Filter by

Lathe Center Type

Shank Type

Material

Total Indicated Runout (TIR) Accuracy

For Use With

U.S.–Mexico–Canada Agreement (USMCA) Qualifying

REACH

DFARS Specialty Metals

Export Control Classification Number (ECCN)

RoHS

Live Centers

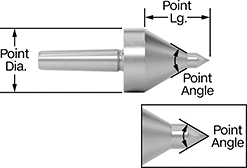

Machine Taper No. | Max. Workpiece Cap., lb. | Max. Rotation Speed, rpm | Total Indicated Runout (TIR) Accuracy | Point Dia. | Point Lg. | Overall Lg. | Point Angle | Material | Each | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

Extended-Cone Point | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Multipurpose | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| Morse 2 | 330 | 5,000 | 0.0001" | 2.25" | 2 17/64" | 5 3/4" | 60° | Hardened Steel | 0000000 | 0000000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| Morse 3 | 685 | 4,000 | 0.0001" | 2.63" | 2 21/32" | 6 15/16" | 60° | Hardened Steel | 0000000 | 000000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| Morse 4 | 1,160 | 3,500 | 0.0001" | 3.5" | 3 31/64" | 8 11/16" | 60° | Hardened Steel | 0000000 | 000000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| Morse 5 | 1,160 | 3,500 | 0.0001" | 3.5" | 3 31/64" | 9 51/64" | 60° | Hardened Steel | 0000000 | 000000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||