How to Install Helical Inserts

More

About Helical Insert Length

More

About Nuts, Materials, and Finishes

More

About Thumb Screw and Binding Post Materials

More

Stainless Steel Helical Inserts

Also known as Heli-Coil inserts, these inserts have coils that expand once installed to securely anchor the insert. All have a prong for ease of installation. An installation tool grips the prong and reduces the coil diameter, enabling the insert to fit in tapped holes. Remove the prong to insert the screw. Installation requires a drill bit, a helical insert tap, an installation tool, and a prong break-off tool.

Inserts | Through-Hole Taps | Closed-End Hole Taps | Installation Tools | Prong Break-Off Tools | ||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Thread Size | Installed Lg. | Drill Bit Size | For Max. Hole Dia. | Pkg. Qty. | Pkg. | Each | Each | Each | Each | |||||

18-8 Stainless Steel—Right-Hand Threaded | ||||||||||||||

| 12-24 | 0.216" | No. 1 | 0.228" | 10 | 000000000 | 00000 | 000000000 | 000000 | 000000000 | 000000 | 000000000 | 0000000 | 000000000 | 0000000 |

| 12-24 | 0.324" | No. 1 | 0.228" | 10 | 000000000 | 0000 | 000000000 | 00000 | 000000000 | 00000 | 000000000 | 000000 | 000000000 | 000000 |

| 12-24 | 0.432" | No. 1 | 0.228" | 10 | 000000000 | 0000 | 000000000 | 00000 | 000000000 | 00000 | 000000000 | 000000 | 000000000 | 000000 |

Stainless Steel Screw-Locking Helical Inserts

A distorted thread grips the screw to resist loosening. Also known as Heli-Coil inserts, these inserts have coils that expand once installed to securely anchor the insert. All have a prong for ease of installation. An installation tool grips the prong and reduces the coil diameter, enabling the insert to fit in tapped holes. Remove the prong to insert the screw. Installation requires a drill bit, a helical insert tap, an installation tool, and a prong break-off tool.

Inserts | Through-Hole Taps | Closed-End Hole Taps | Installation Tools | Prong Break-Off Tools | |||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Thread Size | Installed Lg. | Drill Bit Size | For Max. Hole Dia. | Specifications Met | Pkg. Qty. | Pkg. | Each | Each | Each | Each | |||||

18-8 Stainless Steel | |||||||||||||||

| 12-24 | 0.216" | No. 1 | 0.228" | MS21209C2-10, NASM21209 | 10 | 000000000 | 000000 | 000000000 | 000000 | 000000000 | 000000 | 000000000 | 0000000 | 000000000 | 0000000 |

| 12-24 | 0.324" | No. 1 | 0.228" | MS21209C2-15, NASM21209 | 10 | 000000000 | 00000 | 000000000 | 00000 | 000000000 | 00000 | 000000000 | 000000 | 000000000 | 000000 |

Helical Inserts with Installation Tools

Inserts come with a through-hole tap and installation tool. Also known as Heli-Coil inserts, they have coils that expand once installed to securely anchor the insert. All have a prong for ease of installation. An installation tool grips the prong and reduces the coil diameter, enabling the insert to fit in tapped holes. Remove the prong to insert the screw.

| Thread Size | Installed Lg. | Drill Bit Size | For Max. Hole Dia. | No. of Inserts Included | Includes | Each | |

18-8 Stainless Steel—Right-Hand Threaded | |||||||

|---|---|---|---|---|---|---|---|

| 12-24 | 0.324" | 15/64" | 15/64" | 10 | Drill Bit, Through-Hole Tap, Installation Tool | 000000000 | 000000 |

Helical Insert Assortments with Installation Tools

Assortments include various sizes of helical inserts and a tap, a drill bit, and an installation tool for each thread size. Also known as Heli-Coil inserts, the inserts have coils that expand once installed to securely anchor the insert. All have a prong for ease of installation. An installation tool grips the prong and reduces the coil diameter, enabling the insert to fit in tapped holes. Remove the prong to insert the screw.

| Includes | No. of Inserts Included | Thread Spacing | Drill Bit Size | For Max. Hole Dia. | Each | |

