About Pipe Size

More

About Pressure Gauges

More

Vibration-Resistant Pressure Gauges for Chemicals

These gauges have a glycerin-filled dial that reduces needle flutter for precise readings in high-vibration applications reaching 2,000 psi. A 316 stainless steel guard, also known as an isolator, protects the gauge from damage caused by corrosive chemicals. Use them with pumps, filters, regulators, and in process lines to measure and display pressure.

- For Use With: Air, Water, Hydraulic Fluid, Ammonia, Bleach, Boric Acid, Gasoline, Diesel Fuel, and Natural Gas

- Accuracy: ±1.6% Full Scale (Not Graded)

Available Pressure Gauges | |||||

|---|---|---|---|---|---|

Pressure Range | Graduation Marks | Numeric Increments | |||

| psi | kPa | psi | kPa | psi | kPa |

2 1/2" Dial Diameter | |||||

| 0 to 15 | 0 to 100 | 0.2 | 2 | 3 | 20 |

| 0 to 30 | 0 to 200 | 0.5 | 5 | 5 | 50 |

| 0 to 60 | 0 to 400 | 1 | 10 | 10 | 100 |

| 0 to 100 | 0 to 700 | 2 | 10 | 20 | 100 |

| 0 to 160 | 0 to 1,100 | 2 | 20 | 20 | 200 |

| 0 to 200 | 0 to 1,400 | 5 | 20 | 40 | 200 |

| 0 to 300 | 0 to 2,000 | 5 | 50 | 50 | 400 |

| 0 to 400 | 0 to 2,800 | 10 | 100 | 50 | 500 |

| 0 to 600 | 0 to 4,000 | 10 | 100 | 100 | 1,000 |

| 0 to 1,000 | 0 to 7,000 | 20 | 100 | 200 | 1,000 |

| 0 to 2,000 | 0 to 14,000 | 50 | 200 | 400 | 2,000 |

4" Dial Diameter | |||||

| 0 to 15 | 0 to 100 | 0.1 | 2 | 2 | 20 |

| 0 to 30 | 0 to 200 | 0.5 | 5 | 5 | 50 |

| 0 to 60 | 0 to 400 | 1 | 10 | 10 | 100 |

| 0 to 100 | 0 to 700 | 2 | 10 | 20 | 100 |

| 0 to 160 | 0 to 1,100 | 2 | 20 | 20 | 200 |

| 0 to 200 | 0 to 1,400 | 5 | 50 | 50 | 200 |

| 0 to 300 | 0 to 2,000 | 5 | 50 | 50 | 500 |

| 0 to 400 | 0 to 2,800 | 10 | 100 | 50 | 500 |

| 0 to 600 | 0 to 4,000 | 10 | 100 | 100 | 800 |

| 0 to 1,000 | 0 to 7,000 | 20 | 100 | 200 | 1,000 |

| 0 to 2,000 | 0 to 14,000 | 50 | 200 | 400 | 2,000 |

Bottom Connection | |||||||

|---|---|---|---|---|---|---|---|

| Dial Diameter | Pipe Size | Environment Temp. Range, °F | Process Temp. Range, °F | Guard Material | Mounting Orientation | Each | |

NPT Female | |||||||

| 2 1/2" | 1/4 | 35° to 140° | 0° to 210° | 316 Stainless Steel | Any | 000000 | 0000000 |

| 2 1/2" | 1/2 | 35° to 140° | 0° to 210° | 316 Stainless Steel | Any | 000000 | 000000 |

| 4" | 1/4 | 35° to 140° | 0° to 210° | 316 Stainless Steel | Any | 000000 | 000000 |

| 4" | 1/2 | 35° to 140° | 0° to 210° | 316 Stainless Steel | Any | 000000 | 000000 |

High-Pressure Gauges for Chemicals

A 316 stainless steel guard, also known as an isolator, protects the gauge from damage caused by corrosive chemicals. Gauges are commonly used with pumps, filters, regulators, and in process lines to measure and display pressures up to 2,000 psi.

