Carbide-Tipped Turning Lathe Tool Sets

Constructed of a carbide tip brazed onto a ground steel shank, these tools are more wear resistant than high-speed steel tools. Right-handed tools cut from right to left, left-handed tools cut from left to right, and neutral tools can cut in either direction.

Style AR and AL tools perform along the length turning, facing, boring, and chamfering. They allow for a sharp 90° square shoulder.

Style BR and BL tools perform along the length turning, facing, boring, and chamfering. They are suitable for roughing cuts, interrupted cuts, and cuts where a square shoulder is not required.

Style C tools perform along the length turning, facing, chamfering, and external grooving.

Style D tools perform along the length turning, facing, boring, chamfering, external grooving, and undercutting.

Style E tools are for external threading.

C2 carbide tips are abrasion resistant and less likely to chip or crack than C6 carbide when cutting aluminum, brass, and bronze. C6 carbide tips hold up better than C2 carbide when making cuts in steel. Micrograin carbide tips outperform C2 and C6 tips when cutting metal that’s difficult to machine, such as stainless steel or titanium. They leave a good finish on most materials.

Shank | |||||||

|---|---|---|---|---|---|---|---|

| Wd. | Ht. | O'all Lg. | No. of Pieces | Includes | For Use On | Each | |

C2 Carbide | |||||||

For Along-the-Length Turning, Boring, Chamfering, External Grooving, External Threading, and Facing | |||||||

| 1/4" | 1/4" | 2" | 7 | One AR-4 right hand lathe tool One AL-4 left hand lathe tool One BR-4 right hand lathe tool One BL-4 left hand lathe tool One C-4 neutral lathe tool One D-4 neutral lathe tool One E-4 neutral lathe tool | Aluminum, Brass, Bronze | 0000000 | 000000 |

| 5/16" | 5/16" | 2 1/4" | 7 | One AR-5 right hand lathe tool One AL-5 left hand lathe tool One BR-5 right hand lathe tool One BL-5 left hand lathe tool One C-5 neutral lathe tool One D-5 neutral lathe tool One E-5 neutral lathe tool | Aluminum, Brass, Bronze | 0000000 | 00000 |

| 3/8" | 3/8" | 2 1/2" | 7 | One AR-6 right hand lathe tool One AL-6 left hand lathe tool One BR-6 right hand lathe tool One BL-6 left hand lathe tool One C-6 neutral lathe tool One D-6 neutral lathe tool One E-6 neutral lathe tool | Aluminum, Brass, Bronze | 0000000 | 00000 |

| 1/2" | 1/2" | 3 1/2" | 7 | One AR-8 right hand lathe tool One AL-8 left hand lathe tool One BR-8 right hand lathe tool One BL-8 left hand lathe tool One C-8 neutral lathe tool One D-8 neutral lathe tool One E-8 neutral lathe tool | Aluminum, Brass, Bronze | 0000000 | 00000 |

| 5/8" | 5/8" | 4" | 7 | One AR-10 right hand lathe tool One AL-10 left hand lathe tool One BR-10 right hand lathe tool One BL-10 left hand lathe tool One C-10 neutral lathe tool One D-10 neutral lathe tool One E-10 neutral lathe tool | Aluminum, Brass, Bronze | 0000000 | 00000 |

| 3/4" | 3/4" | 3 1/2" | 7 | One AR-12 right hand lathe tool One AL-12 left hand lathe tool One BR-12 right hand lathe tool One BL-12 left hand lathe tool One C-12 neutral lathe tool One D-12 neutral lathe tool One E-12 neutral lathe tool | Aluminum, Brass, Bronze | 0000000 | 000000 |

C6 Carbide | |||||||

For Along-the-Length Turning, Boring, Chamfering, External Grooving, External Threading, and Facing | |||||||

| 1/4" | 1/4" | 2" | 7 | One AR-4 right hand lathe tool One AL-4 left hand lathe tool One BR-4 right hand lathe tool One BL-4 left hand lathe tool One C-4 neutral lathe tool One D-4 neutral lathe tool One E-4 neutral lathe tool | Steel | 0000000 | 00000 |

| 5/16" | 5/16" | 2 1/4" | 7 | One AR-5 right hand lathe tool One AL-5 left hand lathe tool One BR-5 right hand lathe tool One BL-5 left hand lathe tool One C-5 neutral lathe tool One D-5 neutral lathe tool One E-5 neutral lathe tool | Steel | 0000000 | 00000 |

| 3/8" | 3/8" | 2 1/2" | 7 | One AR-6 right hand lathe tool One AL-6 left hand lathe tool One BR-6 right hand lathe tool One BL-6 left hand lathe tool One C-6 neutral lathe tool One D-6 neutral lathe tool One E-6 neutral lathe tool | Steel | 0000000 | 00000 |

| 1/2" | 1/2" | 3 1/2" | 7 | One AR-8 right hand lathe tool One AL-8 left hand lathe tool One BR-8 right hand lathe tool One BL-8 left hand lathe tool One C-8 neutral lathe tool One D-8 neutral lathe tool One E-8 neutral lathe tool | Steel | 0000000 | 00000 |

| 5/8" | 5/8" | 4" | 7 | One AR-10 right hand lathe tool One AL-10 left hand lathe tool One BR-10 right hand lathe tool One BL-10 left hand lathe tool One C-10 neutral lathe tool One D-10 neutral lathe tool One E-10 neutral lathe tool | Steel | 0000000 | 00000 |

| 3/4" | 3/4" | 3 1/2" | 7 | One AR-12 right hand lathe tool One AL-12 left hand lathe tool One BR-12 right hand lathe tool One BL-12 left hand lathe tool One C-12 neutral lathe tool One D-12 neutral lathe tool One E-12 neutral lathe tool | Steel | 0000000 | 00000 |

