About Paint and Protective Coatings

More

Urethane Potting Compounds

Encase electronic assemblies in a layer of urethane for protection from dust, moisture, chemicals, mechanical shock, and vibration. Urethanes withstand a wide range of temperatures and are the best choice for cold-temperature applications. They have excellent flexibility, good chemical and moisture resistance, and provide good electrical insulation.

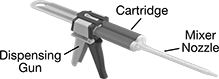

Cartridge potting compounds can be applied precisely through the included mixer nozzle. You’ll need a dispensing gun (sold separately). US2350™ also require a 4:1 plunger (sold separately) to dispense.

Dry Time | |||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|

| Mfr. Model No. | Container Size, fl. oz. | Consistency | Touch, min. | Overall, hrs. | Dielectric Strength, V/mil | Thermal Conductivity, W/m-K | Temp. Range, °F | For Use On | Color | Each | |

Loctite® Compounds—Medium Hard | |||||||||||

| US2350 | 1.69 | Thick Liquid | 90 | 24 | 950 | 0.51 | -40° to 250° | Aluminum, Brass, Bronze, Copper, Steel, Stainless Steel, Ceramic, Glass, Polycarbonate Plastic, Polyurethane Rubber, ABS Plastic, PVC Plastic, Polyimide Plastic, Garolite | Black | 0000000 | 000000 |

Loctite® Compounds—Soft | |||||||||||

| US2651 | 6.76 | Thin Liquid | 10 | 16 | 1,050 | Not Rated | -85° to 250° | Aluminum, Brass, Bronze, Copper, Steel, Stainless Steel, Ceramic, Glass, Polycarbonate Plastic, Polyurethane Rubber, ABS Plastic, PVC Plastic, Polyimide Plastic, Garolite | Amber | 0000000 | 00000 |

Epoxy Potting Compounds

Encase electronic assemblies in a layer of epoxy for protection from dust, chemicals, moisture, mechanical shock, and vibration. The strongest of the potting compounds, epoxies are rigid and wear resistant. They have excellent chemical and moisture resistance, withstand a wide range of temperatures, and provide excellent electrical insulation. All require a mixer nozzle and gun to dispense.

Loctite® ES1001™, ES1902™, and ES2500™ come with a mixer nozzle.

Dry Time | ||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Mfr. Model No. | Container Size, fl. oz. | Consistency | Touch, min. | Overall, hrs. | Dielectric Strength, V/mil | Thermal Conductivity, W/m-K | Temp. Range, °F | Specifications Met | For Use On | Color | Each | |

| ES1001 | 1.7 | Thick Liquid | 60 | 24 | 1,100 | 0.29 | -10° to 220° | __ | Aluminum, Brass, Bronze, Copper, Steel, Stainless Steel, Plastic, Ceramic, Glass | Black | 0000000 | 000000 |

| ES1902 | 1.7 | Thin Liquid | 60 | 24 | 1,350 | Not Rated | -40° to 250° | __ | Aluminum, Brass, Bronze, Copper, Steel, Stainless Steel, Plastic | Clear | 0000000 | 00000 |

| ES2500 | 1.7 | Thin Liquid | 10 | 16 | 410 | 0.28 | -40° to 220° | UL 94 HB | Aluminum, Brass, Bronze, Copper, Steel, Stainless Steel, Plastic, Ceramic, Glass | Black | 0000000 | 00000 |

| Dispensing Gun for 1.7 fl. oz. Cartridges | 00000000 | Each | 000000 |

Optically Clear Epoxy Potting Compounds

Clear enough to read through, these UV-resistant potting compounds allow optimal light transmission for use with LEDs, solar cells, and fiber optics. Use them to encase electronic assemblies for protection from dust, chemicals, moisture, mechanical shock, and vibration. Rigid and wear resistant, epoxies are the strongest of the potting compounds. They have excellent chemical and moisture resistance, withstand a wide range of temperatures, and provide excellent electrical insulation. All require a mixer nozzle and gun to dispense.

Loctite® ES1901™ comes with a mixer nozzle.

Dry Time | |||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|

| Mfr. Model No. | Container Size, fl. oz. | Consistency | Touch, min. | Overall, hrs. | Dielectric Strength, V/mil | Thermal Conductivity, W/m-K | Temp. Range, °F | For Use On | Color | Each | |

Loctite® Compounds—Extra Hard | |||||||||||

| ES1901 | 1.7 | Thick Liquid | 3 | 24 | 400 | Not Rated | -40° to 220° | Aluminum, Brass, Bronze, Copper, Steel, Stainless Steel, Plastic, Ceramic, Glass | Clear | 0000000 | 000000 |

Two-Part Adhesive Dispensing Guns | |||

|---|---|---|---|

| Dispensing Gun for 1.7 fl. oz. Cartridges | 00000000 | Each | 000000 |

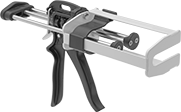

Two-Part Adhesive Dispensing Guns

Use these guns to dispense two-part adhesives. Do not use them with 3M dual cartridges.

Loctite® Plungers for Two-Part Adhesive Cartridges

Use these plungers with a Loctite dispensing gun for adhesives in dual cartridges.

| For Cartridge Size, oz. | Mix Ratio | Material | Each | |

| 1.69 | 10:1 | Nylon Plastic | 00000000 | 000000 |