- For Use With: Air, Water, Hydraulic Fluid, Ammonia, Bleach, Boric Acid, Gasoline, Diesel Fuel, and Natural Gas

- Accuracy: ±1.6% Full Scale (Not Graded)

Pressure Range | Graduation Marks | Numeric Increments | |||

|---|---|---|---|---|---|

| psi | kPa | psi | kPa | psi | kPa |

2 1/2" Dial Diameter | |||||

| 0 to 200 | 0 to 1,400 | 5 | 20 | 40 | 200 |

| 0 to 300 | 0 to 2,000 | 5 | 50 | 50 | 400 |

| 0 to 400 | 0 to 2,800 | 5 | 50 | 50 | 500 |

| 0 to 600 | 0 to 4,000 | 10 | 100 | 100 | 1,000 |

| 0 to 1,000 | 0 to 7,000 | 20 | 100 | 200 | 1,000 |

| 0 to 2,000 | 0 to 14,000 | 50 | 200 | 400 | 2,000 |

4" Dial Diameter | |||||

| 0 to 200 | 0 to 1,400 | 5 | 50 | 50 | 200 |

| 0 to 300 | 0 to 2,000 | 5 | 50 | 50 | 500 |

| 0 to 400 | 0 to 2,800 | 5 | 50 | 50 | 500 |

| 0 to 600 | 0 to 4,000 | 10 | 100 | 100 | 800 |

| 0 to 1,000 | 0 to 7,000 | 20 | 100 | 200 | 1,000 |

| 0 to 2,000 | 0 to 14,000 | 50 | 200 | 400 | 2,000 |

Bottom Connection | |||||||

|---|---|---|---|---|---|---|---|

| Dial Diameter | Pipe Size | Environment Temp. Range, °F | Process Temp. Range, °F | Guard Material | Mounting Orientation | Each | |

NPT Female | |||||||

| 2 1/2" | 1/4 | -40° to 140° | 0° to 210° | 316 Stainless Steel | Any | 000000 | 0000000 |

| 2 1/2" | 1/2 | -40° to 140° | 0° to 210° | 316 Stainless Steel | Any | 000000 | 000000 |

| 4" | 1/4 | -40° to 140° | 0° to 210° | 316 Stainless Steel | Any | 000000 | 000000 |

| 4" | 1/2 | -40° to 140° | 0° to 210° | 316 Stainless Steel | Any | 000000 | 000000 |

Low-Pressure Gauges for Chemicals

A plastic or stainless steel guard, also known as an isolator, protects the gauge from damage caused by corrosive chemicals. Use them with pumps, filters, regulators, and in process lines to measure and display pressures.

Polypropylene and 316 stainless steel guards are more chemical resistant than PVC and CPVC guards.

- For Use With: Air, Water, Hydraulic Fluid, Ammonia, Bleach, Boric Acid, Gasoline, Diesel Fuel, and Natural Gas

- Accuracy: ±1.6% Full Scale (Not Graded)

Available Pressure Ranges | |||||

|---|---|---|---|---|---|

Pressure Range | Graduation Marks | Numeric Increments | |||

| psi | kPa | psi | kPa | psi | kPa |

2 1/2" Dial Diameter | |||||

| 0 to 15 | 0 to 100 | 0.2 | 2 | 3 | 20 |

| 0 to 30 | 0 to 200 | 0.5 | 5 | 5 | 50 |

| 0 to 60 | 0 to 400 | 1 | 10 | 10 | 100 |

| 0 to 100 | 0 to 700 | 2 | 10 | 20 | 100 |

| 0 to 160 | 0 to 1,100 | 2 | 20 | 20 | 200 |

4" Dial Diameter | |||||

| 0 to 15 | 0 to 100 | 0.1 | 2 | 2 | 20 |

| 0 to 30 | 0 to 200 | 0.5 | 5 | 5 | 50 |

| 0 to 60 | 0 to 400 | 1 | 10 | 10 | 100 |

| 0 to 100 | 0 to 700 | 2 | 10 | 20 | 100 |

| 0 to 160 | 0 to 1,100 | 2 | 20 | 20 | 200 |

Bottom Connection | |||||||

|---|---|---|---|---|---|---|---|

| Dial Diameter | Pipe Size | Environment Temp. Range, °F | Process Temp. Range, °F | Mounting Orientation | Guard Material | Each | |

