Filter by

System of Measurement

Material

Tip Type

Thread Size

Thread Length

Specifications Met

Approximate Threads per Inch

Export Control Classification Number (ECCN)

DFARS Specialty Metals

Thread Type

Flange Diameter

Anchor Type

Tensile Strength

Steel Hex Head Wood Screws

|

Lg. | Head Ht. | Approx. Threads per In. | Threading | Tapping Method | Specs. Met | Pkg. Qty. | Pkg. | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

Black-Oxide Steel | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

5/16" | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 1" | 0.219" | 9 | Fully Threaded | Thread Forming | ASME B18.2.1 | 10 | 95452A113 | 00000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 1 1/4" | 0.219" | 9 | Fully Threaded | Thread Forming | ASME B18.2.1 | 10 | 95452A114 | 0000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 1 1/2" | 0.219" | 9 | Partially Threaded | Thread Forming | ASME B18.2.1 | 10 | 95452A115 | 0000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 1 3/4" | 0.219" | 9 | Partially Threaded | Thread Forming | ASME B18.2.1 | 10 | 95452A116 | 0000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 2" | 0.219" | 9 | Partially Threaded | Thread Forming | ASME B18.2.1 | 5 | 95452A117 | 0000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 2 1/2" | 0.219" | 9 | Partially Threaded | Thread Forming | ASME B18.2.1 | 5 | 95452A118 | 0000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 3" | 0.219" | 9 | Partially Threaded | Thread Forming | ASME B18.2.1 | 5 | 95452A119 | 0000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 3 1/2" | 0.219" | 9 | Partially Threaded | Thread Forming | ASME B18.2.1 | 5 | 95452A120 | 0000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 4" | 0.219" | 9 | Partially Threaded | Thread Forming | ASME B18.2.1 | 1 | 95452A121 | 0000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 4 1/2" | 0.219" | 9 | Partially Threaded | Thread Forming | ASME B18.2.1 | 1 | 95452A122 | 0000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 5" | 0.219" | 9 | Partially Threaded | Thread Forming | ASME B18.2.1 | 1 | 95452A123 | 0000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 5 1/2" | 0.219" | 9 | Partially Threaded | Thread Forming | ASME B18.2.1 | 1 | 95452A124 | 0000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 6" | 0.219" | 9 | Partially Threaded | Thread Forming | ASME B18.2.1 | 1 | 95452A125 | 0000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Zinc-Plated Steel | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

5/16" | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 1" | 0.219" | 9 | Fully Threaded | Thread Forming | ASME B18.2.1 | 100 | 91478A583 | 00000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 1 1/4" | 0.219" | 9 | Fully Threaded | Thread Forming | ASME B18.2.1 | 100 | 91478A585 | 00000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 1 1/2" | 0.219" | 9 | Partially Threaded | Thread Forming | ASME B18.2.1 | 100 | 91478A587 | 00000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 1 3/4" | 0.219" | 9 | Partially Threaded | Thread Forming | ASME B18.2.1 | 50 | 91478A588 | 00000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 2" | 0.219" | 9 | Partially Threaded | Thread Forming | ASME B18.2.1 | 50 | 91478A591 | 00000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 2 1/2" | 0.219" | 9 | Partially Threaded | Thread Forming | ASME B18.2.1 | 50 | 91478A593 | 00000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 3" | 0.219" | 9 | Partially Threaded | Thread Forming | ASME B18.2.1 | 50 | 91478A595 | 00000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 3 1/2" | 0.219" | 9 | Partially Threaded | Thread Forming | ASME B18.2.1 | 50 | 91478A597 | 00000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 4" | 0.219" | 9 | Partially Threaded | Thread Forming | ASME B18.2.1 | 25 | 91478A599 | 00000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 5" | 0.219" | 9 | Partially Threaded | Thread Forming | ASME B18.2.1 | 25 | 91478A603 | 00000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 6" | 0.219" | 9 | Partially Threaded | Thread Forming | ASME B18.2.1 | 25 | 91478A607 | 00000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Black-Zinc-Plated Steel | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

