Indexing Collet Fixtures

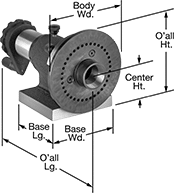

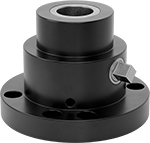

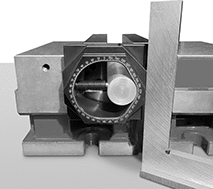

Used with a 5C collet (sold separately), these fixtures rotate round, hex, or square workpieces up to 1 1/8" diameter in precise increments. Also known as spindexers or punch formers, they are commonly used to drill holes into cylindrical parts, grind punches into precision shapes, and sharpen drill bits and end mills. To ensure accurate rotation, spindles are precision ground. Mount fixtures to a machine table for horizontal orientation or an angle plate for vertical. A through-hole accommodates long workpieces.

Fixtures with 1° index increments have an indexing plate with 36 holes for rotating in 10° steps and 10 additional holes for 1° refinements. Fixtures with 15° index increments have 24 locking positions.

Collet Fixtures

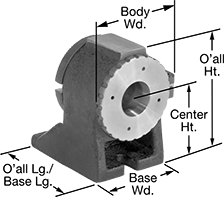

Pair these fixtures with collets to tightly grip workpieces for machining. You can mount them on milling machines, drill presses, and other work surfaces. However, they’re not for use with lathes, grinders, or high-speed rotary tables. All have a through hole to accommodate long workpieces.

Lever fixtures have a handle that can be indexed to any position—no tools required. They’re often used for quickly swapping workpieces in and out, when a simple clamping mechanism is more important than consistent holding force. These fixtures keep the collet stationary while their sleeve clamps. Made from cast iron, they dampen vibration better than steel fixtures, though they’re less durable.

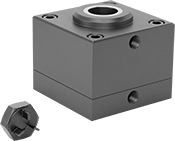

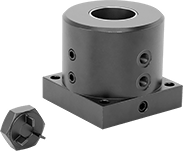

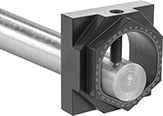

Collet nut fixtures convert ER collets—typically used to hold tool bits—into holders for cylindrical workpieces. The tapered, slit design of the collet distributes clamping force evenly around a workpiece. This creates a stable, consistent grip that keeps your workpiece from shifting, even under 5-axis machining forces. These fixtures are made of steel to withstand the high clamping forces and frequent cycles of production environments.

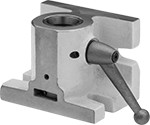

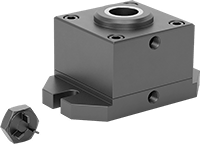

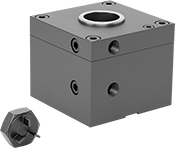

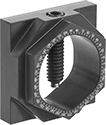

Square-drive fixtures are designed for precise, repeatable workholding with consistent clamping force. They keep the collet stationary while their sleeve clamps. Made of steel, these fixtures are stronger and more wear resistant than cast iron fixtures, and they can hold up to higher clamping forces. They’re precision machined for accuracy. Use the included socket wrench to clamp and unclamp your workpiece or use a calibrated torque wrench to fine-tune the clamping force.

Mounting Slots | ||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|

| For Collet Type | For Max. Workpiece Dia. | Through Hole Dia. | Lg. | Wd. | Ht. | Material | No. of | Wd. | Mounting Orientation | Power Source | Each | |

| 5C | 1 1/16" | 1 1/16" | 3 3/4" | 5" | 4" | Enamel-Coated Cast Iron | 4 | 11/16" | Horizontal, Vertical | Manual | 0000000 | 0000000 |

Mounting Holes | ||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|

| For Collet Type | For Max. Workpiece Dia. | Through Hole Dia. | Dia. | Ht. | Material | No. of | Dia. | Bolt Circle Dia. | Mounting Orientation | Power Source | Each | |

| ER-16 | 3/8" | 7/16" | 2 3/4" | 2 1/2" | Black-Oxide Steel | 4 | 1/4" | 2 1/8" | Horizontal, Vertical | Manual | 0000000 | 0000000 |

| ER-20 | 1/2" | 7/16" | 2 3/4" | 2 1/2" | Black-Oxide Steel | 4 | 1/4" | 2 1/8" | Horizontal, Vertical | Manual | 0000000 | 000000 |

| ER-25 | 5/8" | 7/16" | 2 3/4" | 2 1/2" | Black-Oxide Steel | 4 | 1/4" | 2 1/8" | Horizontal, Vertical | Manual | 0000000 | 000000 |

| ER-25 | 5/8" | 11/16" | 5" | 3" | Black-Oxide Steel | 4 | 7/16" | 4" | Horizontal, Vertical | Manual | 0000000 | 000000 |

| ER-32 | 13/16" | 11/16" | 5" | 3" | Black-Oxide Steel | 4 | 7/16" | 4" | Horizontal, Vertical | Manual | 0000000 | 000000 |

| ER-40 | 1" | 11/16" | 5" | 3" | Black-Oxide Steel | 4 | 7/16" | 4" | Horizontal, Vertical | Manual | 0000000 | 000000 |

