Filter by

Anchor Type

Length

Thread Length

Connection Hardware

Overall Length

Ultimate Pull-Out Strength

DFARS Specialty Metals

Export Control Classification Number (ECCN)

Performance

Conditions Tested In

Ultimate Shear Strength

Lag Anchors for Block and Brick

Ultimate Strength, lbf | |||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|

For Screw Size | Lg. | Drill Bit Size | Min. Installation Dp. | Material | Pull-Out | Shear | Conditions Tested In | Pkg. Qty. | Pkg. | ||

| 1/4" | 1" | 1/2" | 1" | Zinc | 240 | 1,000 | 4,000 psi Concrete | 10 | 97040A029 | 00000 | |

| 1/4" | 1 1/2" | 1/2" | 1 1/2" | Zinc | 300 | 1,000 | 4,000 psi Concrete | 10 | 97039A029 | 0000 | |

| 5/16" | 1 1/4" | 1/2" | 1 1/4" | Zinc | 480 | 1,080 | 4,000 psi Concrete | 10 | 97040A030 | 0000 | |

| 5/16" | 1 3/4" | 1/2" | 1 3/4" | Zinc | 520 | 1,080 | 4,000 psi Concrete | 10 | 97039A030 | 0000 | |

| 3/8" | 1 3/4" | 5/8" | 1 3/4" | Zinc | 840 | 1,400 | 4,000 psi Concrete | 10 | 97040A031 | 00000 | |

| 3/8" | 2 1/2" | 5/8" | 2 1/2" | Zinc | 1,000 | 1,400 | 4,000 psi Concrete | 10 | 97039A031 | 00000 | |

| 1/2" | 2" | 3/4" | 2" | Zinc | 1,080 | 1,600 | 4,000 psi Concrete | 5 | 97040A033 | 0000 | |

| 1/2" | 3" | 3/4" | 3" | Zinc | 2,080 | 1,600 | 4,000 psi Concrete | 5 | 97039A033 | 00000 | |

| 5/8" | 2" | 7/8" | 2" | Zinc | 1,200 | 2,200 | 4,000 psi Concrete | 4 | 97040A035 | 0000 | |

| 5/8" | 3 1/2" | 7/8" | 3 1/2" | Zinc | 2,600 | 2,200 | 4,000 psi Concrete | 4 | 97039A035 | 00000 | |

| 3/4" | 3 1/2" | 1" | 3 1/2" | Zinc | 2,800 | 2,400 | 4,000 psi Concrete | 4 | 97039A036 | 00000 | |

High-Strength Anchors for Block and Brick

|

Ultimate Strength, lbf | |||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|

Thread Size | Lg. | Drill Bit Size | Min. Installation Dp. | Material | Pull-Out | Shear | Conditions Tested In | Pkg. Qty. | Pkg. | ||

| 1/4"-20 | 1 1/4" | 1/2" | 1 1/4" | Zinc | 2,320 | 2,080 | 3,000 psi Concrete | 10 | 92915A110 | 000000 | |

| 5/16"-18 | 1 1/2" | 9/16" | 1 1/2" | Zinc | 2,600 | 3,280 | 3,000 psi Concrete | 10 | 92915A120 | 00000 | |

| 3/8"-16 | 1 3/4" | 11/16" | 1 3/4" | Zinc | 3,600 | 3,840 | 3,000 psi Concrete | 10 | 92915A130 | 00000 | |

| 1/2"-13 | 2 1/4" | 7/8" | 2 1/4" | Zinc | 4,800 | 8,000 | 3,000 psi Concrete | 4 | 92915A140 | 00000 | |

| 5/8"-11 | 2 5/8" | 1 1/8" | 2 5/8" | Zinc | 5,600 | 14,000 | 3,000 psi Concrete | 1 | 92915A150 | 0000 | |

| 3/4"-10 | 3 1/8" | 1 1/4" | 3 1/8" | Zinc | 9,600 | 15,200 | 3,000 psi Concrete | 1 | 92915A160 | 00000 | |

Anchors for Block and Brick

Ultimate Strength, lbf | |||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|

