About Paint and Protective Coatings

More

About Structural Adhesives

More

Epoxy Structural Adhesives

Epoxies are the strongest and most weather- and chemical-resistant structural adhesives. They work especially well on metals.

Two-part epoxies must be mixed. The size listed is the combined total of the two parts.

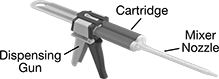

Use cartridges with a dispensing gun and mixer nozzle to simultaneously mix and dispense adhesives.

1838, 11C, and 1C meet ASTM E595, a standard used by NASA, so they produce almost no volatile emissions that could damage sensitive electronics and optics, even in a vacuum.

9460 and E-20NS are nonsagging, so they won't drip from vertical or overhead surfaces. 9460 bonds dissimilar materials.

Container | Strength | |||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Mfr. Model No. | Size | Type | Begins to Harden | Reaches Full Strength | Shear, lbs./sq. in. | Peel, lbs./in. wd. | Mix Ratio | Consistency (Viscosity) | Temp. Range, °F | Color | Specifications Met | For Joining | Each | |

| 11C | 4 fl. oz. | Tube | 20 min. | 72 hrs. | 2,270 | Not Rated | 2.5:1 | Paste (367,850 cP) | -65° to 300° | Black | ASTM E595 | Metal, Plastic, Rubber | 00000000 | 000000 |

| 1C | 4 fl. oz. | Tube | 20 min. | 72 hrs. | 1,500 | Not Rated | 2.5:1 | Paste (350,000 cP) | -65° to 300° | Off-White | ASTM E595 | Metal, Plastic, Rubber, Wood | 00000000 | 00000 |

| 1C-LV | 1.69 fl. oz. | Cartridge | 20 min. | 72 hrs. | 2,100 | Not Rated | 2:1 | Thick Liquid (66,750 cP) | -65° to 250° | Beige | __ | Metal, Plastic, Rubber | 0000000 | 00000 |

| 615 | 3.2 fl. oz. | Tube | 10 min. | 24 hrs. | 3,825 | Not Rated | 1:1 | Paste (200,000 cP) | -65° to 180° | Light Blue | __ | Metal, Plastic, Rubber | 00000000 | 00000 |

| 9460 | 1.69 fl. oz. | Cartridge | 50 min. | 72 hrs. | 3,500 | 30 | 1:1 | Paste (200,000 cP) | -65° to 250° | Gray | __ | Metal, Metal to Plastic, Metal to Rubber, Plastic, Plastic to Rubber, Rubber | 00000000 | 00000 |

| 9460 | 2.5 gal. | Can | 50 min. | 72 hrs. | 3,500 | 30 | 1:1 | Paste (200,000 cP) | -65° to 250° | Gray | __ | Metal, Metal to Plastic, Metal to Rubber, Plastic, Plastic to Rubber, Rubber | 00000000 | 000000 |

| 9460 | 6.76 fl. oz. | Cartridge | 50 min. | 72 hrs. | 3,500 | 30 | 1:1 | Paste (200,000 cP) | -65° to 250° | Gray | __ | Metal, Metal to Plastic, Metal to Rubber, Plastic, Plastic to Rubber, Rubber | 00000000 | 00000 |

| E-20NS | 1.69 fl. oz. | Cartridge | 20 min. | 24 hrs. | 2,790 | Not Rated | 2:1 | Thick Liquid (60,000 cP) | -65° to 250° | Beige | __ | Metal, Plastic, Rubber | 0000000 | 00000 |

| Each | ||

| Mixer Nozzle for 6.76 fl. oz. and 13.5 fl. oz. Loctite® Cartridges | 0000000 | 00000 |

| Mixer Nozzle for 1.69 fl. oz. Cartridges | 00000000 | 0000 |

| Air-Powered Dispensing Gun for 1.69 fl. oz. Loctite® Cartridges | 000000000 | 000000 |

| Dispensing Gun for 1.69 fl. oz. Cartridges | 00000000 | 00000 |

| Dispensing Gun for 6.76 fl. oz. Loctite® Cartridges | 0000000 | 000000 |

Quick-Set Epoxy Structural Adhesives

For quick repairs, these epoxies begin to harden in 6 minutes or less. Epoxies are the strongest and most weather- and chemical-resistant structural adhesives.

These have two parts that must be mixed. The size listed is the combined total of the two parts. Use cartridges with a dispensing gun and mixer nozzle to simultaneously mix and dispense adhesives.

HY4090 is a blend of epoxy and instant-bond adhesive for a balance of strength, cure speed, and temperature resistance.

Container | Strength | ||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Mfr. Model No. | Size, fl. oz. | Type | Begins to Harden | Reaches Full Strength | Shear, lbs./sq. in. | Peel | Mix Ratio | Consistency (Viscosity) | Temp. Range, °F | Color | For Joining | Each | |

| HY4090 | 1.69 | Cartridge | 3 min. | 7 days | 2,420 | Not Rated | 1:1 | Thick Liquid (19,000 cP) | -65° to 300° | Gray | Metal, Plastic, Rubber, Composites, Masonry, Wood | 00000000 | 000000 |

| HY4090 | 1.69 | Cartridge | 3 min. | 7 days | 2,420 | Not Rated | 1:1 | Thick Liquid (19,000 cP) | -65° to 300° | Off-White | Metal, Plastic, Rubber, Composites, Masonry, Wood | 00000000 | 00000 |

| HY4090 | 13.5 | Cartridge | 3 min. | 7 days | 2,420 | Not Rated | 1:1 | Thick Liquid (19,000 cP) | -65° to 300° | Off-White | Metal, Plastic, Rubber, Composites, Masonry, Wood | 0000000 | 000000 |

| Each | ||

| Mixer Nozzle for 1.69 fl. oz. Loctite® Cartridges | 000000000 | 00000 |

| Mixer Nozzle for 6.76 fl. oz. and 13.5 fl. oz. Cartridges | 000000000 | 0000 |

| Air-Powered Dispensing Gun for 1.69 fl. oz. Loctite® Cartridges | 000000000 | 000000 |

| Dispensing Gun for 1.69 fl. oz. Cartridges | 00000000 | 00000 |

| Dispensing Gun for 13.5 fl. oz. Cartridges | 0000000 | 000000 |

Slow-Set Epoxy Structural Adhesives

To allow time to adjust and position parts, these epoxies remain workable for at least 90 minutes. The strongest and most weather- and chemical-resistant structural adhesives, epoxies work especially well on metals.

These have two parts that must be mixed. The size listed is the combined total of the two parts. Use cartridges with a dispensing gun and mixer nozzle to simultaneously mix and dispense adhesives.

M-121HP bonds dissimilar materials and withstands rapid changes in temperature.