Micrograin Carbide | |||||||

For Along-the-Length Turning, Boring, Chamfering, External Grooving, External Threading, and Facing | |||||||

| 1/4" | 1/4" | 2" | 7 | One AR-4 right hand lathe tool One AL-4 left hand lathe tool One BR-4 right hand lathe tool One BL-4 left hand lathe tool One C-4 neutral lathe tool One D-4 neutral lathe tool One E-4 neutral lathe tool | Aluminum, Brass, Bronze, Cast Iron, Nickel, Plastic, Stainless Steel, Steel, Titanium | 0000000 | 00000 |

| 5/16" | 5/16" | 2 1/4" | 7 | One AR-5 right hand lathe tool One AL-5 left hand lathe tool One BR-5 right hand lathe tool One BL-5 left hand lathe tool One C-5 neutral lathe tool One D-5 neutral lathe tool One E-5 neutral lathe tool | Aluminum, Brass, Bronze, Cast Iron, Nickel, Plastic, Stainless Steel, Steel, Titanium | 0000000 | 00000 |

| 3/8" | 3/8" | 2 1/2" | 7 | One AR-6 right hand lathe tool One AL-6 left hand lathe tool One BR-6 right hand lathe tool One BL-6 left hand lathe tool One C-6 neutral lathe tool One D-6 neutral lathe tool One E-6 neutral lathe tool | Aluminum, Brass, Bronze, Cast Iron, Nickel, Plastic, Stainless Steel, Steel, Titanium | 0000000 | 00000 |

| 1/2" | 1/2" | 3 1/2" | 7 | One AR-8 right hand lathe tool One AL-8 left hand lathe tool One BR-8 right hand lathe tool One BL-8 left hand lathe tool One C-8 neutral lathe tool One D-8 neutral lathe tool One E-8 neutral lathe tool | Aluminum, Brass, Bronze, Cast Iron, Nickel, Plastic, Stainless Steel, Steel, Titanium | 0000000 | 00000 |

| 5/8" | 5/8" | 4" | 7 | One AR-10 right hand lathe tool One AL-10 left hand lathe tool One BR-10 right hand lathe tool One BL-10 left hand lathe tool One C-10 neutral lathe tool One D-10 neutral lathe tool One E-10 neutral lathe tool | Aluminum, Brass, Bronze, Cast Iron, Nickel, Plastic, Stainless Steel, Steel, Titanium | 0000000 | 000000 |

| 3/4" | 3/4" | 3 1/2" | 7 | One AR-12 right hand lathe tool One AL-12 left hand lathe tool One BR-12 right hand lathe tool One BL-12 left hand lathe tool One C-12 neutral lathe tool One D-12 neutral lathe tool One E-12 neutral lathe tool | Aluminum, Brass, Bronze, Cast Iron, Nickel, Plastic, Stainless Steel, Steel, Titanium | 0000000 | 000000 |

Boring Lathe Tool Sets

Use these tools to enlarge existing holes to precise diameters. All have an offset taper that provides additional clearance to prevent chips from clogging the hole.

C2 carbide tips are abrasion resistant and less likely to chip or crack than C6 carbide when cutting aluminum, brass, and bronze. C6 carbide tips hold up better than C2 carbide when making cuts in steel.

| Shank Dia. | No. of Pieces | Includes | For Use On | Each | |

C2 Carbide | |||||

|---|---|---|---|---|---|

Right Hand | |||||

| 3/8" | 9 | One 2 15/16" lg. boring tool for 7/16" min. hole dia. and 1 11/16" max. hole dp. One 2 21/32" lg. boring tool for 3/8" min. hole dia. and 1 13/32" max. hole dp. One 2 3/16" lg. boring tool for 3/8" min. hole dia. and 15/16" max. hole dp. One 2 3/4" lg. boring tool for 5/16" min. hole dia. and 1 1/2" max. hole dp. One 2 3/8" lg. boring tool for 5/16" min. hole dia. and 1 1/8" max. hole dp. One 2 3/8" lg. boring tool for 7/16" min. hole dia. and 1 1/8" max. hole dp. One 2" lg. boring tool for 5/16" min. hole dia. and 3/4" max. hole dp. One 3 1/2" lg. boring tool for 7/16" min. hole dia. and 2 1/4" max. hole dp. One 3 1/8" lg. boring tool for 3/8" min. hole dia. and 1 7/8" max. hole dp. | Aluminum, Brass, Bronze | 0000000 | 0000000 |

| 1/2" | 9 | One 2 1/4" lg. boring tool for 5/16" min. hole dia. and 3/4" max. hole dp. One 2 5/8" lg. boring tool for 5/16" min. hole dia. and 1 1/8" max. hole dp. One 2 5/8" lg. boring tool for 7/16" min. hole dia. and 1 1/8" max. hole dp. One 3 3/16" lg. boring tool for 7/16" min. hole dia. and 1 11/16" max. hole dp. One 3 3/4" lg. boring tool for 7/16" min. hole dia. and 2 1/4" max. hole dp. One 3 3/4" lg. boring tool for 9/16" min. hole dia. and 2 1/4" max. hole dp. One 3" lg. boring tool for 5/16" min. hole dia. and 1 1/2" max. hole dp. One 3" lg. boring tool for 9/16" min. hole dia. and 1 1/2" max. hole dp. One 4 1/2" lg. boring tool for 9/16" min. hole dia. and 3" max. hole dp. | Aluminum, Brass, Bronze | 0000000 | 000000 |

