Filter by

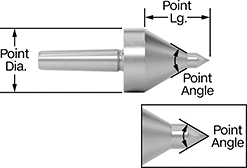

Point Diameter

Head Diameter

Maximum Workpiece Capacity

Point Length

Maximum Rotation Speed

Length

Overall Length

Performance

Total Indicated Runout (TIR) Accuracy

Point Tip Diameter

Shank Length

DFARS Specialty Metals

Export Control Classification Number (ECCN)

Rotation Speed

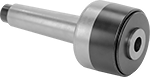

Live Centers

|  |

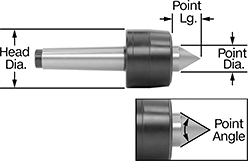

Standard Point | Bull-Nose Point |

|  |

Extended Point Precision | Extended-Cone Point |

Machine Taper No. | Max. Workpiece Cap., lb. | Max. Rotation Speed, rpm | Total Indicated Runout (TIR) Accuracy | Point Dia. | Head Dia. | Point Lg. | Overall Lg. | Point Angle | Material | Each | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

Standard Point | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Lathe Centers | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| Morse 1 | 220 | 5,000 | 0.0003" | 0.59" | 1 1/2" | 45/64" | 4 1/16" | 60° | Hardened Steel | 0000000 | 0000000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| Morse 2 | 460 | 5,000 | 0.0003" | 0.7" | 1 9/16" | 7/8" | 4 47/64" | 60° | Hardened Steel | 0000000 | 000000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| Morse 3 | 925 | 4,000 | 0.0003" | 0.98" | 2 13/64" | 1 1/8" | 6 9/64" | 60° | Hardened Steel | 0000000 | 000000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| Morse 4 | 1,850 | 3,000 | 0.0003" | 1.1" | 2 33/64" | 1 15/64" | 7 15/64" | 60° | Hardened Steel | 0000000 | 000000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| Morse 5 | 4,400 | 2,500 | 0.0003" | 1.61" | 3 11/32" | 1 49/64" | 9 21/64" | 60° | Hardened Steel | 0000000 | 000000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| Morse 6 | 7,700 | 2,000 | 0.0004" | 2.48" | 5 1/8" | 2 33/64" | 13 1/8" | 60° | Hardened Steel | 0000000 | 000000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| Morse 7 | 20,900 | 1,000 | 0.0004" | 2.95" | 5 29/32" | 2 57/64" | 17 19/32" | 60° | Hardened Steel | 0000000 | 00000000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Precision | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| Morse 2 | 725 | 6,000 | 0.00005" | 0.875" | 1 3/4" | 1 1/64" | 5 19/64" | 60° | Hardened Steel | 0000000 | 000000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| Morse 3 | 970 | 5,000 | 0.00005" | 1" | 2 11/32" | 1 15/64" | 6 13/32" | 60° | Hardened Steel | 0000000 | 000000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| Morse 4 | 1,720 | 4,500 | 0.00005" | 1.25" | 2 11/16" | 1 31/64" | 7 57/64" | 60° | Hardened Steel | 0000000 | 00000000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| Morse 5 | 3,260 | 3,500 | 0.00005" | 1.5" | 3 29/64" | 1 27/32" | 10 13/64" | 60° | Hardened Steel | 0000000 | 00000000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| Morse 6 | 4,080 | 3,500 | 0.00005" | 2" | 4" | 2 5/16" | 13 13/64" | 60° | Hardened Steel | 0000000 | 00000000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Bull-Nose Point | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Lathe Centers | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| Morse 2 | 2,000 | 2,500 | 0.00015" | 4" | — | 3 29/32" | 6 27/32" | 60° | Hardened Steel | 0000000 | 000000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| Morse 3 | 3,800 | 2,500 | 0.00015" | 4" | — | 3 29/32" | 7 15/32" | 60° | Hardened Steel | 0000000 | 000000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| Morse 4 | 1,760 | 3,000 | 0.0001" | 4.921" | — | 2 1/4" | 7 9/32" | 80° | Hardened Steel | 0000000 | 000000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| Morse 4 | 4,800 | 2,500 | 0.00015" | 4" | — | 3 29/32" | 8 11/32" | 60° | Hardened Steel | 0000000 | 000000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| Morse 5 | 3,520 | 2,000 | 0.0001" | 5.906" | — | 2 3/4" | 8 29/32" | 80° | Hardened Steel | 0000000 | 00000000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| Morse 5 | 4,800 | 2,500 | 0.00015" | 4" | — | 3 29/32" | 9 15/32" | 60° | Hardened Steel | 0000000 | 000000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

