About Linear Bearings

More

Food Industry Linear Sleeve Bearings

Made of FDA-listed materials for use in food applications, these bearings also have excellent chemical and corrosion resistance. They have a fixed-alignment design for applications where shaft misalignment is unlikely. To install, slide bearings into a housing (not included).

For bearings with retaining ring grooves, secure them in your housing with two retaining rings (sold individually).

Bearings | External Retaining Rings | ||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| For Shaft Dia. | Overall Lg. | For Housing ID | With Retaining Ring Grooves | Retaining Ring Groove End-to-End Lg. | Dynamic Load Capacity | Static Load Capacity, lbs. | Shaft Clearance | Temperature Range, ° F | For Shaft Material | Specifications Met | Each | Pkg. Qty. | Each | ||

Fixed Alignment | |||||||||||||||

Rulon 641-Lined 304 Stainless Steel Bearings | |||||||||||||||

| 3/8" | 7/8" | 0.6250" - 0.6255" | Yes | 0.642" | 30 lbs. @ 100 fpm | 325 | 0.001" | -400° to 375° | Aluminum, Stainless Steel | FDA Compliant 21 CFR 177.1380 | 0000000 | 000000 | __ | 0000000 | 00000 |

| 1/2" | 1 1/4" | 0.8750" - 0.8755" | Yes | 0.969" | 60 lbs. @ 100 fpm | 625 | 0.001" | -400° to 375° | Aluminum, Stainless Steel | FDA Compliant 21 CFR 177.1380 | 0000000 | 00000 | __ | 0000000 | 0000 |

| 5/8" | 1 1/2" | 1.1250" - 1.1255" | Yes | 1.116" | 90 lbs. @ 100 fpm | 935 | 0.001" | -400° to 375° | Aluminum, Stainless Steel | FDA Compliant 21 CFR 177.1380 | 0000000 | 00000 | __ | 0000000 | 0000 |

| 3/4" | 1 5/8" | 1.2500" - 1.2505" | Yes | 1.178" | 100 lbs. @ 100 fpm | 1,200 | 0.001" | -400° to 375° | Aluminum, Stainless Steel | FDA Compliant 21 CFR 177.1380 | 0000000 | 00000 | __ | 0000000 | 0000 |

| 1" | 2 1/4" | 1.5625" - 1.5630" | Yes | 1.765" | 200 lbs. @ 100 fpm | 2,200 | 0.001" | -400° to 375° | Aluminum, Stainless Steel | FDA Compliant 21 CFR 177.1380 | 0000000 | 00000 | __ | 0000000 | 0000 |

| 1 1/4" | 2 5/8" | 2.0000" - 2.0010" | Yes | 2.015" | 325 lbs. @ 100 fpm | 3,200 | 0.0025" | -400° to 375° | Aluminum, Stainless Steel | FDA Compliant 21 CFR 177.1380 | 0000000 | 000000 | __ | 0000000 | 0000 |

| 1 1/2" | 3" | 2.3750" - 2.3760" | Yes | 2.431" | 450 lbs. @ 100 fpm | 4,500 | 0.0025" | -400° to 375° | Aluminum, Stainless Steel | FDA Compliant 21 CFR 177.1380 | 0000000 | 000000 | __ | 0000000 | 0000 |

| 12mm | 28mm | 19.000mm - 19.021mm | No | __ | 50 lbs. @ 100 fpm | 115 | 0.05mm | -400° to 375° | Aluminum, Stainless Steel | FDA Compliant 21 CFR 177.1380 | 000000 | 00000 | __ | 000000 | 00 |

| Each | Pkg. | ||||||||||||||

| 12mm | 32mm | 22.000mm - 22.021mm | Yes | 22.6mm | 55 lbs. @ 100 fpm | 130 | 0.05mm | -400° to 375° | Aluminum, Stainless Steel | FDA Compliant 21 CFR 177.1380 | 0000000 | 00000 | 1 | 0000000 | 0000 |

| 16mm | 30mm | 24.000mm - 24.021mm | No | __ | 70 lbs. @ 100 fpm | 165 | 0.05mm | -400° to 375° | Aluminum, Stainless Steel | FDA Compliant 21 CFR 177.1380 | 0000000 | 00000 | __ | 000000 | 00 |

| 16mm | 36mm | 26.000mm - 26.021mm | Yes | 24.6mm | 85 lbs. @ 100 fpm | 200 | 0.05mm | -400° to 375° | Aluminum, Stainless Steel | FDA Compliant 21 CFR 177.1380 | 0000000 | 00000 | 1 | 0000000 | 0000 |