Container | Strength | ||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Mfr. Model No. | Size, fl. oz. | Type | Begins to Harden | Reaches Full Strength | Shear, lbs./sq. in. | Peel | Mix Ratio | Consistency (Viscosity) | Temp. Range, °F | Specifications Met | For Joining | Each | |

| 9340 | 2.7 | Tube | 90 min. | 24 hrs. | 2,300 | Not Rated | 1:1 | Paste (Not Rated) | -65° to 180° | __ | Metal, Plastic, Rubber | 00000000 | 000000 |

| M-121HP | 1.69 | Cartridge | 2 hrs. | 24 hrs. | 4,800 | Not Rated | 2:1 | Thick Liquid (11,000 cP) | -65° to 300° | ISO 10993 | Metal, Metal to Plastic, Metal to Rubber, Metal to Glass, Plastic, Plastic to Rubber, Plastic to Glass, Rubber, Rubber to Glass, Ceramic, Glass | 0000000 | 00000 |

Toughened Epoxy Structural Adhesives

Toughened adhesives are blended with rubber particles for better impact resistance than standard epoxies. They form flexible, resilient bonds. The most weather- and chemical-resistant structural adhesives, epoxies work especially well on metals. Choose an adhesive that hardens quickly for fast repairs, or one that hardens slowly to allow more time for positioning.

These have two parts that must be mixed. The size listed is the combined total of the two parts. Use with a dispensing gun and mixer nozzle to simultaneously mix and dispense adhesives.

DP420NS, DP460NS, E-40HT, and 9462 are nonsagging, so they won't drip from vertical or overhead surfaces.

E-40FL and E-90FL bond dissimilar materials.

Container | Strength | ||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Mfr. Model No. | Size, fl. oz. | Type | Begins to Harden | Reaches Full Strength | Shear, lbs./sq. in. | Peel, lbs./in. wd. | Mix Ratio | Consistency (Viscosity) | Temp. Range, °F | Color | For Joining | Each | |

| E-20HP | 1.69 | Cartridge | 20 min. | 24 hrs. | 3,270 | Not Rated | 2:1 | Thick Liquid (30,000 cP) | -25° to 250° | Off-White | Metal, Plastic | 0000000 | 000000 |

| E-20HP | 6.76 | Cartridge | 20 min. | 24 hrs. | 3,270 | Not Rated | 2:1 | Thick Liquid (30,000 cP) | -25° to 250° | Off-White | Metal, Plastic | 0000000 | 00000 |

| E-20HP | 13.5 | Cartridge | 20 min. | 24 hrs. | 3,270 | Not Rated | 2:1 | Thick Liquid (37,000 cP) | -25° to 250° | Off-White | Metal, Plastic | 0000000 | 000000 |

| E-40FL | 1.69 | Cartridge | 40 min. | 24 hrs. | 640 | Not Rated | 1:1 | Thick Liquid (70,000 cP) | -25° to 250° | Gray | Metal, Metal to Plastic, Metal to Rubber, Metal to Glass, Plastic, Plastic to Rubber, Plastic to Glass, Plastic to Masonry, Rubber, Rubber to Glass, Rubber to Masonry, Ceramic, Glass, Masonry, Wood, Wood to Glass | 0000000 | 00000 |

| E-40FL | 6.76 | Cartridge | 40 min. | 24 hrs. | 640 | Not Rated | 1:1 | Thick Liquid (70,000 cP) | -25° to 250° | Off-White | Metal, Metal to Plastic, Metal to Rubber, Metal to Glass, Plastic, Plastic to Rubber, Plastic to Glass, Plastic to Masonry, Rubber, Rubber to Glass, Rubber to Masonry, Ceramic, Glass, Masonry, Wood, Wood to Glass | 0000000 | 00000 |

| E-40FL | 13.5 | Cartridge | 40 min. | 24 hrs. | 640 | Not Rated | 1:1 | Thick Liquid (70,000 cP) | -25° to 250° | Off-White | Metal, Metal to Plastic, Metal to Rubber, Metal to Glass, Plastic, Plastic to Rubber, Plastic to Glass, Plastic to Masonry, Rubber, Rubber to Glass, Rubber to Masonry, Ceramic, Glass, Masonry, Wood, Wood to Glass | 0000000 | 000000 |

| E-40HT | 1.69 | Cartridge | 40 min. | 24 hrs. | 4,030 | Not Rated | 2:1 | Paste (430,000 cP) | -65° to 300° | Off-White | Metal, Plastic, Rubber | 0000000 | 00000 |

| E-60HP | 1.69 | Cartridge | 60 min. | 24 hrs. | 4,320 | Not Rated | 2:1 | Thick Liquid (45,000 cP) | -25° to 250° | Off-White | Metal, Plastic, Rubber | 0000000 | 00000 |

| E-60HP | 13.5 | Cartridge | 60 min. | 24 hrs. | 4,320 | Not Rated | 2:1 | Thick Liquid (45,000 cP) | -25° to 250° | Off-White | Metal, Plastic, Rubber | 0000000 | 000000 |

| E-90FL | 1.69 | Cartridge | 90 min. | 24 hrs. | 810 | Not Rated | 1:1 | Thick Liquid (40,000 cP) | -25° to 250° | Gray | Metal, Metal to Plastic, Metal to Rubber, Metal to Glass, Plastic, Plastic to Rubber, Plastic to Glass, Plastic to Masonry, Rubber, Rubber to Glass, Rubber to Masonry, Ceramic, Glass, Masonry, Wood, Wood to Glass | 0000000 | 00000 |

| E-90FL | 13.5 | Cartridge | 90 min. | 24 hrs. | 810 | Not Rated | 1:1 | Thick Liquid (40,000 cP) | -25° to 250° | Off-White | Metal, Metal to Plastic, Metal to Rubber, Metal to Glass, Plastic, Plastic to Rubber, Plastic to Glass, Plastic to Masonry, Rubber, Rubber to Glass, Rubber to Masonry, Ceramic, Glass, Masonry, Wood, Wood to Glass | 0000000 | 000000 |

| 9462 | 1.69 | Cartridge | 55 min. | 72 hrs. | 4,180 | 22 | 1:1 | Thick Liquid (70,000 cP) | -65° to 250° | Beige | Metal, Plastic, Rubber | 0000000 | 00000 |

| Each | ||

| Mixer Nozzle for 1.69 fl. oz. Cartridges | 00000000 | 00000 |

| Mixer Nozzle for 6.76 fl. oz. E-20HP Loctite® Cartridges | 0000000 | 0000 |

| Air-Powered Dispensing Gun for 1.69 fl. oz. Loctite® Cartridges | 000000000 | 000000 |

| Dispensing Gun for 1.69 fl. oz. Cartridges | 00000000 | 00000 |

| Dispensing Gun for 6.76 fl. oz. E-20HP Loctite® Cartridges | 0000000 | 000000 |

Optically Clear Epoxy Structural Adhesives

For invisible bond lines, these adhesives dry clear. Epoxies are the strongest and most weather- and chemical-resistant structural adhesives. Choose an epoxy that hardens quickly for fast repairs, or one that hardens slowly to allow more time for positioning.

