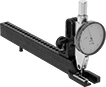

Shallow Inside/Outside Diameter Gauges

Mount your variance indicator onto these gauges to measure the diameter of rims and shallow holes. They show deviation from a set reference to measure both internal and external diameters, while other tools like micrometers and bore gauges only take one type of measurement. Commonly used in cramped machining or assembly processes, these gauges fit in tight spaces. They are made from hardened steel, so they are durable enough to withstand bumps and scrapes and will stay accurate over time.

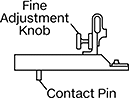

To set your reference measurement, use gauge blocks or a ring gauge. Place the contact pin on one side of the gauge blocks or ring, and slide the indicator away from the contact pin. This pinches the gauge blocks between the contact pin and indicator for outer diameter measurements or presses against the inner edge of the reference gauge for inner diameter measurements. Once the reference measurement is set, lock the gauge. Set the indicator to zero and you're ready to take your measurement. The indicator point stopper will flex slightly to fit the gauge into bores and around outer edges.

For technical drawings and 3-D models, click on a part number.

| Inside Measuring Range | Outside Measuring Range | Max. Dp. Measured | Material | Overall Lg. | Overall Ht. | Heat Treatment | Container Type | Features | Includes | Each | |

| 0.55"-7.2" | 0.24"-6.92" | 0.4" | Black-Oxide Tool Steel | 7 3/4" | 2 3/4" | Hardened | Cardboard Box | Fine-Adjustment Knob, Indicator Contact Point Stopper | Contact Pin, Two L-Keys | 0000000 | 0000000 |

| 2"-12.1" | 1.95"-12.05" | 0.4" | Black-Oxide Tool Steel | 12 7/8" | 2 3/4" | Hardened | Plastic Box | Fine-Adjustment Knob, Indicator Contact Point Stopper | Contact Pin, Two L-Keys | 0000000 | 000000 |