Filter by

System of Measurement

Width

Length

Tolerance Rating

Minimum Hardness

Specifications Met

Hardness

DFARS Specialty Metals

Finish

Thread Size

Head Height

Rate of Taper

Head Length

Certification

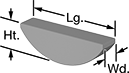

Machine Keys

|

Tolerance | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

Lg. | Tolerance Rating | Ht. | Wd. | Min. Hardness | Specs. Met | Pkg. Qty. | Pkg. | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

1008-1045 Carbon Steel | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

3/16" × 3/16" | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 1/4" | Undersized | -0.002" to 0.000" | -0.002" to 0.000" | Rockwell B97 | ASME B17.1 Class 1 | 10 | 000000000 | 00000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 1/2" | Oversized | 0.000" to 0.002" | 0.000" to 0.002" | Rockwell B50 | — | 10 | 000000000 | 0000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 1/2" | Undersized | -0.002" to 0.000" | -0.002" to 0.000" | Rockwell B50 | ASME B17.1 Class 1 | 10 | 000000000 | 0000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 3/4" | Oversized | 0.000" to 0.002" | 0.000" to 0.002" | Rockwell B50 | — | 10 | 000000000 | 0000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 3/4" | Undersized | -0.002" to 0.000" | -0.002" to 0.000" | Rockwell B50 | ASME B17.1 Class 1 | 10 | 000000000 | 0000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 7/8" | Undersized | -0.002" to 0.000" | -0.002" to 0.000" | Rockwell B97 | ASME B17.1 Class 1 | 10 | 000000000 | 0000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 1" | Oversized | 0.000" to 0.002" | 0.000" to 0.002" | Rockwell B50 | — | 10 | 000000000 | 0000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 1" | Undersized | -0.002" to 0.000" | -0.002" to 0.000" | Rockwell B50 | ASME B17.1 Class 1 | 10 | 000000000 | 0000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 1 1/8" | Undersized | -0.002" to 0.000" | -0.002" to 0.000" | Rockwell B97 | ASME B17.1 Class 1 | 10 | 000000000 | 0000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 1 1/4" | Oversized | 0.000" to 0.002" | 0.000" to 0.002" | Rockwell B50 | — | 10 | 000000000 | 0000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 1 1/4" | Undersized | -0.002" to 0.000" | -0.002" to 0.000" | Rockwell B50 | ASME B17.1 Class 1 | 10 | 000000000 | 0000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 1 3/8" | Oversized | 0.000" to 0.001" | 0.000" to 0.001" | Not Rated | ASME B17.1 Class 2 | 5 | 000000000 | 0000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 1 3/8" | Undersized | -0.002" to 0.000" | -0.002" to 0.000" | Not Rated | ASME B17.1 Class 1 | 5 | 000000000 | 0000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 1 1/2" | Oversized | 0.000" to 0.002" | 0.000" to 0.002" | Rockwell B50 | — | 10 | 000000000 | 0000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 1 1/2" | Undersized | -0.002" to 0.000" | -0.002" to 0.000" | Rockwell B50 | ASME B17.1 Class 1 | 10 | 000000000 | 0000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 1 3/4" | Oversized | 0.000" to 0.002" | 0.000" to 0.002" | Rockwell B50 | — | 10 | 000000000 | 00000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 1 3/4" | Undersized | -0.002" to 0.000" | -0.002" to 0.000" | Rockwell B50 | ASME B17.1 Class 1 | 10 | 000000000 | 0000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 2" | Oversized | 0.000" to 0.002" | 0.000" to 0.002" | Rockwell B50 | — | 10 | 000000000 | 00000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 2" | Undersized | -0.002" to 0.000" | -0.002" to 0.000" | Rockwell B50 | ASME B17.1 Class 1 | 10 | 000000000 | 0000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 2 1/2" | Undersized | -0.002" to 0.000" | -0.002" to 0.000" | Rockwell B50 | ASME B17.1 Class 1 | 10 | 000000000 | 0000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 3" | Undersized | -0.002" to 0.000" | -0.002" to 0.000" | Rockwell B97 | ASME B17.1 Class 1 | 10 | 000000000 | 0000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 4" | Undersized | -0.002" to 0.000" | -0.002" to 0.000" | Rockwell B97 | ASME B17.1 Class 1 | 10 | 000000000 | 00000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Zinc-Plated 1008-1045 Carbon Steel | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

