About Structural Adhesives

More

About Paint and Protective Coatings

More

Epoxy Structural Adhesives

Epoxies are the strongest and most weather- and chemical-resistant structural adhesives. They work especially well on metals.

Two-part epoxies must be mixed. The size listed is the combined total of the two parts.

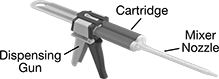

Use cartridges with a dispensing gun and mixer nozzle to simultaneously mix and dispense adhesives.

DP110, 14310, 14260, and 305-1/2 bond dissimilar materials.

DP125, 14255, and 14251 form flexible bonds.

Container | Strength | ||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Mfr. Model No. | Size, fl. oz. | Type | Begins to Harden | Reaches Full Strength | Shear, lbs./sq. in. | Peel, lbs./in. wd. | Mix Ratio | Consistency (Viscosity) | Temp. Range, °F | Color | For Joining | Each | |

| DP110 | 1.64 | Cartridge | 8 min. | 48 hrs. | 1,500 | 20 | 1:1 | Thick Liquid (50,000 cP) | -65° to 350° | Clear | Metal, Metal to Plastic, Metal to Rubber, Plastic, Plastic to Rubber, Rubber | 0000000 | 000000 |

| DP110 | 1.64 | Cartridge | 8 min. | 48 hrs. | 2,500 | 20 | 1:1 | Thick Liquid (65,000 cP) | -65° to 350° | Gray | Metal, Metal to Plastic, Metal to Rubber, Plastic, Plastic to Rubber, Rubber | 0000000 | 00000 |

| DP110 | 6.76 | Cartridge | 8 min. | 48 hrs. | 2,500 | 20 | 1:1 | Thick Liquid (65,000 cP) | -65° to 350° | Gray | Metal, Metal to Plastic, Metal to Rubber, Plastic, Plastic to Rubber, Rubber | 0000000 | 00000 |

| DP125 | 1.64 | Cartridge | 15 min. | 7 days | 1,900 | 35 | 1:1 | Thick Liquid (55,000 cP) | -65° to 300° | Gray | Metal, Plastic, Rubber | 0000000 | 00000 |

| DP125 | 1.64 | Cartridge | 20 min. | 7 days | 1,500 | 35 | 1:1 | Thick Liquid (16,250 cP) | -65° to 300° | Clear | Metal, Plastic, Rubber | 0000000 | 00000 |

| DP190 | 1.64 | Cartridge | 60 min. | 14 days | 850 | 20 | 1:1 | Thick Liquid (8,000 cP) | -65° to 350° | Clear | Metal, Plastic, Rubber, Masonry | 0000000 | 00000 |

| DP190 | 6.76 | Cartridge | 60 min. | 14 days | 850 | 20 | 1:1 | Thick Liquid (8,000 cP) | -65° to 350° | Clear | Metal, Plastic, Rubber, Masonry | 00000000 | 00000 |

| Each | ||

| Mixer Nozzle for 1.64 fl. oz. 3M Cartridges (Step Tip) | 0000000 | 00000 |

| Mixer Nozzle for 1.64 fl. oz. 3M Cartridges (Taper Tip) | 0000000 | 0000 |

| Mixer Nozzle for 6.76 fl. oz. 3M Cartridges | 0000000 | 0000 |

| Replacement Plunger for 1.64 fl. oz. 3M Cartridges | 0000000 | 00000 |

| Dispensing Gun for 1.64 fl. oz. 3M Cartridges | 0000000 | 000000 |

| Dispensing Gun for 6.76 fl. oz. 3M Cartridges | 0000000 | 000000 |

| Air-Powered Dispensing Gun for 1.64 fl. oz. 3M Cartridges | 0000000 | 000000 |

Toughened Epoxy Structural Adhesives

Toughened adhesives are blended with rubber particles for better impact resistance than standard epoxies. They form flexible, resilient bonds. The most weather- and chemical-resistant structural adhesives, epoxies work especially well on metals. Choose an adhesive that hardens quickly for fast repairs, or one that hardens slowly to allow more time for positioning.

These have two parts that must be mixed. The size listed is the combined total of the two parts. Use with a dispensing gun and mixer nozzle to simultaneously mix and dispense adhesives.

DP420NS, DP460NS, E-40HT, and 9462 are nonsagging, so they won't drip from vertical or overhead surfaces.