5/16" | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 1 1/2" | 0.219" | 9 | Partially Threaded | Thread Forming | ASME B18.2.1 | 50 | 92371A521 | 00000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 2" | 0.219" | 9 | Partially Threaded | Thread Forming | ASME B18.2.1 | 50 | 92371A525 | 00000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 2 1/2" | 0.219" | 9 | Partially Threaded | Thread Forming | ASME B18.2.1 | 50 | 92371A529 | 00000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 3" | 0.219" | 9 | Partially Threaded | Thread Forming | ASME B18.2.1 | 25 | 92371A533 | 00000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Hot-Dipped Galvanized Steel | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

5/16" | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 1" | 0.219" | 9 | Partially Threaded | Thread Forming | ASME B18.2.1, ASTM A307, SAE J429 | 50 | 94048A248 | 00000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 1 1/4" | 0.219" | 9 | Partially Threaded | Thread Forming | ASME B18.2.1, ASTM A307, SAE J429 | 50 | 94048A251 | 00000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 1 1/2" | 0.219" | 9 | Partially Threaded | Thread Forming | ASME B18.2.1, ASTM A307, SAE J429 | 50 | 94048A254 | 00000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 2" | 0.219" | 9 | Partially Threaded | Thread Forming | ASME B18.2.1, ASTM A307, SAE J429 | 50 | 94048A257 | 00000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 2 1/2" | 0.219" | 9 | Partially Threaded | Thread Forming | ASME B18.2.1, ASTM A307, SAE J429 | 50 | 94048A260 | 00000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 3" | 0.219" | 9 | Partially Threaded | Thread Forming | ASME B18.2.1, ASTM A307, SAE J429 | 50 | 94048A263 | 00000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 3 1/2" | 0.219" | 9 | Partially Threaded | Thread Forming | ASME B18.2.1, ASTM A307, SAE J429 | 25 | 94048A266 | 00000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 4" | 0.219" | 9 | Partially Threaded | Thread Forming | ASME B18.2.1, ASTM A307, SAE J429 | 25 | 94048A269 | 00000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 4 1/2" | 0.219" | 9 | Partially Threaded | Thread Forming | ASME B18.2.1, ASTM A307, SAE J429 | 25 | 94048A274 | 00000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 5" | 0.219" | 9 | Partially Threaded | Thread Forming | ASME B18.2.1, ASTM A307, SAE J429 | 25 | 94048A275 | 00000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 6" | 0.219" | 9 | Partially Threaded | Thread Forming | ASME B18.2.1, ASTM A307, SAE J429 | 25 | 94048A278 | 00000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Stainless Steel Hex Head Wood Screws

|

Lg. | Head Ht. | Approx. Threads per In. | Threading | Tapping Method | Specs. Met | Pkg. Qty. | Pkg. | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