3/16" × 3/16" | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 1 3/8" | Oversized | 0.000" to 0.002" | 0.000" to 0.002" | Rockwell B50 | ASME B17.1 Class 2 | 10 | 0000000 | 00000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 1 3/8" | Undersized | -0.002" to 0.000" | -0.002" to 0.000" | Rockwell B50 | ASME B17.1 Class 1 | 10 | 0000000 | 00000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

18-8 Stainless Steel | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

3/16" × 3/16" | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 1/4" | Undersized | -0.002" to 0.000" | -0.002" to 0.000" | Rockwell B97 | — | 10 | 000000000 | 00000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 1/2" | Undersized | -0.002" to 0.000" | -0.002" to 0.000" | Rockwell B97 | — | 10 | 000000000 | 00000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 3/4" | Oversized | 0.000" to 0.003" | 0.000" to 0.003" | Rockwell B82 | — | 10 | 000000000 | 0000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 3/4" | Undersized | -0.002" to 0.000" | -0.002" to 0.000" | Rockwell B97 | — | 10 | 000000000 | 00000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 7/8" | Undersized | -0.002" to 0.000" | -0.002" to 0.000" | Rockwell B97 | — | 10 | 000000000 | 00000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 1" | Oversized | 0.000" to 0.003" | 0.000" to 0.003" | Rockwell B82 | — | 10 | 000000000 | 0000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 1" | Undersized | -0.002" to 0.000" | -0.002" to 0.000" | Rockwell B97 | — | 10 | 000000000 | 00000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 1 1/8" | Undersized | -0.002" to 0.000" | -0.002" to 0.000" | Rockwell B97 | — | 10 | 000000000 | 00000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 1 1/4" | Undersized | -0.002" to 0.000" | -0.002" to 0.000" | Rockwell B97 | — | 10 | 000000000 | 00000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 1 1/2" | Undersized | -0.002" to 0.000" | -0.002" to 0.000" | Rockwell B97 | — | 5 | 000000000 | 0000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 1 3/4" | Undersized | -0.002" to 0.000" | -0.002" to 0.000" | Rockwell B97 | — | 5 | 000000000 | 0000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 2" | Undersized | -0.002" to 0.000" | -0.002" to 0.000" | Rockwell B97 | — | 5 | 000000000 | 0000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 2 1/2" | Undersized | -0.002" to 0.000" | -0.002" to 0.000" | Rockwell B97 | — | 5 | 000000000 | 0000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

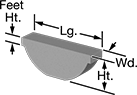

Rounded Machine Keys

|

Tolerance | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

Lg. | Tolerance Rating | Ht. | Wd. | Min. Hardness | Specs. Met | Pkg. Qty. | Pkg. | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

