Threaded Locating and Support Buttons

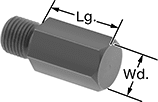

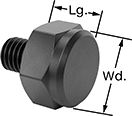

Use these buttons to support and position workpieces and fixtures from the bottom or side. Their hex shape lets you screw them into a threaded hole with a wrench or socket. Threading makes these buttons easier to replace than press-fit, so they are a good choice for high-wear applications. They’re also known as rest buttons.

Hardened steel buttons are stronger and resist wear better than steel buttons. They are precision ground, which helps them maintain their shape and size, even with repeated use. This makes them a good choice for use in modular fixtures where repeatability and exact positioning are important.

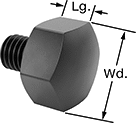

Buttons with a domed head support rounded or irregularly shaped workpieces with minimal contact.

Thread | ||||||

|---|---|---|---|---|---|---|

| Lg. | Wd. | Size | Lg. | Lg. Tolerance | Each | |

Steel with Flat Head | ||||||

| 3/16" | 1/4" | 8-32 | 3/16" | 0" to 0.015" | 0000000 | 00000 |

| 3/16" | 5/16" | 10-32 | 1/4" | 0" to 0.015" | 0000000 | 0000 |

| 3/16" | 3/8" | 1/4"-28 | 5/16" | 0" to 0.015" | 0000000 | 0000 |

| 1/4" | 3/8" | 1/4"-20 | 3/8" | -0.003" to 0.012" | 00000000 | 0000 |

| 1/4" | 3/8" | 1/4"-28 | 5/16" | 0" to 0.015" | 0000000 | 0000 |

| 1/4" | 1/2" | 3/8"-16 | 1/2" | -0.003" to 0.012" | 00000000 | 0000 |

| 1/4" | 1/2" | 3/8"-24 | 7/16" | 0" to 0.015" | 0000000 | 0000 |

| 1/4" | 5/8" | 1/2"-13 | 5/8" | -0.003" to 0.012" | 00000000 | 0000 |

| 1/4" | 3/4" | 5/8"-11 | 3/4" | 0" to 0.012" | 00000000 | 0000 |

| 3/8" | 3/8" | 1/4"-20 | 3/8" | -0.003" to 0.012" | 00000000 | 0000 |

| 3/8" | 3/8" | 1/4"-28 | 5/16" | 0" to 0.015" | 0000000 | 0000 |

| 3/8" | 1/2" | 3/8"-16 | 1/2" | -0.003" to 0.012" | 00000000 | 0000 |

| 3/8" | 1/2" | 3/8"-24 | 7/16" | 0" to 0.015" | 0000000 | 0000 |

| 3/8" | 5/8" | 1/2"-13 | 5/8" | -0.003" to 0.012" | 00000000 | 0000 |

| 3/8" | 3/4" | 5/8"-11 | 3/4" | 0" to 0.012" | 00000000 | 0000 |

| 1/2" | 3/8" | 1/4"-20 | 3/8" | -0.003" to 0.012" | 00000000 | 0000 |

| 1/2" | 1/2" | 3/8"-16 | 1/2" | -0.003" to 0.012" | 00000000 | 0000 |

| 1/2" | 1/2" | 3/8"-24 | 1/2" | 0.005" to 0.015" | 000000 | 0000 |

| 1/2" | 5/8" | 1/2"-13 | 5/8" | -0.003" to 0.012" | 00000000 | 0000 |

| 1/2" | 5/8" | 1/2"-20 | 1/2" | 0.005" to 0.015" | 000000 | 0000 |

| 1/2" | 3/4" | 1/2"-20 | 9/16" | 0" to 0.015" | 0000000 | 0000 |

| 1/2" | 3/4" | 5/8"-11 | 3/4" | 0" to 0.012" | 00000000 | 0000 |

| 3/4" | 3/8" | 1/4"-20 | 3/8" | -0.003" to 0.012" | 00000000 | 0000 |

| 3/4" | 3/8" | 1/4"-28 | 3/8" | 0.005" to 0.015" | 000000 | 0000 |

| 3/4" | 1/2" | 3/8"-16 | 1/2" | -0.003" to 0.012" | 00000000 | 0000 |

| 3/4" | 1/2" | 3/8"-24 | 1/2" | 0.005" to 0.015" | 000000 | 0000 |

| 3/4" | 5/8" | 1/2"-13 | 5/8" | -0.003" to 0.012" | 00000000 | 0000 |

| 3/4" | 5/8" | 1/2"-20 | 1/2" | 0.005" to 0.015" | 000000 | 0000 |

| 3/4" | 3/4" | 5/8"-11 | 3/4" | 0" to 0.012" | 00000000 | 0000 |

| 1" | 3/8" | 1/4"-20 | 3/8" | -0.003" to 0.012" | 00000000 | 0000 |

| 1" | 3/8" | 1/4"-28 | 3/8" | 0.005" to 0.015" | 000000 | 0000 |

| 1" | 1/2" | 3/8"-16 | 1/2" | -0.003" to 0.012" | 00000000 | 0000 |

| 1" | 1/2" | 3/8"-24 | 1/2" | 0.005" to 0.015" | 000000 | 0000 |

| 1" | 5/8" | 1/2"-13 | 5/8" | -0.003" to 0.012" | 00000000 | 0000 |

| 1" | 5/8" | 1/2"-20 | 1/2" | 0.005" to 0.015" | 000000 | 0000 |

| 1" | 3/4" | 5/8"-11 | 3/4" | 0" to 0.012" | 00000000 | 0000 |

Thread | ||||||||

|---|---|---|---|---|---|---|---|---|

| Lg., mm | Wd., mm | Size | Pitch, mm | Lg., mm | Lg. Tolerance, mm | Specifications Met | Each | |

