Filter by

For Workpiece OD

Center Through-Hole Diameter

For Use With

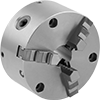

Lathe Chuck Type

Jaw Type

For Workpiece ID

Overall Length

Manufacturer Model Number

Length

Jaw Style

DFARS Specialty Metals

Export Control Classification Number (ECCN)

REACH

Maximum Rotation Speed

Weight

Fabricating and Machining