About Paint and Protective Coatings

More

About Structural Adhesives

More

Optically Clear Epoxy Structural Adhesives

For invisible bond lines, these adhesives dry clear. Epoxies are the strongest and most weather- and chemical-resistant structural adhesives. Choose an epoxy that hardens quickly for fast repairs, or one that hardens slowly to allow more time for positioning.

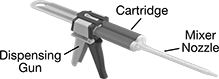

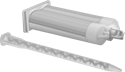

These have two parts that must be mixed. The size listed is the combined total of the two parts. Use cartridges with a dispensing gun and mixer nozzle to simultaneously mix and dispense adhesives.

0151 and E-30CL are suitable for fiber-optic applications.

E-05CL is toughened to form resilient, impact-resistant bonds on dissimilar materials. It's suitable for use on fiber-optic components.

E-05MR has good moisture resistance. It's toughened to form resilient, impact-resistant bonds on dissimilar materials.

Container | Strength | |||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Mfr. Model No. | Size, fl. oz. | Type | Begins to Harden | Reaches Full Strength | Shear, lbs./sq. in. | Peel, lbs./in. wd. | Mix Ratio | Consistency (Viscosity) | Temp. Range, °F | For Joining | Each | |

| 0151 | 1.69 | Cartridge | 60 min. | 24 hrs. | 2,675 | Not Rated | 2.7:1 | Thick Liquid (60,000 cP) | -65 to 160° F | Metal, Plastic, Rubber, Glass | 00000000 | 000000 |

| 0151 | 3.3 | Tube | 60 min. | 24 hrs. | 2,675 | Not Rated | 2.7:1 | Thick Liquid (60,000 cP) | -65 to 160° F | Metal, Plastic, Rubber, Glass | 00000000 | 00000 |

| 0151 | 41.6 | Can | 60 min. | 24 hrs. | 2,675 | Not Rated | 2.7:1 | Thick Liquid (60,000 cP) | -65 to 160° F | Metal, Plastic, Rubber, Glass | 00000000 | 000000 |

| 608 | 1.69 | Cartridge | 5 min. | 24 hrs. | 2,980 | Not Rated | 1:1 | Paste (100,000 cP) | -65 to 130° F | Metal, Plastic, Rubber | 0000000 | 00000 |

| 608 | 2.8 | Tube | 5 min. | 24 hrs. | 2,980 | Not Rated | 1:1 | Paste (100,000 cP) | -65 to 130° F | Metal, Plastic, Rubber | 00000000 | 00000 |

| D609 | 1.69 | Cartridge | 5 min. | 24 hrs. | 1,800 | Not Rated | 1:1 | Thick Liquid (15,000 cP) | -65 to 180° F | Metal, Plastic, Rubber | 00000000 | 00000 |

| E-05CL | 1.69 | Cartridge | 3 min. | 24 hrs. | 1,430 | Not Rated | 1:1 | Thick Liquid (2,500 cP) | -65 to 180° F | Metal, Metal to Plastic, Metal to Rubber, Plastic, Plastic to Rubber, Rubber | 0000000 | 00000 |

| E-05MR | 1.69 | Cartridge | 5 min. | 24 hrs. | 3,380 | Not Rated | 1:1 | Thick Liquid (25,000 cP) | -65 to 250° F | Metal, Metal to Plastic, Metal to Rubber, Plastic, Plastic to Rubber, Rubber | 0000000 | 00000 |

| E-30CL | 1.69 | Cartridge | 30 min. | 24 hrs. | 3,100 | Not Rated | 2:1 | Thick Liquid (10,000 cP) | -65 to 250° F | Metal, Plastic, Ceramic, Glass | 0000000 | 00000 |

| E-30CL | 6.76 | Cartridge | 30 min. | 24 hrs. | 3,100 | Not Rated | 2:1 | Thick Liquid (10,000 cP) | -65 to 250° F | Metal, Plastic, Ceramic, Glass | 0000000 | 00000 |

| M-31CL | 1.69 | Cartridge | 30 min. | 24 hrs. | 3,100 | Not Rated | 2:1 | Thick Liquid (6,000 cP) | -65 to 300° F | Metal, Plastic, Rubber, Glass | 0000000 | 00000 |