These have two parts that must be mixed. The size listed is the combined total of the two parts. Use cartridges with a dispensing gun and mixer nozzle to simultaneously mix and dispense adhesives.

0151 and E-30CL are suitable for fiber-optic applications.

E-05CL is toughened to form resilient, impact-resistant bonds on dissimilar materials. It's suitable for use on fiber-optic components.

E-05MR has good moisture resistance. It's toughened to form resilient, impact-resistant bonds on dissimilar materials.

Container | Strength | |||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Mfr. Model No. | Size, fl. oz. | Type | Begins to Harden | Reaches Full Strength | Shear, lbs./sq. in. | Peel, lbs./in. wd. | Mix Ratio | Consistency (Viscosity) | Temp. Range, °F | For Joining | Each | |

| 0151 | 1.69 | Cartridge | 60 min. | 24 hrs. | 2,675 | Not Rated | 2.7:1 | Thick Liquid (60,000 cP) | -65 to 160° F | Metal, Plastic, Rubber, Glass | 00000000 | 000000 |

| 0151 | 3.3 | Tube | 60 min. | 24 hrs. | 2,675 | Not Rated | 2.7:1 | Thick Liquid (60,000 cP) | -65 to 160° F | Metal, Plastic, Rubber, Glass | 00000000 | 00000 |

| 0151 | 41.6 | Can | 60 min. | 24 hrs. | 2,675 | Not Rated | 2.7:1 | Thick Liquid (60,000 cP) | -65 to 160° F | Metal, Plastic, Rubber, Glass | 00000000 | 000000 |

| 608 | 1.69 | Cartridge | 5 min. | 24 hrs. | 2,980 | Not Rated | 1:1 | Paste (100,000 cP) | -65 to 130° F | Metal, Plastic, Rubber | 0000000 | 00000 |

| 608 | 2.8 | Tube | 5 min. | 24 hrs. | 2,980 | Not Rated | 1:1 | Paste (100,000 cP) | -65 to 130° F | Metal, Plastic, Rubber | 00000000 | 00000 |

| D609 | 1.69 | Cartridge | 5 min. | 24 hrs. | 1,800 | Not Rated | 1:1 | Thick Liquid (15,000 cP) | -65 to 180° F | Metal, Plastic, Rubber | 00000000 | 00000 |

| E-05CL | 1.69 | Cartridge | 3 min. | 24 hrs. | 1,430 | Not Rated | 1:1 | Thick Liquid (2,500 cP) | -65 to 180° F | Metal, Metal to Plastic, Metal to Rubber, Plastic, Plastic to Rubber, Rubber | 0000000 | 00000 |

| E-05MR | 1.69 | Cartridge | 5 min. | 24 hrs. | 3,380 | Not Rated | 1:1 | Thick Liquid (25,000 cP) | -65 to 250° F | Metal, Metal to Plastic, Metal to Rubber, Plastic, Plastic to Rubber, Rubber | 0000000 | 00000 |

| E-30CL | 1.69 | Cartridge | 30 min. | 24 hrs. | 3,100 | Not Rated | 2:1 | Thick Liquid (10,000 cP) | -65 to 250° F | Metal, Plastic, Ceramic, Glass | 0000000 | 00000 |

| E-30CL | 6.76 | Cartridge | 30 min. | 24 hrs. | 3,100 | Not Rated | 2:1 | Thick Liquid (10,000 cP) | -65 to 250° F | Metal, Plastic, Ceramic, Glass | 0000000 | 00000 |

| M-31CL | 1.69 | Cartridge | 30 min. | 24 hrs. | 3,100 | Not Rated | 2:1 | Thick Liquid (6,000 cP) | -65 to 300° F | Metal, Plastic, Rubber, Glass | 0000000 | 00000 |

Container | Strength | ||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Mfr. Model No. | Net Weight, oz. | Type | Begins to Harden | Reaches Full Strength | Shear, lbs./sq. in. | Peel | Mix Ratio | Consistency (Viscosity) | Temp. Range, °F | For Joining | Pkg. Qty. | Pkg. | |

Loctite® Adhesives | |||||||||||||

| 608 | 0.14 | One-Time-Use Packet | 5 min. | 24 hrs. | 2,980 | Not Rated | 1:1 | Paste (100,000 cP) | -65° to 130° | Metal, Plastic, Rubber | 10 | 00000000 | 000000 |

| Each | ||

| Mixer Nozzle for 1.69 fl. oz. Loctite® Cartridges | 00000000 | 00000 |

| Mixer Nozzle for 6.76 fl. oz. Loctite® Cartridges | 0000000 | 0000 |

| Dispensing Gun for 1.69 fl. oz Loctite® Cartridges | 00000000 | 00000 |

| Dispensing Gun for 6.76 fl. oz. Loctite® Cartridges | 0000000 | 000000 |

| Air-Powered Dispensing Gun for 1.69 fl. oz. Loctite® Cartridges | 000000000 | 000000 |

Epoxy Structural Adhesives for Harsh Environments

With excellent resistance to corrosive chemicals and salt water, these epoxies work in tough conditions. Epoxies are the strongest structural adhesives. Choose an adhesive that hardens quickly for fast repairs, or one that hardens slowly to allow more time for positioning.

These have two parts that must be mixed. The size listed is the combined total of the two parts. Use cartridges with a dispensing gun and mixer nozzle to simultaneously mix and dispense adhesives.

E-120HP resists acetone, fuel, and oil. It bonds dissimilar materials and withstands rapid changes in temperature.

9430 bonds dissimilar materials and resists fuel and hydraulic fluid.

Mfr. Model | Container | Strength | ||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| No. | Size | Type | Begins to Harden | Reaches Full Strength | Shear, lbs./sq. in. | Peel, lbs./in. wd. | Mix Ratio | Consistency (Viscosity) | Temp. Range, °F | Color | Environment | For Joining | Each | |