Inch | ||||||

|---|---|---|---|---|---|---|

18-8 Stainless Steel | ||||||

| Prong Break-Off Tool 12-24 Thread × 0.216" Installed Lg. (12 Each) 12-24 Thread × 0.328" Installed Lg. (12 Each) 12-24 Thread × 0.432" Installed Lg. (12 Each) Drill Bit Through-Hole Tap Installation Tool | 36 | Coarse | 15/64" | 15/64" | 000000000 | 000000 |

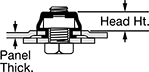

Steel Press-Fit Nuts for Sheet Metal

Add permanent threads to sheet metal, like weld nuts, but without the setup and mess. A zinc plating on these steel press-fit nuts helps prevent rust in wet environments. Also known as clinch-style captive nuts, press them into a drilled or punched hole with an arbor press or similar pressure tool. The pressure forms your sheet metal into the knurls of the nut, making the nut inseparable from the sheet. Installation requires access to both sides of the panel.

Head | |||||||||

|---|---|---|---|---|---|---|---|---|---|

| Thread Size | Drill Bit Size | For Min. Panel Thick. | For Max. Panel Hardness | OD | Ht. | PEM® Part No. | Pkg. Qty. | Pkg. | |

Zinc-Plated Steel | |||||||||

| 12-24 | J | 0.04" | Brinell 150, Rockwell B80 | 0.37" | 0.13" | S-1224-1ZI | 10 | 000000000 | 00000 |

| 12-24 | J | 0.056" | Brinell 150, Rockwell B80 | 0.37" | 0.13" | __ | 10 | 000000000 | 0000 |

| 12-24 | J | 0.09" | Brinell 150, Rockwell B80 | 0.37" | 0.13" | S-1224-3ZI | 10 | 000000000 | 0000 |

Stainless Steel Press-Fit Nuts for Sheet Metal

Create permanent, corrosion-resistant threads in sheet metal without the setup and mess of weld nuts. Made of 18-8 stainless steel, these press-fit nuts withstand water and mild chemicals better than zinc-plated steel nuts. Also known as clinch-style captive nuts, press them into a drilled or punched hole with an arbor press or similar pressure tool. The pressure forms your sheet metal into the knurls of the nut, making the nut inseparable from the sheet. Installation requires access to both sides of the panel.

Head | |||||||||

|---|---|---|---|---|---|---|---|---|---|

| Thread Size | Drill Bit Size | For Min. Panel Thick. | For Max. Panel Hardness | OD | Ht. | PEM® Part No. | Pkg. Qty. | Pkg. | |

18-8 Stainless Steel | |||||||||

| 12-24 | J | 0.04" | Brinell 125, Rockwell B70 | 0.37" | 0.13" | CLS-1224-1 | 5 | 000000000 | 00000 |

| 12-24 | J | 0.056" | Brinell 125, Rockwell B70 | 0.37" | 0.13" | CLS-1224-2 | 10 | 000000000 | 0000 |

| 12-24 | J | 0.09" | Brinell 125, Rockwell B70 | 0.37" | 0.13" | CLS-1224-3 | 10 | 000000000 | 0000 |

Steel Low-Profile Rivet Nuts

These steel low-profile rivet nuts are about twice as strong as aluminum rivet nuts. They have a low profile for light duty fastening in low-clearance applications. A cadmium or tin-zinc plating provides corrosion resistance and adds lubricity so they collapse smoothly. The threaded portion is drawn into the sleeve when installed, creating pressure against the hole to secure the nut. Drill bit size listed in the table is for material with a 0.030"-0.090" thickness. These rivet nuts may be installed in thicker material, but may require larger holes. Install them using a hand- or power-driven rivet nut tool. Length is measured from under the flange. Installed length is the maximum length of the barrel when installed.

Steel Low-Profile Rivet Nuts with Installation Tool

Everything you need to add threads to sheet metal in low-clearance areas. Along with low-profile rivet nuts, these kits include mandrels and an installation tool. As you install these nuts, the threaded portion is drawn into the sleeve, reducing how far they stick out the back of your material. They also have a flange that’s half as thick as those on other rivet nuts, so they have a low profile on both sides of your panel. A tin-zinc plating protects from rust in wet environments and reduces friction, so they collapse smoothly. These rivet nuts create permanent threads in surfaces that are too thin to be tapped. Installation requires access to just one side of your material. The flange distributes the load and holds them against the surface.

