Wall-Mount Ladders

Mount these ladders to the wall for access to mezzanines, roofs, and other elevated areas. The first step is 9" off the floor.

304 stainless steel ladders resist corrosion and have a welded construction to minimize the collection of dust and debris, making them suitable for sanitary environments. Serrated steps give you maximum slip resistance.

Note: Ladders meet OSHA and Cal/OSHA dimensional and construction standards. Check local, state, and federal codes, including OSHA, for safe setup and operating practices.

Overall | Mounting Holes | |||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Max. Climbing Ht. | Ht. | Wd. | Wt., lbs. | No. of Steps | Step Shape | Step Tread | Projection | Mounting Hardware Included | No. of | Dia. | No. of Mounting Brackets | Specifications Met | Each | |

304 Stainless Steel | ||||||||||||||

350-lb. Capacity | ||||||||||||||

| 5'9" | 6' | 17" | 51 | 6 | Flat | Serrated | 7" | No | 2 | 7/16" | 2 | Cal/OSHA Compliant Title 8 Section 3277, OSHA Compliant 29 CFR 1910.23 | 000000000 | 0000000 |

| 7'9" | 8' | 17" | 65 | 8 | Flat | Serrated | 7" | No | 2 | 7/16" | 2 | Cal/OSHA Compliant Title 8 Section 3277, OSHA Compliant 29 CFR 1910.23 | 00000000 | 00000000 |

| 9'9" | 10' | 17" | 85 | 10 | Flat | Serrated | 7" | No | 2 | 7/16" | 2 | Cal/OSHA Compliant Title 8 Section 3277, OSHA Compliant 29 CFR 1910.23 | 00000000 | 00000000 |

| 11'9" | 12' | 17" | 100 | 12 | Flat | Serrated | 7" | No | 4 | 7/16" | 4 | Cal/OSHA Compliant Title 8 Section 3277, OSHA Compliant 29 CFR 1910.23 | 00000000 | 00000000 |

| 13'9" | 14' | 17" | 115 | 14 | Flat | Serrated | 7" | No | 4 | 7/16" | 4 | Cal/OSHA Compliant Title 8 Section 3277, OSHA Compliant 29 CFR 1910.23 | 00000000 | 00000000 |

| 15'9" | 16' | 17" | 130 | 16 | Flat | Serrated | 7" | No | 4 | 7/16" | 4 | Cal/OSHA Compliant Title 8 Section 3277, OSHA Compliant 29 CFR 1910.23 | 00000000 | 00000000 |

Wall-Mount Ladders with Grab Posts

Posts at the top of these ladders give you something to grab when you climb up and descend. Mount ladders to the wall for access to mezzanines, roofs, and other elevated areas.

Serrated steps provide maximum slip resistance.

304 stainless steel ladders resist corrosion and have a welded construction to minimize the collection of dust and debris, making them suitable for sanitary environments. Steps are serrated for maximum slip resistance.

Note: Ladders meet OSHA dimensional standards. Users are responsible for checking local, state, and federal codes, including OSHA, for safe installation and operating practices. Ladders also meet CAL-OSHA standards, which is required for use in California.

Overall | Mounting Holes | |||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Max. Climbing Ht. | Ht. | Wd. | Wt., lbs. | No. of Steps | Step Tread | Grab Post Ht. | Projection | Mounting Hardware Included | No. of | Dia. | No. of Mounting Brackets | Specifications Met | Each | |

304 Stainless Steel | ||||||||||||||

350-lb. Capacity | ||||||||||||||

| 7'9" | 11'3" | 25" | 90 | 8 | Serrated | 42" | 7" | No | 4 | 7/16" | 4 | OSHA Compliant 29 CFR 1910.23, Cal/OSHA Compliant Title 8 Section 3277 | 00000000 | 000000000 |

| 9'9" | 13'3" | 25" | 110 | 10 | Serrated | 42" | 7" | No | 4 | 7/16" | 4 | OSHA Compliant 29 CFR 1910.23, Cal/OSHA Compliant Title 8 Section 3277 | 00000000 | 00000000 |