Loctite® Adhesives | ||||||||||||||

| E-120HP | 1.69 fl. oz. | Cartridge | 2 hrs. | 24 hrs. | 4,300 | Not Rated | 2:1 | Thick Liquid (30,000 cP) | -65° to 250° | Amber | Corrosive, Salt Spray, Submersible | Metal, Metal to Plastic, Metal to Rubber, Plastic, Plastic to Rubber, Rubber, Ceramic | 0000000 | 000000 |

| E-120HP | 6.76 fl. oz. | Cartridge | 2 hrs. | 24 hrs. | 4,300 | Not Rated | 2:1 | Thick Liquid (30,000 cP) | -65° to 250° | Amber | Corrosive, Salt Spray, Submersible | Metal, Metal to Plastic, Metal to Rubber, Plastic, Plastic to Rubber, Rubber, Ceramic | 0000000 | 00000 |

| E-120HP | 13.5 fl. oz. | Cartridge | 2 hrs. | 24 hrs. | 4,300 | Not Rated | 2:1 | Thick Liquid (30,000 cP) | -65° to 250° | Amber | Corrosive, Salt Spray, Submersible | Metal, Metal to Plastic, Metal to Rubber, Plastic, Plastic to Rubber, Rubber, Ceramic | 0000000 | 000000 |

| 9430 | 32 fl. oz. | Can | 50 min. | 5 days | 4,230 | 60 | 3.78:1 | Thick Liquid (12,000 cP) | -65° to 180° | Off-White | Corrosive, Salt Spray, Submersible | Metal, Metal to Plastic, Metal to Rubber, Plastic, Plastic to Rubber, Rubber | 00000000 | 000000 |

| 9430 | 1.25 gal. | Can | 50 min. | 5 days | 4,230 | 60 | 3.78:1 | Thick Liquid (12,000 cP) | -65° to 180° | Off-White | Corrosive, Salt Spray, Submersible | Metal, Metal to Plastic, Metal to Rubber, Plastic, Plastic to Rubber, Rubber | 00000000 | 000000 |

| Each | ||

| Mixer Nozzle for 1.69 fl. oz. Cartridges | 00000000 | 00000 |

| Mixer Nozzle for 6.76 fl. oz. and 13.5 fl. oz. Cartridges | 0000000 | 0000 |

| Replacement Plunger for 13.5 fl. oz. Cartridges (2:1 Mix Ratio) | 00000000 | 0000 |

| Air-Powered Dispensing Gun for 1.69 fl. oz. Loctite® Cartridges | 000000000 | 000000 |

| Dispensing Gun for 1.69 fl. oz. Cartridges | 00000000 | 00000 |

| Dispensing Gun for 6.76 fl. oz. Cartridges | 0000000 | 000000 |

| Dispensing Gun for 13.5 fl. oz. Cartridges | 0000000 | 000000 |

Low-Odor Epoxy Structural Adhesives

Bond most materials without the strong odor of other epoxy adhesives. The strongest and most weather- and chemical-resistant structural adhesives, epoxies work especially well on metals.

These have two parts that must be mixed. The size listed is the combined total of the two parts. Use cartridges with a dispensing gun and mixer nozzle to simultaneously mix and dispense adhesives.

E-00NS is nonsagging, so it won't drip from vertical or overhead surfaces.

Container | Strength | ||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Mfr. Model No. | Size, fl. oz. | Type | Begins to Harden | Reaches Full Strength | Shear, lbs./sq. in. | Peel, lbs./in. wd. | Mix Ratio | Consistency (Viscosity) | Temp. Range, °F | Color | For Joining | Each | |

Loctite® Adhesives | |||||||||||||

| E-00NS | 1.69 | Cartridge | 3 min. | 24 hrs. | 1,600 | Not Rated | 1:1 | Paste (100,000 cP) | -65° to 180° | White | Metal, Plastic, Rubber | 0000000 | 000000 |

Conductive Adhesives for Electronics

An alternative to solder, these flexible, silver-filled adhesives accommodate joint movement. Use them to bond electrical components and repair circuits.

Epoxy adhesives are two-part adhesives that need to be mixed together. The size listed is the combined total of the two parts.

Adhesives that meet ASTM E595, a standard used by NASA, produce almost no volatile emissions that could damage sensitive electronics, even in a vacuum.

Container | |||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Mfr. Model No. | Net Weight, oz. | Type | Surface Resistivity, ohms-cm | Begins to Harden | Reaches Full Strength | Thermal Conductivity, W/m-K | Mix Ratio | Consistency | Max. Temp., °F | Specifications Met | For Joining | Each | |

Loctite® Adhesives | |||||||||||||

| 2902 | 0.09 | One-Time-Use Packet, Syringe | 1 × 10-3 | 60 min. | 24 hrs. | 2.99 | 100:6 | Paste | 230° | ASTM E595 | Ceramic, Glass, Metal | 00000000 | 000000 |

| 2902 | 0.35 | One-Time-Use Packet, Syringe | 1 × 10-3 | 60 min. | 24 hrs. | 2.99 | 100:6 | Paste | 230° | ASTM E595 | Ceramic, Glass, Metal | 00000000 | 000000 |

Insulating Adhesives for Electronics

Secure hardware on circuit boards while insulating current.

Epoxy adhesives are two-part adhesives that need to be mixed. The size listed is the combined total of the two parts. Loctite® 2151 resist salts, mild acids, and oils. They can also handle sudden impacts and shocks.Adhesives that meet ASTM E595, a standard used by NASA, release almost no volatile emissions that could damage sensitive electronics, even in a vacuum.

![]() Certificates with a traceable lot number and product shelf life are available for these products. Download certificates from ORDER HISTORY after your order ships.

Certificates with a traceable lot number and product shelf life are available for these products. Download certificates from ORDER HISTORY after your order ships.

Container | ||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Mfr. Model No. | Size, fl. oz. | Type | Begins to Harden | Reaches Full Strength | Thermal Conductivity, W/m-K | Mix Ratio | Consistency | Max. Temp., °F | Color | Clarity | Specifications Met | For Joining | Each | |

Loctite® Adhesives | ||||||||||||||

| 2151 | 0.1 | One-Time-Use Packet | 45 min. | 4 hrs. | 0.95 | 100:9.5 | Paste | 235° | Blue | Opaque | ASTM E595 | Metal, Plastic | 000000000 | 000000 |

| 2151 | 0.4 | One-Time-Use Packet | 45 min. | 4 hrs. | 0.95 | 100:9.5 | Paste | 235° | Blue | Opaque | ASTM E595 | Metal, Plastic | 000000000 | 00000 |

Surface Fillers for Metal

Mix these two-part surface fillers together to repair leaks and cracks as well as to rebuild rough spots in metal. The size listed is the combined total of the two parts.

Loctite® Fixmaster Aluminum Liquid and Loctite® Fixmaster Aluminum Putty form a nonrusting finish.

Loctite EA 3471 and PC2 35642 have stronger adhesion than any other surface fillers we offer.

Use Loctite® Fixmaster Steel Epoxy with a dispensing gun and mixer nozzle to mix as you dispense.

