Filter by

Height

Adjustment Mechanism

Component

DFARS Specialty Metals

V-Block Type

Workpiece Diameter

Test End Component

Sold As

Electrical Safety Rating

AC Current

Measurement Unit

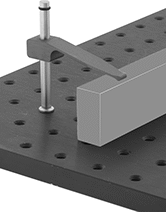

Clamps for Parts Inspection

Hold-Down Clamps

Clamps | Replacement Mounting Shafts | Replacement Clamp Arms | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

Reach Lg. | Ht. | Thread Lg. | Material | Tip Finish | Each | Each | Each | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Tension Spring | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

1/4"-20 Threads | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 13/16" | 1" | 1/4" | Aluminum | — | 0000000 | 000000 | ——— | 0 | ——— | 0 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 13/16" | 2" | 1/4" | Aluminum | — | 0000000 | 00000 | ——— | 0 | ——— | 0 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 1 9/16" | 2 3/4" | 1/4" | Aluminum | — | 0000000 | 00000 | ——— | 0 | ——— | 0 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 1 9/16" | 2 3/4" | 1/4" | Aluminum | Rubber Coated | 0000000 | 00000 | ——— | 0 | ——— | 0 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 2 5/16" | 2 3/4" | 1/4" | Aluminum | — | 0000000 | 00000 | ——— | 0 | ——— | 0 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 2 5/16" | 2 3/4" | 1/4" | Aluminum | Rubber Coated | 0000000 | 00000 | ——— | 0 | ——— | 0 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 3 7/16" | 3" | 1/4" | Aluminum | — | 0000000 | 00000 | ——— | 0 | ——— | 0 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

M4 × 0.7 mm Threads | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 21 mm | 50 mm | 4.5 mm | Aluminum | — | 0000000 | 00000 | ——— | 0 | ——— | 0 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 38 mm | 50 mm | 4.5 mm | Aluminum | — | 0000000 | 00000 | ——— | 0 | ——— | 0 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 58 mm | 50 mm | 4.5 mm | Aluminum | — | 0000000 | 00000 | ——— | 0 | ——— | 0 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

M6 × 1 mm Threads | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 21 mm | 50 mm | 6.2 mm | Aluminum | — | 0000000 | 00000 | ——— | 0 | ——— | 0 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 38 mm | 75 mm | 6.2 mm | Aluminum | — | 0000000 | 00000 | ——— | 0 | ——— | 0 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 58 mm | 75 mm | 6.2 mm | Aluminum | — | 0000000 | 00000 | ——— | 0 | ——— | 0 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

M8 × 1.25 mm Threads | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 38 mm | 75 mm | 6.2 mm | Aluminum | — | 0000000 | 00000 | ——— | 0 | ——— | 0 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 58 mm | 75 mm | 6.2 mm | Aluminum | — | 0000000 | 00000 | ——— | 0 | ——— | 0 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Wire Tension Spring | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

1/4"-20 Threads | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 1 1/4" | 1" | 1/4" | Aluminum | — | 0000000 | 00000 | ——— | 0 | ——— | 0 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 2" | 2" | 1/4" | Aluminum | — | 0000000 | 00000 | ——— | 0 | ——— | 0 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Thumb Screw | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

1/4"-20 Threads | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 1 9/16" | 1 1/2" | 3/8" | Aluminum | — | 0000000 | 00000 | ——— | 0 | ——— | 0 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 3" | 2 1/2" | 1/4" | Aluminum | — | 0000000 | 00000 | ——— | 0 | ——— | 0 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 4 3/8" | 3 1/2" | 3/8" | Aluminum | — | 0000000 | 000000 | ——— | 0 | ——— | 0 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

