Selecting Compatible Lead Screws and Nuts

More

Metric Fast-Travel Ultra-Precision Lead Screws and Nuts

Multiple thread channels (also known as thread starts) create faster linear travel than lead screws with a single thread start. Operating with less backlash (play) than Metric Precision Acme Lead Screws and Nuts, these lead screws and nuts provide increased nut life and more reliable movement in automated systems. To ensure compatibility, select components that have the same thread size, thread pitch, and number of thread starts.

Lead screws with one machinable end let you create your own custom connection to suit your application.

Lead screws with one coupling end connect directly with your shaft without extra machining. Torque down the locknut once inserted. 303 and 304 stainless steel lead screws have good corrosion resistance.

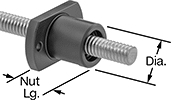

Travel distance per turn, also known as screw lead, is the distance a nut moves with one revolution of the lead screw.

| Thread Size | Thread Pitch, mm | Lg., mm | No. of Thread Starts | Thread Type | Speed Ratio | Travel Distance per Turn, mm | Accuracy for Travel Distance per Turn | Hardness | Tensile Strength, psi | Each | |

303 Stainless Steel | |||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|

| M4 | 1.25 | 150 | 8 | Metric Rounded Trapezoidal | 8:1 | 10 | ±0.089 mm per 300 mm | Brinell 160 | 90,000 | 000000000 | 000000 |

Machinable End | |||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Thread Size | Thread Pitch, mm | Lg., mm | No. of Thread Starts | Thread Type | Dia., mm | Lg., mm | Speed Ratio | Travel Distance per Turn, mm | Accuracy for Travel Distance per Turn | Hardness | Tensile Strength, psi | Each | |

17-4 PH Stainless Steel | |||||||||||||

| M2 | 0.4 | 150 | 2 | Metric Rounded Trapezoidal | 7 | 25 | 2:1 | 0.75 | ±0.15 mm per 300 mm | Rockwell C35 | 145,000 | 00000000 | 0000000 |

| M2 | 0.4 | 150 | 4 | Metric Rounded Trapezoidal | 7 | 25 | 4:1 | 1.5 | ±0.15 mm per 300 mm | Rockwell C35 | 145,000 | 00000000 | 000000 |

| M2 | 0.4 | 150 | 8 | Metric Rounded Trapezoidal | 7 | 25 | 8:1 | 3 | ±0.15 mm per 300 mm | Rockwell C35 | 145,000 | 00000000 | 000000 |

| M3 | 0.5 | 150 | 2 | Metric Rounded Trapezoidal | 7 | 25 | 2:1 | 1 | ±0.15 mm per 300 mm | Rockwell C35 | 145,000 | 00000000 | 000000 |

| M3 | 0.5 | 150 | 6 | Metric Rounded Trapezoidal | 7 | 25 | 6:1 | 3 | ±0.15 mm per 300 mm | Rockwell C35 | 145,000 | 00000000 | 000000 |

| M3 | 0.5 | 150 | 12 | Metric Rounded Trapezoidal | 7 | 25 | 12:1 | 6 | ±0.15 mm per 300 mm | Rockwell C35 | 145,000 | 00000000 | 000000 |

| M4 | 1 | 150 | 4 | Metric Rounded Trapezoidal | 7 | 25 | 4:1 | 4 | ±0.15 mm per 300 mm | Rockwell C35 | 145,000 | 00000000 | 000000 |

| M4 | 1 | 150 | 8 | Metric Rounded Trapezoidal | 7 | 25 | 8:1 | 8 | ±0.15 mm per 300 mm | Rockwell C35 | 145,000 | 00000000 | 000000 |

Compression End | ||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Thread Size | Thread Pitch, mm | Lg., mm | No. of Thread Starts | Thread Type | Dia., mm | Lg., mm | For Shaft Dia., mm | Speed Ratio | Travel Distance per Turn, mm | Accuracy for Travel Distance per Turn | Hardness | Tensile Strength, psi | Each | |