Thread Size | Lg. | Drill Bit Size | Min. Installation Dp. | Material | Pull-Out | Shear | Conditions Tested In | Pkg. Qty. | Pkg. | ||

| 1/4"-20 | 1 3/8" | 1/2" | 1 1/4" | Zinc | 880 | 1,080 | 4,000 psi Concrete | 10 | 97031A039 | 00000 | |

| 5/16"-18 | 1 5/8" | 5/8" | 1 1/2" | Zinc | 1,480 | 2,000 | 4,000 psi Concrete | 10 | 97031A040 | 0000 | |

| 3/8"-16 | 2" | 3/4" | 1 3/4" | Zinc | 2,000 | 3,000 | 4,000 psi Concrete | 5 | 97031A041 | 00000 | |

| 1/2"-13 | 2 1/2" | 7/8" | 2 1/4" | Zinc | 3,480 | 4,000 | 4,000 psi Concrete | 1 | 97031A043 | 0000 | |

| 5/8"-11 | 2 3/4" | 1" | 2 1/2" | Zinc | 6,000 | 10,000 | 4,000 psi Concrete | 4 | 97031A045 | 0000 | |

| 3/4"-10 | 3 15/16" | 1 1/4" | 3 1/2" | Zinc | 8,000 | 13,200 | 4,000 psi Concrete | 1 | 97031A046 | 0000 | |

Wood Screw-Style Hangers

Hanger Bolts | Driver Bits | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

Head | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Screw Size | Lg. | Threading | Thread Lg. | Eye Dia. | Wd. | Thk. | Ht. | Max. Wt. Cap. | For Use In | Specs. Met | Pkg. Qty. | Pkg. | Each | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Zinc-Plated Steel | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 1/4" | 6" | Partially Threaded | 1 1/2" | 3/16" | 13/32" | 3/32" | 23/32" | Not Rated | Wood | — | 25 | 95396A111 | 000000 | 5977A42 | 000000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Zinc-Yellow-Chromate-Plated Steel | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 1/4" | 3" | Partially Threaded | 1 1/2" | 3/16" | 13/32" | 3/32" | 23/32" | Not Rated | Wood | ASME B18.2.1, ASTM B633 | 50 | 90171A554 | 00000 | 5977A42 | 00000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 1/4" | 4" | Partially Threaded | 1 1/2" | 3/16" | 13/32" | 3/32" | 23/32" | Not Rated | Wood | ASME B18.2.1, ASTM B633 | 25 | 90171A558 | 00000 | 5977A42 | 00000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 1/4" | 5" | Partially Threaded | 1 1/2" | 3/16" | 13/32" | 3/32" | 23/32" | Not Rated | Wood | ASME B18.2.1, ASTM B633 | 25 | 90171A562 | 00000 | 5977A42 | 00000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 5/16" | 3 1/2" | Partially Threaded | 1 3/4" | 1/4" | 7/16" | 3/32" | 9/16" | Not Rated | Wood | ASME B18.2.1, ASTM B633 | 25 | 90171A597 | 00000 | 5977A43 | 00000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

316 Stainless Steel | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 1/4" | 3" | Partially Threaded | 1 1/2" | 3/16" | 13/32" | 3/32" | 23/32" | Not Rated | Wood | — | 25 | 95396A112 | 00000 | 5977A42 | 00000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