Container | Strength | ||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Mfr. Model No. | Net Weight, oz. | Type | Begins to Harden | Reaches Full Strength | Shear, lbs./sq. in. | Peel | Mix Ratio | Consistency (Viscosity) | Temp. Range, °F | For Joining | Pkg. Qty. | Pkg. | |

Loctite® Adhesives | |||||||||||||

| 608 | 0.14 | One-Time-Use Packet | 5 min. | 24 hrs. | 2,980 | Not Rated | 1:1 | Paste (100,000 cP) | -65° to 130° | Metal, Plastic, Rubber | 10 | 00000000 | 000000 |

| Each | ||

| Mixer Nozzle for 1.69 fl. oz. Loctite® Cartridges | 00000000 | 00000 |

| Mixer Nozzle for 6.76 fl. oz. Loctite® Cartridges | 0000000 | 0000 |

| Dispensing Gun for 1.69 fl. oz Loctite® Cartridges | 00000000 | 00000 |

| Dispensing Gun for 6.76 fl. oz. Loctite® Cartridges | 0000000 | 000000 |

| Air-Powered Dispensing Gun for 1.69 fl. oz. Loctite® Cartridges | 000000000 | 000000 |

Epoxy Structural Adhesives

Epoxies are the strongest and most weather- and chemical-resistant structural adhesives. They work especially well on metals.

Two-part epoxies must be mixed. The size listed is the combined total of the two parts.

Use cartridges with a dispensing gun and mixer nozzle to simultaneously mix and dispense adhesives.

1838, 11C, and 1C meet ASTM E595, a standard used by NASA, so they produce almost no volatile emissions that could damage sensitive electronics and optics, even in a vacuum.

9460 and E-20NS are nonsagging, so they won't drip from vertical or overhead surfaces. 9460 bonds dissimilar materials.

Container | Strength | |||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Mfr. Model No. | Size | Type | Begins to Harden | Reaches Full Strength | Shear, lbs./sq. in. | Peel, lbs./in. wd. | Mix Ratio | Consistency (Viscosity) | Temp. Range, °F | Color | Specifications Met | For Joining | Each | |

| 11C | 4 fl. oz. | Tube | 20 min. | 72 hrs. | 2,270 | Not Rated | 2.5:1 | Paste (367,850 cP) | -65° to 300° | Black | ASTM E595 | Metal, Plastic, Rubber | 00000000 | 000000 |

| 1C | 4 fl. oz. | Tube | 20 min. | 72 hrs. | 1,500 | Not Rated | 2.5:1 | Paste (350,000 cP) | -65° to 300° | Off-White | ASTM E595 | Metal, Plastic, Rubber, Wood | 00000000 | 00000 |

| 1C-LV | 1.69 fl. oz. | Cartridge | 20 min. | 72 hrs. | 2,100 | Not Rated | 2:1 | Thick Liquid (66,750 cP) | -65° to 250° | Beige | __ | Metal, Plastic, Rubber | 0000000 | 00000 |

| 615 | 3.2 fl. oz. | Tube | 10 min. | 24 hrs. | 3,825 | Not Rated | 1:1 | Paste (200,000 cP) | -65° to 180° | Light Blue | __ | Metal, Plastic, Rubber | 00000000 | 00000 |

| 9460 | 1.69 fl. oz. | Cartridge | 50 min. | 72 hrs. | 3,500 | 30 | 1:1 | Paste (200,000 cP) | -65° to 250° | Gray | __ | Metal, Metal to Plastic, Metal to Rubber, Plastic, Plastic to Rubber, Rubber | 00000000 | 00000 |

