Filter by

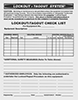

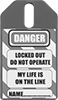

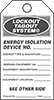

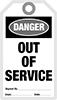

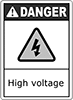

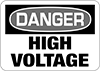

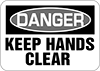

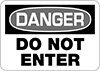

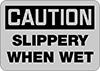

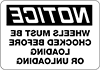

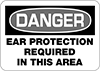

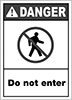

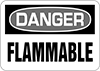

Message

Message Type

Height

Width

Accident Prevention Message Type

Message Contains

Message Color

Specifications Met

Visibility

Export Control Classification Number (ECCN)

DFARS Specialty Metals

For Use With

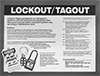

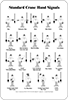

About Accident Prevention Signs

More