Mounting Holes | |||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| For Collet Type | For Max. Workpiece Dia. | Through Hole Dia. | Dia. | Ht. | Material | No. of | Dia. | Bolt Circle Dia. | Mounting Orientation | Power Source | Includes | Each | |

| 5C | 1 1/16" | 1 3/16" | 5" | 3 1/2" | Black-Oxide Steel | 6 | 3/8" | 4 1/8" | Horizontal, Vertical | Manual | Socket Wrench | 0000000 | 000000000 |

| 16C | 1 5/8" | 1 13/16" | 5" | 4 1/2" | Black-Oxide Steel | 6 | 3/8" | 4 1/8" | Horizontal, Vertical | Manual | Socket Wrench | 0000000 | 00000000 |

| 3J | 1 3/4" | 1 15/16" | 5" | 4" | Black-Oxide Steel | 6 | 3/8" | 4 1/8" | Horizontal, Vertical | Manual | Socket Wrench | 0000000 | 00000000 |

Air-Operated Collet Fixtures

Control clamping action with air. Use 5C collets (sold separately) to grip and release parts on milling machines and drill presses.

Mounting Holes | Air Inlet | ||||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Fixture Type | For Max. Workpiece Dia. | Dia. | Ht. | Max. Clamping Force, psi | Max. Air Pressure, psi | Material | No. of | Dia. | Mounting Orientation | No. of Air Ports | Connection Type | Pipe Size | Thread Type | Gender | Includes | Each | |

| Fixture | 1 1/16" | 5 1/2" | 3 1/4" | 1,125 | 150 | Aluminum | 4 | 3/8" | Vertical | 2 | Hose | 1/4 | NPS | Male | __ | 0000000 | 0000000 |

| Fixture, Foot Pedal, and Hose Kit | 1 1/16" | 5 1/2" | 3 1/4" | 1,125 | 150 | Aluminum | 4 | 3/8" | Vertical | 2 | Hose | 1/4 | NPS | Male | Air-Operated Fixture, Four-Way Foot-Operated Air Valve, Three 6-ft. Long Air Hoses | 0000000 | 000000 |

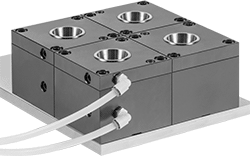

High-Density Air/Hydraulic-Operated Collet Fixtures

Push a button to clamp or release multiple workpieces on your milling machine or drill press. To create a high-density setup, mount these fixtures and join them together using two connector bushings (sold separately) for each fixture you want to add. These fixtures have a through hole for clamping long workpieces.

Air or hydraulic pressure opens and closes the collets (not included). A good choice for heavy machining, these fixtures provide a tighter hold than you can achieve with manual power. You can operate multiple fixtures with a single valve (not included) and two hoses—one for supply and one for return. All are double acting, so they need air or hydraulic pressure both to open and close. This means that the workpiece stays locked in place even if you lose pressure. Clamping force depends on the air or hydraulic pressure of your system.

Fixtures with a top-locking screw allow for direct access to make adjustments without disassembling your setup.

Pull-back fixtures have tapered walls that press all sides of the collet evenly to center the workpiece—like how a mechanical pencil grips lead. They’re less precise than fixed-length fixtures because the workpiece may shift slightly during clamping.

Fixed-length fixtures, also known as dead-length fixtures, keep the collet stationary while they clamp onto a workpiece. Use them to precisely machine holes, slots, and contours exactly where you need them. Since these fixtures position workpieces consistently, they’re often used for high-volume production runs. You can also rotate them on an indexer or rotary table without losing your reference point.

