About Grease

More

About Lubricants

More

About Sleeving

More

About Paint and Protective Coatings

More

About Metal Tubing

More

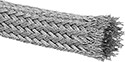

Interference-Shielding Expandable Sleeving

Protect wire and cable from signal distortion caused by nearby equipment and devices. Expandable, this sleeving stretches to fit over items for easy installation, then tightens around its contents for a secure fit. The braided construction permits heat and moisture to dissipate. This sleeving is also used to insulate and organize wire and cable. Cut to size with sheet metal snips.

Copper sleeving is more conductive than aluminum sleeving, so it resists more signal interference.

Aramid fabric sleeving combines the benefits of copper and aluminum sleeving. It’s shielded with copper foil to resist high amounts of signal interference, while the aramid fabric weighs half as much and reflects more heat than copper alone.

Per Ft. | |||||||

|---|---|---|---|---|---|---|---|

| ID | Expanded ID | Wall Thick. | Temperature Range, °F | Lengths, ft. | 1-99 | 100-Up | |

| 1/8" | 5/32" | 1/32" | Not Rated | 00000000 | 00000 | 00000 | |

| 1/4" | 5/16" | 1/32" | Not Rated | 0000000 | 0000 | 0000 | |

| 3/8" | 7/16" | 1/32" | Not Rated | 0000000 | 0000 | 0000 | |

| 1/2" | 9/16" | 1/32" | Not Rated | 0000000 | 0000 | 0000 | |

| 9/16" | 23/32" | 1/32" | Not Rated | 00000000 | 0000 | 0000 | |

| 25/32" | 7/8" | 1/32" | Not Rated | 0000000 | 0000 | 0000 | |

| 7/8" | 1 1/8" | 1/32" | Not Rated | 00000000 | 00000 | 0000 | |

| 1" | 1 1/8" | 1/16" | Not Rated | 0000000 | 00000 | 0000 | |

| 1 1/8" | 1 1/4" | 1/16" | Not Rated | 0000000 | 00000 | 00000 | |

| 1 1/4" | 1 3/8" | 1/16" | Not Rated | 0000000 | 00000 | 00000 | |

| 1 1/2" | 1 5/8" | 1/16" | Not Rated | 0000000 | 00000 | 00000 | |

| 2" | 2 19/32" | 1/16" | Not Rated | 00000000 | 00000 | 00000 | |

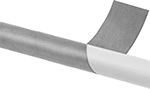

Interference-Shielding Tape Sleeving

With a copper and nickel exterior and conductive lining, this sleeving shields your wire and cable from signal interference. Use it near equipment that creates signal distortion, such as transformers, generators, and motors. It’s made of polyester taffeta cloth, so it’s light and flexible. Plus, its coating resists corrosion.

You can wrap this sleeving like tape around wire and cable while they’re installed, so it’s great for emergency patches. When wrapping, make sure it overlaps itself by half its width. This ensures 98% shielding coverage to keep your components protected.

| Wd. | Thick. | Temperature Range, °F | Shield Type | Color | Each | |

10 ft. Lg. | ||||||

|---|---|---|---|---|---|---|

Nickel-Plated Polyester Fabric with Copper Coating | ||||||

| 1" | 0.006" | -40° to 250° | Conductive Cloth | Gray | 0000000 | 0000000 |

| 2" | 0.006" | -40° to 250° | Conductive Cloth | Gray | 0000000 | 000000 |

25 ft. Lg. | ||||||

Nickel-Plated Polyester Fabric with Copper Coating | ||||||

| 1" | 0.006" | -40° to 250° | Conductive Cloth | Gray | 0000000 | 000000 |

| 2" | 0.006" | -40° to 250° | Conductive Cloth | Gray | 0000000 | 000000 |

50 ft. Lg. | ||||||

Nickel-Plated Polyester Fabric with Copper Coating | ||||||

| 1" | 0.006" | -40° to 250° | Conductive Cloth | Gray | 0000000 | 000000 |

| 2" | 0.006" | -40° to 250° | Conductive Cloth | Gray | 0000000 | 000000 |

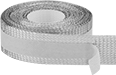

Conductive Mesh Electrical Tape

This polyester tape has a woven mesh edge that conducts electricity. Use it to shield cables and electronic components from EMI (electromagnetic interference). When wrapping objects, tape should overlap half of its width to achieve a highly effective four-ply shielding.

