Lathe Chuck Stops

Fixed Lathe Chuck Stop Shown Installed |  Fixed |  Adjustable |

Adjustable With Hardened Steel Parallels |

Consistently position workpieces in a three-jaw lathe chuck. These stops enable short workpieces to extend beyond the chuck's jaws, providing additional clearance. A magnetic back makes them easy to mount and remove from your chuck face.

Fixed chuck stops are a simple, consistent way to position your piece.

Adjustable chuck stops can be used with parallels or your own custom supports to position workpieces at the exact depth you need. Those that include hardened steel parallels come ready to set at various depths.

| No. of Pieces | Thicknesses Included | For Max. Chuck Jaw Thick. | Parallel Tolerance | Mount Type | No. of Mounting Magnets | Includes | Material | Each | |

Fixed | |||||||||

|---|---|---|---|---|---|---|---|---|---|

| 3 | 15mm, 20mm, 25mm | 2 1/8" | -0.0004" to 0.0004" | Magnetic Back | 3 | __ | Aluminum | 0000000 | 0000000 |

| 5 | 15mm, 20mm, 25mm, 30mm, 35mm | 2 1/8" | -0.0004" to 0.0004" | Magnetic Back | 3 | __ | Aluminum | 00000000 | 000000 |

Adjustable | |||||||||

| 6 | 7/16" | __ | -0.0002" to 0.0002" | Magnetic Back | 3 | Five plastic centering rings (1 3/8" to 4" diameter) | Metal | 00000000 | 00000 |

| 17 | 7/16" | __ | -0.0002" to 0.0002" | Magnetic Back | 3 | Six plastic centering rings (1 3/8" to 4" diameter), Ten sets of hardened steel parallels (1/2" to 1 5/18" height) in a plastic case | Metal | 00000000 | 000000 |

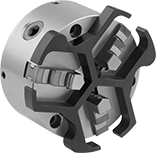

Powered Lathe Chucks

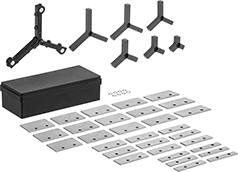

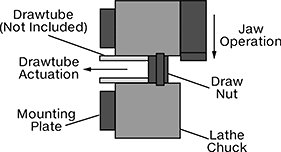

Precise and powerful clamping for high speed, heavy duty CNC turning. These chucks connect to your CNC lathe’s hydraulic system to open and close the jaws—no more cranking with a chuck jaw wrench. To mount the chucks to your lathe, machine the included blank draw nut to match the thread of your drawtube. You can use these as drop-in replacements for major machine brands such as Okuma, Mazak, Haas, Hyundai WIA, and Doosan.

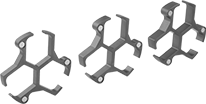

These chucks are self-centering, so all the jaws move in unison to center the workpiece as they close. They come with a set of machinable jaws that you can bore to fit the curves and edges of your unique workpiece for a tighter hold and more stability than standard hardened jaws. For additional sizes and materials, see our full offering of machinable jaws.

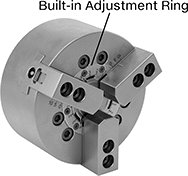

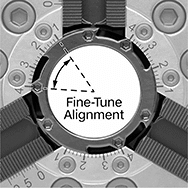

Jaw-boring chucks reduce the time it takes to machine jaws. Instead of a separate boring ring or machined slugs that you have to position and reposition, they have a built-in adjustment ring. All you need is an L-key to fine-tune alignment once before machining. The ring moves in increments as small as 0.004”, so the jaws are machined for a tight fit to your workpiece.

Use high-pressure grease to improve grip and prolong the life of your chuck.

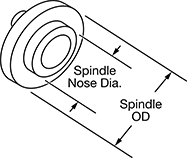

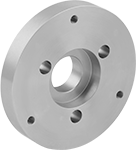

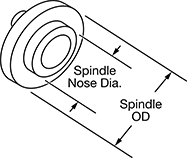

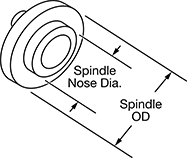

A mounting plate (sold separately) is required to mount the chuck to a lathe. Select a mounting plate that matches the diameter of your lathe’s chuck and spindle OD.