To install, thread a rivet nut onto the mandrel, insert the nut into a drilled or punched round hole, push down on the tool's T-handle, and turn clockwise.

| Thread Size | For Material Thick. | Includes | No. of Nuts Included | Each | |

Tin-Zinc Plated Steel | |||||

|---|---|---|---|---|---|

| 12-24 | 0.03" to 0.09" | Mandrels, Installation Tool | 100 | 000000000 | 0000000 |

Steel Snap-In Nuts

Snap these nuts—also known as cage nuts—into square holes in thin material. They’re often used to mount servers and other equipment in electronics racks. Threads float inside the cage, so you can fasten a bolt at a slight angle to align off-center parts. Mounting legs expand to lock these nuts in place.

Install these nuts by hand, with pliers, or with a snap-in nut installation and removal tool.

Zinc-plated steel nuts resist corrosion in wet environments.

| Thread Size | For Panel Thick. | Square Hole Size | Wd. | Head Ht. | Pkg. Qty. | Pkg. | |

Zinc-Plated Steel | |||||||

|---|---|---|---|---|---|---|---|

| 12-24 | 0.063" to 0.105" | 0.375" to 0.38" | 0.52" | 0.25" | 25 | 000000000 | 000000 |

Grounding Snap-In Nuts

Pave a safe path for electricity—these nuts dig into the mounting surface and cut through coatings to touch the metal below for a proper ground. They’re often used to mount servers and other equipment into electronics racks. All meet EIA-310 (Electronic Industries Alliance) specifications for use in standard 19" electronics racks. Simply snap these nuts, also known as cage nuts, into square holes.

Style A nuts are green, a color commonly used to identify grounding components. They include a bolt with a serrated flange—while the nut’s teeth bite into one side, the bolt's serrations bite from the other. Install the nut by hand, with pliers, or with a snap-in nut installation and removal tool.

| Style | Thread Size | For Panel Thick. | Square Hole Size | Wd. | Head Ht. | Color | Specifications Met | Pkg. Qty. | Pkg. | |

Zinc-Plated Steel | ||||||||||

|---|---|---|---|---|---|---|---|---|---|---|

| A | 12-24 | 0.064" to 0.105" | 0.375" to 0.38" | 0.52" | 0.25" | Green | EIA-310 | 1 | 000000000 | 00000 |

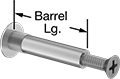

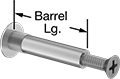

Brass Binding Barrels and Screws for Door Hardware

Brass binding barrels and screws are corrosion resistant in wet environments, electrically conductive, and nonmagnetic. Use them to anchor door closers, kickplates, and other architectural hardware. The barrel head is smooth with no drive to be tampered with on the outside of your door, and the screw has a flat head that sits flush with the surface for a finished look. The screw protrudes from the barrel to leave room for hardware. Install in a hole with a diameter equal to the barrel diameter. Barrel length and screw length are measured from under the head.

Barrel | Screw | ||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| For Material Thick. | Lg. | Dia. | Head Dia. | Head Ht. | Thread Dp. | Lg. | Head Dia. | Head Ht. | Drive Size | Countersink Angle | Appearance | Each | |

Brass | |||||||||||||

12-24 | |||||||||||||

| 1 3/8" | 1 3/16" | 5/16" | 1/2" | 1/8" | 3/4" | 1" | 13/32" | 1/8" | No. 3 | 82° | Dull | 000000000 | 00000 |

| 1 3/4" | 1 9/16" | 5/16" | 1/2" | 1/8" | 3/4" | 1" | 13/32" | 1/8" | No. 3 | 82° | Dull | 000000000 | 0000 |

Chrome-Plated Brass | |||||||||||||

12-24 | |||||||||||||

| 1 3/8" | 1 3/16" | 5/16" | 1/2" | 1/8" | 3/4" | 1" | 13/32" | 1/8" | No. 3 | 82° | Polished | 000000000 | 0000 |

| 1 3/4" | 1 9/16" | 5/16" | 1/2" | 1/8" | 3/4" | 1" | 13/32" | 1/8" | No. 3 | 82° | Polished | 000000000 | 0000 |

