Choosing a Proximity Switch

More

Choosing an Electrical Switch

More

Hazardous Location Limit Switches

Safely open or close a circuit near ignitable gases and dust—the housing on these switches seals in anything that could ignite flammable material. You'll know they're safe because they're NEC Class I, Division 1, Groups B, C, and D; and Class II, Division 1, Groups E, F, and G certified for hazardous locations. These switches send a signal to your circuit when an object hits the actuator—for instance, a box on a conveyor runs into the switch, stopping the conveyor. They open and close circuits as fast as snap-acting switches, but they have a bigger actuator for large objects.

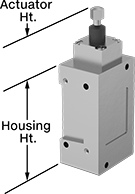

Switches with a plunger actuator let you adjust the actuator’s height to easily align it with your target. They require a push to activate, similar to a button.

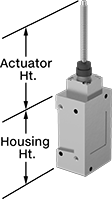

Switches with a wobble stick actuator have an arm that rotates 360°, so you don’t need to align it in a specific direction. The actuator won’t snap if pushed backward, such as if there’s a jam in your system.

Housing | ||||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| No. of Circuits Controlled | Switch Starting Position | Switch Action | Industry Designation | Switching Current @ Voltage | Max. Voltage | Operating Temp. Range, °F | Actuator Ht. | Wire Connection Type | No. of Terminals | Lg. | Ht. | Dp. | Housing Material | Conduit Trade Size | Each | |

Plunger Actuator Style | ||||||||||||||||

| 1 | 1 Off (Normally Open) or 1 On (Normally Closed) | Springs Back (Momentary) | SPDT | 10 A @ 600 V AC, 2.5 A @ 600 V DC | 600V AC 600V DC | 0° to 185° | 2.7"-2.9" | Screw Terminals | 4 | 2.7" | 4.1" | 2.1" | Aluminum | 1/2 | 0000000 | 0000000 |

Wobble Stick Actuator Style | ||||||||||||||||

| 1 | 1 Off (Normally Open) or 1 On (Normally Closed) | Springs Back (Momentary) | SPDT | 10 A @ 600 V AC, 2.5 A @ 600 V DC | 600V AC 600V DC | 0° to 185° | 6.2" | Screw Terminals | 4 | 2.7" | 4.1" | 2.1" | Aluminum | 1/2 | 0000000 | 000000 |

Hazardous Location Rotatable DC Metallic-Object Proximity Switches

Twist the sensor to detect metallic objects where explosive dust or gas may be present—the sensor rotates for front, side, top, or bottom sensing. These switches are UL and C-UL listed as well as ATEX and IECEx certified for hazardous locations. Their NAMUR signal produces low current and low voltage, so they won’t spark or ignite. You must connect them to a barrier (sold separately), which reduces the current and voltage that enters your hazardous area. Install the barrier in a separate location that doesn’t contain explosive gas or dust.

Because you can rotate their sensor, these switches make good replacements for limit switches with actuators that could break when hit. They’re often known as inductive proximity switches and detect objects even if they’re covered by water, oil, dirt, or a surface finish. Sensing distance is based on the type of material that’s sensed; the distance listed is for mild steel. Send signals from these switches to programmable logic controllers (PLCs) to support automated processes.

These switches have a 4-pole micro M12 plug that connects to cables with a socket (sold separately), so you can quickly connect and disconnect them. You can also check on them from any angle, thanks to LED status indicators on their corners. All are CE marked for safety.

To view switch wiring diagrams, select a part number and click Product Detail.

Flush switches, also called embeddable and shielded switches, are more accurate than projecting switches at close range. They also won’t interfere with each other’s signals when installed close together. Their sensor face mounts evenly with any material, including metal.

Projecting switches, also known as non-embeddable and unshielded switches, sense objects farther away than flush switches. But, the area around the sensor must be metal free.

IP rated, all switches seal out dust and water from high-pressure washdowns. IP67- and IP68-rated switches also withstand some submersion.