| 11'9" | 15'3" | 25" | 125 | 12 | Serrated | 42" | 7" | No | 6 | 7/16" | 6 | OSHA Compliant 29 CFR 1910.23, Cal/OSHA Compliant Title 8 Section 3277 | 00000000 | 00000000 |

| 13'9" | 17'3" | 25" | 140 | 14 | Serrated | 42" | 7" | No | 6 | 7/16" | 6 | OSHA Compliant 29 CFR 1910.23, Cal/OSHA Compliant Title 8 Section 3277 | 00000000 | 00000000 |

| 15'9" | 19'3" | 25" | 155 | 16 | Serrated | 42" | 7" | No | 6 | 7/16" | 6 | OSHA Compliant 29 CFR 1910.23, Cal/OSHA Compliant Title 8 Section 3277 | 00000000 | 00000000 |

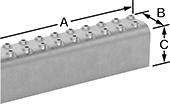

Ladder-Style Steps

Good for use as ladder rungs, cut these steps to size with a metal-cutting saw and weld them in place. For a clean weld, match the step material to the surface you are welding to. These steps must be welded at each end with welds capable of supporting the rated capacity. For those 5 ft. and longer, the maximum cut length is 24". Shorter lengths support higher capacities.

Serrated steps give you maximum slip resistance and allow liquids and debris to pass through. Perforated steps are less slip-resistant than serrated steps but offer a more comfortable hand grip.

Note: Check local, state, and federal codes, including OSHA, for safe set up and operating practices.

Overall | |||||

|---|---|---|---|---|---|

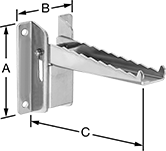

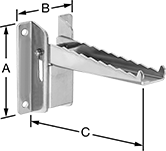

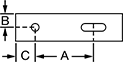

| Wd. (A) | Dp. (B) | Ht. (C) | Capacity | Each | |

304 Stainless Steel | |||||

With Serrated Tread | |||||

| 17" | 1 1/8" | 1 1/4" | 540 lbs. | 0000000 | 000000 |

| 7 ft. | 1 1/8" | 1 1/4" | 250 lbs. for 18"-24" Cut Lengths, 540 lbs. Up to 18" Cut Lengths | 000000 | 000000 |

With Perforated Tread | |||||

| 5 ft. | 1 1/4" | 1 1/2" | 230 lbs. for 18"-24" Cut Lengths, 300 lbs. Up to 18" Cut Lengths | 00000000 | 00000 |

| 5 ft. | 2 1/4" | 1 1/2" | 380 lbs. for 18"-24" Cut Lengths, 510 lbs. Up to 18" Cut Lengths | 00000000 | 000000 |

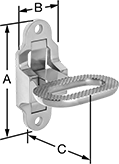

Fold-Up Steps

Flip these steps down when you need them and fold them up when you don’t. They can be bolted onto a stable surface, such as a wall. All steps have a diamond-plate or serrated tread for maximum slip resistance.

Style 1 have a cutout and rounded edges that you can grab with your hand if needed.

Stainless steel steps are corrosion resistant. 304 stainless steel steps have good chemical resistance.

Note: Check local, state, and federal codes, including OSHA, for safe operating practices.

Overall | Step | Mounting Holes | ||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

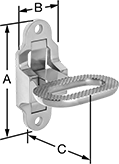

| Ht. (A) | Wd. (B) | Dp. (C) | Wd. | Dp. | Tread | Projection | Wt., lbs. | Cap. | Mounting Hardware Included | No. of | Dia. | Ctr.-to-Ctr. Ht. | Each | |

304 Stainless Steel | ||||||||||||||

| 4 3/4" | 1 3/4" | 3 3/4" | 4 3/8" | 2 1/8" | Diamond Plate | 3 3/4" | 2 | Not Rated | No | 2 | 5/16" | 3 7/8" | 0000000 | 000000 |

Overall | Step | Mounting Holes | |||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Ht. (A) | Wd. (B) | Dp. (C) | Wd. | Dp. | Tread | Projection | Wt., lbs. | Cap. | Mounting Hardware Included | No. of | Dia. | Ctr.-to-Ctr. Ht. | Ctr.-to-Ctr. Wd. | Each | |