Container | Strength | ||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Mfr. Model No. | Size, fl. oz. | Type | Begins to Harden | Reaches Full Strength | Shear, lbs./sq. in. | Peel, lbs./in. wd. | Mix Ratio | Consistency (Viscosity) | Temp. Range, °F | Color | For Joining | Each | |

| DP405 | 1.69 | Cartridge | 3 min. | 7 days | 2,260 | 40 | 2:1 | Thick Liquid (9,500 cP) | -65° to 350° | Black | Metal, Plastic, Rubber | 00000000 | 000000 |

| DP420 | 1.69 | Cartridge | 20 min. | 24 hrs. | 280 | 50 | 2:1 | Thick Liquid (30,000 cP) | -65° to 350° | Off-White | Metal, Plastic, Composites | 0000000 | 00000 |

| DP420 | 1.69 | Cartridge | 20 min. | 24 hrs. | 400 | 50 | 2:1 | Thick Liquid (30,000 cP) | -65° to 350° | Black | Metal, Plastic, Composites | 0000000 | 00000 |

| DP420 | 6.76 | Cartridge | 20 min. | 24 hrs. | 280 | 50 | 2:1 | Thick Liquid (30,000 cP) | -65° to 350° | Off-White | Metal, Plastic, Composites | 0000000 | 000000 |

| DP420 | 6.76 | Cartridge | 20 min. | 24 hrs. | 400 | 50 | 2:1 | Thick Liquid (30,000 cP) | -65° to 350° | Black | Metal, Plastic, Composites | 00000000 | 000000 |

| DP420 | 13.5 | Cartridge | 20 min. | 24 hrs. | 280 | 50 | 2:1 | Thick Liquid (30,000 cP) | -65° to 350° | Off-White | Metal, Plastic, Composites | 00000000 | 000000 |

| DP420 | 13.5 | Cartridge | 20 min. | 24 hrs. | 400 | 50 | 2:1 | Thick Liquid (30,000 cP) | -65° to 350° | Black | Metal, Plastic, Composites | 00000000 | 000000 |

| DP420NS | 1.69 | Cartridge | 20 min. | 24 hrs. | 470 | 50 | 2:1 | Paste (180,000 cP) | -65° to 350° | Black | Metal, Plastic, Composites | 00000000 | 00000 |

| DP420NS | 6.76 | Cartridge | 20 min. | 24 hrs. | 470 | 50 | 2:1 | Paste (180,000 cP) | -65° to 350° | Black | Metal, Plastic, Composites | 00000000 | 000000 |

| DP420NS | 13.5 | Cartridge | 20 min. | 24 hrs. | 470 | 50 | 2:1 | Paste (180,000 cP) | -65° to 350° | Black | Metal, Plastic, Composites | 00000000 | 000000 |

| DP460 | 1.69 | Cartridge | 60 min. | 24 hrs. | 2,500 | 60 | 2:1 | Thick Liquid (30,000 cP) | -65° to 350° | Off-White | Metal, Plastic, Composites | 0000000 | 00000 |

| DP460 | 6.76 | Cartridge | 60 min. | 24 hrs. | 2,500 | 60 | 2:1 | Thick Liquid (30,000 cP) | -65° to 350° | Off-White | Metal, Plastic, Composites | 0000000 | 000000 |

| DP460 | 13.5 | Cartridge | 60 min. | 24 hrs. | 2,500 | 60 | 2:1 | Thick Liquid (30,000 cP) | -65° to 350° | Off-White | Metal, Plastic, Composites | 00000000 | 000000 |

| DP460NS | 1.69 | Cartridge | 60 min. | 24 hrs. | 2,680 | 60 | 2:1 | Paste (125,000 cP) | -65° to 350° | Off-White | Metal, Plastic, Composites | 0000000 | 00000 |

| DP460NS | 6.76 | Cartridge | 60 min. | 24 hrs. | 2,680 | 60 | 2:1 | Paste (125,000 cP) | -65° to 350° | Off-White | Metal, Plastic, Composites | 00000000 | 000000 |

| DP460NS | 13.5 | Cartridge | 60 min. | 24 hrs. | 2,680 | 60 | 2:1 | Paste (125,000 cP) | -65° to 350° | Off-White | Metal, Plastic, Composites | 0000000 | 000000 |

| Each | ||

| Mixer Nozzle for 1.69 fl. oz. 3M Cartridges (Step Tip) | 0000000 | 00000 |

| Mixer Nozzle for 1.69 fl. oz. 3M Cartridges (Taper Tip) | 0000000 | 0000 |

| Mixer Nozzle for 6.76 fl. oz. and 13.5 fl. oz. 3M Cartridges | 0000000 | 0000 |

| Replacement Plunger for 1.69 fl. oz. 3M Cartridges | 0000000 | 00000 |

| Dispensing Gun for 1.69 fl. oz. 3M Cartridges | 0000000 | 000000 |

| Dispensing Gun for 6.76 fl. oz. 3M Cartridges | 0000000 | 000000 |

| Air-Powered Dispensing Gun for 1.69 fl. oz. 3M Cartridges | 0000000 | 000000 |

Quick-Set Epoxy Structural Adhesives

For quick repairs, these epoxies begin to harden in 6 minutes or less. Epoxies are the strongest and most weather- and chemical-resistant structural adhesives.

