Filter by

Thread Size

System of Measurement

Hex Nut Profile

Material

Fastener Strength Grade/Class

Specifications Met

Thread Type

Drive Style

Thread Direction

Thread Spacing

Performance

DFARS Specialty Metals

Export Control Classification Number (ECCN)

REACH

RoHS

Fastener Strength Rating

Thread Fit

Threading

About Hex Nuts

Choose a hex nut with the right profile, material, and strength for your application.

Thin-Profile Hex Nuts

|

About half the height of standard-profile nuts, these fit in spaces with low clearance. You can also use them as jam nuts by threading them against another hex nut to hold it in place.

Medium-Strength Steel

These Grade 5 or Class 04 nuts are your go-to for fastening most machinery and equipment. To avoid stripped threads during installation, make sure your screw has a comparable strength rating.

Zinc-Plated Steel—A step up from plain steel, the zinc plating withstands occasional exposure to moisture.

Steel—Best for dry environments since moisture will cause these nuts to rust.

Corrosion-Resistant Stainless Steel

18-8 Stainless Steel—The choice for wet and outdoor environments, these nuts resist rust. However, they won't hold up to the harsh chemicals that 316 stainless steel can.

Black-Oxide 18-8 Stainless Steel—Typically chosen for their appearance, these nuts have a dark, matte coating to create a finished look. They resist rust in wet and outdoor environments, but won't hold up to the harsh chemicals that 316 stainless steel can.

Super-Corrosion-Resistant 316 Stainless Steel—Superior to 18-8 stainless steel, these nuts won't degrade when exposed to harsh weather, salt water, and most chemicals.

Brass

Brass—Conductive and nonmagnetic, brass nuts are commonly used to secure electrical equipment, such as circuit board assemblies and mounting brackets, inside enclosures. They're also softer than most metals, so they won't damage other fastening components.

Nickel-Plated Brass—The nickel plating offers better corrosion resistance than plain brass to stand up to solvents, salt water, and chemicals. The plating can wear off over time, so these nuts are not recommended for applications that experience a lot of friction or wear.

18-8 Stainless Steel Thin-Profile Square Nuts

|

Two-thirds the height of typical square nuts and made of 18-8 stainless steel, these metric nuts are designed for use in low-clearance applications in humid, damp, and washdown environments. They’re often called square jam nuts because they can be jammed together to hold each other in place. They’re easily gripped with a wrench due to their flat, broad sides, which also prevent them from rotating in channels and square holes. Compared to hex nuts, a greater area is in contact with the fastened surface. And compared to steel nuts, they’re slightly less strong.

DIN 562—These nuts meet DIN 562, an international standard that signifies their material and dimensions are compatible with other products and tools.

Thread Size | Wd., mm | Ht., mm | Specs. Met | Pkg. Qty. | Pkg. | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

18-8 Stainless Steel | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| M2 × 0.4 mm | 4 | 1.2 | DIN 562 | 25 | 97258A121 | 000000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

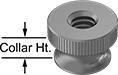

Flanged Knurled-Head Thumb Nuts

|

The slip-resistant head is easy to grip, while the flange distributes pressure evenly across the mounting surface without the need for a separate washer. These nuts are often used to secure screws in oversized or irregularly shaped holes since the flange covers a larger area than standard nuts.

Corrosion-Resistant Stainless Steel

18-8 Stainless Steel—The choice for wet and outdoor environments, these nuts resist rust. However, they won't hold up to the harsh chemicals that 316 stainless steel can.

Knurled-Head Thumb Nuts

|

Get a good grip on these nuts, even with oily fingers. They have a raised, slip-resistant head, so you can tighten them by hand and make controlled adjustments. Knurled-head nuts have a smaller profile than wing nuts, so they fit in tighter spots.

Corrosion-Resistant Stainless Steel

18-8 Stainless Steel—The choice for wet and outdoor environments, these nuts resist rust. However, they won't hold up to the harsh chemicals that 316 stainless steel can.

Black-Oxide 18-8 Stainless Steel—Typically chosen for their appearance, these nuts have a dark, matte coating to create a finished look. They resist rust in wet and outdoor environments, but won't hold up to the harsh chemicals that 316 stainless steel can.