Filter by

Weight Capacity

Power Source

Mount Type

Application

Material

Hoist Mounting Hardware

Trolley Material

Wheel Material

Length

Height

Washer Type

Width

Export Control Classification Number (ECCN)

RoHS

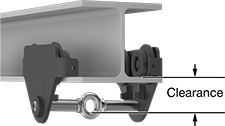

Hoist Trolleys

Mounting Eye Trolleys

For Beam | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

Style | Wt. Cap. | Shape | Wd. | Min. Ht. | Clearance | Min. Curve Radius | Wheel Material | Eye Dia. | Adjustment Mechanism | Features | Each | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Steel | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| C | 1/2 ton/1,100 lb. | Flat, Taper | 2" to 8 5/8" | 2 3/4" | 3" | 35" | Steel | 1" | Screw | Anti-Drop Plates | 0000000 | 0000000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| C | 1 ton/2,200 lb. | Flat, Taper | 2" to 8 5/8" | 2 3/4" | 3 1/4" | 35" | Steel | 1 1/8" | Screw | Anti-Drop Plates | 0000000 | 000000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| C | 2 ton/4,400 lb. | Flat, Taper | 2 1/2" to 8 5/8" | 3 3/4" | 3 7/8" | 45" | Steel | 1 1/2" | Screw | Anti-Drop Plates | 0000000 | 000000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| C | 3 ton/6,600 lb. | Flat, Taper | 3" to 8 5/8" | 5 1/8" | 4 1/2" | 55" | Steel | 2" | Screw | Anti-Drop Plates | 0000000 | 000000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| C | 5 ton/11,000 lb. | Flat, Taper | 3 1/2" to 8 5/8" | 5 5/8" | 5 1/4" | 70" | Steel | 2 1/4" | Screw | Anti-Drop Plates | 0000000 | 000000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

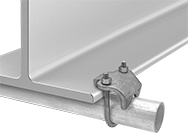

Beam Clamps for Pipe, Tube, and Conduit

For OD | For Beam Thk. | For Perpendicular Mounting | For Parallel Mounting | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

For Beam Shape | Inch | Metric, mm | For Pipe Size | Min. | Max. | Wt. Cap., lb. | Mount Type | Throat Dp. | Fastener Strength Grade/Class | Each | Each | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Bottom and Top Beam Mount | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Galvanized Iron | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| Flat, Taper | 5/8" | 16 | 3/8 | 1/8" | 3/4" | Not Rated | Clamp On | 7/16" | — | 00000000 | 000000 | ——— | 0 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| Flat, Taper | 7/8" | 22 | 1/2 | 1/8" | 3/4" | Not Rated | Clamp On | 7/16" | — | 00000000 | 00000 | 0000000 | 000000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| Flat, Taper | 1" | 25 | 3/4 | 1/8" | 3/4" | Not Rated | Clamp On | 7/16" | — | 00000000 | 00000 | 0000000 | 00000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| Flat, Taper | 1 5/16" | 33 | 1 | 1/8" | 3/4" | Not Rated | Clamp On | 7/16" | — | 00000000 | 00000 | 0000000 | 00000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| Flat, Taper | 1 5/8" | 41 | 1 1/4 | 1/8" | 3/4" | Not Rated | Clamp On | 7/16" | — | 00000000 | 00000 | 0000000 | 00000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| Flat, Taper | 1 7/8" | 48 | 1 1/2 | 1/8" | 3/4" | Not Rated | Clamp On | 7/16" | — | 00000000 | 00000 | 0000000 | 00000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| Flat, Taper | 2 3/8" | 60 | 2 | 1/8" | 3/4" | Not Rated | Clamp On | 7/16" | — | 00000000 | 00000 | 0000000 | 00000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