304 Stainless Steel | |||||||||||||||

| 3 3/8" | 2 3/8" | 5 5/8" | 1" | 4 1/4" | Serrated | 5 5/8" | 1 | Not Rated | No | 4 | 3/16" | 2 5/8" | 1 3/4" | 0000000 | 000000 |

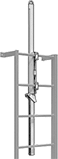

Ladder Support Posts

Add safety and convenience to your wall and tank ladders. Posts extend above the ladder top and lock in place to guide you and provide stability. A release lever lets you lower the post when it's not in use. Mount to the top two rungs of your ladder.

| Material | For Step Dia. | Max. Ctr.-to-Ctr. Step Ht. | Ht. Above Ladder | Height | Wd. | Dp. | Mounting Hardware Included | Wt., lbs. | Features | Each | |

| 304 Stainless Steel | 3/4"-1 1/4" | 14" | 42" | 42"-61 3/8" | 1 1/2" | 1 1/2" | Yes | 24 | Locking Mechanism, Lowering Release Lever | 0000000 | 000000000 |

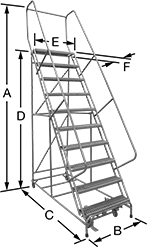

Corrosion-Resistant Rolling Platform Ladders

Made entirely of 304 stainless steel, these ladders are more corrosion resistant than aluminum. They'll withstand repeated washdowns, so they're good for use in food-service applications. Platform and steps are serrated for maximum slip resistance. Use the step lock to keep casters stationary.

You are responsible for adhering to local, state, and federal safety codes, including OSHA.

Note: The number of steps listed includes the platform.

Ladders | ||||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

Overall | Platform | Replacement Nonskid Pads | ||||||||||||||

| Ht. (A) | Wd. (B) | Dp. (C) | Ht. (D) | Wd. (E) | Dp. (F) | Max. Climbing Ht. | No. of Steps | Cap., lbs. | Ground Clearance Ht. | Wheel Configuration | Assembled or Unassembled | Specifications Met | Each | Each | ||

304 Stainless Steel Ladders with Step Lock | ||||||||||||||||

Serrated Steps and Platform | ||||||||||||||||

| 7'8" | 30" | 40" | 4'2" | 24" | 10" | 4'2" | 5 | 450 | 5" | Two Swivel and Two Rigid Casters | Assembled | OSHA Compliant 29 CFR 1910.23, Cal/OSHA Compliant Title 8 Section 3622, Cal/OSHA Compliant Title 8 Section 3627, ANSI A14.7 | 00000000 | 000000000 | 000000 | 00 |

| 9'4" | 30" | 53" | 5'10" | 24" | 10" | 5'10" | 7 | 450 | 5" | Two Swivel and Two Rigid Casters | Assembled | OSHA Compliant 29 CFR 1910.23, Cal/OSHA Compliant Title 8 Section 3622, Cal/OSHA Compliant Title 8 Section 3627, ANSI A14.7 | 00000000 | 00000000 | 000000 | 00 |

| 10'10" | 32" | 72" | 8'4" | 24" | 10" | 8'4" | 10 | 450 | 5" | Two Swivel and Two Rigid Casters | Assembled | OSHA Compliant 29 CFR 1910.23, ANSI A14.7 | 00000000 | 00000000 | 000000 | 00 |

| 11'10" | 42" | 72" | 8'4" | 26" | 10" | 8'4" | 10 | 450 | 5" | Two Swivel and Two Rigid Casters | Assembled | OSHA Compliant 29 CFR 1910.23, Cal/OSHA Compliant Title 8 Section 3622, Cal/OSHA Compliant Title 8 Section 3627, ANSI A14.7 | 00000000 | 00000000 | 00000000 | 000000 |

| 13'6" | 32" | 88" | 10' | 24" | 10" | 10' | 12 | 450 | 5" | Two Swivel and Two Rigid Casters | Unassembled | OSHA Compliant 29 CFR 1910.23, ANSI A14.7 | 00000000 | 00000000 | 000000 | 00 |

| 13'6" | 42" | 88" | 10' | 26" | 10" | 10' | 12 | 450 | 5" | Two Swivel and Two Rigid Casters | Unassembled | OSHA Compliant 29 CFR 1910.23, Cal/OSHA Compliant Title 8 Section 3622, Cal/OSHA Compliant Title 8 Section 3627, ANSI A14.7 | 00000000 | 00000000 | 00000000 | 00000 |