NPT Female | |||||||

| 2 1/2" | 1/4 | -40° to 140° | 0° to 210° | Any | 316 Stainless Steel | 0000000 | 0000000 |

| 2 1/2" | 1/2 | -40° to 140° | 0° to 210° | Any | 316 Stainless Steel | 0000000 | 000000 |

| 4" | 1/4 | -40° to 140° | 0° to 210° | Any | 316 Stainless Steel | 0000000 | 000000 |

| 4" | 1/2 | -40° to 140° | 0° to 210° | Any | 316 Stainless Steel | 0000000 | 000000 |

- For Use With: Water, Salt Water, Hydraulic Fluid, Bleach, Boric Acid, and Carbon Dioxide

- Accuracy: ±2% Mid Scale (Grade B)

Available Pressure Ranges | |||||

|---|---|---|---|---|---|

Pressure Range | Graduation Marks | Numeric Increments | |||

| psi | kg/cm2 | psi | kg/cm2 | psi | kg/cm2 |

| 0 to 30 | 0 to 2.1 | 0.5 | 0.05 | 5 | 0.5 |

| 0 to 60 | 0 to 4.2 | 1 | 0.1 | 10 | 1 |

| 0 to 150 | 0 to 11.2 | 2 | 0.2 | 20 | 2 |

- For Use With: Water, Salt Water, Hydraulic Fluid, Bleach, Boric Acid, and Carbon Dioxide

- Accuracy: ±2% Mid Scale (Grade B)

Available Pressure Ranges | |||||

|---|---|---|---|---|---|

Pressure Range | Graduation Marks | Numeric Increments | |||

| psi | kg/cm2 | psi | kg/cm2 | psi | kg/cm2 |

| 0 to 30 | 0 to 2.1 | 0.5 | 0.05 | 5 | 0.5 |

| 0 to 60 | 0 to 4.2 | 1 | 0.1 | 10 | 1 |

| 0 to 150 | 0 to 11.2 | 2 | 0.2 | 20 | 2 |

- For Use With: Water, Salt Water, Hydraulic Fluid, Boric Acid, and Carbon Dioxide

- Accuracy: ±2% Mid Scale (Grade B)

Available Pressure Ranges | |||||

|---|---|---|---|---|---|

Pressure Range | Graduation Marks | Numeric Increments | |||

| psi | kg/cm2 | psi | kg/cm2 | psi | kg/cm2 |

| 0 to 30 | 0 to 2.1 | 0.5 | 0.05 | 5 | 0.5 |

| 0 to 60 | 0 to 4.2 | 1 | 0.1 | 10 | 1 |

| 0 to 150 | 0 to 11.2 | 2 | 0.2 | 20 | 2 |

Bottom Connection | ||||||||

|---|---|---|---|---|---|---|---|---|

| Dial Diameter | Pipe Size | Environment Temp. Range, °F | Process Temp. Range, °F | Case Color | Guard Material | Guard Color | Each | |

NPT Female | ||||||||

| 2" | 1/4 | 40° to 240° | 40° to 240° | Black | Polypropylene Plastic | White | 0000000 | 0000000 |

Sanitary Gauge Guards

Keeping corrosive substances from touching pressure gauges used in food-processing and pharmaceutical plants, these guards have a sanitary design. Made of 316 stainless steel, they won’t rust from frequent washdowns with harsh cleaners and sanitizers. They have continuously-welded seams and polished surfaces, so there aren’t any pits for bacteria to grow in. Removing them for cleaning and maintenance is easy thanks to their quick-clamp connection, which is sometimes called a tri-clamp.

