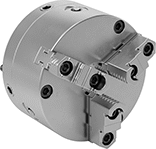

Lathe Chucks

Mount these chucks to a lathe's spindle to hold round workpieces. Also known as scroll chucks, they are self centering—all jaws move in unison, centering the workpiece as they close. Made of forged steel, these chucks are strong and wear resistant, so they maintain their shape even with continuous use. They’re often used for precision machining. You can run them at higher speeds than cast iron chucks, and they’ll last longer. Use the included lathe chuck wrench to open and close the jaws.

Chucks with reversible jaws come with one set of jaws that can be installed for either an inside or outside grip. These jaws are two-piece and tongue-and-groove, so they’re great for when you need to regularly switch top jaws or use soft jaws for custom clamping. This setup offers the best mix of flexibility and repeatable accuracy.

Use high-pressure grease to improve grip and prolong the life of your chuck.

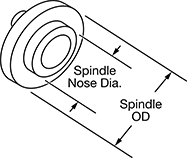

A mounting plate (sold separately) is required to mount the chuck to a lathe. Select a mounting plate that matches the diameter of the lathe chuck, your lathe’s spindle type, and the spindle OD.

Lathe Chucks | |||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

For Workpiece | Replacement Reversible Jaw Set | High-Pressure Grease (13.7 fl. oz.) | |||||||||||

| Dia. | OD | ID | Center Through-Hole Dia. | TIR (Total Indicated Runout) Accuracy | Max. Speed, rpm | Material | Includes | Each | Each | Each | |||

3 Jaws | |||||||||||||

| 5" | 0.118"-4.92" | 1.34"-4.65" | 1.37" | 0.0006" | 5,500 | Steel | One Set of Reversible Jaws, One Set of Reversible Jaw Mounts, Chuck Wrench, Mounting Bolts, Fine Adjustment Screws | 0000000 | 000000000 | 0000000 | 0000000 | 0000000 | 000000 |

Economy Lathe Chucks

Choose these lathe chucks when high precision isn’t critical. Made of cast iron, they don't match up to the same tight tolerances as forged steel lathe chucks. This means they are only rated to half the maximum speed, so they may wobble at high speeds. Also known as scroll chucks, they are self-centering—all three jaws move together, centering the workpiece as they close. Use the included lathe chuck wrench to open and close the jaws. You’ll need a mounting plate (not included) to connect these chucks to your lathe.

Fixed jaw lathe chucks come with a set of inside and outside jaws.

High-pressure grease (sold separately) improves grip and prolongs the life of your lathe chuck.

Lathe Chucks | ||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

For Workpiece | Replacement Inside Jaw Set | Replacement Outside Jaw Set | ||||||||||||

| Dia. | OD | ID | Center Through-Hole Dia. | TIR (Total Indicated Runout) Accuracy | Max. Speed, rpm | Number of Jaws | Material | Includes | Each | Each | Each | |||

| 5" | 0.1"-1.57" | 1.5"-4.92" | 1.18" | 0.0002" | 3,000 | 3 | Cast Iron | One Set of Solid Inside Jaws, One Set of Solid Outside Jaws, Self-Ejecting Lathe Chuck Wrench | 0000000 | 0000000 | 0000000 | 000000 | 0000000 | 000000 |

Container | ||||||||||

|---|---|---|---|---|---|---|---|---|---|---|

| NLGI Viscosity Grade | Base Oil | Additive | Size | Type | Temp. Range, °F | Melting Temp., °F | Weld Load, kgf | Color | Each | |

DuPont Molykote G-4700 Extreme Pressure Synthetic—Lithium Thickener | ||||||||||

| 2 | Synthetic | Moly | 13.7 | Grease Gun Cartridge | -40° to 350° | 545° | 375 | Black | 0000000 | 000000 |