Lathe Chucks | High-Pressure Grease (13.7 fl. oz.) | |||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Dia. | For Workpiece OD | Center Through-Hole Dia. | TIR (Total Indicated Runout) Accuracy | Max. Speed, rpm | Number of Jaws | Serration Size | Material | Includes | Each | Each | ||

Two-Piece Serrated Jaw | ||||||||||||

| 6" | 0.51"-6.65" | 1.81" | 0.0008" | 6,000 | 3 | 1.5 mm × 60° | Steel | One Set of Master Jaws with Machinable Top Jaws, Self-Ejecting Lathe Chuck Wrench, Machinable Draw Nut, Hex Key, Mounting Bolts | 0000000 | 000000000 | 0000000 | 000000 |

| 8" | 0.43"-8.26" | 2.04" | 0.0008" | 5,000 | 3 | 1.5 mm × 60° | Steel | One Set of Master Jaws with Machinable Top Jaws, Self-Ejecting Lathe Chuck Wrench, Machinable Draw Nut, Hex Key, Mounting Bolts | 0000000 | 00000000 | 0000000 | 00000 |

| 8" | 0.43"-8.26" | 2.59" | 0.0008" | 5,000 | 3 | 1.5 mm × 60° | Steel | One Set of Master Jaws with Machinable Top Jaws, Self-Ejecting Lathe Chuck Wrench, Machinable Draw Nut, Hex Key, Mounting Bolts | 0000000 | 00000000 | 0000000 | 00000 |

| 10" | 1.22"-10" | 3.03" | 0.0008" | 4,200 | 3 | 1.5 mm × 60° | Steel | One Set of Master Jaws with Machinable Top Jaws, Self-Ejecting Lathe Chuck Wrench, Machinable Draw Nut, Hex Key, Mounting Bolts | 0000000 | 00000000 | 0000000 | 00000 |

| 10" | 1.22"-10" | 3.22" | 0.0008" | 4,500 | 3 | 1.5 mm × 60° | Steel | One Set of Master Jaws with Machinable Top Jaws, Self-Ejecting Lathe Chuck Wrench, Machinable Draw Nut, Hex Key, Mounting Bolts | 0000000 | 00000000 | 0000000 | 00000 |

| 12" | 1.33"-11.96" | 3.58" | 0.0008" | 3,300 | 3 | 1.5 mm × 60° | Steel | One Set of Master Jaws with Machinable Top Jaws, Self-Ejecting Lathe Chuck Wrench, Machinable Draw Nut, Hex Key, Mounting Bolts | 0000000 | 00000000 | 0000000 | 00000 |

| 12" | 1.77"-12.4" | 4.05" | 0.0008" | 3,000 | 3 | 1.5 mm × 60° | Steel | One Set of Master Jaws with Machinable Top Jaws, Self-Ejecting Lathe Chuck Wrench, Machinable Draw Nut, Hex Key, Mounting Bolts | 0000000 | 00000000 | 0000000 | 00000 |

Lathe Chucks | High-Pressure Grease (13.7 fl. oz.) | |||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Dia. | For Workpiece OD | Center Through-Hole Dia. | TIR (Total Indicated Runout) Accuracy | Max. Speed, rpm | Number of Jaws | Serration Size | Material | Includes | Each | Each | ||

Two-Piece Serrated Jaw | ||||||||||||

| 6" | 0.61"-6.63" | 1.81" | 0.0002" | 6,000 | 3 | 1.5 mm × 60° | Steel | One Set of Master Jaws with Machinable Top Jaws, Self-Ejecting Lathe Chuck Wrench, Machinable Draw Nut, Hex Key, Mounting Bolts, T-Nuts | 0000000 | 000000000 | 0000000 | 000000 |

| 8" | 0.52"-8.25" | 2.04" | 0.0002" | 5,000 | 3 | 1.5 mm × 60° | Steel | One Set of Master Jaws with Machinable Top Jaws, Self-Ejecting Lathe Chuck Wrench, Machinable Draw Nut, Hex Key, Mounting Bolts, T-Nuts | 0000000 | 00000000 | 0000000 | 00000 |

