFR 177.2600, USP Class VI | 50 | 0000000 | 000000 |

| 3/32" | 5/32" | 1/32" | 3/8" | 160 psi @ 72° F | Clear | FDA Compliant 21 CFR 177.1520, FDA Compliant 21 CFR 177.2600, USP Class VI | 50 | 0000000 | 000000 |

| 1/8" | 3/16" | 1/32" | 1/2" | 110 psi @ 72° F | Clear | FDA Compliant 21 CFR 177.1520, FDA Compliant 21 CFR 177.2600, USP Class VI | 50 | 0000000 | 000000 |

| 1/8" | 1/4" | 1/16" | 1/4" | 140 psi @ 72° F | Clear | FDA Compliant 21 CFR 177.1520, FDA Compliant 21 CFR 177.2600, USP Class VI | 50 | 0000000 | 000000 |

| 3/16" | 1/4" | 1/32" | 1" | 95 psi @ 72° F | Clear | FDA Compliant 21 CFR 177.1520, FDA Compliant 21 CFR 177.2600, USP Class VI | 50 | 0000000 | 000000 |

| 3/16" | 5/16" | 1/16" | 5/8" | 130 psi @ 72° F | Clear | FDA Compliant 21 CFR 177.1520, FDA Compliant 21 CFR 177.2600, USP Class VI | 50 | 0000000 | 000000 |

| 1/4" | 3/8" | 1/16" | 1 1/4" | 120 psi @ 72° F | Clear | FDA Compliant 21 CFR 177.1520, FDA Compliant 21 CFR 177.2600, USP Class VI | 50 | 0000000 | 000000 |

| 5/16" | 7/16" | 1/16" | 1 1/2" | 70 psi @ 72° F | Clear | FDA Compliant 21 CFR 177.1520, FDA Compliant 21 CFR 177.2600, USP Class VI | 50 | 0000000 | 000000 |

| 3/8" | 1/2" | 1/16" | 2" | 85 psi @ 72° F | Clear | FDA Compliant 21 CFR 177.1520, FDA Compliant 21 CFR 177.2600, USP Class VI | 50 | 0000000 | 000000 |

| 1/2" | 3/4" | 1/8" | 1 5/8" | 90 psi @ 72° F | Clear | FDA Compliant 21 CFR 177.1520, FDA Compliant 21 CFR 177.2600, USP Class VI | 50 | 0000000 | 000000 |

| 5/8" | 7/8" | 1/8" | 2 1/4" | 70 psi @ 72° F | Clear | FDA Compliant 21 CFR 177.1520, FDA Compliant 21 CFR 177.2600, USP Class VI | 50 | 0000000 | 000000 |

| 3/4" | 1" | 1/8" | 3" | 60 psi @ 72° F | Clear | FDA Compliant 21 CFR 177.1520, FDA Compliant 21 CFR 177.2600, USP Class VI | 50 | 0000000 | 000000 |

- Flexible

- Compatible with Barbed Tube Fittings

- Firm (Durometer 75A)

- Temperature Range: -100° to 130° F

| ID | OD | Wall Thickness | Bend Radius | Maximum Pressure | Maximum Vacuum | Color | Specifications Met | Length, ft. | Each | |

| 1/16" | 1/8" | 1/32" | 1/4" | 40 psi @ 72° F | 29 in. of Hg @ 72° F | Clear | FDA Compliant 21 CFR 170-189, NSF/ANSI 51 | 50 | 0000000 | 000000 |

| 1/8" | 1/4" | 1/16" | 1/4" | 40 psi @ 72° F | 29 in. of Hg @ 72° F | Clear | FDA Compliant 21 CFR 170-189, NSF/ANSI 51 | 50 | 0000000 | 000000 |

| 3/16" | 5/16" | 1/16" | 1/2" | 30 psi @ 72° F | 29 in. of Hg @ 72° F | Clear | FDA Compliant 21 CFR 170-189, NSF/ANSI 51 | 50 | 0000000 | 000000 |

| 1/4" | 3/8" | 1/16" | 3/4" | 25 psi @ 72° F | 29 in. of Hg @ 72° F | Clear | FDA Compliant 21 CFR 170-189, NSF/ANSI 51 | 50 | 0000000 | 000000 |

| 3/8" | 1/2" | 1/16" | 1 1/2" | 15 psi @ 72° F | 20 in. of Hg @ 72° F | Clear | FDA Compliant 21 CFR 170-189, NSF/ANSI 51 | 50 | 0000000 | 000000 |

| 3/8" | 5/8" | 1/8" | 1 1/8" | 25 psi @ 72° F | 29 in. of Hg @ 72° F | Clear | FDA Compliant 21 CFR 170-189, NSF/ANSI 51 | 50 | 0000000 | 000000 |

| 1/2" | 3/4" | 1/8" | 1 1/2" | 25 psi @ 72° F | 29 in. of Hg @ 72° F | Clear | FDA Compliant 21 CFR 170-189, NSF/ANSI 51 | 50 | 0000000 | 000000 |

UV-Resistant Hard Plastic Tubing for Chemicals

Ultraviolet light won’t cause this tubing to degrade or deteriorate.