| 9460 | 2.5 gal. | Can | 50 min. | 72 hrs. | 3,500 | 30 | 1:1 | Paste (200,000 cP) | -65° to 250° | Gray | __ | Metal, Metal to Plastic, Metal to Rubber, Plastic, Plastic to Rubber, Rubber | 00000000 | 000000 |

| 9460 | 6.76 fl. oz. | Cartridge | 50 min. | 72 hrs. | 3,500 | 30 | 1:1 | Paste (200,000 cP) | -65° to 250° | Gray | __ | Metal, Metal to Plastic, Metal to Rubber, Plastic, Plastic to Rubber, Rubber | 00000000 | 00000 |

| E-20NS | 1.69 fl. oz. | Cartridge | 20 min. | 24 hrs. | 2,790 | Not Rated | 2:1 | Thick Liquid (60,000 cP) | -65° to 250° | Beige | __ | Metal, Plastic, Rubber | 0000000 | 00000 |

| Each | ||

| Mixer Nozzle for 6.76 fl. oz. and 13.5 fl. oz. Loctite® Cartridges | 0000000 | 00000 |

| Mixer Nozzle for 1.69 fl. oz. Cartridges | 00000000 | 0000 |

| Air-Powered Dispensing Gun for 1.69 fl. oz. Loctite® Cartridges | 000000000 | 000000 |

| Dispensing Gun for 1.69 fl. oz. Cartridges | 00000000 | 00000 |

| Dispensing Gun for 6.76 fl. oz. Loctite® Cartridges | 0000000 | 000000 |

Slow-Set Epoxy Structural Adhesives

To allow time to adjust and position parts, these epoxies remain workable for at least 90 minutes. The strongest and most weather- and chemical-resistant structural adhesives, epoxies work especially well on metals.

These have two parts that must be mixed. The size listed is the combined total of the two parts. Use cartridges with a dispensing gun and mixer nozzle to simultaneously mix and dispense adhesives.

M-121HP bonds dissimilar materials and withstands rapid changes in temperature.

Container | Strength | ||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Mfr. Model No. | Size, fl. oz. | Type | Begins to Harden | Reaches Full Strength | Shear, lbs./sq. in. | Peel | Mix Ratio | Consistency (Viscosity) | Temp. Range, °F | Specifications Met | For Joining | Each | |

| 9340 | 2.7 | Tube | 90 min. | 24 hrs. | 2,300 | Not Rated | 1:1 | Paste (Not Rated) | -65° to 180° | __ | Metal, Plastic, Rubber | 00000000 | 000000 |

| M-121HP | 1.69 | Cartridge | 2 hrs. | 24 hrs. | 4,800 | Not Rated | 2:1 | Thick Liquid (11,000 cP) | -65° to 300° | ISO 10993 | Metal, Metal to Plastic, Metal to Rubber, Metal to Glass, Plastic, Plastic to Rubber, Plastic to Glass, Rubber, Rubber to Glass, Ceramic, Glass | 0000000 | 00000 |

Toughened Epoxy Structural Adhesives

Toughened adhesives are blended with rubber particles for better impact resistance than standard epoxies. They form flexible, resilient bonds. The most weather- and chemical-resistant structural adhesives, epoxies work especially well on metals. Choose an adhesive that hardens quickly for fast repairs, or one that hardens slowly to allow more time for positioning.

These have two parts that must be mixed. The size listed is the combined total of the two parts. Use with a dispensing gun and mixer nozzle to simultaneously mix and dispense adhesives.

DP420NS, DP460NS, E-40HT, and 9462 are nonsagging, so they won't drip from vertical or overhead surfaces.

E-40FL and E-90FL bond dissimilar materials.

