Filter by

Manufacturer

Mount Type

Base Type

Drive Direction

Power Source

For Surface Thickness

Coolant Included

Column Feed Handle Number of Spokes

DFARS Specialty Metals

Export Control Classification Number (ECCN)

For Holding

No-Load Rotational Speed

REACH

RoHS

Plug Number of Blades

Coolant Reservoir Capacity

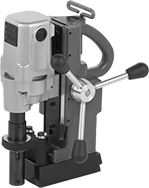

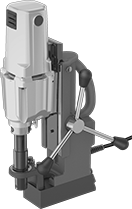

Hougen Magnetic-Base Drills for Hollow-Core Cutters

|  |

Style A | Style B |

These drills work with hollow-core cutters to cut only on the periphery of the hole and produce a solid slug. This allows for a faster and easier cut than drilling with standard drill bits. Also known as magnetic core drilling machines.

They have a feed handle that mounts on the left or right side of the drill. The electromagnetic base attaches to flat ferrous surfaces (such as steel and cast iron). Holding force (also called drill-point breakaway) is calculated against a 1" thick steel plate.

Overall | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

Style | For Max. Cutter Dia. | For Cutter Shank Size | Max. Cutting Dp. | Spindle Travel | Max. No-Load Rotational Speed, rpm | No. of Speeds | Current, amp | Holding Force, lbf | For Min. Surface Thk. | Coolant Included | Lg. | Wd. | Ht. | Wt., lb. | Mfr. Model No. | Each | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

120V AC | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| A | 1 1/2" | 3/4" | 2" | 2" | 450 | 1 | 8 | 995 | 3/8" | Yes | 11 5/8" | 7 3/4" | 19 5/8" | 30 | HMD904 | 2831A31 | 000000000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| B | 2 3/8" | 3/4" | 3" | 3" | 700 | 3 | 12.5 | 1,290 | 3/8" | Yes | 12 3/4" | 8 1/4" | 26" | 49 | HMD920 | 2831A34 | 00000000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||