Also known as isolators and diaphragm seals, these guards have a 316 stainless steel gasket to shield the pressure gauges from corrosion. Before use, fill the guards with fluid such as glycerin or silicone that’s suitable for food contact.

Outlet Quick-Clamp Tube Connection | |||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|

| Inlet Pipe Connection | For Tube OD | Flange OD | Gasket Material | For Use With | Minimum Pressure, psi | Maximum Pressure | Maximum Temperature | Height | Interior Smoothness, Ra | Each | |

316 Stainless Steel Body | |||||||||||

| 1/4 NPT Female | 1 1/2" | 1.984" | 316 Stainless Steel | Acetylene, Air, Ammonia, Beverage, Boric Acid, Carbon Dioxide, Diesel Fuel, Ethanol, Food, Gasoline, Hydraulic Fluid, Hydrogen, Oxygen, Pharmaceuticals, Wastewater, Water | 30 | Not Rated | Not Rated | 1 3/8" | 32 | 0000000 | 0000000 |

| 1/4 NPT Female | 2" | 2.516" | 316 Stainless Steel | Acetylene, Air, Ammonia, Beverage, Boric Acid, Carbon Dioxide, Diesel Fuel, Ethanol, Food, Gasoline, Hydraulic Fluid, Hydrogen, Oxygen, Pharmaceuticals, Wastewater, Water | 30 | Not Rated | Not Rated | 1 1/8" | 32 | 0000000 | 000000 |

| 1/2 NPT Female | 1 1/2" | 1.984" | 316 Stainless Steel | Acetylene, Air, Ammonia, Beverage, Boric Acid, Carbon Dioxide, Diesel Fuel, Ethanol, Food, Gasoline, Hydraulic Fluid, Hydrogen, Oxygen, Pharmaceuticals, Wastewater, Water | 30 | Not Rated | Not Rated | 1 3/8" | 32 | 0000000 | 000000 |

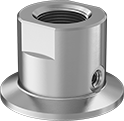

Gauge Guards

Also known as isolators or diaphragm seals, these protect gauges from corrosive process media. Fill guards with hydraulic oil (not included) before use.

316 stainless steel guards provide excellent corrosion and chemical resistance and can handle higher temperatures and pressures than plastic guards.

Polypropylene and PVDF guards are more chemical resistant than PVC and CPVC guards.

Guards with drain port allow you to remove process media.

Pipe Connections | |||||||||

|---|---|---|---|---|---|---|---|---|---|

| Inlet | Outlet | Gasket Material | For Use With | Min. Pressure, psi | Max. Pressure | Max. Temp., °F | Ht. | Each | |

316 Stainless Steel Body | |||||||||

| 1/4 NPT Female | 1/4 NPT Female | 316 Stainless Steel | Acetylene, Air, Ammonia, Argon, Bleach, Boric Acid, Carbon Dioxide, Deionized Water, Diesel Fuel, Ethanol, Ethyl Alcohol, Gasoline, Hydraulic Fluid, Hydraulic Oil, Hydrogen, Liquid Nitrogen, Mineral Oil, Natural Gas, Nitrogen, Oxygen, Refrigerant, Salt Water, Steam, Water | 60 | 2,500 psi @ 72° F | 300° | 1 3/4" | 0000000 | 0000000 |

| 1/2 NPT Female | 1/4 NPT Female | 316 Stainless Steel | Acetylene, Air, Ammonia, Argon, Bleach, Boric Acid, Carbon Dioxide, Deionized Water, Diesel Fuel, Ethanol, Ethyl Alcohol, Gasoline, Hydraulic Fluid, Hydraulic Oil, Hydrogen, Liquid Nitrogen, Mineral Oil, Natural Gas, Nitrogen, Oxygen, Refrigerant, Salt Water, Steam, Water | 60 | 2,500 psi @ 72° F | 300° | 1 3/4" | 0000000 | 000000 |