Container | Strength | ||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Mfr. Model No. | Size, fl. oz. | Type | Begins to Harden | Reaches Full Strength | Shear, lbs./sq. in. | Peel, lbs./in. wd. | Mix Ratio | Consistency (Viscosity) | Temp. Range, °F | Color | For Joining | Each | |

| E-20HP | 1.69 | Cartridge | 20 min. | 24 hrs. | 3,270 | Not Rated | 2:1 | Thick Liquid (30,000 cP) | -25° to 250° | Off-White | Metal, Plastic | 0000000 | 000000 |

| E-20HP | 6.76 | Cartridge | 20 min. | 24 hrs. | 3,270 | Not Rated | 2:1 | Thick Liquid (30,000 cP) | -25° to 250° | Off-White | Metal, Plastic | 0000000 | 00000 |

| E-20HP | 13.5 | Cartridge | 20 min. | 24 hrs. | 3,270 | Not Rated | 2:1 | Thick Liquid (37,000 cP) | -25° to 250° | Off-White | Metal, Plastic | 0000000 | 000000 |

| E-40FL | 1.69 | Cartridge | 40 min. | 24 hrs. | 640 | Not Rated | 1:1 | Thick Liquid (70,000 cP) | -25° to 250° | Gray | Metal, Metal to Plastic, Metal to Rubber, Metal to Glass, Plastic, Plastic to Rubber, Plastic to Glass, Plastic to Masonry, Rubber, Rubber to Glass, Rubber to Masonry, Ceramic, Glass, Masonry, Wood, Wood to Glass | 0000000 | 00000 |

| E-40FL | 6.76 | Cartridge | 40 min. | 24 hrs. | 640 | Not Rated | 1:1 | Thick Liquid (70,000 cP) | -25° to 250° | Off-White | Metal, Metal to Plastic, Metal to Rubber, Metal to Glass, Plastic, Plastic to Rubber, Plastic to Glass, Plastic to Masonry, Rubber, Rubber to Glass, Rubber to Masonry, Ceramic, Glass, Masonry, Wood, Wood to Glass | 0000000 | 00000 |

| E-40FL | 13.5 | Cartridge | 40 min. | 24 hrs. | 640 | Not Rated | 1:1 | Thick Liquid (70,000 cP) | -25° to 250° | Off-White | Metal, Metal to Plastic, Metal to Rubber, Metal to Glass, Plastic, Plastic to Rubber, Plastic to Glass, Plastic to Masonry, Rubber, Rubber to Glass, Rubber to Masonry, Ceramic, Glass, Masonry, Wood, Wood to Glass | 0000000 | 000000 |

| E-40HT | 1.69 | Cartridge | 40 min. | 24 hrs. | 4,030 | Not Rated | 2:1 | Paste (430,000 cP) | -65° to 300° | Off-White | Metal, Plastic, Rubber | 0000000 | 00000 |

| E-60HP | 1.69 | Cartridge | 60 min. | 24 hrs. | 4,320 | Not Rated | 2:1 | Thick Liquid (45,000 cP) | -25° to 250° | Off-White | Metal, Plastic, Rubber | 0000000 | 00000 |

| E-60HP | 13.5 | Cartridge | 60 min. | 24 hrs. | 4,320 | Not Rated | 2:1 | Thick Liquid (45,000 cP) | -25° to 250° | Off-White | Metal, Plastic, Rubber | 0000000 | 000000 |

| E-90FL | 1.69 | Cartridge | 90 min. | 24 hrs. | 810 | Not Rated | 1:1 | Thick Liquid (40,000 cP) | -25° to 250° | Gray | Metal, Metal to Plastic, Metal to Rubber, Metal to Glass, Plastic, Plastic to Rubber, Plastic to Glass, Plastic to Masonry, Rubber, Rubber to Glass, Rubber to Masonry, Ceramic, Glass, Masonry, Wood, Wood to Glass | 0000000 | 00000 |

