Filter by

ID

Material

REACH

DFARS Specialty Metals

Export Control Classification Number (ECCN)

Hardness

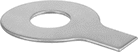

Tab Lock Washers

2 Tabs |

|

1 Tab |

Instead of relying on friction, these washers lock mechanically for more holding power than split and tooth lock washers. Bend the tabs with a wrench to stop both the fastener and washer from rotating. They are often used in applications with moderate vibration, such as motors, mixers, and pumps. These washers are not reusable because the tabs will weaken if you bend them repeatedly.

18-8 Stainless Steel—The choice for wet and outdoor environments, these washers won't rust when exposed to moisture. However, they can't hold up to the harsh chemicals that 316 stainless steel can.

Zinc-Plated Steel—A common choice for areas with occasional exposure to moisture.

2 Tabs—Also known as pantleg washers, these have two tabs for a more secure hold than washers with one tab. Bend one tab up against the flats of your nut or screw and the other tab down over the edge of your mounting surface.

1 Tab—Bend the tab down over the edge of your mounting surface, and bend the side of the washer up against the nut or screw.

For Screw Size | ID | OD | Thk. | No. of Tabs | Specs. Met | Pkg. Qty. | Pkg. | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

18-8 Stainless Steel | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| No. 10 | 0.204" | 0.625" | 0.036" | 2 | — | 1 | 7508N11 | 00000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 1/4" | 0.281" | 0.75" | 0.036" | 2 | — | 1 | 7508N13 | 0000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 5/16" | 0.343" | 0.75" | 0.036" | 2 | — | 1 | 7508N14 | 0000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 3/8" | 0.406" | 0.875" | 0.062" | 2 | — | 1 | 7508N15 | 0000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 7/16" | 0.500" | 1.125" | 0.062" | 2 | — | 1 | 7508N16 | 0000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 1/2" | 0.531" | 1.125" | 0.062" | 2 | — | 1 | 7508N17 | 0000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 9/16" | 0.595" | 1.125" | 0.062" | 2 | — | 1 | 7508N18 | 0000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 5/8" | 0.656" | 1.25" | 0.062" | 2 | — | 1 | 7508N19 | 00000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 3/4" | 0.781" | 1.5" | 0.062" | 2 | — | 1 | 7508N21 | 00000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 7/8" | 0.910" | 1.75" | 0.062" | 2 | — | 1 | 7508N22 | 00000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 1" | 1.031" | 2" | 0.094" | 2 | — | 1 | 7508N23 | 00000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 1 1/4" | 1.281" | 2.5" | 0.125" | 2 | — | 1 | 7508N24 | 00000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 1 1/2" | 1.531" | 3" | 0.125" | 2 | — | 1 | 7508N25 | 00000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| M4 | 4.3 mm | 14.0 mm | 0.4 mm | 1 | DIN 93 | 100 | 97471A141 | 00000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| M5 | 5.3 mm | 17.0 mm | 0.5 mm | 1 | DIN 93 | 50 | 97471A142 | 00000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| M6 | 6.4 mm | 19.0 mm | 0.5 mm | 1 | DIN 93 | 50 | 97471A143 | 00000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| M8 | 8.4 mm | 22.0 mm | 0.8 mm | 1 | DIN 93 | 25 | 97471A144 | 00000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| M10 | 10.5 mm | 26.0 mm | 0.8 mm | 1 | DIN 93 | 25 | 97471A145 | 00000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| M12 | 13.0 mm | 30.0 mm | 1.0 mm | 1 | DIN 93 | 10 | 97471A146 | 0000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Zinc-Plated Steel | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| No. 10 | 0.204" | 0.625" | 0.036" | 2 | — | 1 | 2741N17 | 0000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 1/4" | 0.281" | 0.75" | 0.036" | 2 | — | 1 | 2741N11 | 0000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 5/16" | 0.343" | 0.75" | 0.036" | 2 | — | 1 | 2741N12 | 0000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 3/8" | 0.406" | 0.875" | 0.063" | 2 | — | 1 | 2741N13 | 0000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 7/16" | 0.500" | 1.125" | 0.062" | 2 | — | 1 | 2741N19 | 0000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 1/2" | 0.531" | 1.125" | 0.063" | 2 | — | 1 | 2741N14 | 0000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 9/16" | 0.595" | 1.125" | 0.062" | 2 | — | 1 | 2741N21 | 0000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 5/8" | 0.656" | 1.25" | 0.062" | 2 | — | 1 | 2741N15 | 0000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 3/4" | 0.781" | 1.5" | 0.063" | 2 | — | 1 | 2741N16 | 0000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 7/8" | 0.910" | 1.75" | 0.062" | 2 | — | 1 | 2741N22 | 0000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 1" | 1.031" | 2" | 0.094" | 2 | — | 1 | 2741N23 | 0000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 1 1/4" | 1.281" | 2.5" | 0.125" | 2 | — | 1 | 2741N24 | 0000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 1 1/2" | 1.531" | 3" | 0.125" | 2 | — | 1 | 2741N25 | 0000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||