| 5/8" | 12 | One 2 1/4" lg. boring tool for 5/16" min. hole dia. and 3/4" max. hole dp. One 2 5/8" lg. boring tool for 5/16" min. hole dia. and 1 1/8" max. hole dp. One 2 5/8" lg. boring tool for 7/16" min. hole dia. and 1 1/8" max. hole dp. One 3 3/16" lg. boring tool for 7/16" min. hole dia. and 1 11/16" max. hole dp. One 3 3/4" lg. boring tool for 7/16" min. hole dia. and 2 1/4" max. hole dp. One 3 3/4" lg. boring tool for 9/16" min. hole dia. and 2 1/4" max. hole dp. One 3 3/8" lg. boring tool for 11/16" min. hole dia. and 1 7/8" max. hole dp. One 3" lg. boring tool for 5/16" min. hole dia. and 1 1/2" max. hole dp. One 3" lg. boring tool for 9/16" min. hole dia. and 1 1/2" max. hole dp. One 4 1/2" lg. boring tool for 9/16" min. hole dia. and 3" max. hole dp. One 4 5/16" lg. boring tool for 11/16" min. hole dia. and 2 13/16" max. hole dp. One 5 1/4" lg. boring tool for 11/16" min. hole dia. and 3 3/4" max. hole dp. | Aluminum, Brass, Bronze | 0000000 | 000000 |

| 3/4" | 12 | One 3 1/2" lg. boring tool for 9/16" min. hole dia. and 1 1/2" max. hole dp. One 3 1/8" lg. boring tool for 7/16" min. hole dia. and 1 1/8" max. hole dp. One 3 11/16" lg. boring tool for 7/16" min. hole dia. and 1 11/16" max. hole dp. One 3 7/8" lg. boring tool for 11/16" min. hole dia. and 1 7/8" max. hole dp. One 4 1/4" lg. boring tool for 13/16" min. hole dia. and 2 1/4" max. hole dp. One 4 1/4" lg. boring tool for 7/16" min. hole dia. and 2 1/4" max. hole dp. One 4 1/4" lg. boring tool for 9/16" min. hole dia. and 2 1/4" max. hole dp. One 4 13/16" lg. boring tool for 11/16" min. hole dia. and 2 13/16" max. hole dp. One 5 3/4" lg. boring tool for 11/16" min. hole dia. and 3 3/4" max. hole dp. One 5 3/8" lg. boring tool for 13/16" min. hole dia. and 3 3/8" max. hole dp. One 5" lg. boring tool for 9/16" min. hole dia. and 3" max. hole dp. One 6 1/2" lg. boring tool for 13/16" min. hole dia. and 4 1/2" max. hole dp. | Aluminum, Brass, Bronze | 0000000 | 000000 |

C6 Carbide | |||||

Right Hand | |||||

| 3/8" | 9 | One 2 15/16" lg. boring tool for 7/16" min. hole dia. and 1 11/16" max. hole dp. One 2 21/32" lg. boring tool for 3/8" min. hole dia. and 1 13/32" max. hole dp. One 2 3/16" lg. boring tool for 3/8" min. hole dia. and 15/16" max. hole dp. One 2 3/4" lg. boring tool for 5/16" min. hole dia. and 1 1/2" max. hole dp. One 2 3/8" lg. boring tool for 5/16" min. hole dia. and 1 1/8" max. hole dp. One 2 3/8" lg. boring tool for 7/16" min. hole dia. and 1 1/8" max. hole dp. One 2" lg. boring tool for 5/16" min. hole dia. and 3/4" max. hole dp. One 3 1/2" lg. boring tool for 7/16" min. hole dia. and 2 1/4" max. hole dp. One 3 1/8" lg. boring tool for 3/8" min. hole dia. and 1 7/8" max. hole dp. | Steel | 0000000 | 000000 |

| 1/2" | 9 | One 2 1/4" lg. boring tool for 5/16" min. hole dia. and 3/4" max. hole dp. One 2 5/8" lg. boring tool for 5/16" min. hole dia. and 1 1/8" max. hole dp. One 2 5/8" lg. boring tool for 7/16" min. hole dia. and 1 1/8" max. hole dp. One 3 3/16" lg. boring tool for 7/16" min. hole dia. and 1 11/16" max. hole dp. One 3 3/4" lg. boring tool for 7/16" min. hole dia. and 2 1/4" max. hole dp. One 3 3/4" lg. boring tool for 9/16" min. hole dia. and 2 1/4" max. hole dp. One 3" lg. boring tool for 5/16" min. hole dia. and 1 1/2" max. hole dp. One 3" lg. boring tool for 9/16" min. hole dia. and 1 1/2" max. hole dp. One 4 1/2" lg. boring tool for 9/16" min. hole dia. and 3" max. hole dp. | Steel | 0000000 | 000000 |