| E-90FL | 13.5 | Cartridge | 90 min. | 24 hrs. | 810 | Not Rated | 1:1 | Thick Liquid (40,000 cP) | -25° to 250° | Off-White | Metal, Metal to Plastic, Metal to Rubber, Metal to Glass, Plastic, Plastic to Rubber, Plastic to Glass, Plastic to Masonry, Rubber, Rubber to Glass, Rubber to Masonry, Ceramic, Glass, Masonry, Wood, Wood to Glass | 0000000 | 000000 |

| 9462 | 1.69 | Cartridge | 55 min. | 72 hrs. | 4,180 | 22 | 1:1 | Thick Liquid (70,000 cP) | -65° to 250° | Beige | Metal, Plastic, Rubber | 0000000 | 00000 |

| Each | ||

| Mixer Nozzle for 1.69 fl. oz. Cartridges | 00000000 | 00000 |

| Mixer Nozzle for 6.76 fl. oz. E-20HP Loctite® Cartridges | 0000000 | 0000 |

| Air-Powered Dispensing Gun for 1.69 fl. oz. Loctite® Cartridges | 000000000 | 000000 |

| Dispensing Gun for 1.69 fl. oz. Cartridges | 00000000 | 00000 |

| Dispensing Gun for 6.76 fl. oz. E-20HP Loctite® Cartridges | 0000000 | 000000 |

Epoxy Structural Adhesives for Harsh Environments

With excellent resistance to corrosive chemicals and salt water, these epoxies work in tough conditions. Epoxies are the strongest structural adhesives. Choose an adhesive that hardens quickly for fast repairs, or one that hardens slowly to allow more time for positioning.

These have two parts that must be mixed. The size listed is the combined total of the two parts. Use cartridges with a dispensing gun and mixer nozzle to simultaneously mix and dispense adhesives.

E-120HP resists acetone, fuel, and oil. It bonds dissimilar materials and withstands rapid changes in temperature.

9430 bonds dissimilar materials and resists fuel and hydraulic fluid.

Mfr. Model | Container | Strength | ||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| No. | Size | Type | Begins to Harden | Reaches Full Strength | Shear, lbs./sq. in. | Peel, lbs./in. wd. | Mix Ratio | Consistency (Viscosity) | Temp. Range, °F | Color | Environment | For Joining | Each | |

Loctite® Adhesives | ||||||||||||||

| E-120HP | 1.69 fl. oz. | Cartridge | 2 hrs. | 24 hrs. | 4,300 | Not Rated | 2:1 | Thick Liquid (30,000 cP) | -65° to 250° | Amber | Corrosive, Salt Spray, Submersible | Metal, Metal to Plastic, Metal to Rubber, Plastic, Plastic to Rubber, Rubber, Ceramic | 0000000 | 000000 |

| E-120HP | 6.76 fl. oz. | Cartridge | 2 hrs. | 24 hrs. | 4,300 | Not Rated | 2:1 | Thick Liquid (30,000 cP) | -65° to 250° | Amber | Corrosive, Salt Spray, Submersible | Metal, Metal to Plastic, Metal to Rubber, Plastic, Plastic to Rubber, Rubber, Ceramic | 0000000 | 00000 |

| E-120HP | 13.5 fl. oz. | Cartridge | 2 hrs. | 24 hrs. | 4,300 | Not Rated | 2:1 | Thick Liquid (30,000 cP) | -65° to 250° | Amber | Corrosive, Salt Spray, Submersible | Metal, Metal to Plastic, Metal to Rubber, Plastic, Plastic to Rubber, Rubber, Ceramic | 0000000 | 000000 |

| 9430 | 32 fl. oz. | Can | 50 min. | 5 days | 4,230 | 60 | 3.78:1 | Thick Liquid (12,000 cP) | -65° to 180° | Off-White | Corrosive, Salt Spray, Submersible | Metal, Metal to Plastic, Metal to Rubber, Plastic, Plastic to Rubber, Rubber | 00000000 | 000000 |