M6 × 1 mm Threads | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 40 mm | 38 mm | 9.5 mm | Aluminum | — | 0000000 | 00000 | ——— | 0 | ——— | 0 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 76 mm | 63 mm | 6.4 mm | Aluminum | — | 0000000 | 00000 | ——— | 0 | ——— | 0 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 112 mm | 89 mm | 9.5 mm | Aluminum | — | 0000000 | 000000 | ——— | 0 | ——— | 0 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Squeeze Tabs | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

1/4"-20 Threads | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 3 1/4" | 3" | 3/8" | Plastic | — | 0000000 | 00000 | 0000000 | 000000 | 0000000 | 000000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

M6 × 1 mm Threads | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 83 mm | 76 mm | 9.5 mm | Plastic | — | 0000000 | 00000 | 0000000 | 00000 | 0000000 | 00000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

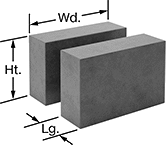

Granite Inspection Parallels

|

Inspection-Grade A Plate | Laboratory-Grade AA Plate | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

Lg. | Thk. | Ht. | Material | Certificate Type | Parallel Tolerance | Pair | Parallel Tolerance | Pair | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Sold as Matched Pair | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

2 Precision-Ground Sides | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 6" | 3/4" | 1" | Black Granite | Accuracy Certificate Traceable to NIST | 0.0001" | 0000000 | 0000000 | 0.00005" | 0000000 | 0000000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 12" | 1" | 2" | Black Granite | Accuracy Certificate Traceable to NIST | 0.0001" | 0000000 | 000000 | 0.00005" | 0000000 | 000000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

4 Precision-Ground Sides | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 6" | 3/4" | 1" | Black Granite | Accuracy Certificate Traceable to NIST | 0.0001" | 0000000 | 000000 | 0.00005" | 0000000 | 000000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 12" | 1" | 2" | Black Granite | Accuracy Certificate Traceable to NIST | 0.0001" | 0000000 | 000000 | 0.00005" | 0000000 | 000000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Meters for Solar Power Systems

Solar Irradiance Meter Kits

UV Light | Current Range, amp | Voltage Range | ||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

Measuring Increments, W/m² | Measurement Range, W/m² | Measurement Accuracy | Temp. Range | AC | DC | AC, V AC | DC, V DC | Data Connection | Batteries Included | Features | Includes | Each | ||

| 1 | 0 to 1,400 | ±5% | -22° F to 212° F -30° C to 100° C | 0 to 999.9 | 0 to 999.9 | 0 to 1,000 | 0 to 1,500 | 3.5 mm Audio, Bluetooth | Yes | Angle Indicator, Compass, Data Hold | Temperature Probe, Voltage/Current Clamp Meter (Rated CAT III 1500 V), 18" Lg. Flexible AC Probe, Magnetic Hanging Strap, Carrying Case | 0000000 | 000000000 | |