| 8" | 0.91"-8.25" | 2.59" | 0.0002" | 5,000 | 3 | 1.5 mm × 60° | Steel | One Set of Master Jaws with Machinable Top Jaws, Self-Ejecting Lathe Chuck Wrench, Machinable Draw Nut, Hex Key, Mounting Bolts, T-Nuts | 0000000 | 00000000 | 0000000 | 00000 |

| 10" | 1.22"-10" | 3.03" | 0.0002" | 4,200 | 3 | 1.5 mm × 60° | Steel | One Set of Master Jaws with Machinable Top Jaws, Self-Ejecting Lathe Chuck Wrench, Machinable Draw Nut, Hex Key, Mounting Bolts, T-Nuts | 0000000 | 00000000 | 0000000 | 00000 |

| 10" | 1.22"-10" | 3.22" | 0.0002" | 4,500 | 3 | 1.5 mm × 60° | Steel | One Set of Master Jaws with Machinable Top Jaws, Self-Ejecting Lathe Chuck Wrench, Machinable Draw Nut, Hex Key, Mounting Bolts, T-Nuts | 0000000 | 00000000 | 0000000 | 00000 |

| 12" | 1.35"-11.95" | 3.58" | 0.0002" | 3,300 | 3 | 1.5 mm × 60° | Steel | One Set of Master Jaws with Machinable Top Jaws, Self-Ejecting Lathe Chuck Wrench, Machinable Draw Nut, Hex Key, Mounting Bolts, T-Nuts | 0000000 | 00000000 | 0000000 | 00000 |

| 12" | 2.14"-12.38" | 4.05" | 0.0002" | 3,000 | 3 | 1.5 mm × 60° | Steel | One Set of Master Jaws with Machinable Top Jaws, Self-Ejecting Lathe Chuck Wrench, Machinable Draw Nut, Hex Key, Mounting Bolts, T-Nuts | 0000000 | 00000000 | 0000000 | 00000 |

For Spindle | For Spindle Nose | ||||||||

|---|---|---|---|---|---|---|---|---|---|

| For Lathe Chuck Center Through-Hole Dia. | Type | OD | Size | Type | Dia. | Center Through-Hole Dia. | Material | Each | |

For 6" Lathe Chuck Dia. | |||||||||

| 1.81" | A2 | 5.512" | 5 | A2-5 | 3.251" | 3.13" | Steel | 0000000 | 0000000 |

For 8" Lathe Chuck Dia. | |||||||||

| 2.04" | A2 | 6.693" | 5 | A2-5 | 3.251" | 3.13" | Steel | 0000000 | 000000 |

| 2.04" | A2 | 6.693" | 6 | A2-6 | 4.188" | 4.05" | Steel | 0000000 | 000000 |

| 2.59" | A2 | 6.693" | 6 | A2-6 | 4.179" | 4.05" | Steel | 0000000 | 000000 |

For 10" Lathe Chuck Dia. | |||||||||

| 3.22" | A2 | 8.661" | 6 | A2-6 | 4.188" | 4.05" | Steel | 0000000 | 000000 |

| 3.22" | A2 | 8.661" | 8 | A2-8 | 5.501" | 5.35" | Steel | 0000000 | 000000 |

For 10", 12" Lathe Chuck Dia. | |||||||||

| 3.03", 3.58" | A2 | 8.661" | 6 | A2-6 | 4.188" | 4.05" | Steel | 0000000 | 000000 |

| 3.03", 3.58" | A2 | 8.661" | 8 | A2-8 | 4.188" | 4.05" | Steel | 0000000 | 000000 |

For 12" Lathe Chuck Dia. | |||||||||

| 4.05" | A2 | 11.811" | 8 | A2-8 | 5.501" | 5.35" | Steel | 0000000 | 000000 |

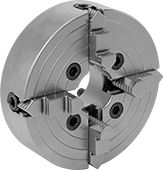

Lathe Chucks

Mount these chucks to a lathe's spindle to hold round workpieces. Also known as scroll chucks, they are self centering—all jaws move in unison, centering the workpiece as they close. Made of forged steel, these chucks are strong and wear resistant, so they maintain their shape even with continuous use. They’re often used for precision machining. You can run them at higher speeds than cast iron chucks, and they’ll last longer. Use the included lathe chuck wrench to open and close the jaws.