High Speed | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| Morse 3 | 2,700 | 7,000 | 0.0001" | 3.5" | — | 2 5/32" | 6 31/32" | 60° | Hardened Steel | 0000000 | 000000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| Morse 4 | 4,000 | 6,000 | 0.0001" | 4.5" | — | 3 1/64" | 9 7/16" | 60° | Hardened Steel | 0000000 | 00000000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| Morse 5 | 4,000 | 6,000 | 0.0001" | 4.5" | — | 3 1/64" | 10 37/64" | 60° | Hardened Steel | 0000000 | 00000000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

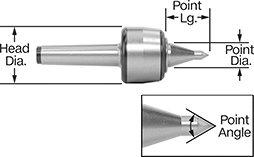

Extended Point | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Precision | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| Morse 2 | 375 | 6,000 | 0.00005" | 0.88" | 1 3/4" | 1 11/32" | 5 5/8" | 60° | Hardened Steel | 0000000 | 000000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| Morse 3 | 740 | 5,000 | 0.00005" | 1" | 2 21/64" | 1 55/64" | 7 3/64" | 60° | Hardened Steel | 0000000 | 000000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| Morse 4 | 1,120 | 4,500 | 0.00005" | 1.25" | 2 11/16" | 2 3/16" | 8 19/32" | 60° | Hardened Steel | 0000000 | 00000000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| Morse 5 | 1,930 | 3,500 | 0.00005" | 1.5" | 3 29/64" | 2 37/64" | 10 61/64" | 60° | Hardened Steel | 0000000 | 00000000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| Morse 6 | 2,420 | 3,500 | 0.00005" | 2" | 4" | 3" | 13 29/32" | 60° | Hardened Steel | 0000000 | 00000000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

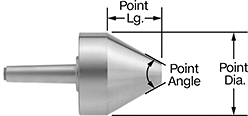

Extended-Cone Point | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Multipurpose | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| Morse 2 | 330 | 5,000 | 0.0001" | 2.25" | — | 2 17/64" | 5 3/4" | 60° | Hardened Steel | 0000000 | 000000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| Morse 3 | 685 | 4,000 | 0.0001" | 2.63" | — | 2 21/32" | 6 15/16" | 60° | Hardened Steel | 0000000 | 000000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| Morse 4 | 1,160 | 3,500 | 0.0001" | 3.5" | — | 3 31/64" | 8 11/16" | 60° | Hardened Steel | 0000000 | 000000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| Morse 5 | 1,160 | 3,500 | 0.0001" | 3.5" | — | 3 31/64" | 9 51/64" | 60° | Hardened Steel | 0000000 | 000000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

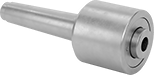

Interchangeable Point Lathe Centers

Center Points

|

Standard Point |

|

Bull-Nose Point |

|

Cup Point |

|

Flat-Knurled Point |

|

Extended-Tip Point Precision |

For Machine Taper No. | Point Dia. | Point Tip Dia. | Point Lg. | Point Angle | Material | Each | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