| Wd. | Lg., ft. | Overall Thick. | Material | Edge Material | Adhesive Type | Temperature Range, °F | Voltage Rating | Shielding Effectiveness @ Volume | Color | Each | |

| 1" | 16 | 0.025" | Aluminum, Polyester Plastic | Tinned Copper Mesh | Acrylic | -40° to 345° | Not Rated | 1 MHz @ 65 dB | Silver | 0000000 | 000000 |

| 1" | 16 | 0.025" | Copper, Polyester Plastic | Tinned Copper Mesh | Acrylic | -40° to 345° | Not Rated | 1 MHz @ 70 dB | Silver | 0000000 | 00000 |

Low-Outgassing Conductive Copper Foil Electrical Tape

Tested to meet ASTM E595, a standard used by NASA, this tape releases almost no volatile emissions that could damage sensitive electronics, even in a vacuum. Use it to repair and prototype circuit boards and shield components from EMI/RFI. With a copper backing and conductive adhesive, it’s useful for making electrical connections—current travels both along and through the tape. Unlike aluminum tape, it can be soldered. It’s also better at resisting chemicals.

Conductive Cloth Electrical Tape

Made of polyester fabric with a copper/nickel filler, this tape is highly conductive throughout, including the adhesive. Use it to shield cables and electronic components from EMI (electromagnetic interference).

| Lg., ft. | Wd. | Overall Thick. | Material | Adhesive Type | Temp. Range, °F | Voltage Rating | Shielding Effectiveness @ Volume | Color | Each | |

| 3 | 1" | 0.0048" | Copper, Nickel, Polyester Cloth | Acrylic | -40° to 155° | Not Rated | 10 MHz @ 95 dB | Gray | 0000000 | 000000 |

| 3 | 2" | 0.0048" | Copper, Nickel, Polyester Cloth | Acrylic | -40° to 155° | Not Rated | 10 MHz @ 95 dB | Gray | 0000000 | 00000 |

| 12 | 1" | 0.0048" | Copper, Nickel, Polyester Cloth | Acrylic | -40° to 155° | Not Rated | 10 MHz @ 95 dB | Gray | 0000000 | 00000 |

| 12 | 2" | 0.0048" | Copper, Nickel, Polyester Cloth | Acrylic | -40° to 155° | Not Rated | 10 MHz @ 95 dB | Gray | 0000000 | 00000 |

| 25 | 1" | 0.0048" | Copper, Nickel, Polyester Cloth | Acrylic | -40° to 155° | Not Rated | 10 MHz @ 95 dB | Gray | 0000000 | 00000 |

| 25 | 2" | 0.0048" | Copper, Nickel, Polyester Cloth | Acrylic | -40° to 155° | Not Rated | 10 MHz @ 95 dB | Gray | 0000000 | 000000 |

| 50 | 1" | 0.0048" | Copper, Nickel, Polyester Cloth | Acrylic | -40° to 155° | Not Rated | 10 MHz @ 95 dB | Gray | 0000000 | 000000 |

| 50 | 2" | 0.0048" | Copper, Nickel, Polyester Cloth | Acrylic | -40° to 155° | Not Rated | 10 MHz @ 95 dB | Gray | 0000000 | 000000 |

Conductive Copper Foil Electrical Tape

Use this tape to modify printed circuit boards, shield components from EMI/RFI (electromagnetic interference/radio-frequency interference), and prototype wiring-board layout and design. Made of copper, it resists chemicals better than aluminum foil electrical tape. Plus, you can solder it.

Tape with nonconductive adhesive is only conductive on the surface, so electrical charge won’t travel through the tape. Choose it for shielding cables without creating unwanted electrical connections.

