Economy Lathe Chucks

Choose these lathe chucks when high precision isn’t critical. Made of cast iron, they don't match up to the same tight tolerances as forged steel lathe chucks. This means they are only rated to half the maximum speed, so they may wobble at high speeds. Also known as scroll chucks, they are self-centering—all three jaws move together, centering the workpiece as they close. Use the included lathe chuck wrench to open and close the jaws. You’ll need a mounting plate (not included) to connect these chucks to your lathe.

Fixed jaw lathe chucks come with a set of inside and outside jaws.

Reversible jaw lathe chucks have one set of jaws that provide either an inside or outside grip.

High-pressure grease (sold separately) improves grip and prolongs the life of your lathe chuck.

Lathe Chucks | ||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

For Workpiece | Replacement Inside Jaw Set | Replacement Outside Jaw Set | ||||||||||||

| Dia. | OD | ID | Center Through-Hole Dia. | TIR (Total Indicated Runout) Accuracy | Max. Speed, rpm | Number of Jaws | Material | Includes | Each | Each | Each | |||

| 3" | 0.08"-0.87" | 0.98"-2.76" | 0.63" | 0.0002" | 4,000 | 3 | Cast Iron | One Set of Solid Inside Jaws, One Set of Solid Outside Jaws, Self-Ejecting Lathe Chuck Wrench | 0000000 | 0000000 | 0000000 | 0000000 | 0000000 | 0000000 |

| 4" | 0.08"-1.18" | 1.18"-3.54" | 0.86" | 0.0002" | 3,500 | 3 | Cast Iron | One Set of Solid Inside Jaws, One Set of Solid Outside Jaws, Self-Ejecting Lathe Chuck Wrench | 0000000 | 000000 | 0000000 | 000000 | 0000000 | 000000 |

| 5" | 0.1"-1.57" | 1.5"-4.92" | 1.18" | 0.0002" | 3,000 | 3 | Cast Iron | One Set of Solid Inside Jaws, One Set of Solid Outside Jaws, Self-Ejecting Lathe Chuck Wrench | 0000000 | 000000 | 0000000 | 000000 | 0000000 | 000000 |

Lathe Chucks | ||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|

For Workpiece | Replacement Reversible Jaw Set | |||||||||||

| Dia. | OD | ID | Center Through-Hole Dia. | TIR (Total Indicated Runout) Accuracy | Max. Speed, rpm | Number of Jaws | Material | Includes | Each | Each | ||

| 6" | 0.12"-5.71" | 1.97"-6.3" | 1.77" | 0.0002" | 2,500 | 3 | Cast Iron | One Set of Reversible Jaws, Self-Ejecting Lathe Chuck Wrench | 0000000 | 0000000 | 0000000 | 0000000 |

Container | ||||||||||

|---|---|---|---|---|---|---|---|---|---|---|

| NLGI Viscosity Grade | Base Oil | Additive | Size | Type | Temp. Range, °F | Melting Temp., °F | Weld Load, kgf | Color | Each | |

DuPont Molykote G-4700 Extreme Pressure Synthetic—Lithium Thickener | ||||||||||

| 2 | Synthetic | Moly | 13.7 | Grease Gun Cartridge | -40° to 350° | 545° | 375 | Black | 0000000 | 000000 |

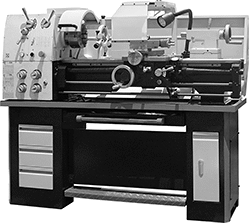

Floor Manual Lathes

Often found in tool rooms and maintenance shops, these powerful lathes are used for turning, facing, threading, boring, and knurling. They’re built and tested to DIN 8606 standards for accuracy and performance. The frame and bed are made of cast iron for stability and a long service life. For precise, repeatable motion, these lathes have hardened and ground ways. They also have helical gears for smooth power transmission.

Twist the knobs on the front to choose from 18 spindle speeds to tailor cuts to different materials and tasks. Because these lathes have set speeds, you can’t fine-tune them with as much precision as variable-speed lathes.

Use the hinged door and drawers in the base for tool storage.

Digital readout attachments display the tool position in real time, which helps you machine more quickly and accurately.

Spindle | Max. Workpiece | Overall | ||||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| No. of Speeds | Speed, rpm | Dia. | Lg. | Turning Dia. | Bed Wd. | Spindle Morse Taper No. | Tailstock Morse Taper No. | Spindle Through-Hole Dia. | Ht. | Wd. | Dp. | Wt., lbs. | TIR (Total Indicated Runout) Accuracy | Features | Includes | Specifications Met | Each | |

120V AC/240V AC—2 hp Brushed Motor | ||||||||||||||||||

| 18 | 65-1,800 | 12" | 36" | 7 15/32" | 7 1/4" | 5 | 3 | 1 1/2" | 56" | 66" | 30" | 1,160 | 0.001" | Built-In Worklight (Bulb included), Chip Guard, Safety Guard | 4-Way Tool Post, Follow Rest, Four-Jaw Manual Lathe Chuck, Gear Set, Live Center, Manual Lathe Chuck, Steady Rest | DIN 8606 | 00000000 | 000000000 |

Display | ||||||

|---|---|---|---|---|---|---|

| No. of Axes | Lg. | Wd. | Ht. | Mounting Fasteners Included | Each | |

| 3 | 11" | 2 3/4" | 7 1/4" | Yes | 00000000 | 0000000 |

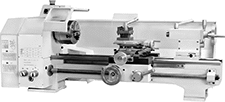

Bench-Top Manual Lathes

Compact enough for a workbench, these lathes are best for prototyping and one-off jobs in tool rooms or fabrication and maintenance shops. They do everything a full-size lathe can—turning, facing, threading, and knurling. Built from cast iron, they’re durable and stable. Plus, they have precision bearings in the headstock and spindle. They meet DIN 8606 for accuracy and performance.