17-4 PH Stainless Steel | ||||||||||||||

| M2 | 0.4 | 150 | 2 | Metric Rounded Trapezoidal | 6.5 | 15 | 2 | 2:1 | 0.75 | ±0.15 mm per 300 mm | Rockwell C35 | 145,000 | 00000000 | 0000000 |

| M2 | 0.4 | 150 | 4 | Metric Rounded Trapezoidal | 6.5 | 15 | 2 | 4:1 | 1.5 | ±0.15 mm per 300 mm | Rockwell C35 | 145,000 | 00000000 | 000000 |

| M2 | 0.4 | 150 | 8 | Metric Rounded Trapezoidal | 6.5 | 15 | 2 | 8:1 | 3 | ±0.15 mm per 300 mm | Rockwell C35 | 145,000 | 00000000 | 000000 |

| M3 | 0.5 | 150 | 2 | Metric Rounded Trapezoidal | 7.5 | 15.5 | 3 | 2:1 | 1 | ±0.15 mm per 300 mm | Rockwell C35 | 145,000 | 00000000 | 000000 |

| M3 | 0.5 | 150 | 6 | Metric Rounded Trapezoidal | 7.5 | 15.5 | 3 | 6:1 | 3 | ±0.15 mm per 300 mm | Rockwell C35 | 145,000 | 00000000 | 000000 |

| M3 | 0.5 | 150 | 12 | Metric Rounded Trapezoidal | 7.5 | 15.5 | 3 | 12:1 | 6 | ±0.15 mm per 300 mm | Rockwell C35 | 145,000 | 00000000 | 000000 |

| M4 | 1 | 150 | 4 | Metric Rounded Trapezoidal | 8.5 | 15.5 | 4 | 4:1 | 4 | ±0.15 mm per 300 mm | Rockwell C35 | 145,000 | 00000000 | 000000 |

| M4 | 1 | 150 | 4 | Metric Rounded Trapezoidal | 9.5 | 15.5 | 5 | 4:1 | 4 | ±0.15 mm per 300 mm | Rockwell C35 | 145,000 | 00000000 | 000000 |

| M4 | 1 | 150 | 8 | Metric Rounded Trapezoidal | 8.5 | 15.5 | 4 | 8:1 | 8 | ±0.15 mm per 300 mm | Rockwell C35 | 145,000 | 00000000 | 000000 |

| M4 | 1 | 150 | 8 | Metric Rounded Trapezoidal | 9.5 | 15.5 | 5 | 8:1 | 8 | ±0.15 mm per 300 mm | Rockwell C35 | 145,000 | 00000000 | 000000 |

Metric Ultra-Precision Lead Screws and Nuts

Operating with less backlash (play) than Metric Precision Acme Lead Screws and Nuts, these provide increased nut life and more reliable movement in automated systems. Also known as single-start and self-locking lead screws and nuts, they have a single thread that runs the length of the screw. The nut travels only when the screw turns, so your system won't unexpectedly move when the lead screw is at rest. To ensure compatibility, select components that have the same thread size, thread type, thread size, thread pitch, and number of thread starts.

Lead screws with one machinable end let you create your own custom connection to suit your application.

Lead screws with one coupling end connect directly with your shaft without extra machining. Torque down the locknut once inserted. 303 stainless steel lead screws have good corrosion resistance.

Travel distance per turn, also known as screw lead, is the distance a nut moves with one revolution of the lead screw.

| Thread Size | Thread Pitch, mm | Lg., mm | No. of Thread Starts | Thread Type | Speed Ratio | Travel Distance per Turn, mm | Accuracy for Travel Distance per Turn | Hardness | Tensile Strength, psi | Each | |

303 Stainless Steel | |||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|

| M4 | 0.3 | 150 | 1 | Metric Rounded Trapezoidal | 1:1 | 0.3 | ±0.089 mm per 300 mm | Brinell 160 | 90,000 | 0000000 | 000000 |