| 5/8" | 12 | One 2 1/4" lg. boring tool for 5/16" min. hole dia. and 3/4" max. hole dp. One 2 5/8" lg. boring tool for 5/16" min. hole dia. and 1 1/8" max. hole dp. One 2 5/8" lg. boring tool for 7/16" min. hole dia. and 1 1/8" max. hole dp. One 3 3/16" lg. boring tool for 7/16" min. hole dia. and 1 11/16" max. hole dp. One 3 3/4" lg. boring tool for 7/16" min. hole dia. and 2 1/4" max. hole dp. One 3 3/4" lg. boring tool for 9/16" min. hole dia. and 2 1/4" max. hole dp. One 3 3/8" lg. boring tool for 11/16" min. hole dia. and 1 7/8" max. hole dp. One 3" lg. boring tool for 5/16" min. hole dia. and 1 1/2" max. hole dp. One 3" lg. boring tool for 9/16" min. hole dia. and 1 1/2" max. hole dp. One 4 1/2" lg. boring tool for 9/16" min. hole dia. and 3" max. hole dp. One 4 5/16" lg. boring tool for 11/16" min. hole dia. and 2 13/16" max. hole dp. One 5 1/4" lg. boring tool for 11/16" min. hole dia. and 3 3/4" max. hole dp. | Steel | 0000000 | 000000 |

| 3/4" | 12 | One 3 1/2" lg. boring tool for 9/16" min. hole dia. and 1 1/2" max. hole dp. One 3 1/8" lg. boring tool for 7/16" min. hole dia. and 1 1/8" max. hole dp. One 3 11/16" lg. boring tool for 7/16" min. hole dia. and 1 11/16" max. hole dp. One 3 7/8" lg. boring tool for 11/16" min. hole dia. and 1 7/8" max. hole dp. One 4 1/4" lg. boring tool for 13/16" min. hole dia. and 2 1/4" max. hole dp. One 4 1/4" lg. boring tool for 7/16" min. hole dia. and 2 1/4" max. hole dp. One 4 1/4" lg. boring tool for 9/16" min. hole dia. and 2 1/4" max. hole dp. One 4 13/16" lg. boring tool for 11/16" min. hole dia. and 2 13/16" max. hole dp. One 5 3/4" lg. boring tool for 11/16" min. hole dia. and 3 3/4" max. hole dp. One 5 3/8" lg. boring tool for 13/16" min. hole dia. and 3 3/8" max. hole dp. One 5" lg. boring tool for 9/16" min. hole dia. and 3" max. hole dp. One 6 1/2" lg. boring tool for 13/16" min. hole dia. and 4 1/2" max. hole dp. | Steel | 0000000 | 000000 |

Small-Diameter Boring Lathe Tool Sets

This set contains some of the smallest boring tools we offer. Use them to enlarge existing holes to precise diameters. Made entirely of micrograin carbide, which outperforms C2 and C6 carbide when cutting difficult-to-machine metal, such as stainless steel or titanium. It provides a good finish on most materials. Tools have flats on the shank for quick alignment.

| Shank Dia. | No. of Pieces | Includes | For Use On | Each | |

Right Hand | |||||

|---|---|---|---|---|---|

| 1/8" | 6 | One 1 1/2" lg. boring tool for 0.020" min. hole dia. and 0.075" max. hole dp. One 1 1/2" lg. boring tool for 0.025" min. hole dia. and 0.100" max. hole dp. One 1 1/2" lg. boring tool for 0.030" min. hole dia. and 0.100" max. hole dp. One 1 1/2" lg. boring tool for 0.035" min. hole dia. and 0.100" max. hole dp. One 1 1/2" lg. boring tool for 0.040" min. hole dia. and 0.150" max. hole dp. One 1 1/2" lg. boring tool for 0.045" min. hole dia. and 0.150" max. hole dp. | Aluminum, Brass, Bronze, Cast Iron, Nickel, Plastic, Stainless Steel, Steel, Titanium | 0000000 | 0000000 |

Long-Reach Boring Lathe Tool Sets

The long steel shank on these tools can reach farther inside the workpiece than standard boring tools and can be cut to length depending on the depth of the hole. Use them to enlarge existing holes to precise diameters.

Tips are micrograin carbide, which outperform C2 and C6 carbide tips when cutting difficult-to-machine metal, such as stainless steel or titanium. They provide a good finish on most materials.

Right-hand tools are for boring when the workpiece is rotating counterclockwise (toward the lathe operator). Left-hand tools are for boring when the workpiece is rotating clockwise (away from the lathe operator).

| No. of Pieces | Includes | For Use On | Each | |

Right Hand | ||||

|---|---|---|---|---|

| 5 | One 1/2" dia. shank boring tool for 5/8" min. hole dia. and 6" max. hole dp. One 1/4" dia. shank boring tool for 0.320" min. hole dia. and 3" max. hole dp. One 3/4" dia. shank boring tool for 0.935" min. hole dia. and 8" max. hole dp. One 3/8" dia. shank boring tool for 0.463" min. hole dia. and 5" max. hole dp. One 5/8" dia. shank boring tool for 0.795" min. hole dia. and 7" max. hole dp. | Aluminum, Brass, Bronze, Nickel, Stainless Steel, Steel, Titanium | 0000000 | 0000000 |

Left Hand | ||||

| 5 | One 1/2" dia. shank boring tool for 5/8" min. hole dia. and 6" max. hole dp. One 1/4" dia. shank boring tool for 0.320" min. hole dia. and 3" max. hole dp. One 3/4" dia. shank boring tool for 0.935" min. hole dia. and 8" max. hole dp. One 3/8" dia. shank boring tool for 0.463" min. hole dia. and 5" max. hole dp. One 5/8" dia. shank boring tool for 0.795" min. hole dia. and 7" max. hole dp. | Aluminum, Brass, Bronze, Nickel, Stainless Steel, Steel, Titanium | 0000000 | 000000 |

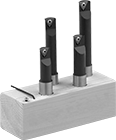

Economy Indexable Turning Tool Sets

Keep a variety of tools on hand to cut and shape workpieces. The tools in these sets come with carbide inserts installed. When one edge of the insert dulls, rotate to a fresh one. When all the edges are dull, you can replace the insert rather than the entire tool. Right-handed tools cut from right to left, left-handed tools cut from left to right, and neutral tools can cut in either direction. All sets come with uncoated C5 inserts.