These have two parts that must be mixed. The size listed is the combined total of the two parts. Use cartridges with a dispensing gun and mixer nozzle to simultaneously mix and dispense adhesives.

DP100NS is nonsagging, so it won't drip from vertical or overhead surfaces.

Container | Strength | ||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Mfr. Model No. | Size, fl. oz. | Type | Begins to Harden | Reaches Full Strength | Shear, lbs./sq. in. | Peel, lbs./in. wd. | Mix Ratio | Consistency (Viscosity) | Temp. Range, °F | Color | For Joining | Each | |

| DP100 | 1.64 | Cartridge | 5 min. | 48 hrs. | 750 | 2 | 1:1 | Thick Liquid (12,000 cP) | -65° to 320° | Clear | Metal, Plastic, Rubber | 0000000 | 000000 |

| DP100 | 6.76 | Cartridge | 5 min. | 48 hrs. | 750 | 2 | 1:1 | Thick Liquid (12,000 cP) | -65° to 320° | Clear | Metal, Plastic, Rubber | 0000000 | 00000 |

| DP100NS | 1.64 | Cartridge | 5 min. | 48 hrs. | 840 | 2 | 1:1 | Paste (93,750 cP) | -65° to 320° | Clear | Metal, Plastic, Rubber | 0000000 | 00000 |

| Each | ||

| Mixer Nozzle for 1.64 fl. oz. 3M Cartridges (Step Tip) | 0000000 | 00000 |

| Mixer Nozzle for 1.64 fl. oz. 3M Cartridges (Taper Tip) | 0000000 | 0000 |

| Mixer Nozzle for 6.76 fl. oz. 3M Cartridges | 0000000 | 0000 |

| Replacement Plunger for 1.64 fl. oz. 3M Cartridges | 0000000 | 00000 |

| Dispensing Gun for 1.64 fl. oz. 3M Cartridges | 0000000 | 000000 |

| Dispensing Gun for 6.76 fl. oz. 3M Cartridges | 0000000 | 000000 |

| Air-Powered Dispensing Gun for 1.64 fl. oz. 3M Cartridges | 0000000 | 000000 |

Optically Clear Epoxy Structural Adhesives

For invisible bond lines, these adhesives dry clear. Epoxies are the strongest and most weather- and chemical-resistant structural adhesives. Choose an epoxy that hardens quickly for fast repairs, or one that hardens slowly to allow more time for positioning.

These have two parts that must be mixed. The size listed is the combined total of the two parts. Use cartridges with a dispensing gun and mixer nozzle to simultaneously mix and dispense adhesives.

DP100 Plus, DP105, and epoxy in 4.5-oz. tubes bond dissimilar materials.

Container | Strength | |||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Mfr. Model No. | Size, fl. oz. | Type | Begins to Harden | Reaches Full Strength | Shear, lbs./sq. in. | Peel, lbs./in. wd. | Mix Ratio | Consistency (Viscosity) | Temp. Range, °F | For Joining | Each | |

| DP100 Plus | 1.64 | Cartridge | 3 min. | 48 hrs. | 1,700 | 13 | 1:1 | Thick Liquid (8,750 cP) | -65 to 300° F | Metal, Metal to Plastic, Metal to Rubber, Plastic, Plastic to Rubber, Rubber | 0000000 | 000000 |

| DP105 | 1.64 | Cartridge | 4 min. | 48 hrs. | 1,300 | 35 | 1:1 | Thick Liquid (7,500 cP) | -65 to 300° F | Metal, Metal to Plastic, Metal to Rubber, Plastic, Plastic to Rubber, Rubber | 0000000 | 00000 |

| Each | ||

| Mixer Nozzle for 1.64 fl. oz. 3M Cartridges (Step Tip) | 0000000 | 00000 |

| Mixer Nozzle for 1.64 fl. oz. 3M Cartridges (Taper Tip) | 0000000 | 0000 |

| Replacement Plunger for 1.64 fl. oz. 3M Cartridges | 0000000 | 00000 |

| Dispensing Gun for 1.64 fl. oz. 3M Cartridges | 0000000 | 000000 |

| Air-Powered Dispensing Gun for 1.64 fl. oz. 3M Cartridges | 0000000 | 000000 |

Slow-Set Epoxy Structural Adhesives

To allow time to adjust and position parts, these epoxies remain workable for at least 90 minutes. The strongest and most weather- and chemical-resistant structural adhesives, epoxies work especially well on metals.

These have two parts that must be mixed. The size listed is the combined total of the two parts. Use cartridges with a dispensing gun and mixer nozzle to simultaneously mix and dispense adhesives.

