Filter by

Capacity per Mount

Overall Height

Performance

Height

Material

Finish

U.S.–Mexico–Canada Agreement (USMCA) Qualifying

Export Control Classification Number (ECCN)

DFARS Specialty Metals

Surface Plate Grade

About Leveling Mounts

Choose the right leveling mounts for your floor conditions, equipment weight, and vibration-control needs.

Heavy Duty Rigid Leveling Mounts

|  |

Grooved Surface | Smooth Surface |

Base | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

Cap. per Mount, lb. | Surface Texture | Lg. | Wd. | Overall Ht. | Anchor Hole Dia. | Each | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Iron Base with Zinc-Plated Steel Bolt | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 3,000 | Grooved | 3 9/16" | 6 1/16" | 1 1/8" to 1 3/8" | — | 0000000 | 0000000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 9,000 | Grooved | 3 5/8" | 5 3/4" | 2 1/4" to 2 5/8" | — | 0000000 | 000000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 15,000 | Grooved | 3 1/2" | 5 3/4" | 2 5/8" to 2 13/16" | 1" | 000000 | 000000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 20,000 | Grooved | 3 1/2" | 6 3/4" | 3" to 3 1/4" | 1 1/8" | 000000 | 000000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 30,000 | Grooved | 3 1/2" | 6 3/4" | 3" to 3 1/4" | 1 1/8" | 0000000 | 000000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Painted Steel Base with Steel Bolt | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 50,000 | Smooth | 7 7/8" | 9 7/8" | 2 5/16" to 3 1/8" | — | 0000000 | 000000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 110,000 | Smooth | 15 3/4" | 11 13/16" | 3 1/8" to 3 13/16" | — | 0000000 | 00000000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Vibration-Damping Heavy Duty Rigid Leveling Mounts

Base | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

Cap. per Mount, lb. | Deflection @ Cap. | Surface Texture | Lg. | Wd. | Overall Ht. | Anchor Hole Dia. | Cushion Material | Each | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Iron Base with Felt Cushion and Zinc-Plated Steel Bolt | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 3,000 | 0.15" | Grooved | 3 9/16" | 6 1/16" | 1 7/8" to 2 1/8" | — | Felt | 0000000 | 0000000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 9,000 | 0.15" | Grooved | 3 5/8" | 6" | 3" to 3 3/8" | — | Felt | 0000000 | 000000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 30,000 | 0.2" | Grooved | 3 1/2" | 6 3/4" | 3 1/2" to 3 3/4" | 1 1/8" | Felt | 0000000 | 000000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Iron Base with Rubber Cushion and Zinc-Plated Steel Bolt | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 15,000 | 0.09" | Grooved | 3 1/2" | 5 3/4" | 3 1/8" to 3 5/16" | 1" | SBR | 0000000 | 000000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 20,000 | 0.09" | Grooved | 3 1/2" | 6 3/4" | 3 1/2" to 3 3/4" | 1 1/8" | SBR | 0000000 | 000000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

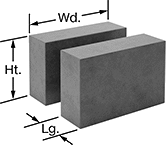

Granite Inspection Parallels

|

Inspection-Grade A Plate | Laboratory-Grade AA Plate | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

Lg. | Thk. | Ht. | Material | Certificate Type | Parallel Tolerance | Pair | Parallel Tolerance | Pair | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Sold as Matched Pair | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

2 Precision-Ground Sides | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 6" | 3/4" | 1" | Black Granite | Accuracy Certificate Traceable to NIST | 0.0001" | 0000000 | 0000000 | 0.00005" | 0000000 | 0000000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 12" | 1" | 2" | Black Granite | Accuracy Certificate Traceable to NIST | 0.0001" | 0000000 | 000000 | 0.00005" | 0000000 | 000000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

4 Precision-Ground Sides | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 6" | 3/4" | 1" | Black Granite | Accuracy Certificate Traceable to NIST | 0.0001" | 0000000 | 000000 | 0.00005" | 0000000 | 000000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 12" | 1" | 2" | Black Granite | Accuracy Certificate Traceable to NIST | 0.0001" | 0000000 | 000000 | 0.00005" | 0000000 | 000000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

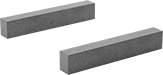

Granite Inspection Setup Blocks

Tolerance | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

Lg. | Wd. | Ht. | Lg. | Wd. | Ht. | Squareness | Parallel | Material | Certificate Type | Pair | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Sold as Matched Pair | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Inspection-Grade A Plate | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 1" | 3" | 2" | -0.0002" to 0.0002" | -0.0002" to 0.0002" | -0.0002" to 0.0002" | 0.0001" | 0.0001" | Black Granite | Accuracy Certificate Traceable to NIST | 00000000 | 0000000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Laboratory-Grade AA Plate | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 1" | 3" | 2" | -0.0001" to 0.0001" | -0.0001" to 0.0001" | -0.0001" to 0.0001" | 0.00005" | 0.00005" | Black Granite | Accuracy Certificate Traceable to NIST | 00000000 | 00000000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||