| 1/2 NPT Female | 1/2 NPT Female | 316 Stainless Steel | Acetylene, Air, Ammonia, Argon, Bleach, Boric Acid, Carbon Dioxide, Deionized Water, Diesel Fuel, Ethanol, Ethyl Alcohol, Gasoline, Hydraulic Fluid, Hydraulic Oil, Hydrogen, Liquid Nitrogen, Mineral Oil, Natural Gas, Nitrogen, Oxygen, Refrigerant, Salt Water, Steam, Water | 60 | 2,500 psi @ 72° F | 300° | 1 1/2" | 0000000 | 000000 |

316 Stainless Steel Body with 1/4 NPT Female Drain Port | |||||||||

| 1/4 NPT Female | 1/4 NPT Female | 316 Stainless Steel | Acetylene, Air, Ammonia, Argon, Bleach, Boric Acid, Carbon Dioxide, Deionized Water, Diesel Fuel, Ethanol, Ethyl Alcohol, Gasoline, Hydraulic Fluid, Hydraulic Oil, Hydrogen, Liquid Nitrogen, Mineral Oil, Natural Gas, Nitrogen, Oxygen, Refrigerant, Salt Water, Steam, Water | 60 | 2,500 psi @ 72° F | 300° | 2" | 0000000 | 000000 |

| 1/2 NPT Female | 1/4 NPT Female | 316 Stainless Steel | Acetylene, Air, Ammonia, Argon, Bleach, Boric Acid, Carbon Dioxide, Deionized Water, Diesel Fuel, Ethanol, Ethyl Alcohol, Gasoline, Hydraulic Fluid, Hydraulic Oil, Hydrogen, Liquid Nitrogen, Mineral Oil, Natural Gas, Nitrogen, Oxygen, Refrigerant, Salt Water, Steam, Water | 60 | 2,500 psi @ 72° F | 300° | 2" | 0000000 | 000000 |

| 1/2 NPT Female | 1/2 NPT Female | 316 Stainless Steel | Acetylene, Air, Ammonia, Argon, Bleach, Boric Acid, Carbon Dioxide, Deionized Water, Diesel Fuel, Ethanol, Ethyl Alcohol, Gasoline, Hydraulic Fluid, Hydraulic Oil, Hydrogen, Liquid Nitrogen, Mineral Oil, Natural Gas, Nitrogen, Oxygen, Refrigerant, Salt Water, Steam, Water | 60 | 2,500 psi @ 72° F | 300° | 2" | 0000000 | 000000 |

PVC Plastic Body | |||||||||

| 1/4 NPT Female | 1/4 NPT Female | Fluoroelastomer Rubber | Bleach, Boric Acid, Hydraulic Fluid, Salt Water, Water | __ | 150 psi @ 72° F | 140° | 2 3/4" | 0000000 | 000000 |

| 1/2 NPT Female | 1/4 NPT Female | Fluoroelastomer Rubber | Bleach, Boric Acid, Hydraulic Fluid, Salt Water, Water | __ | 150 psi @ 72° F | 140° | 2 3/4" | 0000000 | 000000 |

CPVC Plastic Body | |||||||||

| 1/4 NPT Female | 1/4 NPT Female | Fluoroelastomer Rubber | Bleach, Boric Acid, Hydraulic Fluid, Salt Water, Water | __ | 150 psi @ 72° F | 190° | 2 3/4" | 0000000 | 000000 |

| 1/2 NPT Female | 1/4 NPT Female | Fluoroelastomer Rubber | Bleach, Boric Acid, Hydraulic Fluid, Salt Water, Water | __ | 150 psi @ 72° F | 190° | 2 3/4" | 0000000 | 000000 |

Polypropylene Plastic Body | |||||||||

| 1/4 NPT Female | 1/4 NPT Female | Fluoroelastomer Rubber | Bleach, Boric Acid, Carbon Dioxide, Hydraulic Fluid, Salt Water, Water | __ | 150 psi @ 72° F | 240° | 2 3/4" | 0000000 | 000000 |