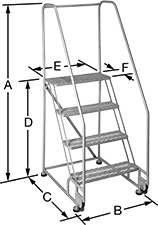

Corrosion-Resistant Tilt-to-Roll High-Stability Platform Ladders

Made entirely of 304 stainless steel, these ladders are more corrosion resistant than aluminum. Steps have a diamond texture, which provides good slip resistance and is more comfortable than serrated. Tilt these ladders to roll them on their wheels. When you set the ladders upright again, the wheels lift off the floor to keep ladders stationary while in use.

Note: The number of steps listed includes the platform.

Note: Ladders meet OSHA dimensional standards. Users are responsible for checking local, state, and federal codes, including OSHA, for safe operating practices. Ladders also meet CAL-OSHA standards, which is required for use in California.

Ladders | |||||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

Overall | Platform | Replacement Nonskid Pads | Replacement Wheels | ||||||||||||||

| Ht. (A) | Wd. (B) | Dp. (C) | Ht. (D) | Wd. (E) | Dp. (F) | Max. Climbing Ht. | No. of Steps | Cap., lbs. | Ground Clearance Ht. | Wheel Configuration | Specifications Met | Each | Each | Each | |||

304 Stainless Steel Ladders | |||||||||||||||||

Diamond Steps and Platform | |||||||||||||||||

| 5' | 28" | 30" | 2'6" | 24" | 10" | 2'6" | 3 | 450 | 2" | Two Rigid Casters | OSHA Compliant 29 CFR 1910.23, Cal/OSHA Compliant Title 8 Section 3622, Cal/OSHA Compliant Title 8 Section 3627, ANSI A14.7 | 0000000 | 000000000 | 00000000 | 000000 | 00000000 | 000000 |

| 5' | 28" | 40" | 2'6" | 24" | 20" | 2'6" | 3 | 450 | 2" | Two Rigid Casters | OSHA Compliant 29 CFR 1910.23, Cal/OSHA Compliant Title 8 Section 3622, Cal/OSHA Compliant Title 8 Section 3627, ANSI A14.7 | 0000000 | 00000000 | 00000000 | 00000 | 00000000 | 00000 |

| 5'10" | 28" | 37" | 3'4" | 24" | 10" | 3'4" | 4 | 450 | 2" | Two Rigid Casters | OSHA Compliant 29 CFR 1910.23, Cal/OSHA Compliant Title 8 Section 3622, Cal/OSHA Compliant Title 8 Section 3627, ANSI A14.7 | 0000000 | 00000000 | 00000000 | 00000 | 00000000 | 00000 |

| 5'10" | 28" | 46" | 3'4" | 24" | 20" | 3'4" | 4 | 450 | 2" | Two Rigid Casters | OSHA Compliant 29 CFR 1910.23, Cal/OSHA Compliant Title 8 Section 3622, Cal/OSHA Compliant Title 8 Section 3627, ANSI A14.7 | 0000000 | 00000000 | 00000000 | 00000 | 00000000 | 00000 |

| 7'8" | 28" | 54" | 4'2" | 24" | 20" | 4'2" | 5 | 450 | 2" | Two Rigid Casters | OSHA Compliant 29 CFR 1910.23, Cal/OSHA Compliant Title 8 Section 3622, Cal/OSHA Compliant Title 8 Section 3627, ANSI A14.7 | 0000000 | 00000000 | 00000000 | 00000 | 00000000 | 00000 |

Corrosion-Resistant Antifatigue Work Platforms

Designed for workstations that are frequently washed down, such as those in food processing plants, these platforms ease the strain of standing for long periods. They’re made from 304 stainless steel, so they resist corrosion in wet areas. The top is lined with soft vinyl foam to cushion your feet. Turn the legs to raise or lower the height of the platform.