316 Stainless Steel | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| Flat, Taper | 13/16" | 21 | 1/2 | 1/8" | 3/4" | 150 | Clamp On | 1/2" | ASTM Grade B8M | 0000000 | 00000 | ——— | 0 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| Flat, Taper | 1" | 25 | 3/4 | 1/8" | 3/4" | 150 | Clamp On | 1/2" | ASTM Grade B8M | 0000000 | 00000 | ——— | 0 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| Flat, Taper | 1 5/16" | 33 | 1 | 1/8" | 3/4" | 200 | Clamp On | 1/2" | ASTM Grade B8M | 0000000 | 00000 | ——— | 0 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| Flat, Taper | 1 5/8" | 41 | 1 1/4 | 1/8" | 3/4" | 225 | Clamp On | 1/2" | ASTM Grade B8M | 0000000 | 00000 | ——— | 0 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| Flat, Taper | 1 7/8" | 48 | 1 1/2 | 1/8" | 3/4" | 250 | Clamp On | 1/2" | ASTM Grade B8M | 0000000 | 00000 | ——— | 0 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| Flat, Taper | 2 3/8" | 60 | 2 | 1/8" | 3/4" | 500 | Clamp On | 1/2" | ASTM Grade B8M | 0000000 | 00000 | ——— | 0 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| Flat, Taper | 2 7/8" | 73 | 2 1/2 | 1/8" | 3/4" | 500 | Clamp On | 1/2" | ASTM Grade B8M | 0000000 | 00000 | ——— | 0 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| Flat, Taper | 3 1/2" | 89 | 3 | 1/8" | 3/4" | 500 | Clamp On | 1/2" | ASTM Grade B8M | 0000000 | 00000 | ——— | 0 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| Flat, Taper | 4" | 102 | 3 1/2 | 1/8" | 3/4" | 600 | Clamp On | 1/2" | ASTM Grade B8M | 0000000 | 00000 | ——— | 0 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| Flat, Taper | 4 1/2" | 114 | 4 | 1/8" | 3/4" | 700 | Clamp On | 1/2" | ASTM Grade B8M | 00000000 | 00000 | ——— | 0 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Beam Clamps for Threaded Rods

Style | For Beam Shape | For Thread Size | For Max. Beam Thk. | Wt. Cap., lb. | Mount Type | Throat Dp. | Lg. | Wd. | Ht. | Threaded Rod Included | Each | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

Bottom Beam Mount | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Zinc-Plated Iron | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| E | Flat, Taper | M10 × 1.5 mm | 3/4" | 525 | Clamp On | 1/2" | 1 5/8" | 1 5/8" | 1 3/4" | No | 000000 | 000000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| E | Flat, Taper | M6 × 1 mm | 1/2" | 275 | Clamp On | 1/2" | 1 1/2" | 1 1/8" | 1 1/2" | No | 000000 | 00000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| E | Flat, Taper | M8 × 1.25 mm | 1/2" | 275 | Clamp On | 1/2" | 1 1/2" | 1 1/8" | 1 1/2" | No | 000000 | 00000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

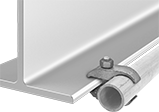

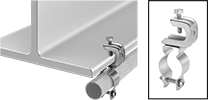

Easy-Position Beam Clamps for Pipe, Tube, and Conduit

For OD | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

Mount Type | For Beam Shape | Inch | Metric, mm | For Pipe Size | For Max. Beam Thk. | Wt. Cap., lb. | Range of Motion | Threaded Hole Size | Throat Dp. | Surface to Pipe Center | Lg. | Wd. | Ht. | Each | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Bottom Beam Mount | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Zinc-Plated Steel | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| Clamp On | Flat, Taper | 1 1/2" | 38 | — | 1/2" | 75 | 360° | 1/4"-20 | 1/2" | 1 11/16" | 1 3/4" | 1" | 1 1/2" | 00000000 | 00000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| Clamp On | Flat, Taper | 1 11/16" | 43 | 1 1/4 | 1/2" | 75 | 360° | 1/4"-20 | 1/2" | 1 13/16" | 1 3/4" | 1" | 1 1/2" | 00000000 | 0000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| Clamp On | Flat, Taper | 1 7/8" | 48 | 1 1/2 | 1/2" | 75 | 360° | 1/4"-20 | 1/2" | 2" | 1 3/4" | 1" | 1 1/2" | 00000000 | 0000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