Micro

M12 Plug

| Switch Starting Position | Lg., mm | Wd., mm | Ht., mm | Max. Sensing Distance, mm | Signal Output Type | Input Voltage | Current Output | Circuit Protection | Temp. Range, °F | Environmental Rating | Each | |

Plastic Housing | ||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|

Flush with 4-Pole Micro M12 Plug | ||||||||||||

| 1 On (Normally Closed) | 67 | 40 | 40 | 20 | NAMUR | 8V DC-8.5V DC | 10mA | Reverse Polarity Short Circuit | -10° to 210° | IEC Zone 0 Groups IIC, IIB, IIA NEC Class III Divisions 1, 2 IEC Zone 20 Groups IIIC, IIIB, IIIA NEC Class I Divisions 1, 2 Groups A, B, C, D NEC Class II Divisions 1, 2 Groups E, F, G IP66 IP69K | 0000000 | 0000000 |

| 1 On (Normally Closed) | 118 | 40 | 40 | 20 | NAMUR | 8V DC-8.5V DC | 10mA | Reverse Polarity Short Circuit | -10° to 210° | IEC Zone 0 Groups IIC, IIB, IIA NEC Class III Divisions 1, 2 IEC Zone 20 Groups IIIC, IIIB, IIIA NEC Class I Divisions 1, 2 Groups A, B, C, D NEC Class II Divisions 1, 2 Groups E, F, G IP67 IP69K | 00000000 | 000000 |

Projecting with 4-Pole Micro M12 Plug | ||||||||||||

| 1 On (Normally Closed) | 67 | 40 | 40 | 40 | NAMUR | 8V DC-8.5V DC | 10mA | Reverse Polarity Short Circuit | -10° to 210° | IEC Zone 0 Groups IIC, IIB, IIA NEC Class III Divisions 1, 2 IEC Zone 20 Groups IIIC, IIIB, IIIA NEC Class I Divisions 1, 2 Groups A, B, C, D NEC Class II Divisions 1, 2 Groups E, F, G IP69K | 0000000 | 000000 |

| 1 On (Normally Closed) | 118 | 40 | 40 | 40 | NAMUR | 8V DC-8.5V DC | 10mA | Reverse Polarity Short Circuit | -10° to 210° | IEC Zone 0 Groups IIC, IIB, IIA NEC Class III Divisions 1, 2 IEC Zone 20 Groups IIIC, IIIB, IIIA NEC Class I Divisions 1, 2 Groups A, B, C, D NEC Class II Divisions 1, 2 Groups E, F, G IP68 IP69K | 00000000 | 000000 |

Inputs | Outputs | ||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|

| Operating Voltage | Voltage | Current | No. of | Signal Type | Current | No. of | Signal Type | Switching Frequency | Environmental Rating | Each | |

Plastic Housing | |||||||||||

| 115V AC | 10V DC | 8mA | 1 | NAMUR | 2 A @ 253 V AC 2 A @ 40 V DC 4 A @ 126 V AC | 1 | Relay | 10 Hz | Associated Apparatus for IEC Zone 0 Groups IIC, IIB, IIA Associated Apparatus for IEC Zone 20 Groups IIIC, IIIB, IIIA IP20 | 0000000 | 0000000 |

| 24V DC | 10V DC | 8mA | 1 | NAMUR | 0.05 A @ 24 V DC | 2 | Transistor | 5 kHz | Associated Apparatus for IEC Zone 0 Groups IIC, IIB, IIA Associated Apparatus for IEC Zone 20 Groups IIIC, IIIB, IIIA IP20 | 0000000 | 000000 |

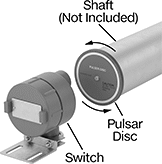

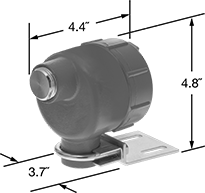

Speed-Monitoring Switches

Detect unwanted slowdowns in a rotary shaft that could cause machine damage and downtime. These switches are often used on drivetrains, conveyors, and other power-driven components. They come with a pulser disc, which you’ll need to attach to the shaft by drilling and tapping a hole. Once mounted, the disc rotates with the shaft and creates magnetic signals that the switch senses. When the speed falls below a set point, the switch will trigger an alarm or turn off the system.

Switches are UL listed and rated NEC Class I, Divisions 1 and 2, Groups C and D; and Class II, Divisions 1 and 2, Groups E, F, and G. They have an explosion-proof housing and are also rated NEMA 4X for washdown and corrosion protection.

Switching | Input | Conduit | Mounting Slot | ||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Activation Point Range, rpm | Current, A | Voltage | Voltage | Frequency, Hz | No. of Terminals | Trade Size | Thread Type | Gender | Lg. | Wd. | No. of | Mounting Fasteners Included | Environmental Rating | Each | |

1 Off (Normally Open), 1 On (Normally Closed) Starting Switch Position | |||||||||||||||

SPDT | |||||||||||||||

| 5-100 | 5 | 120V AC | 120V AC | 60 | 5 | 1 | NPT | Female | 1 1/4" | 0.32" | 2 | Yes | NEC Class I Divisions 1, 2 Groups C, D NEC Class II Divisions 1, 2 Groups E, F, G NEMA 4X | 0000000 | 0000000 |