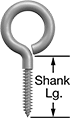

Routing Eyebolts for Wood—Not for Lifting

Zinc-Plated Steel

Without Shoulder | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

Eyebolt Trade Size | Wire Dia. | Thread Lg. | Shank Lg. | Eye Dia. | Threading | Overall Lg. | Pkg. Qty. | Pkg. | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Bent-Closed Eye | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| — | 1/4" | 1 1/2" | 2 3/4" | 1/2" | Partially Threaded | 3 3/4" | 10 | 9589T1 | 00000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| — | 1/4" | 1 1/2" | 4" | 1/2" | Partially Threaded | 5" | 10 | 9496T41 | 0000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| — | 5/16" | 1 5/8" | 2 3/4" | 5/8" | Partially Threaded | 4" | 10 | 9589T2 | 00000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| — | 5/16" | 1 5/8" | 4 3/4" | 5/8" | Partially Threaded | 6" | 5 | 9496T42 | 0000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| — | 23/64" | 2" | 3 1/16" | 3/4" | Partially Threaded | 4 1/2" | 10 | 9589T3 | 00000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 214 1/2 | 5/64" | 3/16" | 3/8" | 1/8" | Partially Threaded | 5/8" | 50 | 9496T36 | 0000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 214 | 5/64" | 3/8" | 1/2" | 1/8" | Partially Threaded | 3/4" | 50 | 9496T35 | 0000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 212 1/2 | 7/64" | 5/16" | 3/8" | 3/16" | Partially Threaded | 3/4" | 50 | 9496T34 | 0000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 212 | 7/64" | 7/16" | 9/16" | 3/16" | Partially Threaded | 7/8" | 50 | 9496T33 | 0000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 210 | 9/64" | 9/16" | 11/16" | 3/16" | Partially Threaded | 1 1/8" | 50 | 9496T32 | 0000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 208 | 5/32" | 11/16" | 13/16" | 3/16" | Partially Threaded | 1 3/8" | 50 | 9496T31 | 00000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 206 | 3/16" | 3/4" | 1" | 1/4" | Partially Threaded | 1 5/8" | 50 | 9496T29 | 00000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 204 | 7/32" | 15/16" | 1 1/8" | 1/4" | Partially Threaded | 1 7/8" | 20 | 9496T28 | 0000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 114 | 5/64" | 3/8" | 1/2" | 1/4" | Partially Threaded | 7/8" | 50 | 9496T27 | 0000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 112 | 7/64" | 7/16" | 9/16" | 1/4" | Partially Threaded | 1 1/8" | 50 | 9496T26 | 0000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 110 | 9/64" | 9/16" | 11/16" | 5/16" | Partially Threaded | 1 1/4" | 50 | 9496T25 | 0000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 108 | 5/32" | 11/16" | 13/16" | 3/8" | Partially Threaded | 1 1/2" | 50 | 9496T24 | 00000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 106 | 3/16" | 3/4" | 1" | 7/16" | Partially Threaded | 1 3/4" | 50 | 9496T23 | 00000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 104 | 7/32" | 15/16" | 1 1/8" | 7/16" | Partially Threaded | 2" | 20 | 9496T22 | 0000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 14 | 5/64" | 3/8" | 1/2" | 5/16" | Partially Threaded | 1" | 50 | 9496T21 | 0000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 12 | 7/64" | 7/16" | 9/16" | 3/8" | Partially Threaded | 1 1/8" | 50 | 9496T19 | 0000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 10 | 9/64" | 9/16" | 11/16" | 3/8" | Partially Threaded | 1 3/8" | 50 | 9496T18 | 0000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 9 | 9/64" | 5/8" | 3/4" | 7/16" | Partially Threaded | 1 1/2" | 50 | 9496T17 | 00000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 8 | 5/32" | 11/16" | 13/16" | 7/16" | Partially Threaded | 1 5/8" | 50 | 9496T16 | 00000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 6 | 3/16" | 3/4" | 1" | 1/2" | Partially Threaded | 1 7/8" | 50 | 9496T15 | 00000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 4 | 7/32" | 15/16" | 1 1/8" | 9/16" | Partially Threaded | 2 1/8" | 20 | 9496T14 | 00000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 2 | 17/64" | 1 1/8" | 1 5/16" | 11/16" | Partially Threaded | 2 5/8" | 10 | 9496T13 | 0000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 0 | 5/16" | 1 1/4" | 1 9/16" | 13/16" | Partially Threaded | 2 7/8" | 10 | 9496T12 | 00000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 000 | 23/64" | 1 5/8" | 2 1/16" | 1 1/8" | Partially Threaded | 3 7/8" | 10 | 9496T11 | 00000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Brass