Collet Fixtures | |||||||||||||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

Mounting Holes | Mounting Slot | Port | Connector Bushings | ||||||||||||||||||||||

| For Collet Type | For No. of Collets | For Max. Workpiece Dia. | Through Hole Dia. | Lg. | Wd. | Ht. | Max. Air Pressure, psi | Max. Hydraulic Pressure, psi | Max. Air-Powered Clamping Force, psi | Max. Hydraulic-Powered Clamping Force, psi | Material | No. of | Thread Size | Dia. | Lg. | Wd. | No. of Ports | Pipe Size | Thread Type | Thread Gender | Includes | Each | Each | ||

Collet Fixtures with Locking Screw | |||||||||||||||||||||||||

Pull Back | |||||||||||||||||||||||||

| 5C | 1 | 1 1/16" | 1 3/16" | 4" | 4" | 3 1/2" | 150 | __ | 1,125 | __ | Aluminum | 4 | 3/8"-24 | __ | __ | __ | 2 | 1/4 | NPT | Female | Collet Wrench | 0000000 | 0000000 | 0000000 | 000000 |

Pull Back—Flange Mount | |||||||||||||||||||||||||

| 5C | 1 | 1 1/16" | 1 3/16" | 6 1/2" | 4" | 3 1/2" | 150 | __ | 1,125 | __ | Aluminum | 4 | 3/8"-24 | __ | 1" | 1/2" | 2 | 1/4 | NPT | Female | Collet Wrench | 0000000 | 000000 | 0000000 | 00000 |

Collet Fixtures with Top-Locking Screw | |||||||||||||||||||||||||

Fixed Length | |||||||||||||||||||||||||

| 1C | 1 | 1/4" | 5/16" | 1 3/4" | 1 3/4" | 1 7/16" | 250 | 750 | 180 | 545 | Aluminum | 4 | 10-24 | __ | __ | __ | 2 | 1/8 | NPT | Female | Collet Wrench | 0000000 | 000000 | 0000000 | 00000 |

| 3C | 1 | 1/2" | 5/8" | 2 1/2" | 2 1/2" | 2 3/4" | 250 | 750 | 300 | 900 | Aluminum | 4 | 1/4"-20 | __ | __ | __ | 2 | 1/8 | NPT | Female | Collet Wrench | 0000000 | 000000 | 0000000 | 00000 |

| 5C | 1 | 1 1/16" | 1 3/16" | 4" | 4" | 3 5/16" | 150 | 400 | 3,825 | 19,125 | Aluminum | 4 | 3/8"-16 | __ | __ | __ | 2 | 1/4 | NPT | Female | Collet Wrench | 0000000 | 000000 | 0000000 | 00000 |

| 5C | 3 | 1 1/16" | 1 3/16" | 8" | 3 1/2" | 3 5/16" | __ | 5,000 | __ | 5,500 | Aluminum | 4 | 5/16"-18 | __ | __ | __ | 2 | 7/16 | UNF | Female | Collet Wrench | 0000000 | 00000000 | 0000000 | 00000 |

| 16C | 1 | 1 5/8" | 1 7/8" | 4" | 4" | 4 1/4" | 250 | 2,000 | 1,450 | 11,600 | Aluminum | 4 | 3/8"-16 | __ | __ | __ | 2 | 1/4 | NPT | Female | Collet Wrench | 0000000 | 000000 | 0000000 | 00000 |

Fixed Length—Flange Mount | |||||||||||||||||||||||||

| 3J | 1 | 1 3/4" | 1 15/16" | 4" | 4" | 3 3/4" | __ | 5,000 | __ | 9,500 | Steel | 4 | __ | 3/8" | __ | __ | 2 | 7/16 | UNF | Female | Collet Wrench | 0000000 | 00000000 | 0000000 | 00000 |

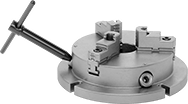

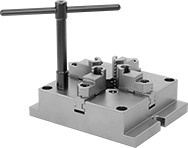

Stationary Jaw Clamping Fixtures

Mount these fixtures to a milling machine, drill press, or other flat surface and use the jaws to grip workpieces. Their low-profile design maximizes tool clearance, which helps you machine efficiently. The jaws are precision ground to tight tolerances for repeatable centering that’s accurate within 0.02 mm. These fixtures are self-centering—they use scroll actuation, which means that all jaws move in unison to center the workpiece as they close.

Each fixture comes with reversible jaws, which you can install for either an inside or outside grip. Use the included wrench to open or close the jaws.

Fixtures with three jaws are best for gripping round workpieces. Fixtures with four jaws have more holding power than those with three jaws, so they’re often used on square or rectangular workpieces.