Standard Point | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Live | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| Morse 2 | 0.59" | — | 3/4" | — | Steel | 0000000 | 000000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| Morse 3 | 0.79" | — | 63/64" | — | Steel | 0000000 | 00000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| Morse 4 | 0.98" | — | 1 3/16" | — | Steel | 0000000 | 00000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| Morse 5 | 1.26" | — | 1 15/32" | — | Steel | 0000000 | 00000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| Morse 6 | 1.42" | — | 1 47/64" | — | Steel | 0000000 | 00000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Precision Live and Dead | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| Morse 2, Morse 3 | 1" | — | 1 11/64" | — | Steel | 0000000 | 000000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| Morse 4 | 1.13" | — | 1 19/64" | — | Steel | 0000000 | 000000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| Morse 5 | 1.5" | — | 1 21/32" | — | Steel | 0000000 | 000000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Bull-Nose Point | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Live | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| Morse 2 | 0.59" | 3/64" | 19/32" | 60° | Steel | 0000000 | 00000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| Morse 2 | 0.87" | 1/8" | 19/32" | 90° | Steel | 0000000 | 00000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| Morse 2 | 1.46" | 23/32" | 19/32" | 90° | Steel | 0000000 | 00000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| Morse 3 | 0.79" | 3/64" | 7/8" | 60° | Steel | 0000000 | 00000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| Morse 3 | 1.42" | 15/64" | 7/8" | 90° | Steel | 0000000 | 00000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| Morse 3 | 2.48" | 1 19/64" | 7/8" | 90° | Steel | 0000000 | 00000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| Morse 4 | 0.98" | 3/32" | 63/64" | 60° | Steel | 0000000 | 00000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| Morse 4 | 1.77" | 25/64" | 63/64" | 90° | Steel | 0000000 | 00000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| Morse 4 | 2.76" | 1 3/8" | 63/64" | 90° | Steel | 0000000 | 00000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| Morse 5 | 1.26" | 3/32" | 1 3/16" | 60° | Steel | 0000000 | 00000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| Morse 5 | 2.2" | 35/64" | 1 3/16" | 90° | Steel | 0000000 | 00000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| Morse 5 | 3.15" | 1 1/2" | 1 3/16" | 90° | Steel | 0000000 | 00000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| Morse 6 | 1.42" | 5/32" | 1 27/64" | 60° | Steel | 0000000 | 00000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| Morse 6 | 2.76" | 23/32" | 1 27/64" | 90° | Steel | 0000000 | 00000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| Morse 6 | 3.94" | 1 31/32" | 1 27/64" | 90° | Steel | 0000000 | 000000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Precision Live and Dead | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| Morse 2, Morse 3 | 1.75" | 7/8" | 1 11/64" | 60° | Steel | 0000000 | 000000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| Morse 4 | 2.25" | 1" | 1 35/64" | 60° | Steel | 0000000 | 000000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| Morse 5 | 2.75" | 1 1/2" | 1 37/64" | 60° | Steel | 0000000 | 000000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Cup Point | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Live | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| Morse 2 | 0.87" | 23/32" | 19/32" | — | Steel | 0000000 | 00000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| Morse 2 | 1.18" | 63/64" | 9/16" | — | Steel | 0000000 | 00000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| Morse 3 | 1.42" | 1 7/64" | 7/8" | — | Steel | 0000000 | 00000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| Morse 3 | 1.77" | 1 1/2" | 7/8" | — | Steel | 0000000 | 00000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| Morse 4 | 1.77" | 1 15/32" | 63/64" | — | Steel | 0000000 | 00000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| Morse 4 | 2.48" | 2 3/32" | 63/64" | — | Steel | 0000000 | 00000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| Morse 5 | 2.2" | 1 47/64" | 1 3/16" | — | Steel | 0000000 | 00000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| Morse 5 | 2.76" | 2 23/64" | 1 3/16" | — | Steel | 0000000 | 00000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| Morse 6 | 2.76" | 2 9/32" | 1 27/64" | — | Steel | 0000000 | 00000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| Morse 6 | 3.94" | 2 15/32" | 1 27/64" | — | Steel | 0000000 | 000000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Precision Live | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| Morse 2, Morse 3 | 1.13" | 7/8" | 1 5/64" | — | Steel | 000000 | 000000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| Morse 4 | 1.38" | 1 1/8" | 1 7/32" | — | Steel | 0000000 | 000000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| Morse 5 | 1.5" | 1 1/4" | 1 7/32" | — | Steel | 0000000 | 000000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Flat-Knurled Point | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Live | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| Morse 2 | 0.71" | — | 19/32" | — | Steel | 0000000 | 00000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| Morse 3 | 0.98" | — | 7/8" | — | Steel | 0000000 | 00000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| Morse 4 | 1.26" | — | 63/64" | — | Steel | 0000000 | 00000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| Morse 5 | 1.77" | — | 1 3/16" | — | Steel | 0000000 | 00000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| Morse 6 | 2.2" | — | 1 27/64" | — | Steel | 0000000 | 00000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Extended-Tip Point | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Precision Live and Dead | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| Morse 2, Morse 3 | 0.75" | 3/8" | 1 19/64" | — | Steel | 0000000 | 000000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| Morse 4 | 0.8" | 1/2" | 1 51/64" | — | Steel | 0000000 | 000000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| Morse 5 | 1.2" | 1/2" | 2 1/8" | — | Steel | 0000000 | 000000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Center Bodies

Lathe Centers | Extractors | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