Container | ||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Mfr. Model No. | Size | Net Weight | Type | Begins to Harden, min. | Reaches Full Strength, hrs. | Consistency | Mix Ratio | Approx. Coverage @ Thick. | Temp. Range, °F | Color | Finishing Method | For Use On | Each | |

Loctite® Fixmaster Aluminum Liquid | ||||||||||||||

| PC 3466 | __ | 1 lbs. | Jar, Can | 20 | 24 | Thick Liquid | 5:1 | 60 sq. in. @ 1/4" | -20° to 200° | Gray | Machine, Drill, Tap | Aluminum | 0000000 | 0000000 |

Loctite® Fixmaster Aluminum Putty | ||||||||||||||

| PC 7254 | __ | 1 lbs. | Jar | 20 | 24 | Paste | 4:1 | 70 sq. in. @ 1/4" | -20° to 200° | Gray | Machine, Drill, Tap | Aluminum | 0000000 | 000000 |

Loctite® Fixmaster Steel Putty | ||||||||||||||

| EA 3471 | __ | 1 lbs. | Jar | 30 | 24 | Thick Liquid | 2.5:1 | 40 sq. in. @ 1/4" | -20° to 220° | Gray | Machine, Drill, Tap | Bronze, Copper, Steel, Stainless Steel, Cast Iron | 0000000 | 00000 |

| EA 3473 | __ | 1 lbs. | Jar | 3 | 24 | Paste | 1:1 | 50 sq. in. @ 1/4" | -20° to 190° | Gray | Machine, Drill, Tap | Bronze, Copper, Steel, Stainless Steel, Cast Iron | 0000000 | 00000 |

| PC 235642 | __ | 4 lbs. | Can | 30 | 24 | Paste | 2.5:1 | 170 sq. in. @ 1/4" | -20° to 220° | Gray | Machine, Drill, Tap | Bronze, Copper, Steel, Stainless Steel, Cast Iron | 0000000 | 000000 |

Loctite® Fixmaster Steel Epoxy | ||||||||||||||

| PC 3965 | 1.7 fl. oz. | __ | Cartridge | 3 | 7 | Paste | 1:1 | 57 sq. in. @ 1/4" | -20° to 200° | Gray | Machine, Drill, Sand, Tap | Bronze, Copper, Steel, Stainless Steel, Cast Iron | 000000 | 00000 |

Loctite® Fixmaster Stainless Steel Putty | ||||||||||||||

| EA 3476 | __ | 1 lbs. | Jar | 20 | 24 | Paste | 4:1 | 30 sq. in. @ 1/4" | -20° to 220° | Gray | Machine, Drill, Tap | Bronze, Copper, Steel, Stainless Steel, Cast Iron | 0000000 | 000000 |

Large-Particle Abrasion-Resistant Surface Fillers for Metal

For use in processing equipment that carries large particles 1/16" in diameter and larger, these ceramic-filled epoxies rebuild and repair surfaces exposed to abrasion from particles, such as pump housings, chute linings, and hoppers. The size listed is the combined total of the two parts.

Container | ||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Mfr. Model No. | Net Weight, lbs. | Type | Begins to Harden, min. | Reaches Full Strength, hrs. | Consistency | Mix Ratio | Approx. Coverage @ Thick. | Max. Thick. | Temp. Range, °F | Color | Finishing Method | For Use On | Each | |

Loctite® Nordbak Wearing Compound | ||||||||||||||

| PC 7218 | 5 | Jar, Can | 30 | 7 | Paste | 2:1 | 260 sq. in. @ 1/4" | 1/4" | -15° to 250° | Gray | Machine, Drill, Sand, Saw, Tap | Aluminum, Brass, Bronze, Copper, Steel, Stainless Steel, Cast Iron, Titanium | 000000 | 0000000 |

| PC 7218 | 25 | Pail, Can | 30 | 7 | Paste | 2:1 | 1,240 sq. in. @ 1/4" | 1/4" | -15° to 250° | Gray | Machine, Drill, Sand, Saw, Tap | Aluminum, Brass, Bronze, Copper, Steel, Stainless Steel, Cast Iron, Titanium | 000000 | 000000 |

| PC 7357 | 6 | Jar, Can | 25 | 8 | Paste | 2:1 | 310 sq. in. @ 1/4" | 1/4" | -20° to 250° | Gray | Machine, Drill, Sand, Saw, Tap | Aluminum, Brass, Bronze, Copper, Steel, Stainless Steel, Cast Iron, Titanium | 0000000 | 000000 |

| PC 9599 | 6 | Jar, Can | 10 | 3 | Paste | 2:1 | 310 sq. in. @ 1/4" | 1/4" | -20° to 220° | Blue | Machine, Drill, Sand, Saw, Tap | Aluminum, Brass, Bronze, Copper, Steel, Stainless Steel, Cast Iron, Titanium | 000000 | 000000 |

Fine-Particle Abrasion-Resistant Surface Fillers for Metal

For use in processing equipment that carries particles smaller than 1/16" in diameter, these ceramic-filled epoxies rebuild and repair surfaces exposed to abrasion from particles, such as dust collectors, fan blades, and fan housings. The size listed is the combined total of the two parts.

Container | |||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Mfr. Model No. | Net Weight, lbs. | Type | Begins to Harden, min. | Reaches Full Strength, hrs. | Consistency | Mix Ratio | Approx. Coverage @ Thick. | Max. Thick. | For Use Outdoors | Temp. Range, °F | Color | Finishing Method | For Use On | Each | |

Loctite® Fixmaster Wear Resistant Putty | |||||||||||||||

| PC 7222 | 1 | Jar | 30 | 24 | Putty | 2:1 | 50 sq. in. @ 1/4" | 1" | Yes | -20° to 220° | Gray | Sand | Aluminum, Brass, Bronze, Copper, Steel, Stainless Steel, Cast Iron, Titanium | 0000000 | 0000000 |

Loctite® Nordbak Pneu-Wear | |||||||||||||||

| PC 7317 | 3 | Can | 30 | 6 | Paste | 4:1 | 150 sq. in. @ 1/4" | 1/4" | Yes | -20° to 250° | Gray | Machine, Drill, Sand, Saw, Tap | Aluminum, Brass, Bronze, Copper, Steel, Stainless Steel, Cast Iron, Titanium | 000000 | 000000 |

| PC 7317 | 25 | Pail, Can | 30 | 6 | Paste | 4:1 | 1,240 sq. in. @ 1/4" | 1/4" | Yes | -20° to 250° | Gray | Machine, Drill, Sand, Saw, Tap | Aluminum, Brass, Bronze, Copper, Steel, Stainless Steel, Cast Iron, Titanium | 000000 | 000000 |

| PC 7455 | 6 | Can | 10 | 3 | Paste | 2:1 | 310 sq. in. @ 1/4" | 1/4" | Yes | -20° to 220° | Blue | Machine, Drill, Sand, Saw, Tap | Aluminum, Brass, Bronze, Copper, Steel, Stainless Steel, Cast Iron, Titanium | 0000000 | 000000 |

Impact-Resistant Surface Fillers for Metal

These rubber-filled epoxies have excellent wear and impact resistance. Use them to repair and rebuild surfaces such as pump liners, hoppers, and vibrating feeders. The size listed is the combined total of the two parts.