| 20mm | 30mm | 28.000mm - 28.021mm | No | __ | 90 lbs. @ 100 fpm | 205 | 0.05mm | -400° to 375° | Aluminum, Stainless Steel | FDA Compliant 21 CFR 177.1380 | 0000000 | 00000 | __ | 000000 | 00 |

| 20mm | 45mm | 32.000mm - 32.025mm | Yes | 31.2mm | 135 lbs. @ 100 fpm | 310 | 0.05mm | -400° to 375° | Aluminum, Stainless Steel | FDA Compliant 21 CFR 177.1380 | 0000000 | 00000 | 1 | 0000000 | 0000 |

| 25mm | 40mm | 35.000mm - 35.025mm | No | __ | 155 lbs. @ 100 fpm | 255 | 0.05mm | -400° to 375° | Aluminum, Stainless Steel | FDA Compliant 21 CFR 177.1380 | 0000000 | 00000 | __ | 000000 | 00 |

| 25mm | 58mm | 40.000mm - 40.025mm | Yes | 43.7mm | 220 lbs. @ 100 fpm | 505 | 0.05mm | -400° to 375° | Aluminum, Stainless Steel | FDA Compliant 21 CFR 177.1380 | 0000000 | 00000 | 1 | 0000000 | 0000 |

| 30mm | 50mm | 40.000mm - 40.025mm | No | __ | 230 lbs. @ 100 fpm | 520 | 0.06mm | -400° to 375° | Aluminum, Stainless Steel | FDA Compliant 21 CFR 177.1380 | 0000000 | 000000 | __ | 000000 | 00 |

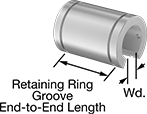

Food Industry Linear Sleeve Bearings for Support Rail Shafts

These bearings for use in food applications also have excellent chemical and corrosion resistance. Mount them on a support rail shaft for applications requiring maximum rigidity. They have a fixed-alignment design for applications where shaft misalignment is unlikely. To install, slide bearings into a housing (not included) and secure in place with two retaining rings (sold individually).

Bearings | External Retaining Rings | |||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| For Shaft Dia. | Overall Lg. | Wd. | For Housing ID | Retaining Ring Groove End-to-End Lg. | Dynamic Load Capacity | Static Load Capacity, lbs. | Shaft Clearance | Temperature Range, ° F | For Shaft Material | Each | Pkg. Qty. | Each | ||

Fixed Alignment | ||||||||||||||

Rulon 641-Lined 304 Stainless Steel Bearings | ||||||||||||||

| 3/8" | 7/8" | 3/16" | 0.6250" - 0.6255" | 0.642" | 30 lbs. @ 100 fpm | 325 | 0.001" | -400° to 375° | Aluminum, Stainless Steel | 0000000 | 000000 | __ | 0000000 | 00000 |

| 1/2" | 1 1/4" | 5/16" | 0.8750" - 0.8755" | 0.969" | 60 lbs. @ 100 fpm | 625 | 0.001" | -400° to 375° | Aluminum, Stainless Steel | 0000000 | 00000 | __ | 0000000 | 0000 |

| 3/4" | 1 5/8" | 7/16" | 1.2500" - 1.2505" | 1.178" | 100 lbs. @ 100 fpm | 1,200 | 0.001" | -400° to 375° | Aluminum, Stainless Steel | 0000000 | 00000 | __ | 0000000 | 0000 |

| 1" | 2 1/4" | 9/16" | 1.5625" - 1.5630" | 1.765" | 200 lbs. @ 100 fpm | 2,200 | 0.001" | -400° to 375° | Aluminum, Stainless Steel | 0000000 | 00000 | __ | 0000000 | 0000 |

| Each | Pkg. | |||||||||||||

| 12mm | 32mm | 7.6mm | 22.0000mm - 22.0210mm | 20mm | 60 lbs. @ 100 fpm | 590 | 0.05mm | -400° to 375° | Aluminum, Stainless Steel | 0000000 | 00000 | 1 | 0000000 | 0000 |

| 16mm | 36mm | 10.4mm | 26.0000mm - 26.0210mm | 22mm | 90 lbs. @ 100 fpm | 890 | 0.05mm | -400° to 375° | Aluminum, Stainless Steel | 0000000 | 00000 | 1 | 0000000 | 0000 |

| 20mm | 45mm | 10.8mm | 32.0000mm - 32.0250mm | 28mm | 130 lbs. @ 100 fpm | 1,350 | 0.05mm | -400° to 375° | Aluminum, Stainless Steel | 0000000 | 00000 | 1 | 0000000 | 0000 |