Max. Workpiece Cap., lb. | Max. Rotation Speed, rpm | Total Indicated Runout (TIR) Accuracy | Head Dia. | Overall Lg. | Material | Includes | Each | Each | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Live | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 220 | 5,000 | 0.0008" | 1 37/64" | 4 3/64" | Steel | — | 0000000 | 0000000 | 0000000 | 000000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 440 | 4,000 | 0.0008" | 2 13/64" | 5 7/32" | Steel | — | 0000000 | 000000 | 0000000 | 00000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 880 | 3,000 | 0.0008" | 2 33/64" | 6 7/32" | Steel | — | 0000000 | 000000 | 0000000 | 00000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 1,770 | 2,500 | 0.0012" | 3 23/64" | 7 13/16" | Steel | — | 0000000 | 000000 | 0000000 | 00000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 3,550 | 2,000 | 0.0012" | 5 1/8" | 10 27/32" | Steel | — | 0000000 | 000000 | 0000000 | 00000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Precision Live | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 100 | 5,000 | 0.00025" | 2 1/8" | 4 15/16" | Steel | 1" dia. Hardened Steel Standard Point | 0000000 | 000000 | 0000000 | 00000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 350 | 5,000 | 0.00025" | 2 1/8" | 5 9/16" | Steel | 1" dia. Hardened Steel Standard Point | 0000000 | 000000 | 0000000 | 00000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 550 | 5,000 | 0.00025" | 3 5/64" | 7 13/64" | Steel | 1.13" dia. Hardened Steel Standard Point | 0000000 | 000000 | 0000000 | 00000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 1,400 | 5,000 | 0.00025" | 3 5/64" | 8 21/64" | Steel | 1.5" dia. Hardened Steel Standard Point | 0000000 | 00000000 | 0000000 | 00000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

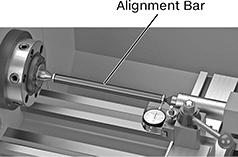

Precision Lathe Alignment Bars

Overall Lg. | OD | ID | Total Indicated Runout (TIR) Accuracy | Bar Shape | Material | Features | Each | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

Flanged End | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 12 1/4" | 1" | 0.201" | 0.0002" | Round | Anodized Aluminum | Hardened Steel Bar Ends | 00000000 | 000000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Interchangeable Point Lathe Center Sets

Live Lathe Center

Machine Taper No. | Max. Workpiece Cap., lb. | Max. Rotation Speed, rpm | Total Indicated Runout (TIR) Accuracy | Head Dia. | Shank Lg. | Overall Lg. | Material | No. of Pieces | Includes | Each | ||

|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Morse 2 | 220 | 5,000 | 0.0008" | 1 37/64" | 2 33/64" | 4 3/64" | Steel | 9 | 0.59" dia. Hardened Steel Bull-Nose Point, 0.59" dia. Hardened Steel Standard Point, 0.71" dia. Hardened Steel Flat-Knurled Point, 0.87" dia. Hardened Steel Bull-Nose Point, 0.87" dia. Hardened Steel Cup Point, 1.18" dia. Hardened Steel Cup Point, 1.46" dia. Hardened Steel Bull-Nose Point, Live Center Body, Point Extractor | 0000000 | 0000000 | |

| Morse 3 | 440 | 4,000 | 0.0008" | 2 13/64" | 3 3/16" | 5 7/32" | Steel | 9 | 0.79" dia. Hardened Steel Bull-Nose Point, 0.79" dia. Hardened Steel Standard Point, 0.98" dia. Hardened Steel Flat-Knurled Point, 1.42" dia. Hardened Steel Bull-Nose Point, 1.42" dia. Hardened Steel Cup Point, 1.77" dia. Hardened Steel Cup Point, 2.48" dia. Hardened Steel Bull-Nose Point, Live Center Body, Point Extractor | 0000000 | 000000 | |

| Morse 4 | 880 | 3,000 | 0.0008" | 2 33/64" | 4 1/32" | 6 7/32" | Steel | 8 | 0.98" dia. Hardened Steel Standard Point, 1.26" dia. Hardened Steel Flat-Knurled Point, 1.77" dia. Hardened Steel Bull-Nose Point, 1.77" dia. Hardened Steel Cup Point, 2.48" dia. Hardened Steel Cup Point, 2.76" dia. Hardened Steel Bull-Nose Point, Live Center Body, Point Extractor | 0000000 | 000000 | |

