Filter by

Manufacturer Model Number

Container Type

Mixer Nozzle Included

Maximum Temperature

Manufacturer

Dielectric Strength

Color

Consistency

Minimum Temperature

Formulation

Hardness Rating

Container Size

Touch Dry Time

Overall Dry Time

Thermal Conductivity

DFARS Specialty Metals

Export Control Classification Number (ECCN)

RoHS

REACH

Material

Hardness

Mixing Required

Tensile Strength

Mix Ratio

About Paint and Protective Coatings

More

Epoxy Potting Compounds

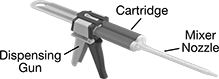

Encase electronic assemblies in a layer of epoxy for protection from dust, chemicals, moisture, mechanical shock, and vibration. The strongest of the potting compounds, epoxies are rigid and wear resistant. They have excellent chemical and moisture resistance, withstand a wide range of temperatures, and provide excellent electrical insulation. All require a mixer nozzle and gun to dispense.

Loctite® ES1001™, ES1902™, and ES2500™ come with a mixer nozzle.

Loctite® Compounds—Extra Hard

Dry Time | |||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|

| Mfr. Model No. | Container Size, fl. oz. | Consistency | Touch, min. | Overall, hrs. | Dielectric Strength, V/mil | Thermal Conductivity, W/m-K | Temp. Range, °F | For Use On | Color | Each | |

| ES1001 | 1.7 | Thick Liquid | 60 | 24 | 1,100 | 0.29 | -10° to 220° | Aluminum, Brass, Bronze, Copper, Steel, Stainless Steel, Plastic, Ceramic, Glass | Black | 0000000 | 000000 |

| Dispensing Gun for 1.7 fl. oz. Cartridges | 00000000 | Each | 000000 |