How to Identify and Measure Fittings

Pipe size is an industry designation, not the actual size. View information about how to measure threaded and unthreaded pipe and pipe fittings.

More

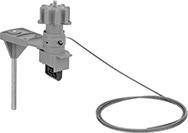

Pinch-Point Lockout Cables

Lock out panel boxes, multiple gate valves, and oversized controls with a pinch. Weave the free end of the cable through the loop and into the lockout clamping hole. Pull the cable taught before giving the lockout a squeeze to keep the cable in place. Secure the lockout with a padlock and lockout tag during maintenance and repair. With multiple padlock holes, each person can attach a padlock before starting their work. They help you comply with OSHA 29 CFR 1910.147 requirements for the control of power sources and supply lines to prevent injuries. To prevent damaging nearby surfaces, they’re coated in plastic.

For technical drawings and 3-D models, click on a part number.

Cable | Body | |||||||||

|---|---|---|---|---|---|---|---|---|---|---|

| Color | For Max. No. of Padlocks | For Max. Padlock Shackle Dia. | Dia. | Material | Lg. | Wd. | Thick. | Specifications Met | Each | |

Plastic | ||||||||||

5-ft. Cable | ||||||||||

| Red | 3 | 1/4" | 3/16" | Plastic-Coated Steel | 4 1/2" | 1" | 5/8" | OSHA Compliant 29 CFR 1910.147 | 00000000 | 000000 |

| Yellow | 3 | 9/32" | 3/16" | Plastic-Coated Steel | 4 1/2" | 1" | 5/8" | OSHA Compliant 29 CFR 1910.147 | 00000000 | 00000 |

10-ft. Cable | ||||||||||

| Red | 3 | 1/4" | 3/16" | Plastic-Coated Steel | 4 1/2" | 1" | 5/8" | OSHA Compliant 29 CFR 1910.147 | 00000000 | 00000 |

| Yellow | 3 | 9/32" | 3/16" | Plastic-Coated Steel | 4 1/2" | 1" | 5/8" | OSHA Compliant 29 CFR 1910.147 | 00000000 | 00000 |

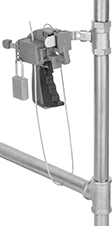

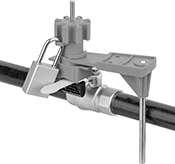

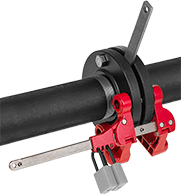

Clamp-On Lockout Cables

More secure than standard lockout cables, these lockouts clamp to a surface nearby, giving you a fixed point to pull the cable tight. Since the body of the lockout doesn’t hang freely like on standard lockout cables, their cable stays taut. After locking out, you can still tighten these cables, but they won’t loosen until you remove all your padlocks and open them up. Clamp them onto anything that fits between their jaws before weaving the cable around the item you’re locking out. They’ll even secure difficult-to-lock devices, such as ball and butterfly valve handles.

With holes for multiple padlocks, each person can add their own as they start a job. Use a hasp in the bottom hole to add more padlocks for larger groups. These cables help you comply with OSHA 29 CFR 1910.147 requirements for locking out controls to prevent injuries. The cable is plastic coated, so it doesn’t scuff up surfaces.

Swap between the included steel and rubber jaws to fit your application. The steel jaws are more durable and will last longer. The rubber jaws are a better choice for delicate surfaces because they won’t leave scratches.

Cable | Body | |||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Color | For Max. No. of Padlocks | For Max. Padlock Shackle Dia. | Max. Jaw Opening | Dia. | Material | Lg. | Wd. | Thick. | Includes | Specifications Met | Each | |

Plastic | ||||||||||||

8-ft. Cable | ||||||||||||

| Red | 4 | 9/32" | 2 3/4" | 1/8" | Plastic-Coated Steel | 8 5/8" | 7" | 2 5/8" | Interchangeable Steel and Rubber Jaws | OSHA Compliant 29 CFR 1910.147 | 0000000 | 000000 |

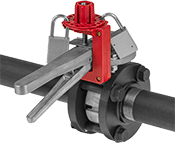

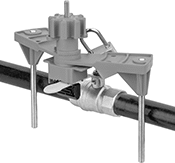

Valve Handle Lockouts

Stop gas and fluid valve handles from opening and closing during maintenance. Valve lockouts like these help you comply with OSHA 29 CFR 1910.147, which requires handles on pneumatic and hydraulic systems to be locked out during maintenance to prevent injuries.