Chucks with fixed jaws come with one set of outside jaws and one set of inside jaws. These jaws are one-piece and keyed, so they’re best for rigid and permanent setups where you don’t need to change your jaw style. They’re commonly used in dedicated turning operations or roughing applications.

Chucks with reversible jaws come with one set of jaws that can be installed for either an inside or outside grip. These jaws are two-piece and tongue-and-groove, so they’re great for when you need to regularly switch top jaws or use soft jaws for custom clamping. This setup offers the best mix of flexibility and repeatable accuracy. Those with six jaws hold your workpiece tighter than chucks with three jaws. They also distribute the clamping force more evenly, so you’re less likely to deform parts with thin walls.

Use high-pressure grease to improve grip and prolong the life of your chuck.

A mounting plate (sold separately) is required to mount the chuck to a lathe. Select a mounting plate that matches the diameter of the lathe chuck, your lathe’s spindle type, and the spindle OD.

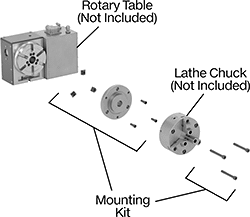

Rotary table mounting kits (sold separately) come with everything you need to mount to rotary tables, including a mounting plate.

Lathe Chucks | |||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

For Workpiece | Replacement Inside Jaw Set | Replacement Outside Jaw Set | High-Pressure Grease (13.7 fl. oz.) | ||||||||||||

| Dia. | OD | ID | Center Through-Hole Dia. | TIR (Total Indicated Runout) Accuracy | Max. Speed, rpm | Material | Includes | Each | Each | Each | Each | ||||

3 Jaws | |||||||||||||||

| 3" | 0.08"-2.72" | 0.98"-2.8" | 0.63" | 0.0006" | 7,000 | Steel | One Set of Solid Inside Jaws, One Set of Solid Outside Jaws, Self-Ejecting Lathe Chuck Wrench, Hex Key, Mounting Bolts, Adjustment Screws | 0000000 | 0000000 | 0000000 | 0000000 | 0000000 | 0000000 | 0000000 | 000000 |

| 4" | 0.12"-3.27" | 0.98"-3.43" | 0.78" | 0.0006" | 6,300 | Steel | One Set of Solid Inside Jaws, One Set of Solid Outside Jaws, Self-Ejecting Lathe Chuck Wrench, Hex Key, Mounting Bolts, Adjustment Screws | 0000000 | 000000 | 0000000 | 000000 | 0000000 | 000000 | 0000000 | 00000 |

Lathe Chucks | |||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

For Workpiece | Replacement Reversible Jaw Set | High-Pressure Grease (13.7 fl. oz.) | |||||||||||

| Dia. | OD | ID | Center Through-Hole Dia. | TIR (Total Indicated Runout) Accuracy | Max. Speed, rpm | Material | Includes | Each | Each | Each | |||

3 Jaws | |||||||||||||

| 5" | 0.118"-4.92" | 1.34"-4.65" | 1.37" | 0.0006" | 5,500 | Steel | One Set of Reversible Jaws, One Set of Reversible Jaw Mounts, Chuck Wrench, Mounting Bolts, Fine Adjustment Screws | 0000000 | 000000000 | 0000000 | 0000000 | 0000000 | 000000 |

| 6" | 0.118"-6.3" | 1.65"-5.75" | 1.65" | 0.0006" | 4,600 | Steel | One Set of Reversible Jaws, One Set of Reversible Jaw Mounts, Chuck Wrench, Mounting Bolts, Fine Adjustment Screws | 0000000 | 00000000 | 0000000 | 000000 | 0000000 | 00000 |

| 8" | 0.157"-7.87" | 1.97"-7.48" | 2.16" | 0.0008" | 4,000 | Steel | One Set of Reversible Jaws, One Set of Reversible Jaw Mounts, Chuck Wrench, Mounting Bolts, Fine Adjustment Screws | 0000000 | 00000000 | 0000000 | 000000 | 0000000 | 00000 |