Tape with conductive adhesive makes easy electrical connections—charge travels both along and through the tape. Since it’s more conductive, it’s better at shielding against EMI than tape with nonconductive adhesive.

| Wd. | Overall Thick. | Adhesive Type | Temperature Range, °F | Voltage Rating | Specifications Met | Lg., ft. | Each | |

Short Roll | ||||||||

|---|---|---|---|---|---|---|---|---|

Nonconductive Adhesive | ||||||||

| 1/4" | 0.0029" | Acrylic | -40° to 325° | Not Rated | UL 510 | 18 | 000000000 | 00000 |

| 1/2" | 0.0029" | Acrylic | -40° to 325° | Not Rated | UL 510 | 18 | 000000000 | 00000 |

| 3/4" | 0.0029" | Acrylic | -40° to 325° | Not Rated | UL 510 | 18 | 000000000 | 00000 |

| 1" | 0.0029" | Acrylic | -40° to 325° | Not Rated | UL 510 | 18 | 000000000 | 00000 |

| 2" | 0.0029" | Acrylic | -40° to 325° | Not Rated | UL 510 | 18 | 000000000 | 00000 |

| 3" | 0.0029" | Acrylic | -40° to 325° | Not Rated | UL 510 | 18 | 000000000 | 00000 |

| 6" | 0.0029" | Acrylic | -40° to 325° | Not Rated | UL 510 | 18 | 00000000 | 000000 |

Conductive Adhesive | ||||||||

| 1/4" | 0.0035" | Acrylic | -40° to 325° | Not Rated | MIL-T-47012, UL 510 | 18 | 000000000 | 00000 |

| 1/2" | 0.0035" | Acrylic | -40° to 325° | Not Rated | MIL-T-47012, UL 510 | 18 | 000000000 | 00000 |

| 3/4" | 0.0035" | Acrylic | -40° to 325° | Not Rated | MIL-T-47012, UL 510 | 18 | 000000000 | 00000 |

| 1" | 0.0035" | Acrylic | -40° to 325° | Not Rated | MIL-T-47012, UL 510 | 18 | 000000000 | 00000 |

| 2" | 0.0035" | Acrylic | -40° to 325° | Not Rated | MIL-T-47012, UL 510 | 18 | 000000000 | 00000 |

| 3" | 0.0035" | Acrylic | -40° to 325° | Not Rated | MIL-T-47012, UL 510 | 18 | 000000000 | 000000 |

| 6" | 0.0035" | Acrylic | -40° to 325° | Not Rated | MIL-T-47012, UL 510 | 18 | 000000000 | 000000 |

Long Roll | ||||||||

Nonconductive Adhesive | ||||||||

| 1/4" | 0.0029" | Acrylic | -40° to 325° | Not Rated | UL 510 | 108 | 000000000 | 00000 |

| 1/2" | 0.0029" | Acrylic | -40° to 325° | Not Rated | UL 510 | 108 | 000000000 | 00000 |

| 3/4" | 0.0029" | Acrylic | -40° to 325° | Not Rated | UL 510 | 108 | 000000000 | 00000 |

| 1" | 0.0029" | Acrylic | -40° to 325° | Not Rated | UL 510 | 108 | 000000000 | 00000 |

| 2" | 0.0029" | Acrylic | -40° to 325° | Not Rated | UL 510 | 108 | 000000000 | 000000 |

| 3" | 0.0029" | Acrylic | -40° to 325° | Not Rated | UL 510 | 108 | 000000000 | 000000 |

Conductive Adhesive | ||||||||

| 1/4" | 0.0035" | Acrylic | -40° to 325° | Not Rated | MIL-T-47012, UL 510 | 54 | 000000000 | 00000 |

| 1/2" | 0.0035" | Acrylic | -40° to 325° | Not Rated | MIL-T-47012, UL 510 | 54 | 000000000 | 00000 |

| 3/4" | 0.0035" | Acrylic | -40° to 325° | Not Rated | MIL-T-47012, UL 510 | 54 | 000000000 | 00000 |

| 1" | 0.0035" | Acrylic | -40° to 325° | Not Rated | MIL-T-47012, UL 510 | 54 | 000000000 | 00000 |

| 2" | 0.0035" | Acrylic | -40° to 325° | Not Rated | MIL-T-47012, UL 510 | 54 | 000000000 | 000000 |

| 3" | 0.0035" | Acrylic | -40° to 325° | Not Rated | MIL-T-47012, UL 510 | 54 | 000000000 | 000000 |

| 6" | 0.0035" | Acrylic | -40° to 325° | Not Rated | MIL-T-47012, UL 510 | 54 | 000000000 | 000000 |

Grease for Electrical Contacts

Lubricate, clean, deoxidize, and prevent corrosion on electrical contacts to improve their performance.