Without Shoulder | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

Eyebolt Trade Size | Wire Dia. | Thread Lg. | Shank Lg. | Eye Dia. | Threading | Overall Lg. | Pkg. Qty. | Pkg. | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Bent-Closed Eye | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 214 1/2 | 5/64" | 3/16" | 5/16" | 1/8" | Partially Threaded | 5/8" | 50 | 9497T57 | 000000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 214 | 5/64" | 3/8" | 1/2" | 1/8" | Partially Threaded | 13/16" | 50 | 9497T51 | 00000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 212 1/2 | 7/64" | 5/16" | 3/8" | 3/16" | Partially Threaded | 3/4" | 50 | 9497T58 | 00000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 212 | 7/64" | 7/16" | 9/16" | 3/16" | Partially Threaded | 15/16" | 50 | 9497T52 | 00000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 210 | 9/64" | 9/16" | 11/16" | 3/16" | Partially Threaded | 1 3/16" | 25 | 9497T53 | 00000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 208 | 5/32" | 11/16" | 13/16" | 1/4" | Partially Threaded | 1 3/8" | 20 | 9497T54 | 00000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 206 | 3/16" | 3/4" | 1" | 1/4" | Partially Threaded | 1 5/8" | 10 | 9497T55 | 0000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 204 | 7/32" | 15/16" | 1 1/8" | 5/16" | Partially Threaded | 1 15/16" | 10 | 9497T56 | 00000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 114 | 5/64" | 3/8" | 1/2" | 1/4" | Partially Threaded | 15/16" | 50 | 9497T41 | 00000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 112 | 7/64" | 7/16" | 9/16" | 9/32" | Partially Threaded | 1 1/8" | 50 | 9497T42 | 00000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 110 | 9/64" | 9/16" | 11/16" | 5/16" | Partially Threaded | 1 5/16" | 25 | 9497T43 | 00000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 108 | 5/32" | 11/16" | 13/16" | 25/64" | Partially Threaded | 1 9/16" | 20 | 9497T44 | 00000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 106 | 3/16" | 3/4" | 1" | 7/16" | Partially Threaded | 1 13/16" | 10 | 9497T45 | 00000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 104 | 7/32" | 15/16" | 1 1/8" | 31/64" | Partially Threaded | 2 1/16" | 10 | 9497T46 | 00000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 14 | 5/64" | 3/8" | 1/2" | 5/16" | Partially Threaded | 1 1/16" | 50 | 9497T31 | 00000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 12 | 7/64" | 7/16" | 9/16" | 3/8" | Partially Threaded | 1 3/16" | 25 | 9497T32 | 00000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 10 | 9/64" | 9/16" | 11/16" | 3/8" | Partially Threaded | 1 3/8" | 25 | 9497T33 | 00000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 9 | 9/64" | 5/8" | 3/4" | 7/16" | Partially Threaded | 1 9/16" | 20 | 9497T34 | 00000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 8 | 5/32" | 11/16" | 13/16" | 7/16" | Partially Threaded | 1 5/8" | 20 | 9497T35 | 00000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 6 | 3/16" | 3/4" | 1" | 1/2" | Partially Threaded | 1 15/16" | 10 | 9497T36 | 00000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 4 | 7/32" | 15/16" | 1 1/8" | 9/16" | Partially Threaded | 2 3/16" | 5 | 9497T37 | 0000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 2 | 17/64" | 1 1/8" | 1 5/16" | 11/16" | Partially Threaded | 2 5/8" | 5 | 9497T38 | 00000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 0 | 5/16" | 1 1/4" | 1 9/16" | 13/16" | Partially Threaded | 2 7/8" | 1 | 9497T39 | 0000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