Clamp-on lockouts adjust to fit a range of handle sizes. Style F lockouts wedge compression handles, preventing them from being squeezed to stop your valve from operating.

| For Handle Thick. | Min. Padlock Vertical Shackle Clearance | For Max. No. of Padlocks | For Max. Padlock Shackle Dia. | Clamp Material | Temp. Range, °F | Color | Label Included | Specifications Met | Each | |

Clamp On—Locks in Closed and Open Position | ||||||||||

|---|---|---|---|---|---|---|---|---|---|---|

Plastic | ||||||||||

| 1/8"-1/2" | 3/4" | 2 | 3/8" | 304 Stainless Steel | 0° to 245° | Red | No | OSHA Compliant 29 CFR 1910.147 | 0000000 | 000000 |

| 1/4"-1" | 3/4" | 2 | 3/8" | 304 Stainless Steel | 0° to 245° | Red | No | OSHA Compliant 29 CFR 1910.147 | 0000000 | 00000 |

Clamp On—Locks in Closed Position | ||||||||||

Plastic | ||||||||||

| 1/8"-2 1/4" | __ | 4 | 1/4" | 304 Stainless Steel | -20° to 140° | Red | No | OSHA Compliant 29 CFR 1910.147 | 0000000 | 00000 |

| 2"-4" | __ | 4 | 1/4" | 304 Stainless Steel | -20° to 140° | Red | No | OSHA Compliant 29 CFR 1910.147 | 0000000 | 00000 |

For Handle | ||||||||||

|---|---|---|---|---|---|---|---|---|---|---|

| Lg. | Thick. | Min. Padlock Vertical Shackle Clearance | For Max. No. of Padlocks | For Max. Padlock Shackle Dia. | Temp. Range, °F | Color | Label Included | Specifications Met | Each | |

Clamp On—Locks in Closed Position | ||||||||||

Plastic | ||||||||||

| __ | 3/4"-1 1/2" | 1" | 6 | 9/32" | -20° to 200° | Red | Yes | OSHA Compliant 29 CFR 1910.147 | 00000000 | 000000 |

Clamp On | ||||||||||

Plastic | ||||||||||

| 3/4"-2" | __ | 3/4" | 2 | 9/32" | 0° to 175° | Red | No | OSHA Compliant 29 CFR 1910.147 | 0000000 | 00000 |

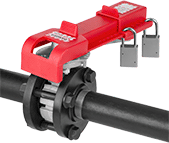

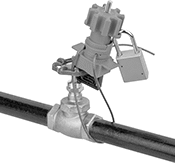

Universal Valve Lockouts

Lock out most valves in your facility with just one device. These lockouts clamp onto a variety of valve handwheels and handles. They’re great for large levers, T-handles, wheels with odd shapes and sizes, and other handles that are hard to secure with specialized lockouts. However, they’re slower to install than specialized lockouts—you’ll have to configure different attachments depending on your handle type. These lockouts help you comply with OSHA 29 CFR 1910.147 requirements for the control of hazardous energy.

To install, first turn your handle to the off position. After assembling your lockout with all necessary attachments, clamp the body to your handle and turn the lockout wheel to tighten. Add a padlock to prevent removal of the lockout.

Each lockout comes with a blocking arm. Wedge the arm against a pipe or other surface in the direction the handle turns in—this will block its movement. If your handle turns in either direction, attach an additional blocking arm (sold separately).

For valve handles that turn with a squeeze trigger, clamp the lockout body to the handle so it wedges between the handle and the trigger.