Container | Strength | |||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Mfr. Model No. | Size | Type | Begins to Harden | Reaches Full Strength | Shear, lbs./sq. in. | Peel, lbs./in. wd. | Mix Ratio | Consistency (Viscosity) | Temp. Range, °F | For Joining | Each | |

| DP190 | 1.64 fl. oz. | Cartridge | 90 min. | 7 days | 1,400 | 20 | 1:1 | Thick Liquid (86,250 cP) | -65° to 350° | Metal, Plastic, Rubber, Masonry | 0000000 | 000000 |

| DP190 | 6.76 fl. oz. | Cartridge | 90 min. | 7 days | 1,400 | 20 | 1:1 | Thick Liquid (86,250 cP) | -65° to 350° | Metal, Plastic, Rubber, Masonry | 0000000 | 00000 |

| Each | ||

| Mixer Nozzle for 1.64-oz. 3M Cartridges (Step Tip) | 0000000 | 00000 |

| Mixer Nozzle for 1.64-oz. 3M Cartridges (Taper Tip) | 0000000 | 0000 |

| Mixer Nozzle for 6.76-oz. 3M Cartridges | 0000000 | 0000 |

| Replacement Plunger for 1.64-oz. 3M Cartridges | 0000000 | 00000 |

| Dispensing Gun for 1.64-oz. 3M Cartridges | 0000000 | 000000 |

| Dispensing Gun for 6.76 fl. oz. 3M Cartridges | 0000000 | 000000 |

| Air-Powered Dispensing Gun for 1.64-oz. 3M Cartridges | 0000000 | 000000 |

Flame-Retardant Epoxy Structural Adhesives

These self-extinguishing epoxies meet UL 94 V-0 for flame retardance. The strongest and most weather- and chemical-resistant structural adhesives, epoxies work especially well on metals.

These have two parts that must be mixed. The size listed is the combined total of the two parts. Use a dispensing gun and mixer nozzle to simultaneously mix and dispense adhesives.

Container | Strength | ||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Mfr. Model No. | Size, fl. oz. | Type | Begins to Harden | Reaches Full Strength | Shear, lbs./sq. in. | Peel, lbs./in. wd. | Mix Ratio | Consistency (Viscosity) | Temp. Range, °F | Color | For Joining | Each | |

3M Scotch-Weld Adhesives | |||||||||||||

| DP100FR | 1.64 | Cartridge | 5 min. | 48 hrs. | 1,100 | 2 | 1:1 | Thick Liquid (73,750 cP) | -65° to 300° | Off-White | Metal, Plastic, Rubber | 0000000 | 000000 |

| Mixer Nozzle for 1.64 fl. oz. 3M Cartridges (Step Tip) | 0000000 | Each | 00000 |

| Replacement Plunger for 1.64 fl. oz. 3M Cartridges | 0000000 | Each | 00000 |

| Mixer Nozzle for 1.64 fl. oz. 3M Cartridges (Taper Tip) | 0000000 | Each | 0000 |

| Dispensing Gun for 1.64 fl. oz. Cartridges | 0000000 | Each | 000000 |

| Air-Powered Dispensing Gun for 1.64 fl. oz. 3M Cartridges | 0000000 | Each | 000000 |

Acrylic Structural Adhesives for Hard-to-Bond Materials

Fasten hard-to-bond plastics, such as polypropylene and polyethylene, with these adhesives. Acrylics bond to the widest range of materials, especially plastics, and require the least amount of surface preparation.

The size listed is the combined total of the two parts. Use a dispensing gun and mixer nozzle to simultaneously mix and dispense adhesives.

DP8005 contains 0.008" glass beads to prevent adhesive from squeezing out during clamping and give a consistent bond thickness.

DP8010 is moisture and corrosion resistant.

Container | Strength | ||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Mfr. Model No. | Size, fl. oz. | Type | Begins to Harden | Reaches Full Strength | Shear, lbs./sq. in. | Peel, lbs./in. wd. | Mix Ratio | Consistency (Viscosity) | Temp. Range, °F | Color | For Joining | Each | |

3M Scotch-Weld Adhesives | |||||||||||||

| DP8005 | 1.52 | Cartridge | 3 min. | 24 hrs. | 2,275 | 9 | 10:1 | Thick Liquid (24,550 cP) | -65° to 200° | Black | Plastic | 00000000 | 000000 |

| DP8005 | 1.52 | Cartridge | 3 min. | 24 hrs. | 2,500 | 17 | 10:1 | Thick Liquid (25,460 cP) | -65° to 200° | Off-White | Plastic | 00000000 | 00000 |

| DP8010 | 1.52 | Cartridge | 10 min. | 24 hrs. | 2,700 | Not Rated | 10:1 | Thick Liquid (20,000 cP) | -40° to 200° | Blue | Plastic | 0000000 | 00000 |

Toughened Acrylic Structural Adhesives

Toughened adhesives are blended with rubber particles for better impact resistance than standard acrylics. They form resilient bonds. Acrylics bond to the widest range of materials, especially plastics, and require the least amount of surface preparation.