PVDF Plastic Body | |||||||||

| 1/2 NPT Female | 1/4 NPT Female | Fluoroelastomer Rubber | Bleach, Boric Acid, Carbon Dioxide, Hydraulic Fluid, Salt Water, Water | __ | 150 psi @ 72° F | 300° | 2 3/4" | 0000000 | 000000 |

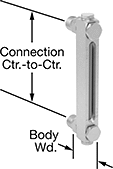

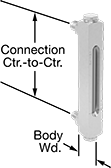

Chemical-Level Indicators

Check the level of liquids containing chemicals such as alcohol-based solvents, boric acid, and sodium bicarbonate. These indicators can be used in pressurized applications where overflow is a concern. All have an aluminum gauge shield that protects the glass window from impact. Clear liquids magnify a red line at the back of the window, so their levels are easier to see.

Screw-in indicators mount from the outside of your tank into threaded pipe or threaded holes.

Through-wall indicators mount from the inside of your tank through unthreaded holes. Secure with nuts on the inside of your tank.

Screw-in/through-wall indicators give you the option to mount from the inside or outside of your tank. Use the mounting nuts on the inside of your tank to attach them through unthreaded holes or thread them into pipe or threaded holes on the tank’s outside.

Temp. Range, °F | |||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

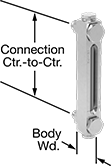

| Connection Ctr.-to-Ctr. | Overall Ht. | Window Ht. | Body Wd. | For Max. Tank Wall Thick. | Max. Pressure | Min. | Max. | Fitting Material | Window Material | Features | Includes | Each | |

Screw-In Mount—Aluminum | |||||||||||||

3/8 NPTF Male Thread | |||||||||||||

| 3" | 4 5/8" | 1 1/2" | 1 3/4" | __ | 290 psi @ 70° F | -15° | 400° | Brass | Glass | Red Line | __ | 0000000 | 000000 |

1/2 NPTF Male Thread | |||||||||||||

| 6" | 7 5/8" | 4 1/2" | 1 9/16" | __ | 290 psi @ 70° F | -15° | 400° | Brass | Glass | Red Line | __ | 0000000 | 00000 |

| 8" | 9 5/8" | 6 1/2" | 1 9/16" | __ | 290 psi @ 70° F | -15° | 400° | Brass | Glass | Red Line | __ | 0000000 | 00000 |

| 10" | 11 5/8" | 8 1/2" | 1 9/16" | __ | 275 psi @ 70° F | -15° | 400° | Brass | Glass | Red Line | __ | 0000000 | 00000 |

| 12" | 13 5/8" | 10 1/2" | 1 9/16" | __ | 270 psi @ 70° F | -15° | 400° | Brass | Glass | Red Line | __ | 0000000 | 00000 |

Through-Wall Mount—Aluminum | |||||||||||||

1/2"-20 UNF Male Thread—For 1/2" Hole Dia. (2 Holes) | |||||||||||||

| 5" | 6 5/8" | 3 1/2" | 7/8" | 3/4" | 290 psi @ 70° F | -15° | 400° | Aluminum | Glass | Red Line | Mounting Nuts | 0000000 | 00000 |

| 10" | 11 5/8" | 8 1/2" | 7/8" | 3/4" | 275 psi @ 70° F | -15° | 400° | Aluminum | Glass | Red Line | Mounting Nuts | 0000000 | 00000 |

| 12" | 13 5/8" | 10 1/2" | 7/8" | 3/4" | 270 psi @ 70° F | -15° | 400° | Aluminum | Glass | Red Line | Mounting Nuts | 0000000 | 00000 |