18-8 Stainless Steel | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

5/16" | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 1" | 0.219" | 9 | Partially Threaded | Thread Forming | ASME B18.2.1 | 25 | 92351A583 | 00000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 1 1/4" | 0.219" | 9 | Partially Threaded | Thread Forming | ASME B18.2.1 | 25 | 92351A585 | 00000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 1 1/2" | 0.219" | 9 | Partially Threaded | Thread Forming | ASME B18.2.1 | 25 | 92351A587 | 00000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 1 3/4" | 0.219" | 9 | Partially Threaded | Thread Forming | ASME B18.2.1 | 10 | 92351A588 | 0000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 2" | 0.219" | 9 | Partially Threaded | Thread Forming | ASME B18.2.1 | 10 | 92351A591 | 0000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 2 1/2" | 0.219" | 9 | Partially Threaded | Thread Forming | ASME B18.2.1 | 10 | 92351A593 | 0000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 3" | 0.219" | 9 | Partially Threaded | Thread Forming | ASME B18.2.1 | 10 | 92351A595 | 0000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 3 1/2" | 0.219" | 9 | Partially Threaded | Thread Forming | ASME B18.2.1 | 10 | 92351A597 | 0000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 4" | 0.219" | 9 | Partially Threaded | Thread Forming | ASME B18.2.1 | 10 | 92351A599 | 00000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 4 1/2" | 0.219" | 9 | Partially Threaded | Thread Forming | ASME B18.2.1 | 10 | 92351A601 | 00000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 5" | 0.219" | 9 | Partially Threaded | Thread Forming | ASME B18.2.1 | 5 | 92351A603 | 0000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 5 1/2" | 0.219" | 9 | Partially Threaded | Thread Forming | ASME B18.2.1 | 5 | 92351A112 | 0000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 6" | 0.219" | 9 | Partially Threaded | Thread Forming | ASME B18.2.1 | 5 | 92351A607 | 0000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 8" | 0.219" | 9 | Partially Threaded | Thread Forming | ASME B18.2.1 | 1 | 92351A118 | 00000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 10" | 0.219" | 9 | Partially Threaded | Thread Forming | ASME B18.2.1 | 1 | 92351A119 | 00000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

316 Stainless Steel | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

5/16" | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 1" | 0.219" | 9 | Partially Threaded | Thread Forming | ASME B18.2.1 | 10 | 90123A206 | 0000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 1 1/4" | 0.219" | 9 | Partially Threaded | Thread Forming | ASME B18.2.1 | 10 | 90123A211 | 0000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 1 1/2" | 0.219" | 9 | Partially Threaded | Thread Forming | ASME B18.2.1 | 10 | 90123A227 | 0000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 2" | 0.219" | 9 | Partially Threaded | Thread Forming | ASME B18.2.1 | 10 | 90123A234 | 0000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 2 1/2" | 0.219" | 9 | Partially Threaded | Thread Forming | ASME B18.2.1 | 5 | 90123A238 | 0000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 3" | 0.219" | 9 | Partially Threaded | Thread Forming | ASME B18.2.1 | 5 | 90123A242 | 0000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 3 1/2" | 0.219" | 9 | Partially Threaded | Thread Forming | ASME B18.2.1 | 5 | 90123A247 | 0000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 4" | 0.219" | 9 | Partially Threaded | Thread Forming | ASME B18.2.1 | 5 | 90123A256 | 0000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 4 1/2" | 0.219" | 9 | Partially Threaded | Thread Forming | ASME B18.2.1 | 1 | 90123A261 | 0000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 5" | 0.219" | 9 | Partially Threaded | Thread Forming | ASME B18.2.1 | 1 | 90123A269 | 0000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 6" | 0.219" | 9 | Partially Threaded | Thread Forming | ASME B18.2.1 | 1 | 90123A278 | 0000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Steel Flanged Hex Head Wood Screws

|

Lg. | Head Ht. | Flange Dia. | Approx. Threads per In. | Threading | Tapping Method | Specs. Met | Pkg. Qty. | Pkg. | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

Hot-Dipped Galvanized Steel | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

5/16" | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 1" | 0.32" | 0.68" | 9 | Fully Threaded | Thread Forming | ASTM A153 | 50 | 95526A325 | 000000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 1 1/2" | 0.32" | 0.68" | 9 | Partially Threaded | Thread Forming | ASTM A153 | 50 | 95526A350 | 00000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 2" | 0.32" | 0.68" | 9 | Partially Threaded | Thread Forming | ASTM A153 | 50 | 95526A375 | 00000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 2 1/2" | 0.32" | 0.68" | 9 | Partially Threaded | Thread Forming | ASTM A153 | 25 | 95526A400 | 00000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