The size listed is the combined total of the two parts. Use cartridges with a dispensing gun and mixer nozzle to simultaneously mix and dispense adhesives.

Container | Strength | ||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Mfr. Model No. | Size, fl. oz. | Type | Begins to Harden | Reaches Full Strength | Shear, lbs./sq. in. | Peel, lbs./in. wd. | Mix Ratio | Consistency (Viscosity) | Temp. Range, °F | Color | For Joining | Each | |

| DP805 | 1.64 | Cartridge | 3 min. | 24 hrs. | 2,800 | 35 | 1:1 | Paste (112,500 cP) | -40° to 180° | Off-White | Metal, Plastic, Rubber, Composites, Wood | 0000000 | 000000 |

| DP810 | 1.64 | Cartridge | 10 min. | 24 hrs. | 3,400 | 30 | 1:1 | Thick Liquid (20,000 cP) | -40° to 180° | Beige | Metal, Plastic, Rubber, Composites, Wood | 00000000 | 00000 |

| DP810NS | 1.64 | Cartridge | 10 min. | 24 hrs. | 3,400 | 23 | 1:1 | Paste (95,000 cP) | -40° to 180° | Beige | Metal, Plastic, Rubber, Composites, Wood | 00000000 | 00000 |

| DP820 | 1.64 | Cartridge | 15 min. | 48 hrs. | 2,500 | 22 | 1:1 | Thick Liquid (57,500 cP) | -40° to 180° | Off-White | Metal, Plastic, Rubber, Composites, Wood | 0000000 | 00000 |

| Each | ||

| Replacement Plunger for 1.64 fl. oz. 3M Cartridges | 0000000 | 000000 |

| Mixer Nozzle for 1.64 fl. oz. 3M Cartridges (Step Tip) | 0000000 | 0000 |

| Mixer Nozzle for 1.64 fl. oz. 3M Cartridges (Taper Tip) | 0000000 | 0000 |

| Dispensing Gun for 1.64 fl. oz. 3M Cartridges | 0000000 | 000000 |

| Air-Powered Dispensing Gun for 1.64 fl. oz. 3M Cartridges | 0000000 | 000000 |

High-Strength Acrylic Structural Adhesives

With excellent shear strength, these acrylics form stronger bonds than our standard acrylic structural adhesives. Acrylics bond to the widest range of materials, especially plastics, and require the least amount of surface preparation.

The size listed is the combined total of the two parts. Use cartridges with a dispensing gun and mixer nozzle to simultaneously mix and dispense adhesives.

DP8407NS and DP8410NS are nonsagging, so they won't drip from vertical or overhead surfaces. They contain 0.01" glass beads to prevent adhesive from squeezing out during clamping and give a consistent bond thickness.

Container | Strength | ||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Mfr. Model No. | Size, fl. oz. | Type | Begins to Harden | Reaches Full Strength | Shear, lbs./sq. in. | Peel, lbs./in. wd. | Mix Ratio | Consistency (Viscosity) | Temp. Range, °F | Color | For Joining | Each | |

3M Scotch-Weld Adhesives | |||||||||||||

| DP8407NS | 1.52 | Cartridge | 7 min. | 24 hrs. | 4,500 | 50 | 10:1 | Thick Liquid (20,000 cP) | -40° to 400° | Gray | Metal, Plastic, Rubber, Composites | 0000000 | 000000 |

Acrylic Structural Adhesives

Acrylics bond to the widest range of materials, especially plastics, and require the least amount of surface preparation.

The size listed is the combined total of the two parts. Use a dispensing gun and mixer nozzle to simultaneously mix and dispense adhesives.

Container | Strength | |||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Size, fl. oz. | Type | Begins to Harden | Reaches Full Strength | Shear, lbs./sq. in. | Peel, lbs./in. wd. | Mix Ratio | Consistency (Viscosity) | Temp. Range, °F | Color | For Joining | Each | |

Adhesives with Mixer Nozzle | ||||||||||||

| 1.69 | Cartridge | 5 min. | 24 hrs. | 3,200 | 7 | 1:1 | Thick Liquid (64,000 cP) | -40° to 250° | Light Green | Metal, Metal to Plastic, Metal to Rubber, Metal to Composites, Plastic, Plastic to Composites, Plastic to Masonry, Rubber, Rubber to Composites, Rubber to Masonry, Composites, Masonry | 000000 | 000000 |

| 13.5 | Cartridge | 5 min. | 24 hrs. | 3,200 | 7 | 1:1 | Thick Liquid (64,000 cP) | -40° to 250° | Light Green | Metal, Metal to Plastic, Metal to Rubber, Metal to Composites, Plastic, Plastic to Composites, Plastic to Masonry, Rubber, Rubber to Composites, Rubber to Masonry, Composites, Masonry | 000000 | 00000 |

Urethane Structural Adhesives

Urethane adhesives are the most flexible, so they bond dissimilar materials and damp vibration.