For handwheels, clamp the lockout body to the edge of the wheel and run the included cable through the spokes and around a nearby pipe or surface. Then pull the cable through the lockout body for a tight hold.

Nylon cable resists corrosion, so it’s good for use in damp areas or on wet or greasy pipes. It also resists many common chemicals. Even as it wears, it won’t scuff surfaces and stays nonconductive.

Metal cable lasts longer than nylon cable. A vinyl coating protects it from rust and prevents it from scuffing surfaces.

Lockouts | |||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

Cable | Additional Blocking Arms | ||||||||||||

| For Handle Thick. | Min. Padlock Vertical Shackle Clearance | For Max. No. of Padlocks | For Max. Padlock Shackle Dia. | Clamp Material | Dia. | Lg., ft. | Temperature Range, °F | Color | Features | Each | Each | ||

Nylon Cable | |||||||||||||

Clamp On—Locks in Closed Position | |||||||||||||

Plastic | |||||||||||||

| 1/8" to 1/2" | 3/4" | 2 | 3/8" | Stainless Steel | 1/8" | 8 | 0° to 245° | Red | Blocking Arm | 0000000 | 000000 | 0000000 | 000000 |

| 1/4" to 1" | 3/4" | 2 | 3/8" | Stainless Steel | 1/8" | 8 | 0° to 245° | Red | Blocking Arm | 0000000 | 000000 | 0000000 | 00000 |

Vinyl-Coated Metal Cable | |||||||||||||

Clamp On—Locks in Closed Position | |||||||||||||

Plastic | |||||||||||||

| 1/8" to 1/2" | 3/4" | 2 | 3/8" | Stainless Steel | 1/8" | 8 | 0° to 245° | Red | Blocking Arm | 0000000 | 00000 | 0000000 | 00000 |

| 1/4" to 1" | 3/4" | 2 | 3/8" | Stainless Steel | 1/8" | 8 | 0° to 245° | Red | Blocking Arm | 0000000 | 000000 | 0000000 | 00000 |

Pipe Flange Lockouts

Lock pipe blinds in place to prevent gas, steam, or chemicals from flowing through your line. These lockouts block access to flange bolts, keeping your team safe during pipeline maintenance. They have slots for four padlocks, so up to four people can lock out at once. Using them helps you comply with OSHA 29 CFR 1910.147, which requires the use of lockouts during work on pressurized pipelines.

These lockouts adjust to fit a range of flange sizes and bolt positions. Made of stainless steel and aluminum, they resist corrosion over time. A bright red powder-coated finish makes them easy to see when they’re in place.

Opening | |||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| For Pipe Size | For Bolt Hole Ctr.-to-Ctr. | For Max. Hex Wd. | Min. | Max. | For Max. No. of Padlocks | For Max. Padlock Shackle Dia. | Lg. | Dp. | Color | Temp. Range, °F | Specifications Met | Each | |

Powder-Coated Aluminum with Stainless Steel Bar | |||||||||||||

| 1/2 to 3 | 1 1/2"-5 7/16" | 1 5/16" | 1 1/2" | 8 1/4" | 4 | 9/32" | 14 3/4" | 4" | Red | -40° to 190° | OSHA Compliant 29 CFR 1910.147 | 0000000 | 000000 |

| 3 to 14 | 2 1/2"-7 1/4" | 2 1/4" | 3 3/4" | 11 1/4" | 4 | 9/32" | 17 3/4" | 5" | Red | -40° to 190° | OSHA Compliant 29 CFR 1910.147 | 0000000 | 000000 |

| 14 to 48 | 3 1/2"-9 5/16" | 3 1/4" | 8 1/4" | 18 1/4" | 4 | 9/32" | 24 3/4" | 6" | Red | -40° to 190° | OSHA Compliant 29 CFR 1910.147 | 0000000 | 000000 |

Trailer Brake Lockouts

Don’t worry about accidents and injuries—these lockouts stop accidental startups and sudden trailer movement, helping you comply with OSHA 29 CFR 1910.147 requirements. Clamp them around your trailer’s emergency air brake connection, also known as the glad hand or glad valve. Secure them with a padlock and add a lockout tag (both not included) so nobody can connect the trailer to a semi-truck.