| 10" | 0.19"-9.84" | 2.28"-9.25" | 3" | 0.0008" | 3,500 | Steel | One Set of Reversible Top Jaws, One Set of Jaw Mounts, Self-Ejecting Lathe Chuck Wrench, Hex Key, Mounting Bolts, Adjustment Screws | 0000000 | 00000000 | 0000000 | 000000 | 0000000 | 00000 |

| 12" | 0.39"-12.4" | 2.56"-10.43" | 4.05" | 0.0006" | 2,800 | Steel | One Set of Reversible Top Jaws, One Set of Jaw Mounts, Self-Ejecting Lathe Chuck Wrench, Hex Key, Mounting Bolts, Adjustment Screws | 0000000 | 00000000 | 0000000 | 000000 | 0000000 | 00000 |

| 16" | 0.39"-15.75" | 2.84"-12.95" | 5.35" | 0.0006" | 2,000 | Steel | One Set of Reversible Top Jaws, One Set of Jaw Mounts, Self-Ejecting Lathe Chuck Wrench, Hex Key, Mounting Bolts, Eyebolts, Adjustment Screws | 0000000 | 00000000 | 0000000 | 000000 | 0000000 | 00000 |

6 Jaws | |||||||||||||

| 6" | 0.31"-6.3" | 1.77"-5.75" | 1.65" | 0.0012" | 4,600 | Steel | One Set of Reversible Top Jaws, One Set of Jaw Mounts, Self-Ejecting Lathe Chuck Wrench, Hex Key, Mounting Bolts, Adjustment Screws | 0000000 | 00000000 | 0000000 | 000000 | 0000000 | 00000 |

| 8" | 0.31"-7.78" | 2.05"-7.48" | 2.16" | 0.0016" | 4,000 | Steel | One Set of Reversible Top Jaws, One Set of Jaw Mounts, Self-Ejecting Lathe Chuck Wrench, Hex Key, Mounting Bolts, Adjustment Screws | 0000000 | 00000000 | 0000000 | 000000 | 0000000 | 00000 |

| 10" | 0.47"-9.84" | 2.68"-10.08" | 3" | 0.0016" | 3,500 | Steel | One Set of Reversible Top Jaws, One Set of Jaw Mounts, Self-Ejecting Lathe Chuck Wrench, Hex Key, Mounting Bolts, Adjustment Screws | 0000000 | 00000000 | 0000000 | 000000 | 0000000 | 00000 |

For Spindle | For Spindle Nose | |||||||||

|---|---|---|---|---|---|---|---|---|---|---|

| Type | OD | Size | Thread Size | Type | Dia. | Lg. | Center Through-Hole Dia. | Material | Each | |

For 3" Lathe Chuck Dia. | ||||||||||

| D1 Camlock | 3.622" | 3 | __ | D1-3 | 2 1/8" | 7/16" | 1" | Steel | 0000000 | 0000000 |

| D1 Camlock | 4.52" | 4 | __ | D1-4 | 2 1/2" | 7/16" | 1" | Steel | 0000000 | 000000 |

For 4" Lathe Chuck Dia. | ||||||||||

| D1 Camlock | 4.528" | 4 | __ | D1-4 | 2 1/2" | 7/16" | 1.97" | Steel | 0000000 | 000000 |

For 5" Lathe Chuck Dia. | ||||||||||

| D1 Camlock | 5.31" | 5 | __ | D1-5 | 3.251" | 1/2" | 1.37" | Steel | 0000000 | 000000 |

| Hardinge | 5" | __ | __ | 4-Degree | 2.36" | 0.36" | 1.38" | Steel | 0000000 | 000000 |

| Threaded | 5" | __ | 2 3/16"-10 | __ | 2 3/16" | 0.55" | 1.38" | Steel | 0000000 | 000000 |