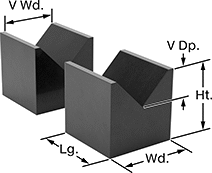

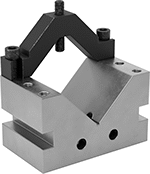

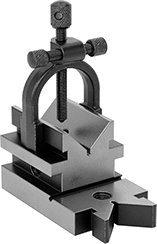

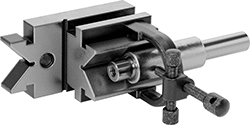

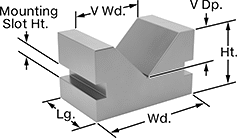

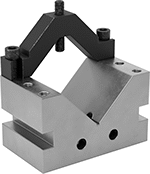

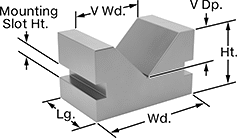

V-Blocks

|  |  |

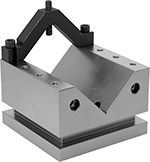

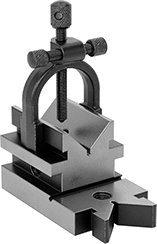

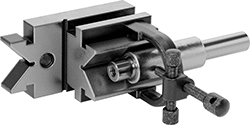

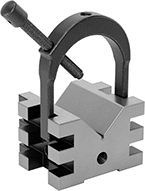

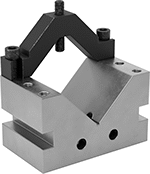

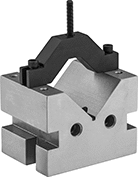

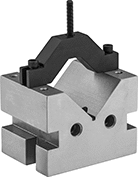

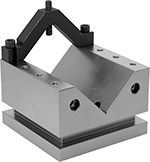

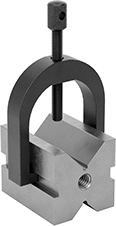

Style A with Clamp | Style B with Clamp | Style C with Clamp |

|  |  |

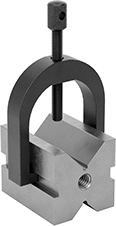

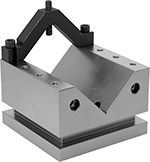

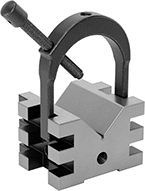

Style D with Clamp | Style D with Clamp (Side Orientation) | Style E with Clamp |

| ||

Style F with Clamp (45° Position Shown) |

Sold Individually

|  |  |

Style A with Clamp | Style B with Clamp | Style C with Clamp |

|  |  |

Style D with Clamp | Style D with Clamp (Side Orientation) |

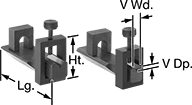

V-Blocks | Replacement Clamps | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

For Workpiece Dia. | Through Holes | Tolerance | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Style | Min. | Max. | Lg. | Wd. | Ht. | V Angle | V Dp. | V Wd. | No. of | Thread Size | Dia. | Squareness | Parallel | Mounting Slot Ht. | Machinable | Each | Each | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

V-Blocks with Clamp | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Steel | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| A | 5/32" | 1 5/8" | 2 1/2" | 2 1/2" | 2" | 90° | 3/4" | 1 1/2" | 2 | — | 5/16" | 0.0002" | 0.0002" | 3/8" | Yes | 0000000 | 0000000 | ——— | 0 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| A | 5/32" | 3 3/4" | 3" | 5" | 3" | 90° | 1 5/8" | 3 1/4" | 2 | — | 5/16" | 0.0002" | 0.0002" | 5/8" | Yes | 0000000 | 000000 | ——— | 0 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| B | 5/32" | 2 7/8" | 3" | 4" | 3" | 90° | 1 3/16" | 2 5/16" | 2 | — | 5/16" | 0.0002" | 0.0002" | 5/8" | Yes | 0000000 | 000000 | ——— | 0 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| C | 5/32" | 4 3/8" | 6" | 6" | 4" | 90° | 2" | 4" | 2 | — | 7/16" | 0.0003" | 0.0003" | 5/8" | Yes | 0000000 | 00000000 | ——— | 0 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Hardened Steel | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| A | 5/32" | 1 5/8" | 2 1/2" | 2 1/2" | 2" | 90° | 3/4" | 1 1/2" | 2 | — | 5/16" | 0.0002" | 0.0002" | 3/8" | No | 0000000 | 000000 | ——— | 0 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| A | 5/32" | 3 3/4" | 3" | 5" | 3" | 90° | 1 5/8" | 3 1/4" | 2 | — | 5/16" | 0.0002" | 0.0002" | 5/8" | No | 0000000 | 000000 | ——— | 0 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| B | 5/32" | 2 7/8" | 3" | 4" | 3" | 90° | 1 3/16" | 2 5/16" | 2 | — | 5/16" | 0.0002" | 0.0002" | 5/8" | No | 0000000 | 000000 | ——— | 0 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| C | 5/32" | 4 3/8" | 6" | 6" | 4" | 90° | 2" | 4" | 2 | — | 7/16" | 0.0003" | 0.0003" | 5/8" | No | 0000000 | 00000000 | ——— | 0 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| D | 1/8" | 1 5/16" | 3 1/2" | 1 7/8" | 1 7/8" | 90° | 5/8" | 1 1/8" | 3 | 3/8"-16 | — | 0.0002" | 0.0002" | 1/2" | No | 00000000 | 000000 | 00000000 | 000000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