The size listed is the combined total of the two parts. Use 1.64 fl. oz. and 1.69 fl. oz. cartridges with a dispensing gun and mixer nozzle to simultaneously mix and dispense adhesives.DP604NS and DP605NS stay flexible at low temperatures.

U-05FL, U-09FL, and U-09LV won't yellow.

Container | Strength | ||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Mfr. Model No. | Size, fl. oz. | Type | Begins to Harden | Reaches Full Strength | Shear, lbs./sq. in. | Peel, lbs./in. wd. | Mix Ratio | Consistency (Viscosity) | Temp. Range, °F | Color | For Joining | Each | |

| DP604NS | 1.64 | Cartridge | 4 min. | 6 hrs. | 660 | 33 | 1:1 | Thick Liquid (1,950 cP) | -60° to 250° | Black | Metal, Metal to Plastic, Metal to Composites, Plastic, Plastic to Composites, Composites, Wood | 0000000 | 000000 |

| DP605NS | 1.64 | Cartridge | 5 min. | 48 hrs. | 660 | 33 | 1:1 | Paste (150,000 cP) | -65° to 250° | Off-White | Metal, Metal to Plastic, Metal to Composites, Plastic, Plastic to Composites, Composites, Wood | 0000000 | 00000 |

Container | Strength | ||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Mfr. Model No. | Size, fl. oz. | Type | Begins to Harden | Reaches Full Strength | Shear, lbs./sq. in. | Peel | Mix Ratio | Consistency (Viscosity) | Temp. Range, °F | Color | For Joining | Each | |

| UK U-09LV | 1.69 | Cartridge | 10 min. | 24 hrs. | 1,145 | Not Rated | 1:1 | Thin Liquid (1,000 cP) | -65° to 250° | Clear | Metal, Metal to Plastic, Metal to Glass, Plastic, Plastic to Glass, Glass, Wood, Wood to Glass | 00000000 | 000000 |

| (Web) For Cartridge Size | Each | ||

| Mixer Nozzle for 1.64 fl. oz. 3M Cartridges (Step Tip) | __ | 0000000 | 00000 |

| Mixer Nozzle for 1.64 fl. oz. 3M Cartridges (Taper Tip) | __ | 0000000 | 0000 |

| Mixer Nozzle for 1.69 fl. oz. Cartridges | 1.58 oz. | 00000000 | 0000 |

| Replacement Plunger for 1.64 fl. oz. 3M Cartridges | __ | 0000000 | 00000 |

| Dispensing Gun for 1.64 fl. oz. 3M Cartridges | __ | 0000000 | 000000 |

| Air-Powered Dispensing Gun for 1.64 fl. oz. 3M Cartridges | __ | 0000000 | 000000 |

| Air-Powered Dispensing Gun for 1.69 fl. oz. Loctite® Cartridges | __ | 000000000 | 000000 |

| Dispensing Gun for 1.69 fl. oz. Cartridges | 1.58 oz. | 00000000 | 00000 |

High-Strength Urethane Structural Adhesives

With high shear strength and peel strength, these form the strongest bonds of our urethane adhesives. Urethanes are the most flexible adhesives, so they bond dissimilar materials and damp vibration.

The size listed is the combined total of the two parts. Use cartridges with a dispensing gun and mixer nozzle to simultaneously mix and dispense adhesives.

Container | Strength | ||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Mfr. Model No. | Size, fl. oz. | Type | Begins to Harden | Reaches Full Strength | Shear, lbs./sq. in. | Peel, lbs./in. wd. | Mix Ratio | Consistency (Viscosity) | Temp. Range, °F | Color | For Joining | Each | |

| DP620NS | 1.64 | Cartridge | 20 min. | 48 hrs. | 1,700 | 30 | 1:1 | Thick Liquid (4,360 cP) | -60° to 250° | Black | Metal, Metal to Plastic, Metal to Rubber, Metal to Composites, Plastic, Plastic to Rubber, Plastic to Composites, Rubber, Rubber to Composites, Composites, Wood | 00000000 | 000000 |

| DP640 | 1.64 | Cartridge | 40 min. | 7 days | 1,960 | 64 | 1:1 | Thick Liquid (30,000 cP) | -65° to 250° | Brown | Metal, Metal to Plastic, Metal to Rubber, Metal to Composites, Plastic, Plastic to Rubber, Plastic to Composites, Plastic to Masonry, Rubber, Rubber to Composites, Rubber to Masonry, Composites, Masonry, Wood | 0000000 | 00000 |