Container | |||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Mfr. Model No. | Net Weight, lbs. | Type | Begins to Harden, min. | Reaches Full Strength, hrs. | Consistency | Mix Ratio | Approx. Coverage @ Thick. | Max. Thick. | For Use Outdoors | Temp. Range, °F | Color | Finishing Method | For Use On | Each | |

Loctite® Nordbak High Impact Wearing Compound | |||||||||||||||

| PC 9313 | 25 | Pail, Can | 30 | 6 | Paste | 2:1 | 1,240 sq. in. @ 1/4" | 1/4" | Yes | -20° to 250° | Gray | Machine, Drill, Sand, Saw, Tap | Aluminum, Brass, Bronze, Copper, Steel, Stainless Steel, Cast Iron, Titanium | 0000000 | 0000000 |

High-Temperature Surface Fillers for Metal

Repair and rebuild metal surfaces that are exposed to heat. These surface fillers withstand temperatures over 450° F. Fillers that have a mix ratio are multi-part fillers. The size listed is the combined total of the parts.

Container | ||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Mfr. Model No. | Size, fl. oz. | Type | Begins to Harden | Reaches Full Strength, hrs. | Consistency | Approx. Coverage @ Thick. | Temp. Range, °F | Color | Finishing Method | For Use On | Each | |

Loctite® Fixmaster 2000° Putty | ||||||||||||

| MR 2000 | 8 | Can | 30 min. | 7 | Putty | 30 sq. in. @ 1/4" | Not Rated to 2000° | Gray | Machine, Drill, Sand, Saw, Tap | Aluminum, Brass, Bronze, Copper, Steel, Stainless Steel, Cast Iron, Titanium | 0000000 | 0000000 |

Chemical-Resistant Surface Fillers for Metal

Chemicals will not affect these two-part epoxies. They repair cracked, worn, and damaged surfaces. The size listed is the combined total of the two parts.

Container | |||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Mfr. Model No. | Net Weight, lbs. | Type | Begins to Harden, min. | Reaches Full Strength | Consistency | Mix Ratio | Approximate Coverage @ Thick. | Max. Thick. | For Use Outdoors | Temp. Range, °F | Color | Finishing Method | For Use On | Each | |

Loctite® Fixmaster Superior Metal | |||||||||||||||

| EA 3478 | 1 | Jar | 20 | 24 hrs. | Paste | 4:1 | 30 sq. in. @ 1/4" | 1" | Yes | -20° to 250° | Gray | Machine, Drill | Aluminum, Brass, Bronze, Copper, Steel, Stainless Steel, Cast Iron, Titanium | 0000000 | 0000000 |

Conductive Surface Fillers for Electronics

A high silver content allows these surface fillers to conduct electricity and heat. Use them to fill gaps and rebuild missing material on electrical connections or to assemble new components. They come as two parts. The size listed is the combined total of the two parts.

Volume resistivity measures how well a material opposes the flow of electricity. The lower the rating, the more electricity it conducts.

Thermal conductivity measures a material’s ability to transfer heat. The higher the rating, the more heat it transfers.

Container | Temp. Range, °F | |||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Mfr. Model No. | Net Weight, oz. | Type | Begins to Harden | Reaches Full Strength | Thermal Conductivity, W/m-K | Volume Resistivity, ohms-cm | Mix Ratio | Min. | Max. | For Use On | Each | |

Loctite® Surface Fillers | ||||||||||||

| 3888 | 0.09 | One-Time-Use Packet | 90 min. | 24 hrs. | 1.44 | 0.001 | 100:6 | -40° | 170° | Aluminum, Brass, Bronze, Copper, Steel, Stainless Steel, Titanium, Polycarbonate Plastic | 0000000 | 000000 |

Surface Fillers

These surface fillers can be used on vertical surfaces without sagging. They repair cracked, worn, and damaged surfaces. The size listed is the combined total of the two parts.

Container | |||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Mfr. Model No. | Size | Net Weight | Type | Begins to Harden, min. | Reaches Full Strength | Consistency | Mix Ratio | Approx. Coverage @ Thick. | Temp. Range, °F | Color | Finishing Method | For Use On | Pkg. Qty. | Pkg. | |

Loctite® Fixmaster Epoxy | |||||||||||||||

| EA 445 | __ | 0.12 oz. | Mixer Cup | 5 | 12 hrs. | Thick Liquid | 1:1 | 1 sq. in. @ 1/4" | -65° to 180° | Gray | Machine, Sand, Tap | Aluminum, Brass, Bronze, Copper, Steel, Stainless Steel, Cast Iron, Titanium, ABS Plastic, CPVC Plastic, PETG Plastic, Polycarbonate Plastic, Polyimide Plastic, Polystyrene Plastic, Polyurethane Rubber, PVC Plastic, PVDF Plastic, Ceramic, Concrete, Glass, Wood | 10 | 0000000 | 000000 |

| EA 445 | __ | 1 oz. | Mixer Cup | 5 | 12 hrs. | Thick Liquid | 1:1 | 1 sq. in. @ 1/4" | -65° to 180° | Gray | Machine, Sand, Tap | Aluminum, Brass, Bronze, Copper, Steel, Stainless Steel, Cast Iron, Titanium, ABS Plastic, CPVC Plastic, PETG Plastic, Polycarbonate Plastic, Polyimide Plastic, Polystyrene Plastic, Polyurethane Rubber, PVC Plastic, PVDF Plastic, Ceramic, Concrete, Glass, Wood | 10 | 0000000 | 000000 |

| EA 9131 | __ | 0.12 oz. | Mixer Cup | 90 | 24 hrs. | Thick Liquid | 1.5:1 | 1 sq. in. @ 1/4" | -65° to 180° | White | Machine, Sand, Tap | Aluminum, Brass, Bronze, Copper, Steel, Stainless Steel, Cast Iron, Titanium, ABS Plastic, CPVC Plastic, PETG Plastic, Polycarbonate Plastic, Polyimide Plastic, Polystyrene Plastic, Polyurethane Rubber, PVC Plastic, PVDF Plastic, Ceramic, Concrete, Glass, Wood | 10 | 0000000 | 00000 |

| Each | |||||||||||||||

Loctite® Fixmaster Poxy Pak™ | |||||||||||||||

| EA 9017 | 0.8 fl. oz. | __ | Syringe | 5 | 60 min. | Thick Liquid | 1:1 | Not Rated | -65° to 300° | Clear | Sand | Aluminum, Brass, Bronze, Copper, Steel, Stainless Steel, Cast Iron, Titanium, ABS Plastic, CPVC Plastic, PETG Plastic, Polycarbonate Plastic, Polyimide Plastic, Polystyrene Plastic, Polyurethane Rubber, PVC Plastic, PVDF Plastic, Concrete, Glass, Wood | __ | 0000000 | 00000 |

Pourable Surface Fillers

Make castings and fill voids with these two-part pourable epoxies. The size listed is the combined total of the two parts.

![]() Certificates with a traceable lot number and product shelf life are available for these products. Download certificates from ORDER HISTORY after your order ships.

Certificates with a traceable lot number and product shelf life are available for these products. Download certificates from ORDER HISTORY after your order ships.