For Workpiece | Base | Mounting Slots | ||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|

| OD | ID | Dia. | Ht. | Dia | Ht. | Center Through-Hole Dia. | Material | No. of | Wd. | Includes | Each | |

| 5/16"-6 5/16" (8-160 mm) | 1 7/8"- 5 29/32" (48-150 mm) | 6 11/16" (170 mm) | 1 9/16" (40 mm) | 8 21/32" (220 mm) | 11/16" (18 mm) | 1 25/32" (45 mm) | Steel | 4 | 1/2" (13 mm) | One Set of Hardened Reversible Jaws, One Chuck Wrench | 0000000 | 000000000 |

| 7/16"-7 7/8" (11-200 mm) | 2 7/16"- 7 1/2" (62-190 mm) | 8 1/4" (210 mm) | 1 25/32" (45 mm) | 10 5/8" (270 mm) | 25/32" (20 mm) | 2 3/8" (60 mm) | Steel | 4 | 1/2" (13 mm) | One Set of Hardened Reversible Jaws, One Chuck Wrench | 0000000 | 00000000 |

| 15/32"-9 27/32" (12-250 mm) | 2 27/32"- 9 7/16" (72-240 mm) | 10 1/32" (255 mm) | 2 3/32" (53 mm) | 12 13/32" (315 mm) | 25/32" (20 mm) | 3 5/32" (80 mm) | Steel | 4 | 5/8" (16 mm) | One Set of Hardened Reversible Jaws, One Chuck Wrench | 0000000 | 00000000 |

| 19/32"-11 13/16" (15-300 mm) | 3 3/8"- 11 13/32" (86-290 mm) | 12" (305 mm) | 2 9/32" (58 mm) | 14 9/16" (370 mm) | 7/8" (22 mm) | 4 1/8" (105 mm) | Steel | 4 | 11/16" (18 mm) | One Set of Hardened Reversible Jaws, One Chuck Wrench | 0000000 | 00000000 |

For Workpiece | Base | Mounting Slots | ||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| OD | ID | Lg. | Wd. | Ht. | Lg. | Wd. | Ht. | Center Through-Hole Dia. | Material | No. of | Wd. | Includes | Each | |

| 5/32"-5 1/32" (4-128 mm) | 2 5/32"- 5 1/32" (55-128 mm) | 6 1/2" (165 mm) | 6 1/2" (165 mm) | 1 17/32" (39 mm) | 8 15/32" (215 mm) | 6 1/2" (165 mm) | 11/16" (18 mm) | 1 19/32" (40 mm) | Steel | 2 | 11/16" (18 mm) | One Set of Hardened Reversible Jaws, One Chuck Wrench | 0000000 | 000000000 |

| 3/16"-6 3/8" (5-162 mm) | 2 7/16"- 6 3/8" (62-162 mm) | 7 7/8" (200 mm) | 7 7/8" (200 mm) | 1 25/32" (45 mm) | 9 27/32" (250 mm) | 7 7/8" (200 mm) | 25/32" (20 mm) | 2 5/32" (55 mm) | Steel | 2 | 11/16" (18 mm) | One Set of Hardened Reversible Jaws, One Chuck Wrench | 0000000 | 00000000 |

| 1/4"-7 7/8" (6-200 mm) | 2 27/32"- 7 7/8" (72-200 mm) | 9 27/32" (250 mm) | 9 27/32" (250 mm) | 1 31/32" (50 mm) | 12 7/32" (310 mm) | 9 27/32" (250 mm) | 7/8" (22 mm) | 2 3/4" (70 mm) | Steel | 2 | 11/16" (18 mm) | One Set of Hardened Reversible Jaws, One Chuck Wrench | 0000000 | 00000000 |

| 13/32"-10 7/16" (10-265 mm) | 3 9/16"- 10 7/16" (90-265 mm) | 12 7/32" (310 mm) | 12 7/32" (310 mm) | 2 3/8" (60 mm) | 14 31/32" (380 mm) | 12 7/32" (310 mm) | 1" (25 mm) | 3 15/16" (100 mm) | Steel | 2 | 7/8" (22 mm) | One Set of Hardened Reversible Jaws, One Chuck Wrench | 0000000 | 00000000 |

Rotary Angle Indexers

Transform your machine vise into an indexing system in seconds. These indexers help you position round workpieces at precise, repeatable angles for machining flats, hexes, and key slots. Slide them onto the end of a workpiece and secure with the set screw. These indexers attach directly to your workpiece, so you can move them from setup to setup without losing your reference point. These indexers are etched with graduation marks up to 360° so you can line up your workpiece with a machinist square. A hex, square, and octagon are cut into the face, so you don’t need to check the graduations for 45°, 60°, or 90° increments.