Overall | ||||||||

|---|---|---|---|---|---|---|---|---|

| For Max. No. of Padlocks | For Max. Padlock Shackle Dia. | Lg. | Wd. | Ht. | Color | Specifications Met | Each | |

Cover | ||||||||

Plastic | ||||||||

| 1 | 9/32" | 4" | 3" | 2" | Red | OSHA Compliant 29 CFR 1910.147 | 0000000 | 000000 |

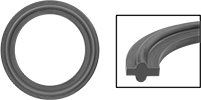

Clamps for High-Polish Metal Quick-Clamp Sanitary Tube Fittings

- Temperature Range: See Gaskets or O-Rings

- Tubing:

Inch 304 Stainless Steel and Nylon Plastic: Use with welded 304/304L and 316/316L stainless steel that meets ASTM A269 or ASTM A270, except ASME BPE: Use with welded or seamless 304/304L stainless steel that meets ASTM A269 or ASTM A270

Metric 304 Stainless Steel: Use with welded 304/304L and 316/316L stainless steel

Inch 316 Stainless Steel: Use with welded 304/304L and 316/316L stainless steel

Metric 316 Stainless Steel: Use with welded 316/316L stainless steel

Connect quick-clamp sanitary tube fittings—also known as aseptic fittings—for a fast and easy way to access your line.

Recessed nut—These clamps are tamper resistant to reduce the risk of product contamination. A hex socket adapter is required to loosen the nut. They have a leak-before-burst design, so rather than burst dangerously if the seal fails, they’ll safely relieve pressure by dripping instead.

Clamps with a hole for a lockout help you comply with Hazard Analysis and Critical Control Point (HACCP) programs and Good Management Practices (GMP).

Clamps with a two-pin hinge require less clearance to open than other clamps. Use these for installation in tight spaces.

316 stainless steel clamps are more corrosion resistant than 304 stainless steel clamps.

For technical drawings and 3-D models, click on a part number.

The temperature rating of the fitting will vary depending on the gasket or O-ring material you choose. Buna-N is oil resistant. EPDM resists water and steam and works well in humid environments. Silicone withstands high temperatures. Fluoroelastomer stands up to fuel, oil, and acid condensates. PTFE withstands harsh chemicals, with the exception of molten alkali metal and elemental fluorine.

| For Tube OD | ID | OD | Thick. | Temp. Range, °F | Color | Specifications Met | Each | |

Gaskets | ||||||||

|---|---|---|---|---|---|---|---|---|

Buna-N Rubber | ||||||||

| 1/2" | 0.380" | 0.860" | 0.178" | -30° to 200° | Black | 3-A Certified 18-03, FDA Compliant 21 CFR 177.1550, FDA Compliant 21 CFR 177.2600 | 0000000 | 00000 |

| 3/4" | 0.620" | 0.860" | 0.178" | -30° to 200° | Black | 3-A Certified 18-03, FDA Compliant 21 CFR 177.1550, FDA Compliant 21 CFR 177.2600 | 0000000 | 0000 |

| 1" | 0.900" | 1.980" | 0.203" | -30° to 200° | Black | 3-A Certified 18-03, FDA Compliant 21 CFR 177.1550, FDA Compliant 21 CFR 177.2600 | 0000000 | 0000 |

| 1 1/2" | 1.400" | 1.980" | 0.203" | -30° to 200° | Black | 3-A Certified 18-03, FDA Compliant 21 CFR 177.1550, FDA Compliant 21 CFR 177.2600 | 0000000 | 000 |

| 2" | 1.900" | 2.520" | 0.203" | -30° to 200° | Black | 3-A Certified 18-03, FDA Compliant 21 CFR 177.1550, FDA Compliant 21 CFR 177.2600 | 0000000 | 000 |

