Filter by

For Use With

Outlet Pressure

Body Material

Valve Function

Maximum Inlet Pressure

Set Pressure

Maximum Temperature

Diaphragm Material

Outlet Pipe Size

Airflow Capacity

Minimum Temperature

DFARS Specialty Metals

Export Control Classification Number (ECCN)

ASME-Code Fast-Acting Pressure-Relief Valves for Cryogenic Fluids

NPT Male Inlet and NPT Female Relief Port

Inlet | Relief | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

Pipe Size | Location | Max. Pressure, psi | Port Pipe Size | Port Location | Shape | Overall Ht. | For Use With | Temp. Range, ° F | Valve Type | Certification | Choose a Set Pressure, psi | Each | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Brass Body—Brass Seal | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 1/2 | Bottom | 600 | 3/4 | Side | 90° Elbow | 6 9/16" | Argon, Carbon Dioxide, Helium, Hydrogen, Methane, Nitrogen, Oxygen | -320 to 150 | Pop Safety | ASME BPVC.VIII | 20 , 30 , 40 , 50 , 60 , 70 , 80 , 90 , 100 , 110 , 120 , 130 , 140 , 150 , 160 , 170 , 180 , 190 , 200 , 210 , 220 , 230 , 240 , 250 , 260 , 270 , 280 , 290 , 300 | 0000000 | 0000000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 3/4 | Bottom | 600 | 1 | Side | 90° Elbow | 6 9/16" | Argon, Carbon Dioxide, Helium, Hydrogen, Methane, Nitrogen, Oxygen | -320 to 150 | Pop Safety | ASME BPVC.VIII | 20 , 30 , 40 , 50 , 60 , 70 , 80 , 90 , 100 , 110 , 120 , 130 , 140 , 150 , 160 , 170 , 180 , 190 , 200 , 210 , 220 , 230 , 240 , 250 , 260 , 270 , 280 , 290 , 300 | 0000000 | 000000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

High-Purity Tank-Mount Pressure-Regulating Valves for Fuel Gases

Inlet | Outlet | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

CGA No. | Location | Thread Direction | Pressure Gauge Reading Range, psi | No. of Stages | For Tube OD | Location | Pressure Range, psi | Pressure Adjustment Method | For Use With | Temp. Range, ° F | Each | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

NGO Female Inlet × Swagelok® Female Outlet | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Brass Body/Stainless Steel Body—316 Stainless Steel Diaphragm and PTFE Seal with Relief Valve | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 350 | Side | Left Hand | 0 to 4,000 | Single | 1/4" | Side | 0 to 15 | Knob | Hydrogen, Methane | -20 to 120 | 0000000 | 0000000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 350 | Side | Left Hand | 0 to 4,000 | Single | 1/4" | Side | 0 to 125 | Knob | Hydrogen, Methane | -20 to 120 | 0000000 | 000000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 350 | Side | Left Hand | 0 to 4,000 | Two | 1/4" | Side | 0 to 15 | Knob | Hydrogen, Methane | -20 to 120 | 0000000 | 000000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 350 | Side | Left Hand | 0 to 4,000 | Two | 1/4" | Side | 0 to 125 | Knob | Hydrogen, Methane | -20 to 120 | 0000000 | 000000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 350 | Side | Left Hand | 0 to 4,000 | Two | 1/4" | Side | 0 to 500 | Knob | Hydrogen, Methane | -20 to 120 | 0000000 | 000000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Pressure-Regulating Valves for Fuel Gases

Inlet | Outlet | Lg. | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

For Use With | Pipe Size | Location | Max. Pressure, psi | Pipe Size | Location | Pressure Adjustment Method | Pressure Gauge Measurement Range, psi | Temp. Range, ° F | End-to-End | Port-to-Port | Each | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

NPT Female | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Brass Body—Stainless Steel Diaphragm and Neoprene Seal | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| Hydrogen, Propane | 1/4 | Side | 500 | 1/4 | Bottom, Side | T-Handle | 0 to 60 | 0 to 120 | 2.400" | 1.01" | 0000000 | 0000000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| Hydrogen, Propane | 1/4 | Side | 500 | 1/4 | Bottom, Side | T-Handle | 0 to 200 | 0 to 120 | 2.400" | 1.01" | 0000000 | 000000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Tank-Mount Pressure-Regulating Valves for Fuel Gases

Single Stage

Inlet | Outlet | Material | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

CGA No. | Location | Thread Direction | Pressure Gauge Reading Range, psi | Thread Size | Location | Thread Direction | Pressure Range, psi | Pressure Adjustment Method | Body | Seal | Diaphragm | Temp. Range, ° F | Each | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

For Hydrogen | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

UNF Male Outlet × NGO Female Inlet | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 350 | Side | Left Hand | 0 to 4,000 | 9/16"-18 | Side | Left Hand | 0 to 125 | T-Handle | Brass | PTFE | Rubber | -20 to 120 | 000000 | 0000000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Two Stage

Inlet | Outlet | Material | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

CGA No. | Location | Thread Direction | Pressure Gauge Reading Range, psi | Thread Size | Location | Thread Direction | Pressure Range, psi | Pressure Adjustment Method | Body | Seal | Diaphragm | Temp. Range, ° F | Each | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

For Hydrogen and Methane | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

UNF Male Outlet × NGO Female Inlet | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 350 | Side | Left Hand | 0 to 4,000 | 9/16"-18 | Side | Left Hand | 0 to 80 | Knob | Brass | Neoprene | Stainless Steel | -20 to 120 | 0000000 | 0000000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

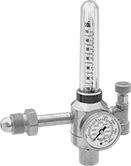

Easy-Read Tank-Mount Pressure-Regulating Valves with Flowmeter for Inert Gas

For Helium and Hydrogen

Inlet | Outlet | Material | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

CGA No. | Location | Thread Direction | Pressure Gauge Reading Range, psi | No. of Stages | Thread Size | Location | Thread Direction | Flow Range | No. of Flowmeters | Body | Seal | Diaphragm | Each | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

UNF Female Outlet × NGO Male Inlet | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 580 | Side | Right Hand | 0 to 4,000 | Single | 5/8"-18 | Side | Right Hand | 0 to 100 scfh (Helium), 0 to 140 scfh (Hydrogen) | 1 | Brass | PTFE | Neoprene | 000000000 | 0000000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

For Hydrogen

Inlet | Outlet | Material | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

CGA No. | Location | Thread Direction | Pressure Gauge Reading Range, psi | No. of Stages | Thread Size | Location | Thread Direction | Flow Range | No. of Flowmeters | Body | Seal | Diaphragm | Each | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

UNF Male Outlet × NGO Female Inlet | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 350 | Side | Left Hand | 0 to 3,000 | Single | 9/16"-18 | Side | Left Hand | 0 scfh to 40 scfh | 1 | Brass | PTFE | Neoprene | 000000000 | 0000000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||