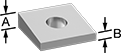

Leveling Washers for U-Channels

Thk., mm | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

For Screw Size | ID, mm | Lg., mm | Wd., mm | (A) | (B) | Hardness | Specs. Met | Pkg. Qty. | Pkg. | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Zinc-Plated Steel | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| M8 | 9.0 | 22.0 | 22.0 | 3.8 | 2.0 | Rockwell B56 | DIN 434 | 10 | 000000000 | 000000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| M10 | 11.0 | 22.0 | 22.0 | 3.8 | 2.0 | Rockwell B56 | DIN 434 | 10 | 000000000 | 00000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| M12 | 14.0 | 30.0 | 26.0 | 4.9 | 2.5 | Rockwell B56 | DIN 434 | 5 | 000000000 | 00000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| M16 | 18.0 | 36.0 | 32.0 | 5.9 | 3.0 | Rockwell B56 | DIN 434 | 5 | 000000000 | 00000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| M20 | 22.0 | 44.0 | 40.0 | 7.0 | 3.5 | Rockwell B56 | DIN 434 | 1 | 000000000 | 0000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Leveling Washers for I-Beams

Thk., mm | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

For Screw Size | ID, mm | Wd., mm | (A) | (B) | Hardness | Specs. Met | Pkg. Qty. | Pkg. | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

18-8 Stainless Steel | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| M8 | 9.0 | 22.0 | 4.6 | 1.5 | Rockwell B52 | DIN 435 | 1 | 000000000 | 00000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| M10 | 11.0 | 22.0 | 4.6 | 1.5 | Rockwell B52 | DIN 435 | 1 | 000000000 | 0000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| M12 | 14.0 | 26.0 | 6.2 | 2.0 | Rockwell B52 | DIN 435 | 1 | 000000000 | 0000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| M16 | 18.0 | 32.0 | 7.5 | 2.5 | Rockwell B52 | DIN 435 | 1 | 000000000 | 0000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| M20 | 22.0 | 40.0 | 9.2 | 3.0 | Rockwell B52 | DIN 435 | 1 | 000000000 | 00000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| M24 | 26.0 | 56.0 | 10.8 | 3.0 | Rockwell B52 | DIN 435 | 1 | 000000000 | 00000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Zinc-Plated Steel | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| M8 | 9.0 | 22.0 | 4.6 | 1.5 | Rockwell B52 | DIN 435 | 10 | 000000000 | 00000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| M10 | 11.0 | 22.0 | 4.6 | 1.5 | Rockwell B52 | DIN 435 | 10 | 000000000 | 0000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| M12 | 14.0 | 26.0 | 6.2 | 2.0 | Rockwell B52 | DIN 435 | 10 | 000000000 | 00000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| M16 | 18.0 | 32.0 | 7.5 | 2.5 | Rockwell B52 | DIN 435 | 10 | 000000000 | 00000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| M20 | 22.0 | 40.0 | 9.2 | 3.0 | Rockwell B52 | DIN 435 | 5 | 000000000 | 00000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| M24 | 26.0 | 56.0 | 10.8 | 3.0 | Rockwell B52 | DIN 435 | 1 | 000000000 | 0000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Galvanized Steel | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| M8 | 9.0 | 22.0 | 4.6 | 1.5 | Rockwell B52 | DIN 435 | 10 | 000000000 | 00000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| M10 | 11.0 | 22.0 | 4.6 | 1.5 | Rockwell B52 | DIN 435 | 5 | 000000000 | 0000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| M12 | 14.0 | 26.0 | 6.2 | 2.0 | Rockwell B52 | DIN 435 | 5 | 000000000 | 0000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| M16 | 18.0 | 32.0 | 7.5 | 2.5 | Rockwell B52 | DIN 435 | 5 | 000000000 | 00000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| M20 | 22.0 | 40.0 | 9.2 | 3.0 | Rockwell B52 | DIN 435 | 1 | 000000000 | 00000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| M24 | 26.0 | 56.0 | 10.8 | 3.0 | Rockwell B52 | DIN 435 | 1 | 000000000 | 0000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||