| 3" | 2.900" | 3.580" | 0.203" | -30° to 200° | Black | 3-A Certified 18-03, FDA Compliant 21 CFR 177.1550, FDA Compliant 21 CFR 177.2600 | 0000000 | 0000 |

| 4" | 3.870" | 4.680" | 0.203" | -30° to 200° | Black | 3-A Certified 18-03, FDA Compliant 21 CFR 177.1550, FDA Compliant 21 CFR 177.2600 | 0000000 | 0000 |

| 6" | 5.820" | 6.510" | 0.203" | -30° to 200° | Black | 3-A Certified 18-03, FDA Compliant 21 CFR 177.1550, FDA Compliant 21 CFR 177.2600 | 0000000 | 00000 |

EPDM Rubber | ||||||||

| 1/2" | 0.380" | 0.860" | 0.178" | -20° to 300° | Black | 3-A Certified 18-03, FDA Compliant 21 CFR 177.1550, FDA Compliant 21 CFR 177.2600 | 0000000 | 0000 |

| 3/4" | 0.620" | 0.860" | 0.178" | -20° to 300° | Black | 3-A Certified 18-03, FDA Compliant 21 CFR 177.1550, FDA Compliant 21 CFR 177.2600 | 0000000 | 0000 |

| 1" | 0.900" | 1.980" | 0.203" | -20° to 300° | Black | 3-A Certified 18-03, FDA Compliant 21 CFR 177.1550, FDA Compliant 21 CFR 177.2600 | 0000000 | 0000 |

| 1 1/2" | 1.400" | 1.980" | 0.203" | -20° to 300° | Black | 3-A Certified 18-03, FDA Compliant 21 CFR 177.1550, FDA Compliant 21 CFR 177.2600 | 0000000 | 0000 |

| 2" | 1.900" | 2.520" | 0.203" | -20° to 300° | Black | 3-A Certified 18-03, FDA Compliant 21 CFR 177.1550, FDA Compliant 21 CFR 177.2600 | 0000000 | 0000 |

| 3" | 2.900" | 3.580" | 0.203" | -20° to 300° | Black | 3-A Certified 18-03, FDA Compliant 21 CFR 177.1550, FDA Compliant 21 CFR 177.2600 | 0000000 | 0000 |

| 4" | 3.870" | 4.680" | 0.203" | -20° to 300° | Black | 3-A Certified 18-03, FDA Compliant 21 CFR 177.1550, FDA Compliant 21 CFR 177.2600 | 0000000 | 0000 |

| 6" | 5.820" | 6.670" | 0.203" | -20° to 300° | Black | 3-A Certified 18-03, FDA Compliant 21 CFR 177.1550, FDA Compliant 21 CFR 177.2600 | 0000000 | 00000 |

Silicone Rubber | ||||||||

| 1/2" | 0.380" | 0.860" | 0.178" | -40° to 450° | Clear | 3-A Certified 18-03, FDA Compliant 21 CFR 177.1550, FDA Compliant 21 CFR 177.2600 | 0000000 | 0000 |

| 3/4" | 0.620" | 0.860" | 0.178" | -40° to 450° | Clear | 3-A Certified 18-03, FDA Compliant 21 CFR 177.1550, FDA Compliant 21 CFR 177.2600 | 0000000 | 0000 |

| 1" | 0.900" | 1.980" | 0.203" | -40° to 450° | Clear | 3-A Certified 18-03, FDA Compliant 21 CFR 177.1550, FDA Compliant 21 CFR 177.2600 | 0000000 | 0000 |

| 1 1/2" | 1.400" | 1.980" | 0.203" | -40° to 450° | Clear | 3-A Certified 18-03, FDA Compliant 21 CFR 177.1550, FDA Compliant 21 CFR 177.2600 | 0000000 | 0000 |

| 2" | 1.900" | 2.520" | 0.203" | -40° to 450° | Clear | 3-A Certified 18-03, FDA Compliant 21 CFR 177.1550, FDA Compliant 21 CFR 177.2600 | 0000000 | 0000 |