Container | |||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Mfr. Model No. | Net Weight, lbs. | Type | Begins to Harden, min. | Reaches Full Strength, hrs. | Consistency | Mix Ratio | Approximate Coverage @ Thick. | Max. Thick. | For Use Outdoors | Temp. Range, °F | Color | Finishing Method | For Use On | Each | |

Loctite® Fixmaster Steel Liquid | |||||||||||||||

| EA 3472 | 1 | Can | 25 | 24 | Thick Liquid | 4:1 | 50 sq. in. @ 1/4" | 1" | Yes | -20° to 220° | Gray | Machine, Tap | Bronze, Copper, Steel, Stainless Steel, Cast Iron, Concrete | 0000000 | 0000000 |

| EA 3472 | 4 | Can | 25 | 24 | Thick Liquid | 4:1 | 200 sq. in. @ 1/4" | 1" | Yes | -20° to 220° | Gray | Machine, Tap | Bronze, Copper, Steel, Stainless Steel, Cast Iron, Concrete | 0000000 | 000000 |

Water-Resistant Surface Fillers

Mix these two-part epoxy surface fillers to create a strong repair in wet environments or underwater. Use them to repair cracked, worn, and damaged surfaces. Size listed is the combined total of the two parts.

Putty fillers come in a stick with a resin on the outside and a hardener on the inside. Cut the desired amount from the sticks, knead to a uniform color to mix, and press into place. NSF/ANSI 61 surface fillers meet safety standards for use with drinking water.

Container | ||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Mfr. Model No. | Net Weight, oz. | Type | Begins to Harden, min. | Reaches Full Strength | Consistency | Approx. Coverage @ Thick. | Max. Thick. | Temp. Range, °F | Color | Finishing Method | For Use On | Specifications Met | Each | |

Loctite® Fixmaster Metal Magic Steel | ||||||||||||||

| EA 3463 | 4 | Stick | 3 | 24 hrs. | Putty | 10 sq. in. @ 1/4" | 1" | -20° to 250° | Gray | Sand | Bronze, Copper, Steel, Stainless Steel, Cast Iron, Concrete | NSF/ANSI 61 | 0000000 | 000000 |

Loctite® Fixmaster Underwater Repair Epoxy | ||||||||||||||

| EA 9490 | 4 | Stick | 15 | 60 min. | Putty | 16 sq. in. @ 1/4" | 1/4" | Not Rated to 300° | White | Machine, Drill, Sand, Tap | Aluminum, Brass, Bronze, Copper, Steel, Stainless Steel, Cast Iron, Titanium, Polystyrene Plastic, Polycarbonate Plastic, Polyurethane Rubber, ABS Plastic, PVC Plastic, CPVC Plastic, PETG Plastic, PVDF Plastic, Polyimide Plastic, Fiberglass, Concrete, Wood | __ | 0000000 | 00000 |

Epoxy Potting Compounds

Encase electronic assemblies in a layer of epoxy for protection from dust, chemicals, moisture, mechanical shock, and vibration. The strongest of the potting compounds, epoxies are rigid and wear resistant. They have excellent chemical and moisture resistance, withstand a wide range of temperatures, and provide excellent electrical insulation. All require a mixer nozzle and gun to dispense.

Loctite® ES1001™, ES1902™, and ES2500™ come with a mixer nozzle.

Dry Time | ||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Mfr. Model No. | Container Size, fl. oz. | Consistency | Touch, min. | Overall, hrs. | Dielectric Strength, V/mil | Thermal Conductivity, W/m-K | Temp. Range, °F | Specifications Met | For Use On | Color | Each | |

| E-60NC | 1.7 | Thick Liquid | 60 | 24 | 550 | Not Rated | -65° to 250° | __ | Aluminum, Brass, Bronze, Copper, Steel, Stainless Steel, Silver, Titanium, Plastic, Composites, Fiberglass | Black | 0000000 | 000000 |

| E-60NC | 6.8 | Thick Liquid | 60 | 24 | 550 | Not Rated | -65° to 250° | __ | Aluminum, Brass, Bronze, Copper, Steel, Stainless Steel, Silver, Titanium, Plastic, Composites, Fiberglass | Black | 0000000 | 00000 |

| E-60NC | 13.5 | Thick Liquid | 60 | 24 | 550 | Not Rated | -65° to 250° | __ | Aluminum, Brass, Bronze, Copper, Steel, Stainless Steel, Silver, Titanium, Plastic, Composites, Fiberglass | Black | 0000000 | 00000 |

| ES1001 | 1.7 | Thick Liquid | 60 | 24 | 1,100 | 0.29 | -10° to 220° | __ | Aluminum, Brass, Bronze, Copper, Steel, Stainless Steel, Plastic, Ceramic, Glass | Black | 0000000 | 00000 |

| ES1902 | 1.7 | Thin Liquid | 60 | 24 | 1,350 | Not Rated | -40° to 250° | __ | Aluminum, Brass, Bronze, Copper, Steel, Stainless Steel, Plastic | Clear | 0000000 | 00000 |

| ES2500 | 1.7 | Thin Liquid | 10 | 16 | 410 | 0.28 | -40° to 220° | UL 94 HB | Aluminum, Brass, Bronze, Copper, Steel, Stainless Steel, Plastic, Ceramic, Glass | Black | 0000000 | 00000 |

| Dispensing Gun for 1.7 fl. oz. Cartridges | 00000000 | Each | 000000 |

| Mixer Nozzle for 1.7 fl. oz. E-60NC Cartridges | 00000000 | Each | 0000 |

| Mixer Nozzle for 6.8 fl. oz. and 13.5 fl. oz. Cartridges | 0000000 | Each | 0000 |

| Dispensing Gun for 6.8 fl. oz. Cartridges | 0000000 | Each | 000000 |

| Dispensing Gun for 13.5 fl. oz. Cartridges | 0000000 | Each | 000000 |

Light-Activated Epoxy Potting Compounds

Handle potted items within minutes—these potting compounds dry quickly when exposed to UV light. For added strength and durability, cure them with heat. Since they’re epoxy, they won’t break down from chemicals or moisture. They’re also excellent electrical insulators and withstand a wide range of temperatures. Use them to shield components from dust, moisture, chemicals, mechanical shock, and vibration. You need a mixer nozzle (not included) and a gun and plunger (both sold separately) to dispense. The nozzle lets you apply these compounds precisely.

For maximum effectiveness, these compounds need to be heat cured after they’re cured with UV light. Overall dry time includes heat curing at 149° F.