| Each | ||

| Mixer Nozzle for 1.64 fl. oz. 3M Cartridges (Step Tip) | 0000000 | 00000 |

| Mixer Nozzle for 1.64 fl. oz. 3M Cartridges (Taper Tip) | 0000000 | 0000 |

| Replacement Plunger for 1.64 fl. oz. 3M Cartridges | 0000000 | 00000 |

| Dispensing Gun for 1.64 fl. oz. 3M Cartridges | 0000000 | 000000 |

| Air-Powered Dispensing Gun for 1.64 fl. oz. 3M Cartridges | 0000000 | 000000 |

Instant-Bond Adhesive Gel for Large Gaps

These thick gels fill the largest gaps of any of our instant-bond adhesives. They won't drip on vertical surfaces. Use the included mixer nozzles to simultaneously mix and dispense adhesive.

![]() Certificates with a traceable lot number and product shelf life are available for these products. Download certificates from ORDER HISTORY after your order ships.

Certificates with a traceable lot number and product shelf life are available for these products. Download certificates from ORDER HISTORY after your order ships.

Container | ||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Mfr. Model No. | Size, fl. oz. | Type | Max. Gap Size Filled | Begins to Harden | Reaches Full Strength | Mix Ratio | Consistency (Viscosity) | Temp. Range, °F | Color | For Joining | Each | |

Loctite® Adhesives | ||||||||||||

| 3092 | 0.3 | Syringe | 0.2" | 15 sec. | 24 hrs. | 10:1 | Gel (Not Rated) | 0° to 170° | Clear | Metal, Plastic, Rubber, Wood | 0000000 | 000000 |

Air-Powered 3M Two-Part Adhesive Dispensing Guns

Deep-Crack Concrete Fillers

Fill cracks up to 10" deep on vertical and overhead surfaces. To use this filler, secure the included injection ports to the crack with the two-part epoxy sealer, then spread sealer over the entire crack. Allow sealer 24 hours to cure. Application time for sealer, after mixing, is 40 minutes. To fill the rest of the void, use the cartridge with a standard caulk gun (sold separately) to dispense the two-part epoxy filler into the injection ports.

Sealant | Filler | ||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Container Size, fl. oz. | Container Type | Container Size, fl. oz. | Container Type | Begins to Harden, min. | Reaches Full Strength, hrs. | Consistency | Mix Ratio | Color | For Max. Crack Wd. | Approx. Coverage @ Thick. | Application Temp. Range, °F | Finishing Method | For Use On | Each | |

| 34 | Jar | 10 | Cartridge | 15 | 24 | Thin Liquid | 1:1 | Light Amber | 1/4" | 8 ft. @ 10" | 50° to 90° | Sand, Tap | Concrete | 00000000 | 0000000 |

Self-Leveling Concrete Crack Fillers

Pour these ready-to-use fillers in cracks up to 1/2" wide and 1/4" deep on horizontal surfaces to make fast, light duty repairs.

Container | |||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|

| Size, qt. | Type | Reaches Full Strength, hrs. | Formulation | Consistency | Approx. Coverage @ Thick. | For Use Outdoors | Application Temp. Range, °F | Color | For Use On | Each | |

| 1 | Bottle | 48 | Acrylic | Thick Liquid | 35 ft. @ 1/4" | Yes | 50° to 90° | Gray | Concrete | 00000000 | 000000 |

Concrete Crack Fillers

Fill cracks in horizontal, vertical, and overhead concrete surfaces. Surface fillers that have a mix ratio are multi-part fillers. Size listed is the combined total of the parts.

Surface fillers in a 10.1 fl. oz. cartridge can be dispensed with a standard caulk gun (sold separately). They flex as concrete expands and contracts with temperature changes. Acrylic fillers are textured to blend in easily and clean up with water. Polyurethane fillers allow for more joint movement than acrylic fillers.

Container | ||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Size | Type | Begins to Harden | Reaches Full Strength | Consistency | For Max. Crack Wd. | Approx. Coverage @ Thick. | Max. Thick. | For Use Outdoors | Application Temp. Range, °F | Color | Finishing Method | For Use On | Each | |

Acrylic Formulation | ||||||||||||||

| 10.1 fl. oz. | Cartridge | 30 min. | 7 days | Paste | 3/8" | 40 ft. @ 1/4" | 1/4" | Yes | 40° to 90° | Gray | __ | Concrete, Masonry, Stone | 0000000 | 00000 |