For 6" Lathe Chuck Dia. | ||||||||||

| D1 Camlock | 6" | 4 | __ | D1-4 | 3.38" | 0.62" | 1.65" | Steel | 0000000 | 000000 |

| D1 Camlock | 6.29" | 5 | __ | D1-5 | 3.251" | 1/2" | 1.65" | Steel | 0000000 | 000000 |

| Hardinge | 6" | __ | __ | 4-Degree | 3.32" | 0.69" | 2.07" | Steel | 0000000 | 000000 |

| Threaded | 6" | __ | 2 3/16"-10 | __ | 3.39" | 0.63" | 2.2" | Steel | 0000000 | 000000 |

For 8" Lathe Chuck Dia. | ||||||||||

| D1 Camlock | 7.87" | 5 | __ | D1-5 | 3.251" | 1/2" | 2.16" | Steel | 0000000 | 000000 |

| D1 Camlock | 8" | 4 | __ | D1-4 | 4.33" | 0.66" | 2.16" | Steel | 0000000 | 000000 |

| D1 Camlock | 8" | 6 | __ | D1-6 | 4.33" | 0.66" | 2.16" | Steel | 000000 | 000000 |

For 10" Lathe Chuck Dia. | ||||||||||

| A1, A2 | 9.843" | 5 | __ | A2-5 | 3.251" | 9/16" | 2.99" | Steel | 0000000 | 000000 |

| A1, A2 | 9.843" | 6 | __ | A2-6 | 4.188" | 5/8" | 2.99" | Steel | 0000000 | 000000 |

| D1 Camlock | 9.84" | 6 | __ | D1-6 | 4.188" | 9/16" | 3.01" | Steel | 0000000 | 000000 |

| D1 Camlock | 9.84" | 8 | __ | D1-8 | 5.501" | 5/8" | 3.01" | Steel | 0000000 | 000000 |

For 12" Lathe Chuck Dia. | ||||||||||

| A1, A2 | 12.402" | 6 | __ | A2-6 | 4.188" | 5/8" | 4.05" | Steel | 0000000 | 000000 |

| A1, A2 | 12.402" | 8 | __ | A2-8 | 5.501" | 11/16" | 4.05" | Steel | 0000000 | 000000 |

| D1 Camlock | 12.4" | 6 | __ | D1-6 | 4.188" | 9/16" | 4.05" | Steel | 0000000 | 000000 |

| D1 Camlock | 12.4" | 8 | __ | D1-8 | 5.501" | 5/8" | 4.05" | Steel | 0000000 | 000000 |

For 16" Lathe Chuck Dia. | ||||||||||

| A1, A2 | 11 3/4" | 8 | __ | A2-8 | 5.501" | 11/16" | 5.35" | Steel | 0000000 | 000000 |

| A1, A2 | 11 3/4" | 11 | __ | A2-11 | 7.751" | 3/4" | 5.35" | Steel | 0000000 | 000000 |

| D1 Camlock | 11 3/4" | 8 | __ | D1-8 | 5.501" | 5/8" | 5.35" | Steel | 0000000 | 000000 |

| D1 Camlock | 11 3/4" | 11 | __ | D1-11 | 7.751" | 11/16" | 5.35" | Steel | 0000000 | 000000 |

| For Lathe Chuck Dia. | For Manufacturer Model No. | Includes | Each | |

Haas | ||||

|---|---|---|---|---|

| 6" | HRC160, HRT160, HRT160SP, HRT160SS, TR160, TR200Y, TRT160 | Mounting Hardware | 00000000 | 0000000 |

| 8" | HRC210, HRT210, HRT210SP, HRT210SS, TR210, TRT210 | Mounting Hardware | 00000000 | 000000 |

| 10" | HRC210, HRT210, HRT210SP, HRT210SS, TR210, TRT210 | Mounting Hardware | 00000000 | 000000 |

| 12" | HRT310, HRT310SP, TR310 | Mounting Hardware | 00000000 | 000000 |

Kitagawa | ||||

| 8" | GT200, MR200 | Mounting Hardware | 00000000 | 000000 |

| 10" | GT250, MR250 | Mounting Hardware | 00000000 | 00000000 |

DMG Mori | ||||

| 8" | DDRT200 | Mounting Hardware | 00000000 | 000000 |

| 10" | DDRT260 | Mounting Hardware | 00000000 | 00000000 |

Hurco | ||||

| 8" | H200 | Mounting Hardware | 00000000 | 000000 |

| 10" | H250 | Mounting Hardware | 00000000 | 00000000 |

Economy Lathe Chucks

Choose these lathe chucks when high precision isn’t critical. Made of cast iron, they don't match up to the same tight tolerances as forged steel lathe chucks. This means they are only rated to half the maximum speed, so they may wobble at high speeds. Also known as scroll chucks, they are self-centering—all three jaws move together, centering the workpiece as they close. Use the included lathe chuck wrench to open and close the jaws. You’ll need a mounting plate (not included) to connect these chucks to your lathe.