Note: Work platforms meet OSHA and Cal/OSHA dimensional and construction standards. Users are responsible for checking local, state, and federal codes, including OSHA, for safe setup and operating practices.

Platforms | ||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

Overall | Top Step | Mat | Replacement Rubber Nonskid Feet | |||||||||||

| Wd. | Dp. | Wd. | Dp. | Cap., lbs. | Wt., lbs. | Material | Color | Assembled or Unassembled | Features | Specifications Met | Each | Pkg. | ||

304 Stainless Steel | ||||||||||||||

5"-8" Overall Ht. | ||||||||||||||

| 24" | 19" | 24" | 19" | 800 | 24 | Vinyl Foam | Black | Assembled | Nonskid Feet | OSHA Compliant 29 CFR 1910 Subpart D, Cal/OSHA Compliant Title 8 Section 3622, Cal/OSHA Compliant Title 8 Section 3627, ANSI A14.7 | 00000000 | 0000000 | 00000000 | 000000 |

| 24" | 24" | 24" | 24" | 800 | 28 | Vinyl Foam | Black | Assembled | Nonskid Feet | OSHA Compliant 29 CFR 1910 Subpart D, Cal/OSHA Compliant Title 8 Section 3622, Cal/OSHA Compliant Title 8 Section 3627, ANSI A14.7 | 00000000 | 000000 | 00000000 | 00000 |

| 36" | 19" | 36" | 19" | 800 | 34 | Vinyl Foam | Black | Assembled | Nonskid Feet | OSHA Compliant 29 CFR 1910 Subpart D, Cal/OSHA Compliant Title 8 Section 3622, Cal/OSHA Compliant Title 8 Section 3627, ANSI A14.7 | 00000000 | 000000 | 00000000 | 00000 |

| 36" | 24" | 36" | 24" | 800 | 39 | Vinyl Foam | Black | Assembled | Nonskid Feet | OSHA Compliant 29 CFR 1910 Subpart D, Cal/OSHA Compliant Title 8 Section 3622, Cal/OSHA Compliant Title 8 Section 3627, ANSI A14.7 | 00000000 | 000000 | 00000000 | 00000 |

9"-14" Overall Ht. | ||||||||||||||

| 24" | 19" | 24" | 19" | 800 | 27 | Vinyl Foam | Black | Assembled | Nonskid Feet | OSHA Compliant 29 CFR 1910 Subpart D, Cal/OSHA Compliant Title 8 Section 3622, Cal/OSHA Compliant Title 8 Section 3627, ANSI A14.7 | 00000000 | 000000 | 00000000 | 00000 |

| 24" | 24" | 24" | 24" | 800 | 31 | Vinyl Foam | Black | Assembled | Nonskid Feet | OSHA Compliant 29 CFR 1910 Subpart D, Cal/OSHA Compliant Title 8 Section 3622, Cal/OSHA Compliant Title 8 Section 3627, ANSI A14.7 | 00000000 | 000000 | 00000000 | 00000 |

| 36" | 19" | 36" | 19" | 800 | 36 | Vinyl Foam | Black | Assembled | Nonskid Feet | OSHA Compliant 29 CFR 1910 Subpart D, Cal/OSHA Compliant Title 8 Section 3622, Cal/OSHA Compliant Title 8 Section 3627, ANSI A14.7 | 00000000 | 000000 | 00000000 | 00000 |

| 36" | 24" | 36" | 24" | 800 | 41 | Vinyl Foam | Black | Assembled | Nonskid Feet | OSHA Compliant 29 CFR 1910 Subpart D, Cal/OSHA Compliant Title 8 Section 3622, Cal/OSHA Compliant Title 8 Section 3627, ANSI A14.7 | 00000000 | 000000 | 00000000 | 00000 |

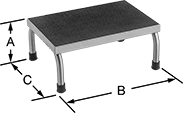

Step Stools

Get a secure and stable step up.

304 stainless steel stools stand up to repeated washdowns and resist damage from grease and chemicals.