Choose from six spindle speeds to tailor cuts to different materials and tasks. Because the speeds are set, you can’t fine-tune these lathes like you can with a variable-speed lathe.

Digital readout attachments display real-time tool positioning along two axes for increased machining accuracy.

Workbenches are made of steel and sized specifically for these lathes.

Spindle | Max. Workpiece | Overall | ||||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| No. of Speeds | Speed, rpm | Dia. | Lg. | Turning Dia. | Bed Wd. | Spindle Morse Taper No. | Tailstock Morse Taper No. | Spindle Through-Hole Dia. | Ht. | Wd. | Dp. | Wt., lbs. | TIR (Total Indicated Runout) Accuracy | Features | Includes | Specifications Met | Each | |

120V AC—1 hp Brushless Motor | ||||||||||||||||||

| 6 | 150-2,400 | 9" | 21 5/8" | 9 13/16" | 5 5/16" | 4 | 2 | 1 1/64" | 19" | 50" | 23" | 280 | 0.001" | Chip Guard, Safety Guard | Gear Set, Manual Lathe Chuck, 4-Way Tool Post, Two Dead Centers | DIN 8606 | 00000000 | 000000000 |

Display | ||||||

|---|---|---|---|---|---|---|

| No. of Axes | Lg. | Wd. | Ht. | Mounting Fasteners Included | Each | |

| 2 | 3 7/8" | 2 1/2" | 5 1/4" | Yes | 00000000 | 0000000 |

Shelves | Machine Mounting | Floor Mounting | |||||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Ht. | Wd. | Dp. | Overall Cap., lbs. | Material | Color | Gauge | No. of Doors | No. of | Type | Cap., lbs. | Fasteners Included | No. of Holes | Hole Dia. | Fasteners Included | No. of Holes | Hole Dia. | Assembled or Unassembled | Each | |

| 29 1/4" | 35 1/2"-47" | 16" | 700 | Powder-Coated Steel | Blue | 16 | 2 | 2 | Fixed | 150 | No | 9 | 1/2" | No | 8 | 3/4" | Unassembled | 00000000 | 0000000 |

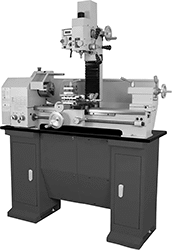

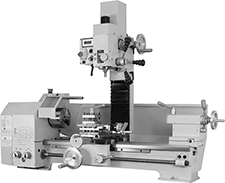

Bench-Top Combination Lathe, Mill, and Drill Machines

Turn, knurl, thread, mill, and drill workpieces with these compact machines. They can switch between rotating a blade and rotating a workpiece, so you can complete every step of fabrication. Small enough to fit on a workbench, they’re often used in tool rooms and maintenance shops—they’re best for prototyping and one-off jobs. A cast iron frame makes these machines durable and stable. For smooth motion, they have precision bearings in the headstock and spindle. All are built and tested to DIN 8606 standards for accuracy and performance.

Twist knobs on the front to choose from six spindle speeds, and you can tailor the cuts to different materials and tasks. These machines have set speeds, so you can’t fine-tune them with as much precision as variable-speed machines.

Digital readout attachments display the tool position in real time, which helps you machine more accurately. Two-axis attachments show the X and Y axes, which give you the position of the lathe. Three-axis attachments also show the Z axis.

Workbenches are made of steel and sized specifically for these machines.

Lathe Spindle | Max. Workpiece | Overall | ||||||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| No. of Speeds | Speed, rpm | Mill/Drill Spindle Speed, rpm | Dia. | Lg. | Turning Dia. | Bed Wd. | Lathe Spindle Morse Taper No. | Lathe Tailstock Morse Taper No. | Lathe Spindle Through-Hole Dia. | Spindle Morse Taper No. | Ht. | Wd. | Dp. | Wt., lbs. | TIR (Total Indicated Runout) Accuracy | Features | Includes | Specifications Met | Each | |

120V AC | ||||||||||||||||||||

1 hp Lathe Brushless Motor—0.625 hp Mill and Drill Brushless Motor | ||||||||||||||||||||

| 6 | 125-2,000 | 100-3,000 | 9" | 20" | 9 13/16" | 5 7/8" | 3 | 2 | 1" | 4 | 34" | 49" | 23" | 463 | 0.0005" | Chip Guard, Safety Guard | Gear Set, Manual Lathe Chuck, 4-Way Tool Post, Two Dead Centers | DIN 8606 | 00000000 | 000000000 |

1 hp Lathe Brushless Motor—1 hp Mill and Drill Brushless Motor | ||||||||||||||||||||

| 6 | 150-2,000 | 100-3,000 | 11" | 27" | 11" | 7 1/16" | 4 | 2 | 1" | 4 | 39" | 55" | 29" | 550 | 0.0005" | Chip Guard, Safety Guard | Gear Set, Manual Lathe Chuck, 4-Way Tool Post, Two Dead Centers | DIN 8606 | 00000000 | 00000000 |

Shelves | Machine Mounting | Floor Mounting | |||||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Ht. | Wd. | Dp. | Overall Cap., lbs. | Material | Color | Gauge | No. of Doors | No. of | Type | Cap., lbs. | Fasteners Included | No. of Holes | Hole Dia. | Fasteners Included | No. of Holes | Hole Dia. | Assembled or Unassembled | Each | |

| 29 1/4" | 35 1/2"-47" | 16" | 700 | Powder-Coated Steel | Blue | 16 | 2 | 2 | Fixed | 150 | No | 9 | 1/2" | No | 8 | 3/4" | Unassembled | 00000000 | 0000000 |