Fixed jaw lathe chucks come with a set of inside and outside jaws.

Reversible jaw lathe chucks have one set of jaws that provide either an inside or outside grip.

High-pressure grease (sold separately) improves grip and prolongs the life of your lathe chuck.

Lathe Chucks | ||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

For Workpiece | Replacement Inside Jaw Set | Replacement Outside Jaw Set | ||||||||||||

| Dia. | OD | ID | Center Through-Hole Dia. | TIR (Total Indicated Runout) Accuracy | Max. Speed, rpm | Number of Jaws | Material | Includes | Each | Each | Each | |||

| 3" | 0.08"-0.87" | 0.98"-2.76" | 0.63" | 0.0002" | 4,000 | 3 | Cast Iron | One Set of Solid Inside Jaws, One Set of Solid Outside Jaws, Self-Ejecting Lathe Chuck Wrench | 0000000 | 0000000 | 0000000 | 0000000 | 0000000 | 000000 |

| 4" | 0.08"-1.18" | 1.18"-3.54" | 0.86" | 0.0002" | 3,500 | 3 | Cast Iron | One Set of Solid Inside Jaws, One Set of Solid Outside Jaws, Self-Ejecting Lathe Chuck Wrench | 0000000 | 000000 | 0000000 | 00000 | 0000000 | 00000 |

| 5" | 0.1"-1.57" | 1.5"-4.92" | 1.18" | 0.0002" | 3,000 | 3 | Cast Iron | One Set of Solid Inside Jaws, One Set of Solid Outside Jaws, Self-Ejecting Lathe Chuck Wrench | 0000000 | 000000 | 0000000 | 00000 | 0000000 | 00000 |

Lathe Chucks | ||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|

For Workpiece | Replacement Reversible Jaw Set | |||||||||||

| Dia. | OD | ID | Center Through-Hole Dia. | TIR (Total Indicated Runout) Accuracy | Max. Speed, rpm | Number of Jaws | Material | Includes | Each | Each | ||

| 6" | 0.12"-5.71" | 1.97"-6.3" | 1.77" | 0.0002" | 2,500 | 3 | Cast Iron | One Set of Reversible Jaws, Self-Ejecting Lathe Chuck Wrench | 0000000 | 0000000 | 0000000 | 0000000 |

Container | ||||||||||

|---|---|---|---|---|---|---|---|---|---|---|

| NLGI Viscosity Grade | Base Oil | Additive | Size | Type | Temp. Range, °F | Melting Temp., °F | Weld Load, kgf | Color | Each | |

DuPont Molykote G-4700 Extreme Pressure Synthetic—Lithium Thickener | ||||||||||

| 2 | Synthetic | Moly | 13.7 | Grease Gun Cartridge | -40° to 350° | 545° | 375 | Black | 0000000 | 000000 |

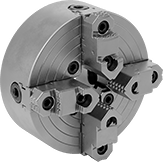

Lathe Chucks for Non-Round Workpieces

Adjust each jaw on these chucks separately to hold rectangular or odd-shaped workpieces. Also known as independent chucks, they have four jaws that each have their own adjustment screw. For quicker setups, you can also remove two jaws and clamp with the remaining two. All jaws are reversible, so you can install them for either an inside or an outside grip. Use the included wrench to move them in or out. Made of forged steel, these chucks are strong and wear resistant, so they maintain their shape even with continuous use. They’re often used for precision machining. They last longer than cast iron chucks, and you can run them at higher speeds.

Use high-pressure grease to improve grip and prolong the life of your chuck.

You’ll need a mounting plate to attach the chuck to your lathe. Choose a mounting plate that matches the diameter of the lathe chuck, your lathe’s spindle type, and the spindle OD.