Machinable End | |||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Thread Size | Thread Pitch, mm | Lg., mm | No. of Thread Starts | Thread Type | Dia., mm | Lg., mm | Speed Ratio | Travel Distance per Turn | Accuracy for Travel Distance per Turn | Hardness | Tensile Strength, psi | Each | |

17-4 PH Stainless Steel | |||||||||||||

| M2 | 0.4 | 150 | 1 | Metric Rounded Trapezoidal | 7 | 25 | 1:1 | 0.375mm | ±0.15 mm per 300 mm | Rockwell C35 | 145,000 | 000000000 | 0000000 |

| M3 | 0.5 | 150 | 1 | Metric Rounded Trapezoidal | 7 | 25 | 1:1 | 0.5mm | ±0.15 mm per 300 mm | Rockwell C35 | 145,000 | 000000000 | 000000 |

| M4 | 1 | 150 | 1 | Metric Rounded Trapezoidal | 7 | 25 | 1:1 | 1mm | ±0.15 mm per 300 mm | Rockwell C35 | 145,000 | 000000000 | 000000 |

Coupling End | ||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Thread Size | Thread Pitch, mm | Lg., mm | No. of Thread Starts | Thread Type | Dia., mm | Lg., mm | For Shaft Dia., mm | Speed Ratio | Travel Distance per Turn | Accuracy for Travel Distance per Turn | Hardness | Tensile Strength, psi | Each | |

17-4 PH Stainless Steel | ||||||||||||||

| M2 | 0.4 | 150 | 1 | Metric Rounded Trapezoidal | 6.5 | 15 | 2 | 1:1 | 0.375mm | ±0.15 mm per 300 mm | Rockwell C35 | 145,000 | 000000000 | 0000000 |

| M3 | 0.5 | 150 | 1 | Metric Rounded Trapezoidal | 7.5 | 15.5 | 3 | 1:1 | 0.5mm | ±0.15 mm per 300 mm | Rockwell C35 | 145,000 | 000000000 | 000000 |

| M4 | 1 | 150 | 1 | Metric Rounded Trapezoidal | 8.5 | 15.5 | 4 | 1:1 | 1mm | ±0.15 mm per 300 mm | Rockwell C35 | 145,000 | 000000000 | 000000 |

| M4 | 1 | 150 | 1 | Metric Rounded Trapezoidal | 9.5 | 15.5 | 5 | 1:1 | 1mm | ±0.15 mm per 300 mm | Rockwell C35 | 145,000 | 000000000 | 000000 |

Ball Screws and Nuts

Internal ball bearings provide smooth low-friction travel in applications that require high speeds, accurate positioning, and repeatable movement. Also known as single-start ball screws and nuts, they have a single thread that runs the length of the screw. They operate with more torque than fast-travel ball screws and nuts. To ensure compatibility, select components that have the same thread direction and size. Ball nuts are furnished with a tube to keep ball bearings in place. Do not remove the tube until you are ready to install the nuts onto the screws.

Travel distance per turn, also known as screw lead, is the distance a ball nut moves with one revolution of the ball screw.

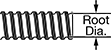

Root diameter indicates the diameter the ball screw will be after machining away the threads.

Ball Screw | Flange Ball Nut | ||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Thread Size | Lg., mm | Root Dia., mm | Tensile Strength, psi | Lg., mm | Dia., mm | Length Tolerance | No. of Thread Starts | Travel Distance per Turn, mm | Accuracy for Travel Distance per Turn | Hardness | Dynamic Thrust Load Capacity, lbs. | Max. Backlash, mm | Temp. Range, °F | Each | |

Carbon Steel Ball Screw with Alloy Steel Flange Ball Nut | |||||||||||||||

| M6 | 150 | 5.3 | 21,000 | 21 | 13 | Plus | 1 | 1 | ±0.210 mm per 300 mm | Rockwell C58 | 150 | 0.05 | 5° to 175° | 0000000 | 0000000 |

| M8 | 150 | 6.6 | 21,000 | 28 | 20 | Plus | 1 | 2 | ±0.210 mm per 300 mm | Rockwell C58 | 470 | 0.05 | 5° to 175° | 0000000 | 000000 |