1008-1045 Carbon Steel | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

3/16" × 3/16" | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 1/2" | Oversized | 0.000" to 0.002" | 0.000" to 0.002" | Rockwell B50 | — | 5 | 000000000 | 00000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 1/2" | Undersized | -0.002" to 0.000" | -0.002" to 0.000" | Not Rated | ASME B17.1 Class 1 | 5 | 000000000 | 0000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 3/4" | Oversized | 0.000" to 0.002" | 0.000" to 0.002" | Rockwell B50 | — | 5 | 000000000 | 0000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 3/4" | Undersized | -0.002" to 0.000" | -0.002" to 0.000" | Rockwell B50 | ASME B17.1 Class 1 | 5 | 000000000 | 0000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 1" | Oversized | 0.000" to 0.001" | 0.000" to 0.001" | Not Rated | ASME B17.1 Class 2 | 5 | 000000000 | 0000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 1" | Undersized | -0.002" to 0.000" | -0.002" to 0.000" | Rockwell B50 | ASME B17.1 Class 1 | 5 | 000000000 | 0000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 1 1/4" | Oversized | 0.000" to 0.001" | 0.000" to 0.001" | Not Rated | ASME B17.1 Class 2 | 5 | 000000000 | 0000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 1 1/4" | Undersized | -0.002" to 0.000" | -0.002" to 0.000" | Not Rated | ASME B17.1 Class 1 | 5 | 000000000 | 0000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 1 3/8" | Undersized | -0.002" to 0.000" | -0.002" to 0.000" | Not Rated | ASME B17.1 Class 1 | 5 | 000000000 | 0000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 1 1/2" | Oversized | 0.000" to 0.002" | 0.000" to 0.002" | Rockwell B50 | — | 5 | 000000000 | 0000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 1 1/2" | Undersized | -0.002" to 0.000" | -0.002" to 0.000" | Rockwell B50 | ASME B17.1 Class 1 | 5 | 000000000 | 00000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 2" | Oversized | 0.000" to 0.001" | 0.000" to 0.001" | Not Rated | ASME B17.1 Class 2 | 5 | 000000000 | 0000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 2" | Undersized | -0.002" to 0.000" | -0.002" to 0.000" | Not Rated | ASME B17.1 Class 1 | 5 | 000000000 | 0000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Zinc-Plated 1008-1045 Carbon Steel | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

3/16" × 3/16" | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 1/2" | Oversized | 0.000" to 0.002" | 0.000" to 0.002" | Rockwell B50 | ASME B17.1 Class 2 | 5 | 000000000 | 0000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 1/2" | Undersized | -0.002" to 0.000" | -0.002" to 0.000" | Not Rated | ASME B17.1 Class 1 | 5 | 000000000 | 0000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 3/4" | Oversized | 0.000" to 0.002" | 0.000" to 0.002" | Rockwell B50 | ASME B17.1 Class 2 | 5 | 000000000 | 0000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 3/4" | Undersized | -0.002" to 0.000" | -0.002" to 0.000" | Not Rated | ASME B17.1 Class 1 | 5 | 000000000 | 0000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 1" | Oversized | 0.000" to 0.001" | 0.000" to 0.001" | Not Rated | ASME B17.1 Class 2 | 5 | 000000000 | 00000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 1" | Undersized | -0.002" to 0.000" | -0.002" to 0.000" | Not Rated | ASME B17.1 Class 1 | 5 | 000000000 | 0000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 1 1/4" | Undersized | -0.002" to 0.000" | -0.002" to 0.000" | Not Rated | ASME B17.1 Class 1 | 5 | 000000000 | 0000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 1 1/2" | Undersized | -0.002" to 0.000" | -0.002" to 0.000" | Not Rated | ASME B17.1 Class 1 | 5 | 000000000 | 0000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 1 3/4" | Undersized | -0.002" to 0.000" | -0.002" to 0.000" | Not Rated | ASME B17.1 Class 1 | 5 | 000000000 | 0000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 2" | Undersized | -0.002" to 0.000" | -0.002" to 0.000" | Not Rated | ASME B17.1 Class 1 | 5 | 000000000 | 0000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Woodruff Keys

Tolerance | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

Woodruff Key No. | Wd. | For Keyway Dia. | Ht. | Lg. | Wd. | Ht. | Specs. Met | System of Measurement | Pkg. Qty. | Pkg. | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