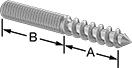

Thread-Mount Studs for Wood

|

(A) | (B) | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

Screw Size | Thread Lg. | Thread Size | Thread Lg. | Lg. | Tensile Strength | Hardness | Pkg. Qty. | Pkg. | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Black-Oxide Steel | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 5/16" | 1 1/2" | 5/16"-18 | 1" | 2 1/2" | Not Rated | Not Rated | 10 | 90207A311 | 000000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 5/16" | 1 1/2" | 5/16"-18 | 1 1/2" | 3" | Not Rated | Not Rated | 5 | 90207A312 | 0000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 5/16" | 2" | 5/16"-18 | 1 1/2" | 3 1/2" | Not Rated | Not Rated | 5 | 90207A313 | 0000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Zinc-Plated Steel | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 5/16" | 1 1/2" | 5/16"-18 | 1" | 2 1/2" | Not Rated | Not Rated | 25 | 90207A593 | 00000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 5/16" | 1 1/2" | 5/16"-18 | 1 1/2" | 3" | Not Rated | Not Rated | 25 | 90207A595 | 00000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 5/16" | 2" | 5/16"-18 | 1 1/2" | 3 1/2" | Not Rated | Not Rated | 25 | 90207A597 | 00000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

18-8 Stainless Steel | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 5/16" | 7/8" | 5/16"-18 | 5/8" | 1 1/2" | Not Rated | Not Rated | 10 | 90915A646 | 00000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 5/16" | 1" | 5/16"-18 | 1" | 2" | Not Rated | Not Rated | 10 | 90915A647 | 00000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 5/16" | 1 1/2" | 5/16"-18 | 1" | 2 1/2" | Not Rated | Not Rated | 10 | 90915A593 | 00000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 5/16" | 1 1/2" | 5/16"-18 | 1 1/2" | 3" | Not Rated | Not Rated | 10 | 90915A595 | 00000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 5/16" | 2" | 5/16"-18 | 1 1/2" | 3 1/2" | Not Rated | Not Rated | 10 | 90915A597 | 00000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 5/16" | 2" | 5/16"-18 | 2" | 4" | Not Rated | Not Rated | 5 | 90915A648 | 00000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 5/16" | 3" | 5/16"-18 | 1 1/4" | 5" | Not Rated | Not Rated | 5 | 90915A656 | 00000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 5/16" | 3" | 5/16"-18 | 1 1/2" | 6" | Not Rated | Not Rated | 5 | 90915A657 | 00000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Wood Screw-Style Hangers

High-Strength Anchors for Block and Brick

|

Ultimate Strength, lbf | |||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|

Thread Size | Lg. | Drill Bit Size | Min. Installation Dp. | Material | Pull-Out | Shear | Conditions Tested In | Pkg. Qty. | Pkg. | ||

| 5/16"-18 | 1 1/2" | 9/16" | 1 1/2" | Zinc | 2,600 | 3,280 | 3,000 psi Concrete | 10 | 92915A120 | 000000 | |

Anchors for Block and Brick

|

Ultimate Strength, lbf | |||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|

Thread Size | Lg. | Drill Bit Size | Min. Installation Dp. | Material | Pull-Out | Shear | Conditions Tested In | Pkg. Qty. | Pkg. | ||

| 5/16"-18 | 1 5/8" | 5/8" | 1 1/2" | Zinc | 1,480 | 2,000 | 4,000 psi Concrete | 10 | 97031A040 | 00000 | |

Anchors for Hollow Block and Brick

Ultimate Strength, lbf | ||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|

Thread Size | Lg. | Drill Bit Size | Min. Installation Dp. | Sleeve Material | Material | Pull-Out | Shear | Conditions Tested In | Pkg. Qty. | Pkg. | ||

| 5/16"-18 | 1 5/16" | 5/8" | 1" | Zinc Alloy | Steel | 1,600 | 1,880 | 4,000 psi Concrete | 5 | 97016A973 | 000000 | |