Polyurethane Formulation | ||||||||||||||

| 10.1 fl. oz. | Cartridge | 2 hrs. | 48 hrs. | Paste | 1/2" | 40 ft. @ 1/4" | 1/2" | Yes | 40° to 110° | Gray | Saw | Concrete, Masonry, Stone | 00000000 | 00000 |

| 10.1 fl. oz. | Cartridge | 24 hrs. | 7 days | Paste | 1" | 24 ft. @ 1/4" | 1/2" | Yes | 40° to 90° | White | __ | Concrete, Masonry, Stone | 000000 | 00000 |

| 10.1 fl. oz. | Cartridge | 72 hrs. | 7 days | Putty | 1/2" | 24 ft. @ 1/4" | 1/2" | Yes | 40° to 120° | Gray | Sand | Concrete, Masonry, Stone, Stucco | 00000000 | 0000 |

Self-Leveling Deep-Crack Concrete Fillers

Fill cracks up to 4" deep on horizontal surfaces such as floors and sidewalks. These epoxies are shrink, impact, and chemical resistant, and can also be used on wood, fiberglass, and metal surfaces. Use the cartridges with a standard caulk gun (sold separately) for dispensing.

Container | |||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Size, fl. oz. | Type | Begins to Harden, min. | Reaches Full Strength, hrs. | Temp. to Begin to Harden, °F | Consistency | Mix Ratio | For Max. Crack Wd. | Approx. Coverage @ Thick. | For Use Outdoors | Application Temp. Range, °F | Color | Finishing Method | For Use On | Each | |

| 10 | Cartridge | 15 | 24 | 77° | Thin Liquid | 1:1 | 1/16" | 24 ft. @ 4" | Yes | 50° to 90° | Light Amber | Sand, Tap | Concrete | 00000000 | 000000 |

| 10 | Cartridge | 15 | 24 | 77° | Thick Liquid | 1:1 | 1/4" | 6 ft. @ 4" | Yes | 50° to 90° | Light Amber | Sand, Tap | Concrete | 00000000 | 00000 |

Leak-Stopping Concrete Crack Fillers

Stop slow-flowing and weeping leaks in concrete. These crack fillers begin to harden in three to five minutes to create a permanent fix that won't shrink.

Polyurethane fillers are thin to penetrate deep into cracks. When fully cured they create a seal that can withstand pressure of up to 2,000 psi. Apply with a standard caulk gun (sold separately). For especially large cracks, use a packer (sold separately) with a grease gun or a grout pump.

Container | |||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Size, fl. oz. | Type | Begins to Harden, min. | Reaches Full Strength | Consistency | For Max. Crack Wd. | Approx. Coverage @ Thick. | Max. Thick. | Application Temp. Range, °F | Color | Finishing Method | For Use On | Each | |

Polyurethane | |||||||||||||

| 10.1 | Cartridge | 3 | 24 hrs. | Thin Liquid | 3/4" | 15 ft. @ 1/2" | 1/2" | 35° to 90° | Amber | Sand | Concrete, Ceramic, Porcelain, Grout, Masonry, Asphalt, Stone | 000000 | 000000 |

| Material | For Hole Dia. | Each | |

| Steel | 5/8" | 000000 | 00000 |

High-Flow Leak-Stopping Concrete Crack Fillers

Stop active leaks of up to 50 gallons per minute in concrete, brick, and stone. These crack fillers begin to harden within seconds to create a permanent fix that won't shrink. When fully cured they create a seal that can withstand pressure of up to 2,000 psi. Apply with a dispensing gun (sold separately). The size listed is the combined total of the two parts. A mixer nozzle is included.

Container | |||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Size, fl. oz. | Type | Begins to Harden, sec. | Reaches Full Strength, min. | Consistency | For Max. Crack Wd. | Approx. Coverage @ Thick. | Max. Thick. | Application Temp. Range, °F | Color | Finishing Method | For Use On | Each | |

| 20.2 | Cartridge | 3 | 60 | Thin Liquid | 3/4" | 5 ft. @ 1/2" | 1/2" | 35° to 90° | Amber | Drill, Sand, Saw | Concrete, Ceramic, Porcelain, Grout, Masonry, Asphalt, Stone | 000000 | 000000 |

| Dispensing Gun | 000000 | Each | 000000 |

Epoxy Potting Compounds

Encase electronic assemblies in a layer of epoxy for protection from dust, chemicals, moisture, mechanical shock, and vibration. The strongest of the potting compounds, epoxies are rigid and wear resistant. They have excellent chemical and moisture resistance, withstand a wide range of temperatures, and provide excellent electrical insulation. All require a mixer nozzle and gun to dispense.

Dry Time | ||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Mfr. Model No. | Container Size, fl. oz. | Consistency | Touch | Overall | Dielectric Strength, V/mil | Thermal Conductivity, W/m-K | Temp. Range, °F | Specifications Met | For Use On | Choose a Color | Each | |

| DP270 | 6.8 | Thick Liquid | 3 hrs. | 48 hrs. | 850 | 0.18 | -65° to 210° | UL 94 HB | Aluminum, Brass, Bronze, Copper, Steel, Stainless Steel, Plastic, Rubber, Glass | 00000000 | 000000 | |