Lathe Chucks | |||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

For Workpiece | Jaw | Replacement Reversible Jaw Set | High-Pressure Grease (13.7 fl. oz.) | ||||||||||||

| Dia. | OD | ID | Center Through-Hole Dia. | Maximum Speed, rpm | Number of Jaws | Style | Construction | Material | Includes | Each | Each | Each | |||

| 6" | 0.31"-6.3" | 1.34"-4.33" | 1.65" | 3,000 | 4 | Stepped | One Piece | Steel | One Set of Reversible Jaws, Self-Ejecting Lathe Chuck Wrench, Mounting Bolts | 00000000 | 0000000 | 00000000 | 0000000 | 0000000 | 000000 |

| 8" | 0.39"-7.87" | 2.12"-6.85" | 1.96" | 2,500 | 4 | Tongue and Groove | Two Piece | Steel | One Set of Reversible Jaw Mounts, Self-Ejecting Lathe Chuck Wrench, Mounting Bolts, One Set of Reversible Top Jaws | 00000000 | 00000000 | 00000000 | 000000 | 0000000 | 00000 |

| 10" | 0.39"-9.84" | 3.7"-7.95" | 2.55" | 2,000 | 4 | Tongue and Groove | Two Piece | Steel | One Set of Reversible Jaw Mounts, Self-Ejecting Lathe Chuck Wrench, Mounting Bolts, One Set of Reversible Top Jaws | 00000000 | 00000000 | 00000000 | 000000 | 0000000 | 00000 |

For Spindle | For Spindle Nose | ||||||||

|---|---|---|---|---|---|---|---|---|---|

| Type | OD | Size | Type | Dia. | Lg. | Center Through-Hole Dia. | Material | Each | |

For 6" Lathe Chuck Dia. | |||||||||

| D1 Camlock | 4 3/4" | 4 | D1-4 | 3.25" | 0.11" | 1.65" | Steel | 00000000 | 0000000 |

| D1 Camlock | 5 3/4" | 5 | D1-5 | 3.25" | 0.11" | 1.65" | Steel | 00000000 | 000000 |

For 8" Lathe Chuck Dia. | |||||||||

| D1 Camlock | 4 5/8" | 4 | D1-4 | 4.33" | 0.21" | 1.96" | Steel | 00000000 | 000000 |

| D1 Camlock | 7 1/8" | 6 | D1-6 | 4.33" | 0.21" | 1.96" | Steel | 00000000 | 000000 |

For 10" Lathe Chuck Dia. | |||||||||

| D1 Camlock | 7 1/8" | 6 | D1-6 | 5.9" | 0.29" | 2.55" | Steel | 00000000 | 000000 |

Lathe Spindle Stops

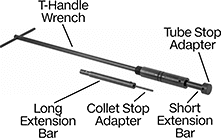

Position workpieces in the same spot every time to quicken setup, improve repeatability, and cut down on scrap. These stops create a repeatable position within your lathe spindle for clamping parts loaded through a chuck or collet. They fit a range of spindle bore diameters—the jaws expand outward for a secure, self-centering fit. To lock these stops in place, expand them with just a few turns of the T-handle wrench. They can be used on both CNC and manual lathes.

| For Spindle Dia. | Overall Lg. | Includes | Material | Each | |

| 1 5/16"-1 11/16" | 31"-34 1/2" | Collet Stop Adapter, Tube Stop Adapter, Long Extension Bar, Short Extension Bar, T-Handle Socket Wrench | Black-Oxide Alloy Steel | 00000000 | 0000000 |

| 1 3/4"-2 7/16" | 37 1/4"-43 3/4" | Collet Stop Adapter, Tube Stop Adapter, Long Extension Bar, Short Extension Bar, T-Handle Socket Wrench | Black-Oxide Alloy Steel | 00000000 | 000000 |

| 2 1/2"-3 1/2" | 40"-46 1/2" | Collet Stop Adapter, Tube Stop Adapter, Long Extension Bar, Short Extension Bar, T-Handle Socket Wrench | Black-Oxide Alloy Steel | 00000000 | 000000 |