Screw-In/Through-Wall Mount—Aluminum | |||||||||||||

1/2"-20 UNF Male Thread—For 1/2" Hole Dia. (2 Holes) | |||||||||||||

| 3" | 4 5/8" | 1 1/2" | 1 1/8" | 1/2" | 290 psi @ 70° F | -15° | 400° | Aluminum | Glass | Red Line | Mounting Nuts | 0000000 | 00000 |

| 5" | 6 5/8" | 3 1/2" | 1 1/8" | 1/2" | 290 psi @ 70° F | -15° | 400° | Aluminum | Glass | Red Line | Mounting Nuts | 0000000 | 00000 |

| 6" | 7 5/8" | 4 1/2" | 1 1/8" | 1/2" | 290 psi @ 70° F | -15° | 400° | Aluminum | Glass | Red Line | Mounting Nuts | 0000000 | 00000 |

| 8" | 9 5/8" | 6 1/2" | 1 1/8" | 1/2" | 290 psi @ 70° F | -15° | 400° | Aluminum | Glass | Red Line | Mounting Nuts | 0000000 | 00000 |

| 10" | 11 5/8" | 8 1/2" | 1 1/8" | 1/2" | 275 psi @ 70° F | -15° | 400° | Aluminum | Glass | Red Line | Mounting Nuts | 0000000 | 00000 |

| 12" | 13 5/8" | 10 1/2" | 1 1/8" | 1/2" | 270 psi @ 70° F | -15° | 400° | Aluminum | Glass | Red Line | Mounting Nuts | 0000000 | 00000 |

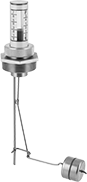

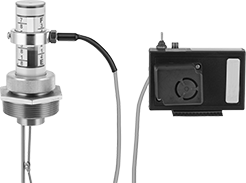

Chemical-Resistant Vertical-Mount Liquid-Level Gauges for Tanks

With a stainless steel float and float rod, these gauges resist corroding from chemicals. Their indicator moves up as your tank fills. Check the indicator against the graduation marks to see how full your tank is and if you need to fill or drain it. Plastic protects the indicator's movement, saving you from inaccurate readings.

Alarms can be set to flash and sound at levels critical to your system.

Remote-reading displays let you check readings from up to 100 ft. away. They have an alarm that sounds when the level is too high or too low.

Temp. Range, °F | |||||||||

|---|---|---|---|---|---|---|---|---|---|

| For Tank Dp. | Max. Pressure, psi | Window Ht. | Min. | Max. | Float Material | Graduation Marks | Window Material | Each | |

1 1/2 NPT Male | |||||||||

316 Stainless Steel Float Rod | |||||||||

| 12" | 70 | 3" | -50° | 400° | 316 Stainless Steel | Full, 7/8, 3/4, 5/8, 1/2, 3/8, 1/4, 1/8, Empty | Plastic | 0000000 | 0000000 |

| 20" | 70 | 3" | -50° | 400° | 316 Stainless Steel | Full, 7/8, 3/4, 5/8, 1/2, 3/8, 1/4, 1/8, Empty | Plastic | 0000000 | 000000 |

| 24" | 70 | 3" | -50° | 400° | 316 Stainless Steel | Full, 7/8, 3/4, 5/8, 1/2, 3/8, 1/4, 1/8, Empty | Plastic | 0000000 | 000000 |

| 30" | 70 | 3" | -50° | 400° | 316 Stainless Steel | Full, 7/8, 3/4, 5/8, 1/2, 3/8, 1/4, 1/8, Empty | Plastic | 0000000 | 000000 |

| 36" | 70 | 3" | -50° | 400° | 316 Stainless Steel | Full, 7/8, 3/4, 5/8, 1/2, 3/8, 1/4, 1/8, Empty | Plastic | 0000000 | 000000 |

| 48" | 70 | 3" | -50° | 400° | 316 Stainless Steel | Full, 7/8, 3/4, 5/8, 1/2, 3/8, 1/4, 1/8, Empty | Plastic | 0000000 | 000000 |