1018-1045 Carbon Steel | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 9 | 3/16" | 3/4" | 0.303" | 0.74" | 0.000" to 0.001" | -0.006" to 0.000" | ASME B17.2 | Inch | 100 | 000000000 | 000000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 11 | 3/16" | 7/8" | 0.365" | 0.866" | 0.000" to 0.001" | -0.006" to 0.000" | ASME B17.2 | Inch | 50 | 000000000 | 00000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 13 | 3/16" | 1" | 0.428" | 0.992" | 0.000" to 0.001" | -0.006" to 0.000" | ASME B17.2 | Inch | 25 | 000000000 | 00000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 16 | 3/16" | 1 1/8" | 0.475" | 1.114" | 0.000" to 0.001" | -0.006" to 0.000" | ASME B17.2 | Inch | 25 | 000000000 | 00000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 19 | 3/16" | 1 1/4" | 0.537" | 1.24" | 0.000" to 0.001" | -0.006" to 0.000" | ASME B17.2 | Inch | 25 | 000000000 | 00000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 61 | 3/16" | 5/8" | 0.24" | 0.612" | 0.000" to 0.001" | -0.006" to 0.000" | ASME B17.2 | Inch | 100 | 000000000 | 00000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 126 | 3/16" | 2 1/8" | 0.396" | 1.38" | 0.000" to 0.001" | -0.006" to 0.000" | ASME B17.2 | Inch | 25 | 000000000 | 00000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

8630 Alloy Steel | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 9 | 3/16" | 3/4" | 0.303" | 0.74" | 0.000" to 0.001" | -0.006" to 0.000" | ASME B17.2 | Inch | 50 | 000000000 | 00000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 11 | 3/16" | 7/8" | 0.365" | 0.866" | 0.000" to 0.001" | -0.006" to 0.000" | ASME B17.2 | Inch | 25 | 000000000 | 00000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 13 | 3/16" | 1" | 0.428" | 0.992" | 0.000" to 0.001" | -0.006" to 0.000" | ASME B17.2 | Inch | 25 | 000000000 | 00000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 16 | 3/16" | 1 1/8" | 0.475" | 1.114" | 0.000" to 0.001" | -0.006" to 0.000" | ASME B17.2 | Inch | 10 | 000000000 | 0000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 19 | 3/16" | 1 1/4" | 0.537" | 1.24" | 0.000" to 0.001" | -0.006" to 0.000" | ASME B17.2 | Inch | 10 | 000000000 | 00000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 61 | 3/16" | 5/8" | 0.24" | 0.612" | 0.000" to 0.001" | -0.006" to 0.000" | ASME B17.2 | Inch | 50 | 000000000 | 00000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 126 | 3/16" | 2 1/8" | 0.396" | 1.38" | 0.000" to 0.001" | -0.006" to 0.000" | ASME B17.2 | Inch | 25 | 000000000 | 00000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

316 Stainless Steel | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 9 | 3/16" | 3/4" | 0.303" | 0.74" | 0.000" to 0.001" | -0.006" to 0.000" | ASME B17.2 | Inch | 5 | 000000000 | 00000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 11 | 3/16" | 7/8" | 0.365" | 0.866" | 0.000" to 0.001" | -0.006" to 0.000" | ASME B17.2 | Inch | 1 | 000000000 | 0000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 61 | 3/16" | 5/8" | 0.25" | 0.612" | 0.000" to 0.001" | -0.005" to 0.000" | ASME B17.2 | Inch | 5 | 000000000 | 00000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Machine Key Stock

1008-1045 Carbon Steel

Tolerance | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

Ht. × Wd. | Tolerance Rating | Ht. | Wd. | Min. Hardness | Each | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

12" Long | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 1/8" × 3/16" | Oversized | 0.000" to 0.003" | 0.000" to 0.003" | Rockwell B50 | 000000000 | 00000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 1/8" × 3/16" | Undersized | -0.003" to 0.000" | -0.003" to 0.000" | Rockwell B50 | 000000000 | 0000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 3/16" × 3/16" | Oversized | 0.000" to 0.002" | 0.000" to 0.002" | Rockwell B50 | 000000000 | 0000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 3/16" × 3/16" | Undersized | -0.002" to 0.000" | -0.002" to 0.000" | Rockwell B50 | 000000000 | 0000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