Styles AR and AL help you create a sharp 90° square shoulder.

Styles BR and BL are used for roughing, interrupted cuts, and cuts where a square shoulder is not required.

Style E are for external threading.

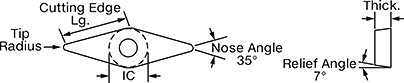

Style V fit into tighter areas than Style A and B. They also create cleaner edges and a finer surface finish.

Tool Sets | |||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

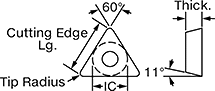

Shank | Insert | Replacement Hex Screws | |||||||||||

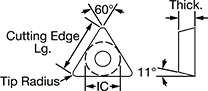

| Wd. | Ht. | O'all Lg. | No. of Pieces | Includes | Material | For Use On | Code | Inscribed Circle Dia. (IC) | Thick. | Each | Each | ||

Along-the-Length Turning, Boring, Chamfering, External Threading, and Facing | |||||||||||||

| 3/8" | 3/8" | 2 1/2" | 9 | Five TPMT-221 Inserts One AR-6 right hand lathe tool One AL-6 left hand lathe tool One BR-6 right hand lathe tool One BL-6 left hand lathe tool One E-6 neutral lathe tool Plastic Stand Two Hex Screws Two L-Keys | Carbon Steel | Steel | TPMT-221 | 1/4" | 1/8" | 00000000 | 0000000 | 00000000 | 00000 |

| 1/2" | 1/2" | 3 1/2" | 9 | Five TPMT-321 Inserts One AR-8 right hand lathe tool One AL-8 left hand lathe tool One BR-8 right hand lathe tool One BL-8 left hand lathe tool One E-8 neutral lathe tool Plastic Stand Two Hex Screws Two L-Keys | Carbon Steel | Steel | TPMT-321 | 3/8" | 1/8" | 00000000 | 000000 | 00000000 | 0000 |

| 5/8" | 5/8" | 4" | 9 | Five TPMT-321 Inserts One AR-10 right hand lathe tool One AL-10 left hand lathe tool One BR-10 right hand lathe tool One BL-10 left hand lathe tool One E-10 neutral lathe tool Plastic Stand Two Hex Screws Two L-Keys | Carbon Steel | Steel | TPMT-321 | 3/8" | 1/8" | 00000000 | 000000 | 00000000 | 0000 |

| 3/4" | 3/4" | 4 1/2" | 9 | Five TPMT-321 Inserts One AR-12 right hand lathe tool One AL-12 left hand lathe tool One BR-12 right hand lathe tool One BL-12 left hand lathe tool One E-12 neutral lathe tool Plastic Stand Two Hex Screws Two L-Keys | Carbon Steel | Steel | TPMT-321 | 3/8" | 1/8" | 00000000 | 000000 | 00000000 | 0000 |

| 1" | 1" | 6" | 9 | Five TPMT-431 Inserts One AR-16 right hand lathe tool One AL-16 left hand lathe tool One BR-16 right hand lathe tool One BL-16 left hand lathe tool One E-16 neutral lathe tool Plastic Stand Two Hex Screws Two L-Keys | Carbon Steel | Steel | TPMT-431 | 1/2" | 3/16" | 00000000 | 000000 | 00000000 | 0000 |

Along-the-Length Turning, Chamfering, External Profiling, Facing, and Internal Profiling | |||||||||||||

| 1/2" | 1/2" | 3 1/2" | 5 | Three VCMT-32.52 Inserts One VR-8 right hand lathe tool One VL-8 left hand lathe tool One VE-8 neutral lathe tool Plastic Stand One Hex Screw One L-Key | Carbon Steel | Steel | VCMT-32.52 | 3/8" | 5/32" | 00000000 | 000000 | 00000000 | 0000 |

| 5/8" | 5/8" | 4" | 5 | Three VCMT-32.52 Inserts One VR-10 right hand lathe tool One VL-10 left hand lathe tool One VE-10 neutral lathe tool Plastic Stand One Hex Screw One L-Key | Carbon Steel | Steel | VCMT-32.52 | 3/8" | 5/32" | 00000000 | 000000 | 00000000 | 0000 |

| 3/4" | 3/4" | 4 1/2" | 5 | Three VCMT-32.52 Inserts One VR-12 right hand lathe tool One VL-12 left hand lathe tool One VE-12 neutral lathe tool Plastic Stand One Hex Screw One L-Key | Carbon Steel | Steel | VCMT-32.52 | 3/8" | 5/32" | 00000000 | 000000 | 00000000 | 0000 |

| 1" | 1" | 6" | 5 | Three VCMT-32.52 Inserts One VR-16 right hand lathe tool One VL-16 left hand lathe tool One VE-16 neutral lathe tool Plastic Stand One Hex Screw One L-Key | Carbon Steel | Steel | VCMT-32.52 | 3/8" | 5/32" | 00000000 | 000000 | 00000000 | 0000 |

Coated inserts last longer and can be run at faster speeds than uncoated inserts.

Inserts sold individually come packed in a clear plastic case to protect cutting edges during shipment. Inserts sold in packs come factory sealed from the manufacturer for maximum traceability.