Perforated, coated, and ribbed steps provide good slip resistance while being easy on your shoes. Note: Stools that have OSHA or Cal/OSHA specifications listed meet dimensional and construction standards. Check local, state, and federal codes, including OSHA, for safe set up and operating practices.

Overall | Top Step | Bottom Step | |||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Style | No. of Steps | Cap., lbs. | Ht. (A) | Wd. (B) | Dp. (C) | Ht. | Wd. | Dp. | Wd. | Dp. | Assembled or Unassembled | Features | Specifications Met | Each | |

304 Stainless Steel | |||||||||||||||

With Vinyl-Coated Steps | |||||||||||||||

| 7 | 1 | 375 | 8" | 14 1/2" | 11 1/2" | 7" | 14" | 10" | __ | __ | Assembled | Nonskid Feet | OSHA Compliant 29 CFR 1910.23 | 0000000 | 0000000 |

| 7 | 1 | 375 | 8" | 18" | 14" | 7" | 18" | 12" | __ | __ | Assembled | Nonskid Feet | OSHA Compliant 29 CFR 1910.23 | 0000000 | 000000 |

| 7 | 1 | 375 | 8" | 31" | 14" | 7" | 30" | 12" | __ | __ | Assembled | Nonskid Feet | OSHA Compliant 29 CFR 1910.23 | 0000000 | 000000 |

| 7 | 2 | 300 | 16" | 18" | 25" | 15" | 18" | 11 1/2" | 18" | 11 1/2" | Assembled | Nonskid Feet | OSHA Compliant 29 CFR 1910.23 | 0000000 | 000000 |

| Replacement Rubber Nonskid Feet for Style 7 Step Stools (Pkg. of 4) | 0000000 | Pkg. | 000000 |

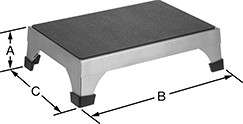

Stackable Step Stools

Stack these stools on top of each other to reach your ideal height. They lock together to create a stable platform while you work. Made of 304 stainless steel, they withstand repeated washdowns and won’t corrode in wet environments. Rubber-coated steps prevent slipping and are easy on your shoes.

Note: Check local, state, and federal codes, including OSHA, for safe set up and operating practices.

Overall | Top Step | ||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|

| No. of Steps | Cap., lbs. | Ht. (A) | Wd. (B) | Dp. (C) | Ht. | Wd. | Dp. | Assembled or Unassembled | Specifications Met | Each | |

304 Stainless Steel | |||||||||||

With Rubber-Coated Steps | |||||||||||

| 1 | 400 | 5" | 18" | 12" | 5" | 18" | 12" | Assembled | OSHA Compliant 29 CFR 1910.23 | 00000000 | 0000000 |

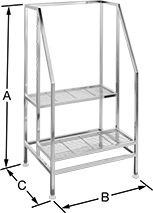

Clean Room Step Stools with Handrail

Designed for use in clean rooms, these step stools with a handrail are also used in other sanitary environments such as food-processing and pharmaceutical plants. Made of 304 stainless steel, they hold up to strong cleaners and sanitizers without corroding. Water flows easily through their bar grating steps when you wash them down. To account for uneven floors, adjust their nonskid leveling feet; these feet are nonmarring.

Electropolished stools are polished smooth to leave no crevices for bacteria growth and make cleaning easier.

Overall | Top Step | Bottom Step | |||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Number of Steps | Capacity, lbs. | Height (A) | Width (B) | Depth (C) | Height | Width | Depth | Width | Depth | Assembled or Unassembled | Environmental Rating | Each | |

304 Stainless Steel | |||||||||||||

With Bar Grating Steps | |||||||||||||

| 2 | 250 | 54" | 30" | 24" | 24" | 30" | 12 1/2" | 30" | 12 1/2" | Assembled | Fed. Std. Class 1,000 | 00000000 | 000000000 |

Electropolished 304 Stainless Steel | |||||||||||||

With Bar Grating Steps | |||||||||||||

| 2 | 250 | 54" | 30" | 24" | 24" | 30" | 12 1/2" | 30" | 12 1/2" | Assembled | Fed. Std. Class 100 | 00000000 | 00000000 |

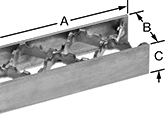

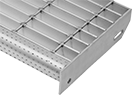

Metal Bar Grating Stair Treads

Choose these stair treads for greater durability than metal plank grating stair treads. They have an open surface that prevents debris from accumulating. Nosing is textured for traction.