TPE tubing was originally developed for transferring inks that react to UV light in digital and 3D printing. It blocks UV light to protect fluid running through the tube. It’s also compatible with a variety of solvents commonly used in ink transfer applications.

Opaque tubing does not allow you to see inside the line.

Semi-flexible tubing is good for gradual bends.

For technical drawings and 3-D models, click on a part number.

- Semi-Flexible

- Compatible with Compression Tube Fittings

- Hard (Durometer 50D)

- Temperature Range: -100° to 130° F

| ID | OD | Wall Thick. | Flexibility | Bend Radius | Max. Pressure | Max. Vacuum | Color | Length, ft. | Per Ft. | |

Metric | ||||||||||

|---|---|---|---|---|---|---|---|---|---|---|

| 3mm | 5mm | 1mm | Semi-Flexible | 9mm | 130 psi @ 72° F | 29 in. of Hg @ 72° F | Black | 50 | 0000000 | 00000 |

| 4mm | 6mm | 1mm | Semi-Flexible | 15mm | 105 psi @ 72° F | 29 in. of Hg @ 72° F | Black | 50 | 0000000 | 0000 |

| 6mm | 8mm | 1mm | Semi-Flexible | 19mm | 75 psi @ 72° F | 29 in. of Hg @ 72° F | Black | 50 | 0000000 | 0000 |

High-Purity Soft Plastic and Rubber Tubing

Designed for high-purity processes, this tubing is made without plasticizers like DEHP that can contaminate the fluid passing through it. It meets USP Class VI specifications for material testing; it is not for use in medical applications. Tubing is clear or semi-clear, so you can monitor flow. It’s also flexible and easily bends around objects.

TPE plastic tubing is extremely flexible. It’s often used as an alternative to silicone tubing for high-purity bioprocessing, pharmaceutical, laboratory, and peristaltic pump applications.

Tubing with braid reinforcement has extra strength to handle higher pressures than nonreinforced tubing.

For technical drawings and 3-D models, click on a part number.

- Flexible

- Compatible with Barbed Tube Fittings

- Soft (Durometer 65A)

- Environment: Clean Room, Sanitary

- Temperature Range: -110° to 270° F

| ID | OD | Wall Thick. | Bend Radius | Max. Pressure | Max. Vacuum | Color | Specifications Met | Lengths, ft. | Each | |

Without Polyester Braid Reinforcement | ||||||||||

|---|---|---|---|---|---|---|---|---|---|---|

| 1/32" | 3/32" | 3/64" | 0.06" | 49 psi @ 72° F | Not Rated | Clear | ISO 9001, ISO 13485, USP 661, USP Class VI | 50 | 00000000 | 000000 |

| 1/16" | 1/8" | 1/32" | 0.06" | 33 psi @ 72° F | Not Rated | Clear | ISO 9001, ISO 13485, USP 661, USP Class VI | 50 | 00000000 | 00000 |

| 1/16" | 3/16" | 1/8" | Not Rated | Not Rated | Not Rated | Clear | ISO 9001, ISO 13485, USP 661, USP Class VI | 50 | 00000000 | 00000 |

| 3/32" | 5/32" | 1/32" | 0.19" | 25 psi @ 72° F | Not Rated | Clear | ISO 9001, ISO 13485, USP 661, USP Class VI | 50 | 00000000 | 00000 |

| 1/8" | 3/16" | 1/32" | 0.3" | 18 psi @ 72° F | Not Rated | Clear | ISO 9001, ISO 13485, USP 661, USP Class VI | 50 | 00000000 | 00000 |

| 1/8" | 1/4" | 1/16" | 0.2" | 34 psi @ 72° F | Not Rated | Clear | ISO 9001, ISO 13485, USP 661, USP Class VI | 50 | 00000000 | 000000 |

| 3/16" | 1/4" | 1/32" | 0.6" | 13 psi @ 72° F | Not Rated | Clear | ISO 9001, ISO 13485, USP 661, USP Class VI | 50 | 00000000 | 000000 |

| 3/16" | 5/16" | 1/16" | 0.4" | 23 psi @ 72° F | Not Rated | Clear | ISO 9001, ISO 13485, USP 661, USP Class VI | 50 | 00000000 | 000000 |

| 3/16" | 3/8" | 3/32" | 0.3" | 33 psi @ 72° F | Not Rated | Clear | ISO 9001, ISO 13485, USP 661, USP Class VI | 50 | 00000000 | 000000 |

| 1/4" | 3/8" | 1/16" | 0.8" | 18 psi @ 72° F | Not Rated | Clear | ISO 9001, ISO 13485, USP 661, USP Class VI | 50 | 00000000 | 000000 |

| 1/4" | 7/16" | 3/32" | 0.9" | 24 psi @ 72° F | Not Rated | Clear | ISO 9001, ISO 13485, USP 661, USP Class VI | 50 | 00000000 | 000000 |