Each | Package | |||||||||

|---|---|---|---|---|---|---|---|---|---|---|

| Insert Code | Inscribed Circle Diameter (IC) | Thick. | Cutting Edge Lg. | Tip Radius | For Tool Bit Code | Each | Pkg. Qty. | Pkg. | ||

For Use On Aluminum, Brass, Bronze | ||||||||||

| TPMT-221 | 1/4" | 1/8" | 0.38" | 1/64" | AL-6, AR-6, BL-6, BR-6, E-6 | 00000000 | 000000 | 10 | 00000000 | 000000 |

| TPMT-222 | 1/4" | 1/8" | 0.38" | 1/32" | AL-6, AR-6, BL-6, BR-6, E-6 | 00000000 | 00000 | 10 | 00000000 | 00000 |

| TPMT-321 | 3/8" | 1/8" | 0.56" | 1/64" | AL-10, AL-12, AL-8, AR-10, AR-12, AR-8, BL-10, BL-12, BL-8, BR-10, BR-12, BR-8, E-10, E-12, E-8 | 00000000 | 00000 | 10 | 00000000 | 000000 |

| TPMT-322 | 3/8" | 1/8" | 0.56" | 1/32" | AL-10, AL-12, AL-8, AR-10, AR-12, AR-8, BL-10, BL-12, BL-8, BR-10, BR-12, BR-8, E-10, E-12, E-8 | 00000000 | 00000 | 10 | 0000000 | 000000 |

| TPMT-431 | 1/2" | 3/16" | 0.8" | 1/64" | AL-16, AR-16, BL-16, BR-16, E-16 | 00000000 | 00000 | 10 | 00000000 | 000000 |

| TPMT-432 | 1/2" | 3/16" | 0.75" | 1/32" | AL-16, AR-16, BL-16, BR-16, E-16 | 00000000 | 00000 | 10 | 00000000 | 000000 |

| VCMT-32.52 | 3/8" | 5/32" | 0.65" | 1/32" | VE-10, VE-12, VE-16, VE-8, VL-10, VL-12, VL-16, VL-8, VR-10, VR-12, VR-16, VR-8 | 00000000 | 00000 | 10 | 00000000 | 000000 |

For Use On Steel | ||||||||||

| TPMT-221 | 1/4" | 1/8" | 0.38" | 1/64" | AL-6, AR-6, BL-6, BR-6, E-6 | 00000000 | 00000 | 10 | 00000000 | 00000 |

| TPMT-222 | 1/4" | 1/8" | 0.38" | 1/32" | AL-6, AR-6, BL-6, BR-6, E-6 | 00000000 | 00000 | 10 | 0000000 | 00000 |

| TPMT-321 | 3/8" | 1/8" | 0.56" | 1/64" | AL-10, AL-12, AL-8, AR-10, AR-12, AR-8, BL-10, BL-12, BL-8, BR-10, BR-12, BR-8, E-10, E-12, E-8 | 00000000 | 00000 | 10 | 00000000 | 000000 |

| TPMT-322 | 3/8" | 1/8" | 0.56" | 1/32" | AL-10, AL-12, AL-8, AR-10, AR-12, AR-8, BL-10, BL-12, BL-8, BR-10, BR-12, BR-8, E-10, E-12, E-8 | 00000000 | 00000 | 10 | 00000000 | 000000 |

| TPMT-431 | 1/2" | 3/16" | 0.8" | 1/64" | AL-16, AR-16, BL-16, BR-16, E-16 | 00000000 | 00000 | 10 | 00000000 | 000000 |

| TPMT-432 | 1/2" | 3/16" | 0.75" | 1/32" | AL-16, AR-16, BL-16, BR-16, E-16 | 00000000 | 00000 | 10 | 00000000 | 000000 |

| VCMT-32.52 | 3/8" | 5/32" | 0.65" | 1/32" | VE-10, VE-12, VE-16, VE-8, VL-10, VL-12, VL-16, VL-8, VR-10, VR-12, VR-16, VR-8 | 00000000 | 00000 | 10 | 00000000 | 000000 |

Each | Package | |||||||||

|---|---|---|---|---|---|---|---|---|---|---|

| Insert Code | Inscribed Circle Diameter (IC) | Thick. | Cutting Edge Lg. | Tip Radius | For Tool Bit Code | Each | Pkg. Qty. | Pkg. | ||

For Use On Steel | ||||||||||

| TPMT-221 | 1/4" | 1/8" | 0.38" | 1/64" | AL-6, AR-6, BL-6, BR-6, E-6 | 00000000 | 000000 | 10 | 0000000 | 0000000 |

| TPMT-222 | 1/4" | 1/8" | 0.38" | 1/32" | AL-6, AR-6, BL-6, BR-6, E-6 | 00000000 | 00000 | 10 | 00000000 | 000000 |

| TPMT-321 | 3/8" | 1/8" | 0.56" | 1/64" | AL-10, AL-12, AL-8, AR-10, AR-12, AR-8, BL-10, BL-12, BL-8, BR-10, BR-12, BR-8, E-10, E-12, E-8 | 00000000 | 00000 | 10 | 00000000 | 000000 |

| TPMT-322 | 3/8" | 1/8" | 0.56" | 1/32" | AL-10, AL-12, AL-8, AR-10, AR-12, AR-8, BL-10, BL-12, BL-8, BR-10, BR-12, BR-8, E-10, E-12, E-8 | 00000000 | 00000 | 10 | 00000000 | 000000 |

| TPMT-431 | 1/2" | 3/16" | 0.8" | 1/64" | AL-16, AR-16, BL-16, BR-16, E-16 | 00000000 | 00000 | 10 | 00000000 | 000000 |

| TPMT-432 | 1/2" | 3/16" | 0.75" | 1/32" | AL-16, AR-16, BL-16, BR-16, E-16 | 00000000 | 00000 | 10 | 00000000 | 000000 |

| VCMT-32.52 | 3/8" | 5/32" | 0.65" | 1/32" | VE-10, VE-12, VE-16, VE-8, VL-10, VL-12, VL-16, VL-8, VR-10, VR-12, VR-16, VR-8 | 00000000 | 00000 | 10 | 00000000 | 000000 |

Economy Indexable Boring Carbide Insert Holder Sets

These tools come with an insert installed. When one edge of the insert dulls, rotate it to use a sharp edge. When all edges dull, replace the insert rather than the whole tool. Inserts are C5 carbide for general purpose machining.