| 9430 | 1.25 gal. | Can | 50 min. | 5 days | 4,230 | 60 | 3.78:1 | Thick Liquid (12,000 cP) | -65° to 180° | Off-White | Corrosive, Salt Spray, Submersible | Metal, Metal to Plastic, Metal to Rubber, Plastic, Plastic to Rubber, Rubber | 00000000 | 000000 |

| Each | ||

| Mixer Nozzle for 1.69 fl. oz. Cartridges | 00000000 | 00000 |

| Mixer Nozzle for 6.76 fl. oz. and 13.5 fl. oz. Cartridges | 0000000 | 0000 |

| Replacement Plunger for 13.5 fl. oz. Cartridges (2:1 Mix Ratio) | 00000000 | 0000 |

| Air-Powered Dispensing Gun for 1.69 fl. oz. Loctite® Cartridges | 000000000 | 000000 |

| Dispensing Gun for 1.69 fl. oz. Cartridges | 00000000 | 00000 |

| Dispensing Gun for 6.76 fl. oz. Cartridges | 0000000 | 000000 |

| Dispensing Gun for 13.5 fl. oz. Cartridges | 0000000 | 000000 |

Quick-Set Epoxy Structural Adhesives

For quick repairs, these epoxies begin to harden in 6 minutes or less. Epoxies are the strongest and most weather- and chemical-resistant structural adhesives.

These have two parts that must be mixed. The size listed is the combined total of the two parts. Use cartridges with a dispensing gun and mixer nozzle to simultaneously mix and dispense adhesives.

HY4090 is a blend of epoxy and instant-bond adhesive for a balance of strength, cure speed, and temperature resistance.

Container | Strength | ||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Mfr. Model No. | Size, fl. oz. | Type | Begins to Harden | Reaches Full Strength | Shear, lbs./sq. in. | Peel | Mix Ratio | Consistency (Viscosity) | Temp. Range, °F | Color | For Joining | Each | |

| HY4090 | 1.69 | Cartridge | 3 min. | 7 days | 2,420 | Not Rated | 1:1 | Thick Liquid (19,000 cP) | -65° to 300° | Gray | Metal, Plastic, Rubber, Composites, Masonry, Wood | 00000000 | 000000 |

| HY4090 | 1.69 | Cartridge | 3 min. | 7 days | 2,420 | Not Rated | 1:1 | Thick Liquid (19,000 cP) | -65° to 300° | Off-White | Metal, Plastic, Rubber, Composites, Masonry, Wood | 00000000 | 00000 |

| HY4090 | 13.5 | Cartridge | 3 min. | 7 days | 2,420 | Not Rated | 1:1 | Thick Liquid (19,000 cP) | -65° to 300° | Off-White | Metal, Plastic, Rubber, Composites, Masonry, Wood | 0000000 | 000000 |

| Each | ||

| Mixer Nozzle for 1.69 fl. oz. Loctite® Cartridges | 000000000 | 00000 |

| Mixer Nozzle for 6.76 fl. oz. and 13.5 fl. oz. Cartridges | 000000000 | 0000 |

| Air-Powered Dispensing Gun for 1.69 fl. oz. Loctite® Cartridges | 000000000 | 000000 |

| Dispensing Gun for 1.69 fl. oz. Cartridges | 00000000 | 00000 |

| Dispensing Gun for 13.5 fl. oz. Cartridges | 0000000 | 000000 |

Low-Odor Epoxy Structural Adhesives

Bond most materials without the strong odor of other epoxy adhesives. The strongest and most weather- and chemical-resistant structural adhesives, epoxies work especially well on metals.

These have two parts that must be mixed. The size listed is the combined total of the two parts. Use cartridges with a dispensing gun and mixer nozzle to simultaneously mix and dispense adhesives.

E-00NS is nonsagging, so it won't drip from vertical or overhead surfaces.