NLGI viscosity grade is a rating of a grease's consistency. NLGI 2 is about the consistency of peanut butter.

Grease with copper has copper particles to assist oxidize breakup and resist abrasion on surfaces that require conductivity.

Grease lubricates most efficiently within the listed temperature range. Melting temperature is the point at which grease will fail and run out of equipment, leaving it to run dry.

Container | Each | |||||||||

|---|---|---|---|---|---|---|---|---|---|---|

| NLGI Viscosity Grade | Base Oil | Additive | Size, fl. oz. | Type | Temp. Range, °F | Melting Temp., °F | Dielectric Strength, V/mil | Color | Each | |

Lithium Thickener | ||||||||||

| 2 | Synthetic | Deoxidizer, Copper | 8 | Tube | -30° to 200° | 285° | 115 | Amber | 0000000 | 000000 |

Insulated Copper Tubing

- Temperature Range: -290° to 220° F

- Bending Method: Tube Bender

- Compatible Tube Fittings: Compression and Solder Connect

Often used in heating and cooling systems, this tubing insulates refrigerant to efficiently transfer heat between components. It's frequently referred to as refrigeration and air conditioning tubing. This tubing consists of a copper tube insulated in rubber. The copper tubing resists corrosion and has excellent heat transfer qualities. The outer insulation has a closed-cell design, so it prevents moisture from seeping through and corroding the copper tubing. This tubing is generally rigid because of the copper tubing inside and is stronger than plastic and rubber tubing. Use it in medium- to high-pressure applications.

50 ft. | ||||||||

|---|---|---|---|---|---|---|---|---|

| Copper Tube Size | OD | Wall Thick. | ID | Max. Pressure | Temper Rating | Specifications Met | Each | |

| 1/4 | 3/8" | 0.025" | 0.35" | 4,220 psi @ 72° F | Soft | ASTM B743, ASTM C534, ASTM E84 25/50 for Flame and Smoke, ASTM E96 | 0000000 | 0000000 |

| 3/8 | 1/2" | 0.028" | 0.472" | 3,120 psi @ 72° F | Soft | ASTM B743, ASTM C534, ASTM E84 25/50 for Flame and Smoke, ASTM E96 | 0000000 | 000000 |

| 1/2 | 5/8" | 0.03" | 0.595" | 2,580 psi @ 72° F | Soft | ASTM B743, ASTM C534, ASTM E84 25/50 for Flame and Smoke, ASTM E96 | 0000000 | 000000 |

Heavy Duty EMI/RFI Shielding Coatings for Electronics

Coat electronics for durability in tough conditions while blocking EMI/RFI signals. Made of epoxy mixed with silver-coated copper, these coatings are stronger than acrylic EMI/RFI coatings. They are rigid enough to withstand the wear of access panels and industrial cabinets. You can also use them in engine compartments because they resist damage from high temperatures and chemicals. Also known as conductive paint, they shield your parts from interference that could cause circuit malfunction and data loss. Mix the two parts of these compounds together and paint them on components. These coatings cannot be sold to Canada due to product labeling requirements.

Dry Time | ||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Container Size, fl. oz. | Consistency | Touch, min. | Overall, hrs. | Interference Reduction @ Frequency | Surface Resistivity | Temperature Range, °F | Heating Requirements to Reach Full Strength | For Use On | Color | Cannot Be Sold To | Each | |

| 27 | Thin Liquid | 5 | 4 | 55 dB @ 1 GHz | 0.31 ohms/sq. | -40° to 245° | 4 hrs. @ 150° F | Aluminum, Steel, Stainless Steel, Ceramic, Glass, Plastic, Chrome, Galvanized Steel | Brown | Canada | 0000000 | 0000000 |