Insert | |||||||||

|---|---|---|---|---|---|---|---|---|---|

| Shank Dia. | No. of Pieces | Includes | Material | For Use On | Code | Inscribed Circle Dia. (IC) | Thick. | Each | |

| 1/2" | 4 | One 2 3/4" lg. boring tool for 7/16" min. hole dia. and 1 1/4" max. hole dp. One 3" lg. boring tool for 1/2" min. hole dia. and 1 1/2" max. hole dp. One 3 5/8" lg. boring tool for 7/16" min. hole dia. and 2 1/8" max. hole dp. One 4" lg. boring tool for 1/2" min. hole dia. and 2 1/2" max. hole dp. Four TPMT-221 Inserts | Steel | Steel | TPMT-221 | 1/4" | 1/8" | 00000000 | 0000000 |

| 3/4" | 8 | One 3 3/8" lg. boring tool for 7/16" min. hole dia. and 1 3/8" max. hole dp. One 3 5/8" lg. boring tool for 1/2" min. hole dia. and 1 5/8" max. hole dp. One 3 7/8" lg. boring tool for 9/16" min. hole dia. and 1 7/8" max. hole dp. One 4 1/4" lg. boring tool for 7/16" min. hole dia. and 2 1/4" max. hole dp. One 4 1/4" lg. boring tool for 11/16" min. hole dia. and 2 1/4" max. hole dp. One 4 5/8" lg. boring tool for 1/2" min. hole dia. and 2 5/8" max. hole dp. One 5" lg. boring tool for 9/16" min. hole dia. and 3" max. hole dp. One 5 1/2" lg. boring tool for 11/16" min. hole dia. and 3 1/2" max. hole dp. Eight TPMT-221 Inserts | Steel | Steel | TPMT-221 | 1/4" | 1/8" | 00000000 | 000000 |

| Replacement Hex Screw (2-56 × 1/4") | 00000000 | Each | 00000 |

Interchangeable Point Lathe Center Sets

Keep a variety of lathe center points on hand so you always have the right tool for the job. These sets include at least four different points, as well as a lathe center body and a point extractor. Use the point extractor to remove a point from the body and swap in another. You can replace bodies, points, and extractors individually if they become worn or damaged.

Live centers sit in the tailstock to support the end of a workpiece. They spin with the workpiece to reduce friction between the tip and the material. For smooth rotation, these centers turn on lubricated bearings. The bearings are sealed to protect against chips and liquid, which extends the life of the tool. Precision live centers wobble less than standard live centers for three to five times greater accuracy as they spin.

Use dead centers in your headstock to support a workpiece when machining between centers. When friction isn’t a concern, you can also use them in the tailstock to support the end of a workpiece. Dead centers don’t spin freely, so they provide a fixed point that stabilizes your workpiece. They can handle heavier loads than live centers. However, under high pressure, they can become lodged in the tailstock. To remove them without damaging your equipment, tighten a hex nut (sold separately) onto the threaded end. Use a wrench to turn the nut against the tailstock and push the center out.

Standard points provide tool clearance for CNC applications, making it easier to machine complex shapes and features. Bull-nose points have a wide head for holding hollow workpieces with large diameters. They’re often used with pipes and tubes. Cup points are designed to grip the outer diameter of a workpiece—instead of a tip, they have a cup-shaped recess. They’re also known as female points. Flat knurled points sit flush against workpieces for a tight grip. Their knurls create friction that keeps your workpiece from slipping. Half points are cut away on one side to hold shafts with keyways, flats, or irregular shapes. They’re used only in dead centers. Extended-tip points are shaped to provide more tool clearance than standard points without adding much length. They’re also used for machining complex shapes and features.

Carbide-tipped points are more wear resistant than hardened steel points. They're a good choice for high-volume operations and for holding hard or highly abrasive materials.

TIR (total indicated runout) is a measure of rotational smoothness. The lower the value, the less wobble a rotating tool will have and the more accurate it will be.

| Morse Taper No. | Max. Workpiece Cap., lbs. | Max. Speed, rpm | TIR (Total Indicated Runout) Accuracy | Head Dia. | Thread Size | Shank Lg. | Overall Lg. | Material | No. of Pieces | Includes | Each | |

