About Gradual On/Off Valves

More

Safety-Lockout Air On/Off Valves

A padlock (not included) locks the handle of these valves in the shut-off position. When valves are closed, the exhaust port vents air pressure so you can disconnect air tools safely. They meet OSHA lockout requirements to maintain safety and control in a compressed air system.

Flow coefficient (Cv) is a measurement that indicates how much airflow can pass through a valve. When selecting between valves with the same port size, choose the valve with the higher flow coefficient to ensure it provides enough airflow to operate your system.

Valves that comply with OSHA 29 CFR 1910.147 meet standards for the control of energy sources that could injure workers.

Flow Rate @ 100 psi | Overall | |||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Inlet Pipe Size | Outlet Pipe Size | Exhaust Pipe Size | Flow Coefficient (Cv) | Min. | Max. | Max. Pressure, psi | Temp. Range, °F | Lg. | Wd. | Ht. | For Max. Padlock Shackle Dia. | Specifications Met | Each | |

Aluminum Body | ||||||||||||||

| 1/2 | 1/2 | 3/4 | 4 | 0 scfm | 91 scfm | 300 | 40° to 175° | 4 1/4" | 2" | 9" | 1/4" | OSHA Compliant 29 CFR 1910.147 | 0000000 | 0000000 |

| 3/4 | 3/4 | 3/4 | 4 | 0 scfm | 93 scfm | 300 | 40° to 175° | 4 1/4" | 2" | 9" | 1/4" | OSHA Compliant 29 CFR 1910.147 | 0000000 | 000000 |

| 1 | 1 | 1 1/4 | 9.4 | 0 scfm | 216 scfm | 300 | 40° to 175° | 4 1/4" | 2 1/4" | 9" | 1/4" | OSHA Compliant 29 CFR 1910.147 | 0000000 | 000000 |

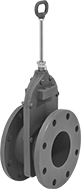

Flanged Gradual On/Off Valves

Rising Stem, and

Eight Bolt Holes

Easier to install and remove than threaded or weld-on valves, these valves bolt to flanges. They’re often used in lines requiring frequent cleaning and maintenance, such as those for slurries. They open and close gradually, preventing system damage from sudden starts and stops in flow. Also known as gate valves.

Valves with a pull handle, also known as slide valves, open and close faster than valves with a wheel handle. They’re often used as blast gates for precise flow control in low-pressure air conditioning and ventilation systems.

Valves with a rising stem lift the handle as they open and lower it as they close. At a glance, you can see if flow is on or off. The stem is isolated from what’s flowing through your line, giving these valves a longer lifespan than valves with a nonrising stem. This makes them good for critical lines and lines that need to be opened and closed frequently.

Cast iron valves are stronger than steel valves but more brittle than steel, ductile iron, and stainless steel valves.

Flow coefficient (Cv) is the amount of water (in gallons per minute) at 60° F that will flow through a fully open valve with a difference of 1 psi between the inlet and the outlet.

- Valve Type: Gate

- For Use With: Oil, Air

O'all | ||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Pipe Size | Pressure Class | Flange OD | Bolt Circle Dia. | No. of Bolt Holes | Bolt Hole Dia. | Bolts Included | Flow Coefficient (Cv) | Max. Pressure | Temp. Range, °F | End-to-End Lg. | Ht. | Lg. | Each | |

Flanged Stem Housing | ||||||||||||||

| 4 | 125 | 9" | 7 1/2" | 8 | 3/4" | No | 685 | 10 psi @ 1000° F | -40° to 1000° | 5 1/4" | 15 5/8" | 6" | 0000000 | 0000000 |

| 6 | 125 | 11" | 9 1/2" | 8 | 7/8" | No | 2,150 | 5 psi @ 1000° F | -40° to 1000° | 5 3/4" | 20" | 8" | 0000000 | 00000000 |

Threaded Gradual On/Off Valves

Also known as gate valves, these valves gradually open and close to prevent system damage from suddenly starting and stopping flow.

Valves with a pull handle open and close faster than valves with a wheel handle. Also known as slide valves, they’re often used to control flow in air conditioning and ventilation systems.

Valves with a rising stem lift the handle as they open and lower it as they close. At a glance, you can see if flow is on or off. The stem is isolated from what’s flowing through your line, giving these valves a longer lifespan than valves with a nonrising stem.

Flow coefficient (Cv) is the amount of water (in gallons per minute) at 60° F that will flow through a fully open valve with a difference of 1 psi between the inlet and the outlet.

- Valve Type: Gate

- For Use With: Oil, Air, Argon, Helium, Krypton, Neon, Xenon