Dry Time | |||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|

| Mfr. Model No. | Container Size, fl. oz. | Consistency | Touch, min. | Overall, hrs. | Light Intensity Requirements to Reach Full Strength | Cure Type | Temp. Range, °F | For Use On | Color | Each | |

Loctite® Compounds—Extra Hard | |||||||||||

| 3336 | 1.4 | Thick Liquid | 5 | 16 | 60 seconds @ 30 mW/cm2 | UV Light | -65° to 350° | Aluminum, Brass, Bronze, Copper, Steel, Stainless Steel, Titanium, Fiberglass, Composites, Plastic, Silver | Amber | 0000000 | 000000 |

| For Cartridge Size | Each | |

| 1.4 fl. oz. | 0000000 | 000000 |

| For Cartridge Size | Each | |

| 1.4 fl oz. | 00000000 | 00000 |

Optically Clear Epoxy Potting Compounds

Clear enough to read through, these UV-resistant potting compounds allow optimal light transmission for use with LEDs, solar cells, and fiber optics. Use them to encase electronic assemblies for protection from dust, chemicals, moisture, mechanical shock, and vibration. Rigid and wear resistant, epoxies are the strongest of the potting compounds. They have excellent chemical and moisture resistance, withstand a wide range of temperatures, and provide excellent electrical insulation. All require a mixer nozzle and gun to dispense.

Loctite® ES1901™ comes with a mixer nozzle.

Dry Time | |||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|

| Mfr. Model No. | Container Size, fl. oz. | Consistency | Touch, min. | Overall, hrs. | Dielectric Strength, V/mil | Thermal Conductivity, W/m-K | Temp. Range, °F | For Use On | Color | Each | |

Loctite® Compounds—Extra Hard | |||||||||||

| ES1901 | 1.7 | Thick Liquid | 3 | 24 | 400 | Not Rated | -40° to 220° | Aluminum, Brass, Bronze, Copper, Steel, Stainless Steel, Plastic, Ceramic, Glass | Clear | 0000000 | 000000 |

Two-Part Adhesive Dispensing Guns | |||

|---|---|---|---|

| Dispensing Gun for 1.7 fl. oz. Cartridges | 00000000 | Each | 000000 |

Heavy Duty High-Purity Coatings for Electronics

This coating is formulated for use in sensitive applications such as manufacturing semiconductors. Thinner than potting compounds, the coating flows easily into small spaces between electrical components. Use it to secure and insulate hardware on printed circuit boards. Rigid and wear resistant, has excellent chemical and moisture resistance, withstands a wide range of temperatures, and provides excellent electrical insulation. It requires a gun and a mixer nozzle (each sold separately) to dispense.

Dry Time | ||||||||||

|---|---|---|---|---|---|---|---|---|---|---|

| Mfr. Model No. | Container Size | Consistency | Touch, min. | Overall, hrs. | Dielectric Strength, V/mil | Temp. Range, °F | For Use On | Color | Each | |

Loctite® Coatings—Extra Hard | ||||||||||

| M-21HP | 1.7 fl. oz. | Paste | 20 | 24 | 500 | -65° to 300° | Aluminum, Brass, Bronze, Copper, Steel, Stainless Steel, Titanium, Silver, Plastic, Composites, Fiberglass | Off-White | 0000000 | 000000 |

Heavy Duty Coatings for Electronics

Thinner than potting compounds, these coatings flow easily into small spaces between electrical components. Use them to secure and insulate hardware on printed circuit boards. Rigid and wear resistant, epoxies have excellent chemical and moisture resistance, withstand a wide range of temperatures, and provide excellent electrical insulation. Dispense with a mixer nozzle and a gun (each sold separately).

Dry Time | ||||||||||

|---|---|---|---|---|---|---|---|---|---|---|

| Mfr. Model No. | Container Size, fl. oz. | Consistency | Touch, min. | Overall, hrs. | Dielectric Strength, V/mil | Temp. Range, °F | For Use On | Color | Each | |

Loctite® Coatings—Extra Hard | ||||||||||

| E-00CL | 1.7 | Thick Liquid | 5 | 24 | 400 | -65° to 180° | Aluminum, Brass, Bronze, Copper, Steel, Stainless Steel, Titanium, Silver, Plastic, Composites, Fiberglass | Clear | 0000000 | 000000 |

| E-00CL | 6.8 | Thick Liquid | 5 | 24 | 400 | -65° to 180° | Aluminum, Brass, Bronze, Copper, Steel, Stainless Steel, Titanium, Silver, Plastic, Composites, Fiberglass | Clear | 0000000 | 00000 |

Low-Friction Epoxy Coatings

Use these coatings on tanks to create a low-friction lining that prevents bubble formation and turbulence in the liquids within. These thick coatings can also be used in chutes and on foundations for a smooth, glossy surface that resists abrasion, chemicals, and extreme temperatures once cured. Apply with a brush or roller. The size listed is the combined total of the two parts.

Dry Time | ||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Mfr. Model Name | Mfr. Model No. | Container Size, gal. | Composition | Touch, hrs. | O'all, hrs. | Approximate Coverage @ Thickness | Application Time After Mixing, min. | Application Temp. Range, °F | For Use On | Color (Appearance) | Each | |

Loctite® Coatings | ||||||||||||

| Nordbak Chemical Resistant Coating | PC 7319 | 1 1/2 | Solvent Based | 4 | 16 | 150 sq. ft. @ 10 mil | 25 | 65° to 80° | Aluminum, Brass, Bronze, Copper, Steel, Stainless Steel, Galvanized Iron, Galvanized Steel, Plastic, Composites, Fiberglass, Ceramic, Glass, Masonry, Concrete, Stone, Asphalt, Drywall, Wood | Gray (Gloss) | 000000 | 0000000 |

Structural Support Epoxies for Heavy Machinery

Fill the void beneath motors, pumps, and other large machinery to create a structural support for your equipment. Also known as chocking epoxies, these epoxies replace traditional metal chocks, which often need to be machined. Mix these two-part epoxies and pour them in between your equipment and your base—they flow into every nook and cranny for a strong, long-lasting bond. As these epoxies cure, they won’t shrink. Designed to withstand demanding environments, these epoxies handle heavy loads, vibration, and chemicals without cracking. Especially good for harsh marine applications, you can use them when installing marine engines and deck-supported equipment, such as hoists and winches.

![]() Certificates with a traceable lot number and product shelf life are available for these products. Download certificates from ORDER HISTORY after your order ships.

Certificates with a traceable lot number and product shelf life are available for these products. Download certificates from ORDER HISTORY after your order ships.

Container | |||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|

| Net Weight, lbs. | Type | Consistency | Viscosity, cP | Color | Begins to Harden, min. | Reaches Full Strength, hrs. | Approx. Coverage @ Thick. | Mix Ratio | Temp. Range, °F | Each | |

Loctite® PC 7202 | |||||||||||

| 7 | Can | Thick Liquid | 15,000 | Orange | 10 | 24 | 123.2 sq. in. @ 1" | 100:11.6 | -20° to 250° | 000000000 | 0000000 |

| 21 1/2 | Pail | Thick Liquid | 15,000 | Orange | 10 | 24 | 378.4 sq. in. @ 1" | 100:11.6 | -20° to 250° | 000000000 | 000000 |