| 1/4" | 1/2" | 1/8" | 1/2" | 29 psi @ 72° F | Not Rated | Clear | ISO 9001, ISO 13485, USP 661, USP Class VI | 50 | 00000000 | 000000 |

| 5/16" | 7/16" | 1/16" | 1" | 16 psi @ 72° F | Not Rated | Clear | ISO 9001, ISO 13485, USP 661, USP Class VI | 50 | 00000000 | 000000 |

| 5/16" | 1/2" | 3/16" | Not Rated | Not Rated | Not Rated | Clear | ISO 9001, ISO 13485, USP 661, USP Class VI | 50 | 00000000 | 000000 |

| 3/8" | 1/2" | 1/16" | 1.8" | 14 psi @ 72° F | Not Rated | Clear | ISO 9001, ISO 13485, USP 661, USP Class VI | 50 | 00000000 | 000000 |

| 3/8" | 9/16" | 3/16" | Not Rated | Not Rated | Not Rated | Clear | ISO 9001, ISO 13485, USP 661, USP Class VI | 50 | 00000000 | 000000 |

| 3/8" | 5/8" | 1/8" | 1" | 22 psi @ 72° F | Not Rated | Clear | ISO 9001, ISO 13485, USP 661, USP Class VI | 50 | 00000000 | 000000 |

| 1/2" | 3/4" | 1/8" | 1.4" | 19 psi @ 72° F | Not Rated | Clear | ISO 9001, ISO 13485, USP 661, USP Class VI | 50 | 00000000 | 000000 |

| 5/8" | 7/8" | 1/8" | 1.8" | 15 psi @ 72° F | Not Rated | Clear | ISO 9001, ISO 13485, USP 661, USP Class VI | 50 | 00000000 | 000000 |

| 3/4" | 1" | 1/8" | 2.8" | 14 psi @ 72° F | Not Rated | Clear | ISO 9001, ISO 13485, USP 661, USP Class VI | 50 | 00000000 | 000000 |

| 1" | 1 1/4" | 1/8" | 6" | 8 psi @ 72° F | Not Rated | Clear | ISO 9001, ISO 13485, USP 661, USP Class VI | 50 | 00000000 | 000000 |

- Flexible

- Compatible with Barbed Tube Fittings

- Soft (Durometer 65A)

- Environment: Clean Room, Sanitary

- Temperature Range: -50° to 270° F

| ID | OD | Wall Thick. | Bend Radius | Max. Pressure | Max. Vacuum | Color | Specifications Met | Lengths, ft. | Each | |

With Polyester Braid Reinforcement | ||||||||||

|---|---|---|---|---|---|---|---|---|---|---|

| 1/8" | 3/8" | 1/8" | 1/4" | 162 psi @ 72° F | Not Rated | White | ISO 9001, ISO 13485, USP 661, USP Class VI | 25 | 00000000 | 0000000 |

| 1/4" | 1/2" | 1/8" | 0.44" | 116 psi @ 72° F | Not Rated | White | ISO 9001, ISO 13485, USP 661, USP Class VI | 25 | 00000000 | 000000 |

| 3/8" | 5/8" | 1/8" | 0.88" | 95 psi @ 72° F | Not Rated | White | ISO 9001, ISO 13485, USP 661, USP Class VI | 25 | 00000000 | 000000 |

| 1/2" | 3/4" | 1/8" | 1.13" | 110 psi @ 72° F | Not Rated | White | ISO 9001, ISO 13485, USP 661, USP Class VI | 25 | 00000000 | 000000 |

| 5/8" | 1" | 1/8" | 1 1/2" | 118 psi @ 72° F | Not Rated | White | ISO 9001, ISO 13485, USP 661, USP Class VI | 25 | 00000000 | 000000 |

| 3/4" | 1 1/8" | 3/16" | 2" | 90 psi @ 72° F | Not Rated | White | ISO 9001, ISO 13485, USP 661, USP Class VI | 25 | 00000000 | 000000 |

| 1" | 1 3/8" | 3/16" | 2 1/2" | 56 psi @ 72° F | Not Rated | White | ISO 9001, ISO 13485, USP 661, USP Class VI | 25 | 00000000 | 000000 |

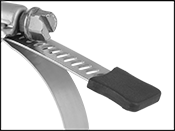

Guards for Hose and Tube Clamps

Cover the ends of hose and tube clamps to prevent them from cutting people and nearby objects. Made of flexible TPE plastic, these guards can be cut to size for shorter bands or T-bolts.

For technical drawings and 3-D models, click on a part number.

Drain Hose for Plumbing Fixtures

Drain water from washing machines and dishwashers. You’ll need a hose clamp to attach to your appliance.

Hose for washing machines has an end that can be trimmed to fit 1", 1 1/8", and 1 1/4" outlets. The hook end makes it easy to hang this hose from the lip of a sink.

| Lg., ft. | ID | OD | Wall Thick. | Material | Max. Temp., °F | Color | Includes | Each | |

| 6 | 1" | 1 1/4" | 1/8" | TPE Rubber | 150° | Black | One Hose Clamp | 0000000 | 000000 |