2 NPT Male | |||||||||

316 Stainless Steel Float Rod | |||||||||

| 12" | 70 | 3" | -50° | 400° | 316 Stainless Steel | Full, 7/8, 3/4, 5/8, 1/2, 3/8, 1/4, 1/8, Empty | Plastic | 0000000 | 000000 |

| 20" | 70 | 3" | -50° | 400° | 316 Stainless Steel | Full, 7/8, 3/4, 5/8, 1/2, 3/8, 1/4, 1/8, Empty | Plastic | 0000000 | 000000 |

| 24" | 70 | 3" | -50° | 400° | 316 Stainless Steel | Full, 7/8, 3/4, 5/8, 1/2, 3/8, 1/4, 1/8, Empty | Plastic | 0000000 | 000000 |

| 30" | 70 | 3" | -50° | 400° | 316 Stainless Steel | Full, 7/8, 3/4, 5/8, 1/2, 3/8, 1/4, 1/8, Empty | Plastic | 0000000 | 000000 |

| 36" | 70 | 3" | -50° | 400° | 316 Stainless Steel | Full, 7/8, 3/4, 5/8, 1/2, 3/8, 1/4, 1/8, Empty | Plastic | 0000000 | 000000 |

| 42" | 70 | 3" | -50° | 400° | 316 Stainless Steel | Full, 7/8, 3/4, 5/8, 1/2, 3/8, 1/4, 1/8, Empty | Plastic | 0000000 | 000000 |

| 48" | 70 | 3" | -50° | 400° | 316 Stainless Steel | Full, 7/8, 3/4, 5/8, 1/2, 3/8, 1/4, 1/8, Empty | Plastic | 0000000 | 000000 |

| 60" | 70 | 3" | -50° | 400° | 316 Stainless Steel | Full, 7/8, 3/4, 5/8, 1/2, 3/8, 1/4, 1/8, Empty | Plastic | 0000000 | 000000 |

Light | ||||||||||

|---|---|---|---|---|---|---|---|---|---|---|

| Cord Length, ft. | Signal Type | Color | Pattern | No. of | Bulb Type | Volume | Housing Material | Batteries Included | Each | |

Direct Mount | ||||||||||

| __ | Audible Alarm, Signal Light | Red | Flashing | 1 | LED | 110 dB | ABS Plastic | No | 00000000 | 0000000 |

Remote Mount | ||||||||||

| 25 | Audible Alarm, Signal Light | Red | Flashing | 1 | LED | 110 dB | ABS Plastic | No | 00000000 | 000000 |

| 50 | Audible Alarm, Signal Light | Red | Flashing | 1 | LED | 110 dB | ABS Plastic | No | 00000000 | 000000 |

| 75 | Audible Alarm, Signal Light | Red | Flashing | 1 | LED | 110 dB | ABS Plastic | No | 00000000 | 000000 |

| 100 | Audible Alarm, Signal Light | Red | Flashing | 1 | LED | 110 dB | ABS Plastic | No | 00000000 | 000000 |

Light | ||||||||||

|---|---|---|---|---|---|---|---|---|---|---|

| Cord Length, ft. | Signal Type | Display Type | Color | Indicator Display Type | No. of | Volume | Housing Material | Batteries Included | Each | |

| 25 | Audible Alarm | Light Indicator | Green/Red/Yellow | LED | 9 | 0 dB, 90 dB, 100 dB | ABS Plastic | No | 00000000 | 0000000 |

| 50 | Audible Alarm | Light Indicator | Green/Red/Yellow | LED | 9 | 0 dB, 90 dB, 100 dB | ABS Plastic | No | 00000000 | 000000 |

| 75 | Audible Alarm | Light Indicator | Green/Red/Yellow | LED | 9 | 0 dB, 90 dB, 100 dB | ABS Plastic | No | 00000000 | 000000 |

| 100 | Audible Alarm | Light Indicator | Green/Red/Yellow | LED | 9 | 0 dB, 90 dB, 100 dB | ABS Plastic | No | 00000000 | 000000 |