Container | Strength | ||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Mfr. Model No. | Size, fl. oz. | Type | Begins to Harden | Reaches Full Strength | Shear, lbs./sq. in. | Peel, lbs./in. wd. | Mix Ratio | Consistency (Viscosity) | Temp. Range, °F | Color | For Joining | Each | |

Loctite® Adhesives | |||||||||||||

| E-00NS | 1.69 | Cartridge | 3 min. | 24 hrs. | 1,600 | Not Rated | 1:1 | Paste (100,000 cP) | -65° to 180° | White | Metal, Plastic, Rubber | 0000000 | 000000 |

Epoxy Potting Compounds

Encase electronic assemblies in a layer of epoxy for protection from dust, chemicals, moisture, mechanical shock, and vibration. The strongest of the potting compounds, epoxies are rigid and wear resistant. They have excellent chemical and moisture resistance, withstand a wide range of temperatures, and provide excellent electrical insulation. All require a mixer nozzle and gun to dispense.

Loctite® ES1001™, ES1902™, and ES2500™ come with a mixer nozzle.

Dry Time | ||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Mfr. Model No. | Container Size, fl. oz. | Consistency | Touch, min. | Overall, hrs. | Dielectric Strength, V/mil | Thermal Conductivity, W/m-K | Temp. Range, °F | Specifications Met | For Use On | Color | Each | |

| E-60NC | 1.7 | Thick Liquid | 60 | 24 | 550 | Not Rated | -65° to 250° | __ | Aluminum, Brass, Bronze, Copper, Steel, Stainless Steel, Silver, Titanium, Plastic, Composites, Fiberglass | Black | 0000000 | 000000 |

| E-60NC | 6.8 | Thick Liquid | 60 | 24 | 550 | Not Rated | -65° to 250° | __ | Aluminum, Brass, Bronze, Copper, Steel, Stainless Steel, Silver, Titanium, Plastic, Composites, Fiberglass | Black | 0000000 | 00000 |

| E-60NC | 13.5 | Thick Liquid | 60 | 24 | 550 | Not Rated | -65° to 250° | __ | Aluminum, Brass, Bronze, Copper, Steel, Stainless Steel, Silver, Titanium, Plastic, Composites, Fiberglass | Black | 0000000 | 00000 |

| ES1001 | 1.7 | Thick Liquid | 60 | 24 | 1,100 | 0.29 | -10° to 220° | __ | Aluminum, Brass, Bronze, Copper, Steel, Stainless Steel, Plastic, Ceramic, Glass | Black | 0000000 | 00000 |

| ES1902 | 1.7 | Thin Liquid | 60 | 24 | 1,350 | Not Rated | -40° to 250° | __ | Aluminum, Brass, Bronze, Copper, Steel, Stainless Steel, Plastic | Clear | 0000000 | 00000 |

| ES2500 | 1.7 | Thin Liquid | 10 | 16 | 410 | 0.28 | -40° to 220° | UL 94 HB | Aluminum, Brass, Bronze, Copper, Steel, Stainless Steel, Plastic, Ceramic, Glass | Black | 0000000 | 00000 |

| Dispensing Gun for 1.7 fl. oz. Cartridges | 00000000 | Each | 000000 |

| Mixer Nozzle for 1.7 fl. oz. E-60NC Cartridges | 00000000 | Each | 0000 |

| Mixer Nozzle for 6.8 fl. oz. and 13.5 fl. oz. Cartridges | 0000000 | Each | 0000 |

| Dispensing Gun for 6.8 fl. oz. Cartridges | 0000000 | Each | 000000 |

| Dispensing Gun for 13.5 fl. oz. Cartridges | 0000000 | Each | 000000 |

Optically Clear Epoxy Potting Compounds

Clear enough to read through, these UV-resistant potting compounds allow optimal light transmission for use with LEDs, solar cells, and fiber optics. Use them to encase electronic assemblies for protection from dust, chemicals, moisture, mechanical shock, and vibration. Rigid and wear resistant, epoxies are the strongest of the potting compounds. They have excellent chemical and moisture resistance, withstand a wide range of temperatures, and provide excellent electrical insulation. All require a mixer nozzle and gun to dispense.