300 Series Stainless Steel

Without Shoulder | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

Eyebolt Trade Size | Wire Dia. | Thread Lg. | Shank Lg. | Eye Dia. | Threading | Overall Lg. | Pkg. Qty. | Pkg. | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Bent-Closed Eye | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| — | 1/4" | 1 5/16" | 2 3/4" | 1/2" | Partially Threaded | 3 3/4" | 5 | 30455T61 | 000000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| — | 1/4" | 1 7/8" | 4" | 1/2" | Partially Threaded | 5" | 5 | 30455T62 | 00000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| — | 5/16" | 1 3/4" | 2 3/4" | 5/8" | Partially Threaded | 4" | 5 | 30455T63 | 00000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| — | 5/16" | 1 3/4" | 4 3/4" | 5/8" | Partially Threaded | 6" | 1 | 30455T51 | 0000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| — | 3/8" | 1 3/4" | 2 3/4" | 3/4" | Partially Threaded | 4 1/4" | 1 | 30455T52 | 0000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 214 1/2 | 5/64" | 3/16" | 3/8" | 1/8" | Partially Threaded | 5/8" | 25 | 30425T21 | 00000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 214 | 5/64" | 3/8" | 1/2" | 1/8" | Partially Threaded | 3/4" | 25 | 30425T22 | 00000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 212 1/2 | 7/64" | 5/16" | 3/8" | 3/16" | Partially Threaded | 3/4" | 25 | 30425T23 | 00000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 212 | 7/64" | 7/16" | 9/16" | 3/16" | Partially Threaded | 7/8" | 25 | 30425T24 | 00000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 210 | 9/64" | 9/16" | 11/16" | 3/16" | Partially Threaded | 1 1/8" | 25 | 30425T25 | 00000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 208 | 5/32" | 11/16" | 13/16" | 3/16" | Partially Threaded | 1 3/8" | 20 | 30425T26 | 00000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 206 | 3/16" | 3/4" | 1" | 1/4" | Partially Threaded | 1 5/8" | 10 | 30425T27 | 00000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 204 | 7/32" | 15/16" | 1 1/8" | 1/4" | Partially Threaded | 1 7/8" | 5 | 30425T28 | 00000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 114 | 5/64" | 3/8" | 1/2" | 1/4" | Partially Threaded | 7/8" | 25 | 30425T29 | 00000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 112 | 7/64" | 7/16" | 9/16" | 1/4" | Partially Threaded | 1 1/8" | 25 | 30425T31 | 00000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 110 | 9/64" | 9/16" | 11/16" | 5/16" | Partially Threaded | 1 1/4" | 25 | 30425T32 | 00000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 108 | 5/32" | 11/16" | 13/16" | 3/8" | Partially Threaded | 1 1/2" | 10 | 30425T33 | 00000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 106 | 3/16" | 3/4" | 1" | 7/16" | Partially Threaded | 1 3/4" | 10 | 30425T34 | 00000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 104 | 7/32" | 15/16" | 1 1/8" | 7/16" | Partially Threaded | 2" | 5 | 30425T35 | 0000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 14 | 5/64" | 3/8" | 1/2" | 5/16" | Partially Threaded | 1" | 25 | 30425T36 | 00000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 12 | 7/64" | 7/16" | 9/16" | 3/8" | Partially Threaded | 1 1/8" | 25 | 30425T37 | 00000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 10 | 9/64" | 9/16" | 11/16" | 3/8" | Partially Threaded | 1 3/8" | 25 | 30425T38 | 00000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 9 | 9/64" | 5/8" | 3/4" | 7/16" | Partially Threaded | 1 1/2" | 20 | 30425T39 | 00000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 8 | 5/32" | 11/16" | 13/16" | 7/16" | Partially Threaded | 1 5/8" | 20 | 30425T17 | 00000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 6 | 3/16" | 3/4" | 1" | 1/2" | Partially Threaded | 1 7/8" | 10 | 30425T41 | 00000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 4 | 7/32" | 15/16" | 1 1/8" | 9/16" | Partially Threaded | 2 1/8" | 10 | 30425T18 | 00000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 2 | 17/64" | 1 1/8" | 1 5/16" | 11/16" | Partially Threaded | 2 5/8" | 5 | 30425T42 | 00000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 0 | 5/16" | 1 1/4" | 1 9/16" | 13/16" | Partially Threaded | 2 7/8" | 5 | 30425T19 | 00000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 000 | 23/64" | 1 5/8" | 2 1/16" | 1 1/8" | Partially Threaded | 3 7/8" | 1 | 30425T43 | 0000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Anchors for Hollow Block and Brick

Ultimate Strength, lbf | |||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

Thread Size | Lg. | Drill Bit Size | Min. Installation Dp. | Sleeve Material | Material | Pull-Out | Shear | Conditions Tested In | Certification | Pkg. Qty. | Pkg. | ||

| 1/4"-20 | 7/8" | 3/8" | 3/4" | Zinc Alloy | Steel | 1,080 | 1,200 | 4,000 psi Concrete | — | 5 | 97016A972 | 000000 | |

| 1/4"-20 | 7/8" | 3/8" | 3/4" | 304 Stainless Steel | Steel | 1,040 | 1,200 | 4,000 psi Concrete | — | 1 | 97016A977 | 0000 | |

| 5/16"-18 | 1 5/16" | 5/8" | 1" | Zinc Alloy | Steel | 1,600 | 1,880 | 4,000 psi Concrete | — | 5 | 97016A973 | 00000 | |

| 3/8"-16 | 1 5/16" | 5/8" | 1" | Zinc Alloy | Steel | 2,000 | 2,480 | 4,000 psi Concrete | FM Approved, UL Listed | 5 | 97016A974 | 00000 | |

| 3/8"-16 | 1 5/16" | 5/8" | 1" | 304 Stainless Steel | Steel | 1,800 | 2,480 | 4,000 psi Concrete | — | 1 | 97016A978 | 0000 | |

| 1/2"-13 | 1 3/4" | 3/4" | 1 1/2" | Zinc Alloy | Steel | 4,000 | 4,000 | 4,000 psi Concrete | FM Approved, UL Listed | 1 | 97016A975 | 0000 | |

| 5/8"-11 | 2" | 1" | 2 1/4" | Zinc Alloy | Steel | 9,200 | 6,400 | 4,000 psi Concrete | FM Approved, UL Listed | 1 | 97016A976 | 0000 | |

Screw Eyes

|

Zinc-Plated Steel

Wire Dia. | Projection | Overall Ht. | Thread Lg. | Pkg. Qty. | Pkg. | |||

|---|---|---|---|---|---|---|---|---|

| 0.063" | 7/16" | 5/16" | 1/4" | 14 | 1311T18 | 00000 | ||