Live | ||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|

| 2 | 220 | 5,000 | 0.0008" | 1 37/64" | __ | 2 33/64" | 4 3/64" | Hardened Steel | 9 | 0.59" dia. Hardened Steel Bull-Nose Point 0.59" dia. Hardened Steel Standard Point 0.71" dia. Hardened Steel Flat-Knurled Point 0.87" dia. Hardened Steel Bull-Nose Point 0.87" dia. Hardened Steel Cup Point 1.18" dia. Hardened Steel Cup Point 1.46" dia. Hardened Steel Bull-Nose Point Live Center Body Point Extractor | 0000000 | 0000000 |

| 3 | 440 | 4,000 | 0.0008" | 2 13/64" | __ | 3 3/16" | 5 7/32" | Hardened Steel | 9 | 0.79" dia. Hardened Steel Bull-Nose Point 0.79" dia. Hardened Steel Standard Point 0.98" dia. Hardened Steel Flat-Knurled Point 1.42" dia. Hardened Steel Bull-Nose Point 1.42" dia. Hardened Steel Cup Point 1.77" dia. Hardened Steel Cup Point 2.48" dia. Hardened Steel Bull-Nose Point Live Center Body Point Extractor | 0000000 | 000000 |

| 4 | 880 | 3,000 | 0.0008" | 2 33/64" | __ | 4 1/32" | 6 7/32" | Hardened Steel | 8 | 0.98" dia. Hardened Steel Standard Point 1.26" dia. Hardened Steel Flat-Knurled Point 1.77" dia. Hardened Steel Bull-Nose Point 1.77" dia. Hardened Steel Cup Point 2.48" dia. Hardened Steel Cup Point 2.76" dia. Hardened Steel Bull-Nose Point Live Center Body Point Extractor | 0000000 | 000000 |

| 5 | 1,770 | 2,500 | 0.0012" | 3 23/64" | __ | 5 3/32" | 7 13/16" | Hardened Steel | 8 | 1.26" dia. Hardened Steel Bull-Nose Point 1.26" dia. Hardened Steel Standard Point 1.77" dia. Hardened Steel Flat-Knurled Point 2.2" dia. Hardened Steel Bull-Nose Point 2.2" dia. Hardened Steel Cup Point 3.15" dia. Hardened Steel Bull-Nose Point Live Center Body Point Extractor | 0000000 | 000000 |

| 6 | 3,550 | 2,000 | 0.0012" | 5 1/8" | __ | 7 9/64" | 10 27/32" | Hardened Steel | 9 | 1.42" dia. Hardened Steel Bull-Nose Point 1.42" dia. Hardened Steel Standard Point 2.2" dia. Hardened Steel Flat-Knurled Point 2.76" dia. Hardened Steel Bull-Nose Point 2.76" dia. Hardened Steel Cup Point 3.94" dia. Hardened Steel Bull-Nose Point 3.94" dia. Hardened Steel Cup Point Live Center Body Point Extractor | 0000000 | 00000000 |

Precision Live | ||||||||||||

| 2 | 100 | 5,000 | 0.00025" | 2 1/8" | __ | 2 9/16" | 4 15/16" | Hardened Steel | 6 | 0.75" dia. Hardened Steel Extended-Tip Point 1" dia. Hardened Steel Standard Point 1.13" dia. Hardened Steel Cup Point 1.75" dia. Hardened Steel Bull-Nose Point Live Center Body Point Extractor | 0000000 | 000000 |

| 3 | 350 | 5,000 | 0.00025" | 2 1/8" | __ | 3 3/16" | 5 9/16" | Hardened Steel | 6 | 0.75" dia. Hardened Steel Extended-Tip Point 1" dia. Hardened Steel Standard Point 1.13" dia. Hardened Steel Cup Point 1.75" dia. Hardened Steel Bull-Nose Point Live Center Body Point Extractor | 0000000 | 000000 |

| 4 | 550 | 5,500 | 0.00025" | 3 5/64" | __ | 4 1/16" | 7 13/64" | Hardened Steel | 6 | 0.8" dia. Hardened Steel Extended-Tip Point 1.13" dia. Hardened Steel Standard Point 1.38" dia. Hardened Steel Cup Point 2.25" dia. Hardened Steel Bull-Nose Point Live Center Body Point Extractor | 0000000 | 00000000 |

| 5 | 1,400 | 5,500 | 0.00025" | 3 5/64" | __ | 5 3/16" | 8 21/64" | Hardened Steel | 6 | 1.2" dia. Hardened Steel Extended-Tip Point 1.5" dia. Hardened Steel Cup Point 1.5" dia. Hardened Steel Standard Point 2.75" dia. Hardened Steel Bull-Nose Point Live Center Body Point Extractor | 0000000 | 00000000 |

Dead | ||||||||||||

| 3 | __ | __ | 0.00025" | 3/4" | 7/8"-14 | 3 3/16" | 4 3/8" | Hardened Steel | 7 | 0.75" dia. Hardened Steel Extended-Tip Point 1" dia. Carbide-Tipped Hardened Steel Standard Point 1" dia. Hardened Steel Half Point 1" dia. Hardened Steel Standard Point 1.75" dia. Hardened Steel Bull-Nose Point Dead Center Body Point Extractor | 0000000 | 00000000 |

| 4 | __ | __ | 0.00025" | 1" | 1 1/8"-12 | 4 1/16" | 5 1/2" | Hardened Steel | 7 | 0.8" dia. Hardened Steel Extended-Tip Point 1" dia. Carbide-Tipped Hardened Steel Standard Point 1.13" dia. Hardened Steel Half Point 1.13" dia. Hardened Steel Standard Point 2.25" dia. Hardened Steel Bull-Nose Point Dead Center Body Point Extractor | 0000000 | 00000000 |

| 5 | __ | __ | 0.00025" | 1 1/4" | 1 5/8"-12 | 5 3/16" | 6 13/16" | Hardened Steel | 7 | 1.2" dia. Hardened Steel Extended-Tip Point 1.25" dia. Carbide-Tipped Hardened Steel Standard Point 1.5" dia. Hardened Steel Half Point 1.5" dia. Hardened Steel Standard Point 2.75" dia. Hardened Steel Bull-Nose Point Dead Center Body Point Extractor | 0000000 | 00000000 |