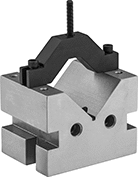

Sold as Matched Pair

|  |  |

Style A with Clamp | Style B with Clamp | Style C with Clamp |

|  |  |

Style E with Clamp | Style F with Clamp (45° Position Shown) |

V-Blocks | Replacement Clamps | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

For Workpiece Dia. | Through Holes | Tolerance | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Style | Min. | Max. | Lg. | Wd. | Ht. | V Angle | V Dp. | V Wd. | No. of | Thread Size | Dia. | Squareness | Parallel | Mounting Slot Ht. | Machinable | Pair | Each | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

V-Blocks with Clamp | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Steel | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| A | 5/32" | 1 5/8" | 2 1/2" | 2 1/2" | 2" | 90° | 3/4" | 1 1/2" | 2 | — | 5/16" | 0.0002" | 0.0002" | 3/8" | Yes | 0000000 | 0000000 | ——— | 0 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| A | 5/32" | 3 3/4" | 3" | 5" | 3" | 90° | 1 5/8" | 3 1/4" | 2 | — | 5/16" | 0.0002" | 0.0002" | 5/8" | Yes | 0000000 | 00000000 | ——— | 0 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| B | 5/32" | 2 7/8" | 3" | 4" | 3" | 90° | 1 3/16" | 2 5/16" | 2 | — | 5/16" | 0.0002" | 0.0002" | 5/8" | Yes | 0000000 | 00000000 | ——— | 0 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| C | 5/32" | 4 3/8" | 6" | 6" | 4" | 90° | 2" | 4" | 2 | — | 7/16" | 0.0003" | 0.0003" | 5/8" | Yes | 0000000 | 00000000 | ——— | 0 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Hardened Steel | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| A | 5/32" | 1 5/8" | 2 1/2" | 2 1/2" | 2" | 90° | 3/4" | 1 1/2" | 2 | — | 5/16" | 0.0002" | 0.0002" | 3/8" | No | 0000000 | 000000 | ——— | 0 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| A | 5/32" | 3 3/4" | 3" | 5" | 3" | 90° | 1 5/8" | 3 1/4" | 2 | — | 5/16" | 0.0002" | 0.0002" | 5/8" | No | 0000000 | 00000000 | ——— | 0 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| A | 5/32" | 5 1/4" | 6" | 7" | 4" | 90° | 2 1/2" | 4 15/16" | 2 | — | 7/16" | 0.0003" | 0.0003" | 5/8" | No | 0000000 | 00000000 | ——— | 0 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| B | 5/32" | 2 7/8" | 3" | 4" | 3" | 90° | 1 3/16" | 2 5/16" | 2 | — | 5/16" | 0.0002" | 0.0002" | 5/8" | No | 0000000 | 00000000 | ——— | 0 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| C | 5/32" | 4 3/8" | 6" | 6" | 4" | 90° | 2" | 4" | 2 | — | 7/16" | 0.0003" | 0.0003" | 5/8" | No | 0000000 | 00000000 | ——— | 0 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| E | 1/8" | 1" | 1 5/8" | 1 1/4" | 1 1/4" | 90° | 7/16" | 13/16" | 1 | 1/4"-20 | — | 0.0002" | 0.0002" | 1/4" | No | 0000000 | 000000 | 0000000 | 000000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| F | 1/8" | 2" | 2 1/2" | 3" | 2" | 90° | 3/4" | 1 1/2" | 1 | 3/8"-16 | — | 0.0002" | 0.0002" | 3/8" | No | 0000000 | 000000 | 0000000 | 00000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