Stainless steel treads have better corrosion resistance than steel or aluminum.

Drainage Opening | Mounting Hole | |||||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Wd. | Dp. | Ht. | Thick. | Bearing Bar Ht. | Wd. | Lg. | Load Capacity, lbs. | No. of | Dia. | Lg. | Wd. | Ctr.-to-Ctr. (A) | Ctr.-to-Tread Top (B) | Ctr.-to-Tread Nosing (C) | Mounting Hardware Included | For Use Outdoors | Each | |

Smooth | ||||||||||||||||||

304 Stainless Steel | ||||||||||||||||||

| 36" | 9 3/4" | 2 1/2" | 3/16" | 1 1/4" | 1" | 3 3/4" | 300 | 4 | 7/16" | 1 7/16" | 7/16" | 7" | 1 3/4" | 1 1/8" | No | Yes | 000000 | 0000000 |

| 36" | 10 15/16" | 2 1/2" | 3/16" | 1 1/4" | 1" | 3 3/4" | 300 | 4 | 7/16" | 1 7/16" | 7/16" | 7" | 1 3/4" | 1 1/8" | No | Yes | 000000 | 000000 |

| 36" | 12 1/8" | 2 1/2" | 3/16" | 1" | 1" | 3 3/4" | 300 | 4 | 7/16" | 1 7/16" | 7/16" | 7" | 1 3/4" | 1 1/8" | No | Yes | 000000 | 000000 |

| 36" | 12 1/8" | 2 1/2" | 3/16" | 1 1/4" | 1" | 3 3/4" | 300 | 4 | 7/16" | 1 7/16" | 7/16" | 7" | 1 3/4" | 1 1/8" | No | Yes | 000000 | 000000 |

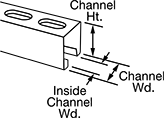

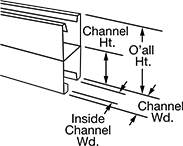

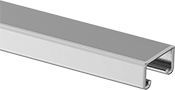

Strut Channel

304 stainless steel channel is more corrosion resistant than galvanized steel. It also has good chemical resistance.

6'8" length channel is for use with beams spaced 6 ft. apart. The length allows 4" on each end to attach the channel to the beam.

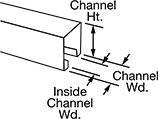

Low-Profile Strut Channel

Half the height and the same width as regular strut channel, this low-profile strut channel fits into tight spots and is compatible with many of the same brackets.

304 stainless steel channel is more corrosion resistant than galvanized steel. It also has good chemical resistance.

6'8" length channel is for use with beams spaced 6 ft. apart. The length allows 4" on each end to attach the channel to the beam.

Extra Low-Profile Strut Channel

Run cable and tubing in the tightest spaces with channel that is one-quarter the height and one-half the width of regular strut channel.

304 stainless steel channel has better corrosion resistance than zinc-plated steel. It also has good chemical resistance.

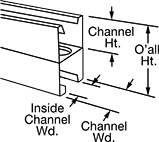

Back-to-Back Stacked Strut Channel

This welded, one-piece strut channel combines two strut channels back-to-back.

304 stainless steel channel is more corrosion resistant than galvanized steel. It also has good chemical resistance.

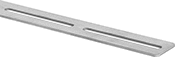

Food Industry Strut Rails

A flat or half-round shape keeps water from pooling on these strut rails. Unlike a traditional C-shape strut, these rails prevent the buildup of bacteria and debris, making them ideal for use in sanitary or food production environments. Made of stainless steel, they’re more corrosion resistant than zinc-plated and galvanized steel rails. They also have good chemical resistance.

Flat rails can be mounted on walls horizontally or vertically.

Half-round rails are dome-shaped, so they protect threads.