| Morse 5 | 1,770 | 2,500 | 0.0012" | 3 23/64" | 5 3/32" | 7 13/16" | Steel | 8 | 1.26" dia. Hardened Steel Bull-Nose Point, 1.26" dia. Hardened Steel Standard Point, 1.77" dia. Hardened Steel Flat-Knurled Point, 2.2" dia. Hardened Steel Bull-Nose Point, 2.2" dia. Hardened Steel Cup Point, 3.15" dia. Hardened Steel Bull-Nose Point, Live Center Body, Point Extractor | 0000000 | 000000 | |

| Morse 6 | 3,550 | 2,000 | 0.0012" | 5 1/8" | 7 9/64" | 10 27/32" | Steel | 9 | 1.42" dia. Hardened Steel Bull-Nose Point, 1.42" dia. Hardened Steel Standard Point, 2.2" dia. Hardened Steel Flat-Knurled Point, 2.76" dia. Hardened Steel Bull-Nose Point, 2.76" dia. Hardened Steel Cup Point, 3.94" dia. Hardened Steel Bull-Nose Point, 3.94" dia. Hardened Steel Cup Point, Live Center Body, Point Extractor | 0000000 | 00000000 |

Precision, Live Lathe Center

Machine Taper No. | Max. Workpiece Cap., lb. | Max. Rotation Speed, rpm | Total Indicated Runout (TIR) Accuracy | Head Dia. | Shank Lg. | Overall Lg. | Material | No. of Pieces | Includes | Each | ||

|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Morse 2 | 100 | 5,000 | 0.00025" | 2 1/8" | 2 9/16" | 4 15/16" | Steel | 6 | 0.75" dia. Hardened Steel Extended-Tip Point, 1" dia. Hardened Steel Standard Point, 1.13" dia. Hardened Steel Cup Point, 1.75" dia. Hardened Steel Bull-Nose Point, Live Center Body, Point Extractor | 0000000 | 0000000 | |

| Morse 3 | 350 | 5,000 | 0.00025" | 2 1/8" | 3 3/16" | 5 9/16" | Steel | 6 | 0.75" dia. Hardened Steel Extended-Tip Point, 1" dia. Hardened Steel Standard Point, 1.13" dia. Hardened Steel Cup Point, 1.75" dia. Hardened Steel Bull-Nose Point, Live Center Body, Point Extractor | 0000000 | 000000 | |

| Morse 4 | 550 | 5,500 | 0.00025" | 3 5/64" | 4 1/16" | 7 13/64" | Steel | 6 | 0.8" dia. Hardened Steel Extended-Tip Point, 1.13" dia. Hardened Steel Standard Point, 1.38" dia. Hardened Steel Cup Point, 2.25" dia. Hardened Steel Bull-Nose Point, Live Center Body, Point Extractor | 0000000 | 00000000 | |

| Morse 5 | 1,400 | 5,500 | 0.00025" | 3 5/64" | 5 3/16" | 8 21/64" | Steel | 6 | 1.2" dia. Hardened Steel Extended-Tip Point, 1.5" dia. Hardened Steel Cup Point, 1.5" dia. Hardened Steel Standard Point, 2.75" dia Hardened Steel Bull-Nose Point, Live Center Body, Point Extractor | 0000000 | 00000000 |

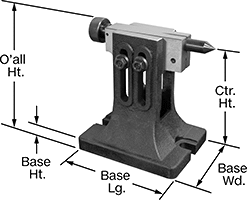

Tailstocks

Base | Mounting Slot | |||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|

Ctr. Ht. | Lg. | Wd. | Ht. | Overall Ht. | No. of | Wd. | Mounting Fasteners Included | Material | Includes | Each | ||

| 3 1/4" to 4 1/4" | 5 3/8" | 3 3/4" | 4 1/8" | 4 1/4" | 2 | 5/8" | No | Cast Iron | Standard-Point Dead Center | 0000000 | 0000000 | |

| 4 1/2" to 5 3/4" | 6 1/8" | 4 3/8" | 5 7/8" | 5 3/4" | 2 | 5/8" | No | Cast Iron | Standard-Point Dead Center | 0000000 | 000000 | |

| 5 1/4" to 7 3/4" | 7 1/4" | 5 1/2" | 8 1/2" | 8" | 2 | 5/8" | No | Cast Iron | Standard-Point Dead Center | 0000000 | 000000 | |

| 7 1/2" to 10 1/4" | 7 7/8" | 5 3/4" | 10" | 10 1/4" | 2 | 5/8" | No | Cast Iron | Standard-Point Dead Center | 0000000 | 000000 | |