Steel with Flat Head | ||||||||

| 10 | 10 | M6 | 1 | 11 | -0.2 to 0.2 | DIN 6320 | 0000000 | 00000 |

| 15 | 13 | M8 | 1.25 | 13 | -0.2 to 0.2 | DIN 6320 | 0000000 | 0000 |

| 20 | 17 | M10 | 1.5 | 16 | -0.2 to 0.2 | DIN 6320 | 0000000 | 0000 |

| 25 | 19 | M12 | 1.75 | 20 | -0.2 to 0.2 | DIN 6320 | 0000000 | 0000 |

Hardened Steel with Flat Head | ||||||||

| 10 | 17 | M8 | 1.25 | 10 | -0.01 to 0.01 | __ | 0000000 | 00000 |

| 10 | 19 | M10 | 1.5 | 12 | -0.01 to 0.01 | __ | 0000000 | 00000 |

| 10 | 22 | M12 | 1.75 | 14 | -0.01 to 0.01 | __ | 0000000 | 00000 |

Hardened Steel with Domed Head | ||||||||

| 10 | 17 | M8 | 1.25 | 10 | -0.1 to 0.1 | __ | 0000000 | 00000 |

| 10 | 19 | M10 | 1.5 | 12 | -0.1 to 0.1 | __ | 0000000 | 00000 |

| 10 | 22 | M12 | 1.75 | 14 | -0.1 to 0.1 | __ | 0000000 | 00000 |

Screw-Mount Locating and Support Buttons

Also known as rest buttons, these buttons support workpieces and fixtures from the bottom or side. Mount them onto a screw or stud extending from your jig or table.

Hardened steel buttons are stronger and resist wear better than steel buttons. They are precision ground, which helps them maintain their shape and size, even with repeated use. This makes them a good choice for use in modular fixtures where repeatability and exact positioning are important.

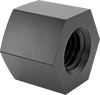

Hex buttons are easy to turn with a wrench. They have a threaded hole, so you can mount them to a threaded bolt or stud. Those with a domed head support round or irregularly shaped workpieces with minimal contact.

Thread | |||||||

|---|---|---|---|---|---|---|---|

| Wd., mm | Lg., mm | Lg. Tolerance, mm | Size | Pitch, mm | Mounting Fasteners Included | Each | |

Hardened Steel—Hex with Flat Head | |||||||

| 17 | 15 | -0.01 to 0.01 | M8 | 1.25 | No | 0000000 | 000000 |

| 19 | 20 | -0.01 to 0.01 | M10 | 1.5 | No | 0000000 | 00000 |

| 22 | 20 | -0.01 to 0.01 | M12 | 1.75 | No | 0000000 | 00000 |

Hardened Steel—Hex with Domed Head | |||||||

| 17 | 15 | -0.1 to 0.1 | M8 | 1.25 | No | 0000000 | 00000 |

| 19 | 20 | -0.1 to 0.1 | M10 | 1.5 | No | 0000000 | 00000 |

| 22 | 20 | -0.1 to 0.1 | M12 | 1.75 | No | 0000000 | 00000 |

Swiveling Locating and Support Buttons

The swiveling tip supports uneven and angled surfaces on workpieces and fixtures. These buttons screw into a threaded hole. Also known as rest buttons.

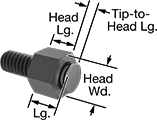

Head | Thread | |||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Tip Dia. | Lg. | Wd. | Tip-to-Head Lg. | Lg. | Size | Lg. | Range of Motion | Head Lg. Tolerance | Load Capacity, lbs. | Tip Material | Each | |

Steel | ||||||||||||

| 1/4" | 1/4" | 3/8" | 1/16" | 5/16" | 10-32 | 1/2" | 28° | -0.002" to 0.002" | 1,150 | Stainless Steel | 0000000 | 000000 |

| 5/16" | 5/16" | 7/16" | 1/8" | 7/16" | 1/4"-20 | 1/2" | 28° | -0.002" to 0.002" | 2,400 | Stainless Steel | 0000000 | 00000 |

| 7/16" | 3/8" | 1/2" | 1/8" | 1/2" | 5/16"-18 | 1/2" | 28° | -0.002" to 0.002" | 2,750 | Stainless Steel | 0000000 | 00000 |

| 9/16" | 1/2" | 5/8" | 1/8" | 5/8" | 3/8"-16 | 1/2" | 28° | -0.002" to 0.002" | 3,400 | Stainless Steel | 0000000 | 00000 |

| 3/4" | 5/8" | 13/16" | 1/8" | 3/4" | 1/2"-13 | 1" | 32° | -0.002" to 0.002" | 5,900 | Stainless Steel | 0000000 | 00000 |

| 13/16" | 11/16" | 15/16" | 1/8" | 13/16" | 5/8"-11 | 1" | 32° | -0.002" to 0.002" | 9,900 | Stainless Steel | 0000000 | 00000 |