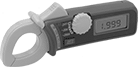

Analog Clamp-on-Jaw Multimeters

Batteries | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

Jaw Opening | Measures | Max. AC Voltage, V AC | Max. DC Voltage, V DC | DC Voltage Accuracy | Max. AC Current, amp | Hardware Features | Includes | Size | Req. | Each | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Average-Sensing AC Calculation | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 1.5" | AC Current, AC Voltage, DC Voltage, Resistance | 600 | 60 | 4% | 600 | Overload Protection | Test Leads | AA | Yes | 0000000 | 0000000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Clamp-on-Jaw Current Meters

Electrical Safety Rating | AC Current | Current Accuracy | Measures | Jaw Opening | Includes | Display Count | Batteries Included | Each | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

Average-Sensing AC Calculation | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| CAT III, 300V | 0 amp to 20 amp, 0 amp to 200 amp | 2% to 3% | AC Current | 1.25" | Carrying Case | 2,000 | Yes | 0000000 | 0000000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

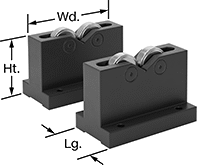

Miniature V-Blocks

For Workpiece Dia. | Tolerance | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

No. of Pieces | Min. | Max. | Lg. | V Angle | V Dp. | Squareness | Parallel | Material | Machinable | Includes | Each | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

V-Blocks with Clamp | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 2 | 1/32" | 9/32" | 2 3/8" | 90° | 1/8" | 0.0002" | 0.0002" | Steel | No | 1 V-Block for 1/32" to 5/32" Workpieces—5/8" Wd. × 1" Ht. × 1/4" V Wd. 1 V-Block for 3/64" to 9/32" Workpieces—3/4" Wd. × 1 1/4" Ht. × 5/16" V Wd. | 00000000 | 0000000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Fluke Wireless Remote-Reading Clamp-on-Jaw Current Meters

Mfr. Model No. | Test End Component | Jaw Opening | Electrical Safety Rating | Measures | Max. AC Current, amp | Data Log Cap. | Display Count | Includes | Certification | Batteries Included | Each | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

True RMS AC Calculation | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| a3000 FC | Current Clamp | 1.33" | CAT III, 600V | AC Current | 400 | 65,000 | 1,000 | — | CSA Certified, CSA-US Certified | Yes | 00000000 | 0000000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| a3001 FC | Current Loop | 10" | CAT IV, 600V | AC Current | 2,500 | 65,000 | 2,500 | Magnetic Hanger | CSA Certified, CSA-US Certified | Yes | 00000000 | 000000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Granite Inspection Setup Blocks

Tolerance | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

Lg. | Wd. | Ht. | Lg. | Wd. | Ht. | Squareness | Parallel | Material | Certificate Type | Pair | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Sold as Matched Pair | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Inspection-Grade A Plate | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 1" | 3" | 2" | -0.0002" to 0.0002" | -0.0002" to 0.0002" | -0.0002" to 0.0002" | 0.0001" | 0.0001" | Black Granite | Accuracy Certificate Traceable to NIST | 00000000 | 0000000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Laboratory-Grade AA Plate | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 1" | 3" | 2" | -0.0001" to 0.0001" | -0.0001" to 0.0001" | -0.0001" to 0.0001" | 0.00005" | 0.00005" | Black Granite | Accuracy Certificate Traceable to NIST | 00000000 | 00000000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

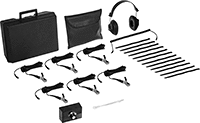

Noise-Filtering Stethoscopes with Microphone Clamps

Headphones Type | Microphone Type | No. of Microphones Included | Batteries Included | Includes | Container Type | Each | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