Loctite® ES1901™ comes with a mixer nozzle.

Dry Time | |||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|

| Mfr. Model No. | Container Size, fl. oz. | Consistency | Touch, min. | Overall, hrs. | Dielectric Strength, V/mil | Thermal Conductivity, W/m-K | Temp. Range, °F | For Use On | Color | Each | |

Loctite® Compounds—Extra Hard | |||||||||||

| ES1901 | 1.7 | Thick Liquid | 3 | 24 | 400 | Not Rated | -40° to 220° | Aluminum, Brass, Bronze, Copper, Steel, Stainless Steel, Plastic, Ceramic, Glass | Clear | 0000000 | 000000 |

Two-Part Adhesive Dispensing Guns | |||

|---|---|---|---|

| Dispensing Gun for 1.7 fl. oz. Cartridges | 00000000 | Each | 000000 |

Heavy Duty High-Purity Coatings for Electronics

This coating is formulated for use in sensitive applications such as manufacturing semiconductors. Thinner than potting compounds, the coating flows easily into small spaces between electrical components. Use it to secure and insulate hardware on printed circuit boards. Rigid and wear resistant, has excellent chemical and moisture resistance, withstands a wide range of temperatures, and provides excellent electrical insulation. It requires a gun and a mixer nozzle (each sold separately) to dispense.

![]() Certificates with a traceable lot number and product shelf life are available for these products. Download certificates from ORDER HISTORY after your order ships.

Certificates with a traceable lot number and product shelf life are available for these products. Download certificates from ORDER HISTORY after your order ships.

Dry Time | ||||||||||

|---|---|---|---|---|---|---|---|---|---|---|

| Mfr. Model No. | Container Size | Consistency | Touch, min. | Overall, hrs. | Dielectric Strength, V/mil | Temp. Range, °F | For Use On | Color | Each | |

Loctite® Coatings—Extra Hard | ||||||||||

| M-21HP | 1.7 fl. oz. | Paste | 20 | 24 | 500 | -65° to 300° | Aluminum, Brass, Bronze, Copper, Steel, Stainless Steel, Titanium, Silver, Plastic, Composites, Fiberglass | Off-White | 0000000 | 000000 |

Heavy Duty Coatings for Electronics

Thinner than potting compounds, these coatings flow easily into small spaces between electrical components. Use them to secure and insulate hardware on printed circuit boards. Rigid and wear resistant, epoxies have excellent chemical and moisture resistance, withstand a wide range of temperatures, and provide excellent electrical insulation. Dispense with a mixer nozzle and a gun (each sold separately).

![]() Certificates with a traceable lot number and product shelf life are available for these products. Download certificates from ORDER HISTORY after your order ships.

Certificates with a traceable lot number and product shelf life are available for these products. Download certificates from ORDER HISTORY after your order ships.

Dry Time | ||||||||||

|---|---|---|---|---|---|---|---|---|---|---|

| Mfr. Model No. | Container Size, fl. oz. | Consistency | Touch, min. | Overall, hrs. | Dielectric Strength, V/mil | Temp. Range, °F | For Use On | Color | Each | |

Loctite® Coatings—Extra Hard | ||||||||||

| E-00CL | 1.7 | Thick Liquid | 5 | 24 | 400 | -65° to 180° | Aluminum, Brass, Bronze, Copper, Steel, Stainless Steel, Titanium, Silver, Plastic, Composites, Fiberglass | Clear | 0000000 | 000000 |

| E-00CL | 6.8 | Thick Liquid | 5 | 24 | 400 | -65° to 180° | Aluminum, Brass, Bronze, Copper, Steel, Stainless Steel, Titanium, Silver, Plastic, Composites, Fiberglass | Clear | 0000000 | 00000 |