36" Long | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 3/16" × 3/16" | Oversized | 0.000" to 0.002" | 0.000" to 0.002" | Rockwell B50 | 000000000 | 0000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 3/16" × 3/16" | Undersized | -0.002" to 0.000" | -0.002" to 0.000" | Rockwell B50 | 000000000 | 0000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

72" Long | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 3/16" × 3/16" | Oversized | 0.000" to 0.002" | 0.000" to 0.002" | Rockwell B50 | 000000000 | 0000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Zinc-Plated 1008-1045 Carbon Steel

Tolerance | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

Ht. × Wd. | Tolerance Rating | Ht. | Wd. | Min. Hardness | Each | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

12" Long | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 1/8" × 3/16" | Oversized | 0.000" to 0.003" | 0.000" to 0.003" | Rockwell B50 | 000000000 | 00000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 1/8" × 3/16" | Undersized | -0.003" to 0.000" | -0.003" to 0.000" | Rockwell B50 | 000000000 | 0000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 3/16" × 3/16" | Oversized | 0.000" to 0.002" | 0.000" to 0.002" | Rockwell B50 | 000000000 | 0000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 3/16" × 3/16" | Undersized | -0.002" to 0.000" | -0.002" to 0.000" | Rockwell B50 | 000000000 | 0000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

36" Long | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 3/16" × 3/16" | Oversized | 0.000" to 0.002" | 0.000" to 0.002" | Rockwell B50 | 000000000 | 0000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 3/16" × 3/16" | Undersized | -0.002" to 0.000" | -0.002" to 0.000" | Rockwell B50 | 000000000 | 0000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

1095 Spring Steel

Tolerance | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

Ht. × Wd. | Tolerance Rating | Ht. | Wd. | Min. Hardness | Each | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

12" Long | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 1/8" × 3/16" | Standard | -0.001" to 0.001" | -0.001" to 0.001" | Rockwell B90 | 000000000 | 000000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 3/16" × 3/16" | Standard | -0.001" to 0.001" | -0.001" to 0.001" | Rockwell B90 | 000000000 | 0000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

36" Long | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 3/16" × 3/16" | Standard | -0.001" to 0.001" | -0.001" to 0.001" | Rockwell B90 | 000000000 | 00000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

18-8 Stainless Steel

|

Tolerance | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

Ht. × Wd. | Tolerance Rating | Ht. | Wd. | Min. Hardness | Each | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

12" Long | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 3/16" × 3/16" | Oversized | 0.000" to 0.003" | 0.000" to 0.003" | Rockwell B82 | 000000000 | 00000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 3/16" × 3/16" | Undersized | -0.002" to 0.000" | -0.002" to 0.000" | Rockwell B82 | 000000000 | 0000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

36" Long | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 3/16" × 3/16" | Undersized | -0.002" to 0.000" | -0.002" to 0.000" | Rockwell B82 | 000000000 | 00000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

316/316L Stainless Steel

|

Tolerance | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

Ht. × Wd. | Tolerance Rating | Ht. | Wd. | Min. Hardness | Each | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

12" Long | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 3/16" × 3/16" | Oversized | 0.000" to 0.002" | 0.000" to 0.002" | Not Rated | 000000000 | 000000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 3/16" × 3/16" | Undersized | -0.002" to 0.000" | -0.002" to 0.000" | Rockwell B86 | 000000000 | 0000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 1/4" × 3/16" | Oversized | 0.000" to 0.003" | 0.000" to 0.003" | Not Rated | 000000000 | 00000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

36" Long | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 3/16" × 3/16" | Undersized | -0.002" to 0.000" | -0.002" to 0.000" | Rockwell B86 | 000000000 | 00000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

6061 Aluminum

|

Tolerance | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

Ht. × Wd. | Tolerance Rating | Ht. | Wd. | Min. Hardness | Each | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

12" Long | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 3/16" × 3/16" | Standard | -0.008" to 0.008" | -0.008" to 0.008" | Not Rated | 000000000 | 000000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Acetal

Tolerance | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

Ht. × Wd. | Tolerance Rating | Ht. | Wd. | Min. Hardness | Each | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