Dial Control | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| Earmuff | Corded | 6 | Yes | Clamp Storage Pouch | Plastic Carrying Case | 0000000 | 0000000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Touch-Screen Control | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| Earmuff | Wireless | 4 | Yes | Transmitter Charging Station, USB Charging Cord (6 ft.), 4 Transmitter Extension Cords (3 ft.) | Canvas Bag | 0000000 | 000000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Granite Inspection V-Blocks

For Workplace Dia. | Tolerance | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

Min. | Max. | Lg. | Wd. | Ht. | V Angle | V Dp. | V Wd. | Squareness | Parallel | Material | Certificate Type | Pair | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Sold as Matched Pair | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Inspection Grade A | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 1/2" | 2" | 3" | 3" | 3" | 90° | 1 1/4" | 2 1/2" | 0.0002" | 0.0002" | Black Granite | Accuracy Certificate Traceable to NIST | 00000000 | 000000000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 3/4" | 4 1/2" | 6" | 6" | 6" | 90° | 2 1/2" | 5" | 0.0002" | 0.0002" | Black Granite | Accuracy Certificate Traceable to NIST | 00000000 | 00000000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Laboratory Grade AA | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 1/2" | 2" | 3" | 3" | 3" | 90° | 1 1/4" | 2 1/2" | 0.0001" | 0.0001" | Black Granite | Accuracy Certificate Traceable to NIST | 00000000 | 00000000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 3/4" | 4 1/2" | 6" | 6" | 6" | 90° | 2 1/2" | 5" | 0.0001" | 0.0001" | Black Granite | Accuracy Certificate Traceable to NIST | 00000000 | 00000000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

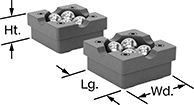

Ball Inspection V-Blocks

For Workplace Dia. | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

Min. | Max. | Max. Workpiece Cap., lb. | Ball Dia. | Roller Dia. | Lg. | Wd. | Ht. | Total Indicated Runout (TIR) Accuracy | Parallel Tolerance | Material | Pair | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Sold as Matched Pair | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Ball Support | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 3/64" | 2 1/2" | 220 | 1/2" | — | 2 1/4" | 2 1/4" | 2" | — | — | Iron | 00000000 | 0000000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 1/4" | 5" | 1,100 | 1" | — | 3 1/2" | 3 1/2" | 2 1/2" | — | — | Iron | 00000000 | 000000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 1/4" | 15" | 2,000 | 1 1/2" | — | 4 3/4" | 4 3/4" | 3 7/8" | — | — | Iron | 00000000 | 000000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Ball Bearing Support | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 1/4" | 2 1/8" | 2,200 | — | 1 3/4" | 3 1/4" | 6" | 4" | 0.0002" | 0.0005" | Iron | 00000000 | 000000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 1" | 2 3/4" | 1,100 | — | 1 5/8" | 2 1/2" | 6" | 4" | 0.0002" | 0.0005" | Iron | 00000000 | 000000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 2 3/4" | 7 3/4" | 2,200 | — | 2 3/4" | 4" | 9" | 6" | 0.0002" | 0.0005" | Iron | 00000000 | 00000000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Clamp-on-Jaw Multimeters

Multimeters | Test Leads | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

Jaw Opening | Electrical Safety Rating | Measures | Max. AC Voltage, V AC | Max. DC Voltage, V DC | DC Voltage Accuracy | Max. AC Current, amp | Max. DC Current, amp | Display Count | Includes | Each | Pair | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Average-Sensing AC Calculation | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 1" | CAT III, 600V | AC Current, AC Voltage, Capacitance, DC Voltage, Frequency, Resistance, Temperature | 600 | 600 | 1% | 600 | — | 4,000 | Carrying Case, Temperature Probe, Test Leads | 0000000 | 0000000 | 0000000 | 000000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