| 3" | 2.900" | 3.580" | 0.203" | -40° to 450° | Clear | 3-A Certified 18-03, FDA Compliant 21 CFR 177.1550, FDA Compliant 21 CFR 177.2600 | 0000000 | 0000 |

| 4" | 3.870" | 4.680" | 0.203" | -40° to 450° | Clear | 3-A Certified 18-03, FDA Compliant 21 CFR 177.1550, FDA Compliant 21 CFR 177.2600 | 0000000 | 0000 |

| 6" | 5.820" | 6.510" | 0.203" | -40° to 450° | Clear | 3-A Certified 18-03, FDA Compliant 21 CFR 177.1550, FDA Compliant 21 CFR 177.2600 | 0000000 | 00000 |

Fluoroelastomer Rubber | ||||||||

| 1/2" | 0.380" | 0.860" | 0.178" | -15° to 400° | Black | 3-A Certified 18-03, FDA Compliant 21 CFR 177.2600 | 0000000 | 0000 |

| 3/4" | 0.620" | 0.860" | 0.178" | -15° to 400° | Black | 3-A Certified 18-03, FDA Compliant 21 CFR 177.2600 | 0000000 | 0000 |

| 1" | 0.900" | 1.980" | 0.203" | -15° to 400° | Black | 3-A Certified 18-03, FDA Compliant 21 CFR 177.2600 | 0000000 | 0000 |

| 1 1/2" | 1.400" | 1.980" | 0.203" | -15° to 400° | Black | 3-A Certified 18-03, FDA Compliant 21 CFR 177.2600 | 0000000 | 0000 |

| 2" | 1.900" | 2.520" | 0.203" | -15° to 400° | Black | 3-A Certified 18-03, FDA Compliant 21 CFR 177.2600 | 0000000 | 0000 |

| 3" | 2.900" | 3.580" | 0.203" | -15° to 400° | Black | 3-A Certified 18-03, FDA Compliant 21 CFR 177.2600 | 0000000 | 0000 |

| 4" | 3.870" | 4.680" | 0.203" | -15° to 400° | Black | 3-A Certified 18-03, FDA Compliant 21 CFR 177.2600 | 0000000 | 0000 |

| 6" | 5.820" | 6.510" | 0.203" | -15° to 400° | Black | 3-A Certified 18-03, FDA Compliant 21 CFR 177.2600 | 0000000 | 00000 |

PTFE Plastic | ||||||||

| 1/2" | 0.380" | 0.860" | 0.178" | -100° to 500° | White | 3-A Certified 20-27, FDA Compliant 21 CFR 177.1550 | 00000000 | 0000 |

| 3/4" | 0.620" | 0.860" | 0.178" | -100° to 500° | White | 3-A Certified 20-27, FDA Compliant 21 CFR 177.1550 | 00000000 | 0000 |

| 1" | 0.900" | 1.980" | 0.203" | -100° to 500° | White | 3-A Certified 20-27, FDA Compliant 21 CFR 177.1550 | 00000000 | 0000 |

| 1 1/2" | 1.400" | 1.980" | 0.203" | -100° to 500° | White | 3-A Certified 20-27, FDA Compliant 21 CFR 177.1550 | 00000000 | 0000 |

| 2" | 1.900" | 2.520" | 0.203" | -100° to 500° | White | 3-A Certified 20-27, FDA Compliant 21 CFR 177.1550 | 00000000 | 0000 |

| 3" | 2.900" | 3.580" | 0.203" | -100° to 500° | White | 3-A Certified 20-27, FDA Compliant 21 CFR 177.1550 | 00000000 | 0000 |

| 4" | 3.870" | 4.680" | 0.203" | -100° to 500° | White | 3-A Certified 20-27, FDA Compliant 21 CFR 177.1550 | 00000000 | 0000 |

| 6" | 5.820" | 6.510" | 0.203" | -100° to 500° | White | 3-A Certified 20-27, FDA Compliant 21 CFR 177.1550 | 00000000 | 00000 |