12" Long | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 3/16" × 3/16" | Undersized | -0.003" to 0.000" | -0.003" to 0.000" | Durometer 85D | 000000000 | 000000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Nylon 6/6

Tolerance | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

Ht. × Wd. | Tolerance Rating | Ht. | Wd. | Min. Hardness | Each | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

12" Long | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 3/16" × 3/16" | Undersized | -0.003" to 0.000" | -0.003" to 0.000" | Durometer 80D | 000000000 | 000000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

PEEK

Tolerance | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

Ht. × Wd. | Tolerance Rating | Ht. | Wd. | Min. Hardness | Mil. Spec. | Each | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

12" Long | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 3/16" × 3/16" | Undersized | -0.003" to 0.000" | -0.003" to 0.000" | Durometer 85D | MIL-P-46183 Type 1 | 000000000 | 000000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Tapped Rounded Machine Keys

Tolerance | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

Lg. | Tolerance Rating | Ht. | Wd. | Min. Hardness | Thread Size | Specs. Met | Each | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

1018-1045 Carbon Steel | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

3/16" × 3/16" | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 1/2" | Oversized | 0.000" to 0.001" | 0.000" to 0.001" | Not Rated | 4-40 | ASME B17.1 Class 2 | 000000000 | 00000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 3/4" | Oversized | 0.000" to 0.001" | 0.000" to 0.001" | Not Rated | 4-40 | ASME B17.1 Class 2 | 000000000 | 0000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 1" | Oversized | 0.000" to 0.001" | 0.000" to 0.001" | Not Rated | 4-40 | ASME B17.1 Class 2 | 000000000 | 0000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 1 1/2" | Oversized | 0.000" to 0.001" | 0.000" to 0.001" | Not Rated | 4-40 | ASME B17.1 Class 2 | 000000000 | 0000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 1 3/4" | Oversized | 0.000" to 0.001" | 0.000" to 0.001" | Not Rated | 4-40 | ASME B17.1 Class 2 | 000000000 | 0000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 2" | Oversized | 0.000" to 0.001" | 0.000" to 0.001" | Not Rated | 4-40 | ASME B17.1 Class 2 | 000000000 | 0000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

High-Profile Woodruff Keys

Tolerance | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

Woodruff Key No. | Wd. | Ht. | For Keyway Dia. | Lg. | Wd. | Ht. | Feet Ht. | Pkg. Qty. | Pkg. | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

1018-1045 Carbon Steel | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 9 | 3/16" | 0.303" | 3/4" | 0.781" | 0.000" to 0.001" | 0.000" to 0.006" | 0.057" | 5 | 000000000 | 00000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 11 | 3/16" | 0.365" | 7/8" | 0.938" | 0.000" to 0.001" | 0.000" to 0.006" | 0.086" | 5 | 000000000 | 0000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 61 | 3/16" | 0.24" | 5/8" | 0.656" | 0.000" to 0.001" | 0.000" to 0.006" | 0.086" | 5 | 000000000 | 0000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

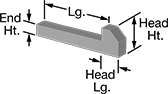

Tapered Gib Keys

Tolerance | Head | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

Lg. | Ht. | Wd. | Ht. | Lg. | End Ht. | Rate of Taper | Specs. Met | System of Measurement | Each | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

1018-1045 Carbon Steel | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

3/16" × 3/16" | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 1 1/2" | -0.002" to 0.000" | -0.002" to 0.000" | 5/16" | 9/32" | 0.174" | 1:96 | ASME B17.1 Class 1 | Inch | 000000000 | 00000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 2" | -0.002" to 0.000" | -0.002" to 0.000" | 5/16" | 9/32" | 0.169" | 1:96 | ASME B17.1 Class 1 | Inch | 000000000 | 0000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 3" | -0.002" to 0.000" | -0.002" to 0.000" | 5/16" | 9/32" | 0.158" | 1:96 | ASME B17.1 Class 1 | Inch | 000000000 | 0000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||