True RMS AC Calculation | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 1.18" | CAT III, 600V | AC Current, AC Voltage, Capacitance, DC Current, DC Voltage, Frequency, Resistance, Temperature | 750 | 1,000 | 0.8% | 600 | 600 | 6,000 | Temperature Probe, Test Leads | 0000000 | 000000 | 0000000 | 00000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 1.18" | CAT IV, 300V | AC Current, AC Voltage, Capacitance, DC Current, DC Voltage, Frequency, Resistance | 600 | 600 | 1% | 600 | 600 | 6,000 | Carrying Case, Test Leads | 0000000 | 000000 | 0000000 | 00000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 1.7" | CAT IV, 600V | AC Current, AC Voltage, Capacitance, DC Voltage, Frequency, Resistance, Temperature | 1,000 | 1,000 | 1.5% | 1,000 | — | 6,000 | Built-In Infrared Temperature Sensor, Carrying Case, Test Leads | 0000000 | 000000 | 0000000 | 00000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 1.7" | CAT IV, 600V | AC Current, AC Voltage, Capacitance, DC Current, DC Voltage, Frequency, Resistance, Temperature | 1,000 | 1,000 | 2.0% | 1,000 | 1,000 | 6,000 | Built-In Infrared Temperature Sensor, Carrying Case, Temperature Probe, Test Leads | 0000000 | 000000 | 0000000 | 00000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 2" | CAT IV, 600V | AC Current, AC Voltage, Capacitance, DC Current, DC Voltage, Frequency, Resistance | 1,000 | 1,000 | 0.8% | 1,000 | 1,000 | 6,000 | Carrying Case, Test Leads | 0000000 | 000000 | 0000000 | 00000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Fluke Clamp-on-Jaw Multimeters

Multimeters | Test Leads | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

Multimeters | Multimeters with Calibration Certificate | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Mfr. Model No. | Jaw Opening | Electrical Safety Rating | Measures | Max. AC Voltage, V AC | Max. DC Voltage, V DC | DC Voltage Accuracy | Max. AC Current, amp | Max. DC Current, amp | Display Count | Includes | Each | Each | Pair | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

True RMS AC Calculation | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 325 | 1.18" | CAT III, 600V; CAT IV, 300V | AC Current, AC Voltage, Capacitance, DC Voltage, Resistance, Temperature | 600 | 600 | 1% | 400 | — | 6,000 | Carrying Case, Temperature Probe, Test Leads | 00000000 | 0000000 | 00000000 | 0000000 | 00000000 | 000000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 355 | 2.3" | CAT IV, 600V | AC Current, AC Voltage, DC Current, DC Voltage, Frequency, Resistance | 600 | 1,000 | 1% | 2,000 | 2,000 | 10,000 | Alligator Clips, Carrying Case, Test Leads, Test Probes | 00000000 | 00000000 | ——— | 0 | ——— | 0 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 374 FC | 1.3" | CAT IV, 600V | AC Current, AC Voltage, Capacitance, DC Current, DC Voltage, Resistance | 1,000 | 1,000 | 1% | 600 | 600 | 6,000 | Carrying Case, Test Leads | 00000000 | 000000 | 00000000 | 000000 | ——— | 0 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 376 FC | 1.3" | CAT IV, 600V | AC Current, AC Voltage, Capacitance, DC Current, DC Voltage, Frequency, Resistance | 1,000 | 1,000 | 1% | 2,500 | 999.9 | 6,000 | Carrying Case, Flexible Current Loop, Test Leads | 00000000 | 000000 | 00000000 | 000000 | ——— | 0 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 381 | 1.34" | CAT IV, 600V | AC Current, AC Voltage, DC Current, DC Voltage, Frequency, Resistance | 1,000 | 1,000 | 1% | 2,500 | 999.9 | 6,000 | Alligator Clips, Carrying Case, Flexible Current Loop, Removable Wireless Display, Test Leads | 00000000 | 000000 | 00000000 | 00000000 | ——— | 0 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||