Bronze-Plated Brass | |||||||||||||

12-24 | |||||||||||||

| 1 3/8" | 1 3/16" | 5/16" | 1/2" | 1/8" | 3/4" | 1" | 13/32" | 9/64" | No. 3 | 82° | Dark | 000000000 | 0000 |

| 1 3/4" | 1 9/16" | 5/16" | 1/2" | 1/8" | 3/4" | 1" | 13/32" | 9/64" | No. 3 | 82° | Dark | 000000000 | 0000 |

18-8 Stainless Steel Binding Barrels and Screws for Door Hardware

Made from 18-8 stainless steel, these binding barrels and screws are chemical resistant and may be mildly magnetic. Use them to anchor door closers, kickplates, and other architectural hardware. The barrel head is smooth with no drive to be tampered with on the outside of your door, and the screw has a flat head that sits flush with the surface for a finished look. The screw protrudes from the barrel to leave room for hardware. Install in a hole with a diameter equal to the barrel diameter. Barrel length and screw length are measured from under the head.

Installation Tools for Helical Inserts

Screw an insert onto these tools and drive them a quarter to half-turn below the material’s surface. They’re compatible with helical inserts that have a prong.

| For Thread Size | Style | Each | |

For Right-Hand Thread | |||

|---|---|---|---|

| 12-24 | E | 000000000 | 0000000 |

Prong Break-Off Tools for Helical Inserts

Place the tip of these tools into installed inserts and push down to trigger the spring-loaded punch to break off the prong.

| For Thread Size | Each | |

| 10-24, 10-32, 12-24 | 000000000 | 0000000 |

Extraction Tools for Helical Inserts

Place the tip of these tools into an insert and strike a light blow to the tool’s head. Then turn the tools counterclockwise with pressure to extract the insert.

| For Thread Size | Each | |

| 10-24, 10-32, 12-24, 12-28, 1/4"-20, 1/4"-28, 1/4"-32, 1/4"-80, 5/16"-18, 5/16"-24, 5/16"-32, 3/8"-16, 3/8"-24, M5, M6, M7, M8, M10 | 000000000 | 000000 |

Threaded-Shank Phillips Bits

Thread these bits directly into your driving tool for minimal wobble in assembly applications.

Hand-Driven Tools for Low-Profile Rivet Nuts

Turn these tools by hand to install low-profile rivet nuts. The required mandrels are sold separately. To use, thread the nut onto a mandrel of the same size, then place it into a hole, push down on the tool's T-handle, and turn clockwise.

| For Thread Size | For Rivet Nut Body Type | For Rivet Nut Material | Overall Lg. | Each | |

| 4-40, 6-32, 8-32, 10-24, 10-32, 12-24, 1/4"-20, 1/4"-28, 5/16"-18, 5/16"-24, 3/8"-16, 3/8"-24, M3, M4, M5, M6, M8, M10 | Sleeve | 18-8 Stainless Steel, Aluminum, Steel | 5 7/8" | 000000000 | 000000 |

| For Thread Size | Each | |

| 4-40 | 000000000 | 000000 |

| 6-32 | 000000000 | 00000 |

| 8-32 | 000000000 | 00000 |

| 10-24 | 000000000 | 00000 |

| 10-32 | 000000000 | 00000 |

| 12-24 | 000000000 | 00000 |

| 1/4"-20 | 000000000 | 00000 |

| 1/4"-28 | 000000000 | 00000 |

| 5/16"-18 | 000000000 | 00000 |

| 5/16"-24 | 000000000 | 00000 |

| 3/8"-16 | 000000000 | 00000 |

| 3/8"-24 | 000000000 | 00000 |

| M3 × 0.5 mm | 000000000 | 00000 |

| M4 × 0.7 mm | 000000000 | 00000 |

| M5 × 0.8 mm | 000000000 | 00000 |

| M6 × 1 mm | 000000000 | 00000 |

| M8 × 1.25 mm | 000000000 | 00000 |

| M10 × 1.5 mm | 000000000 | 00000 |

Wrench-Driven Rivet Nut Tools

Use these tools to install most styles of rivet nuts. A wrench and ratchet are required to hold the tool and tighten the nut.

| For Thread Size | For Wrench Size | For Ratchet Size | For Rivet Nut Body Type | For Rivet Nut Material | Each | |

| 12-24 | 7/8" | 11/16" | Smooth, Ribbed, Hex, Bulbed, Sleeve | 18-8 Stainless Steel, Aluminum, Steel, Titanium | 000000000 | 000000 |