About Precision Flow-Adjustment Valves

More

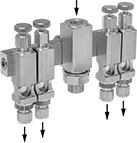

Oil Manifolds

Deliver an equal amount of oil to multiple lubrication points at once. They come with tubing to access hard-to-reach areas. These manifolds can be used with any oil grade.

Oil Outlet | Oil Inlet | Overall | ||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| No. of | Thread Type | Pipe Size | Gender | No. of | Thread Type | Pipe Size | Gender | Ht. | Wd. | Dp. | Flow Rate, oz./min. | Max. Oil Outlet Pressure, psi | Mounting Fasteners Included | Includes | Each | |

| 4 | NPT | 1/8 | Female | 1 | NPT | 1/8 | Female | 1 15/16" | 3 1/8" | 2 5/16" | 2 | 2,130 | Yes | 6 ft. of Nylon Tubing per Outlet, Two Brass Tube Fittings for 1/4" OD Tube per Outlet, Two Steel Tube Clamps with Mounting Screws per Outlet | 000000 | 0000000 |

| 6 | NPT | 1/8 | Female | 1 | NPT | 1/8 | Female | 1 15/16" | 3 5/16" | 2 5/16" | 3 | 2,130 | Yes | 6 ft. of Nylon Tubing per Outlet, Two Brass Tube Fittings for 1/4" OD Tube per Outlet, Two Steel Tube Clamps with Mounting Screws per Outlet | 000000 | 000000 |

| 8 | NPT | 1/8 | Female | 1 | NPT | 1/8 | Female | 1 15/16" | 3 5/16" | 2 5/16" | 4 | 2,130 | Yes | 6 ft. of Nylon Tubing per Outlet, Two Brass Tube Fittings for 1/4" OD Tube per Outlet, Two Steel Tube Clamps with Mounting Screws per Outlet | 000000 | 000000 |

| 12 | NPT | 1/8 | Female | 1 | NPT | 1/8 | Female | 2 7/16" | 3 5/16" | 2 7/16" | 6 | 2,130 | Yes | 6 ft. of Nylon Tubing per Outlet, Two Brass Tube Fittings for 1/4" OD Tube per Outlet, Two Steel Tube Clamps with Mounting Screws per Outlet | 000000 | 000000 |

Flow-Adjustment Valve Manifolds for Sealed Systems

A sealed design prevents contamination in dirty and dusty environments. Use these manifolds to serve multiple lubrication points from a single location. Adjust the flow to individual lubrication points by turning the dial on the corresponding valve. Each valve can be removed for cleaning without disturbing the rest of the system. They can be used with any oil grade. Flow rate depends on temperature. They have NPTF (Dryseal) threads, which are compatible with NPT threads.

Oil Outlet | Oil Inlet | Overall | ||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| No. of | For Tube OD | Gender | Location | Thread Type | Pipe Size | Gender | Ht. | Wd. | Dp. | Max. Oil Outlet Pressure, psi | Material | Temp. Range, °F | Mounting Thread Size | Features | Each | |

| 2 | 1/4" | Female | Top | NPTF | 1/4 | Female | 3 13/16" | 4 3/16" | 1 11/16" | 125 | Aluminum | -30° to 250° | 5/8"-18 | Glass Flow Sight | 0000000 | 0000000 |

| 3 | 1/4" | Female | Top | NPTF | 1/4 | Female | 3 13/16" | 4 15/16" | 1 11/16" | 125 | Aluminum | -30° to 250° | 5/8"-18 | Glass Flow Sight | 0000000 | 000000 |

| 4 | 1/4" | Female | Top | NPTF | 1/4 | Female | 3 13/16" | 5 11/16" | 1 11/16" | 125 | Aluminum | -30° to 250° | 5/8"-18 | Glass Flow Sight | 0000000 | 000000 |

Flow-Adjustment Valve Manifolds for Vented Systems

For use in clean environments, these manifolds have multiple air vents that keep pressure balanced. Use them to serve multiple lubrication points from a single location. Adjust the flow to individual lubrication points by turning the dial on the corresponding valve. Each valve can be removed for cleaning without disturbing the rest of the system. They can be used with any oil grade. Flow rate depends on temperature. They have NPTF (Dryseal) threads, which are compatible with NPT threads.

Oil Outlet | Oil Inlet | Overall | |||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| No. of | For Tube OD | Gender | Location | Thread Type | Pipe Size | Gender | Ht. | Wd. | Dp. | Material | Temp. Range, °F | Mounting Thread Size | Features | Each | |

| 2 | 1/4" | Female | Top | NPTF | 1/4 | Female | 3 13/16" | 4 3/16" | 1 11/16" | Aluminum | -30° to 250° | 5/8"-18 | Glass Flow Sight | 0000000 | 0000000 |

| 3 | 1/4" | Female | Top | NPTF | 1/4 | Female | 3 13/16" | 4 15/16" | 1 11/16" | Aluminum | -30° to 250° | 5/8"-18 | Glass Flow Sight | 0000000 | 000000 |

| 4 | 1/4" | Female | Top | NPTF | 1/4 | Female | 3 13/16" | 5 11/16" | 1 11/16" | Aluminum | -30° to 250° | 5/8"-18 | Glass Flow Sight | 0000000 | 000000 |

Air-Powered Oil-Dispensing Pumps

Connect these modular pumps to your air system and add a reservoir and solenoid valve to automate the flow of oil. Install or remove pumps as your lubrication needs change. Each pump has a separate flow adjustment; use a screwdriver to turn the flow-adjustment screw.

Pumps with spray nozzle provide a broader dispensing pattern. Nozzle bends and stays in position.

Note: For proper operation, pumps require a three-way solenoid valve (sold separately). The solenoid can be controlled by a timer or PLC (programmable logic controller).

Oil Outlet | Oil Inlet | Overall | Air Inlet | Mounting | |||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| No. of Pumps | Oz. per Cycle | Max. Oil Outlet Pressure, psi | Thread Type | Pipe Size | Gender | Thread Type | Pipe Size | Gender | Ht. | Wd. | Air Inlet Pressure, psi | Thread Type | Pipe Size | Gender | Hole Dia. | Fasteners Included | For Max. ISO Viscosity Grade | Each | |

Pumps | |||||||||||||||||||

| 1 | 0-0.007 | 1,080 | NPT | 1/8 | Female | NPT | 1/8 | Female | 4" | 2" | 40-120 | NPT | 1/8 | Female | 9/32" | No | 220 | 0000000 | 0000000 |

| 2 | 0-0.007 | 1,080 | NPT | 1/8 | Female | NPT | 1/8 | Female | 4" | 3 1/4" | 40-120 | NPT | 1/8 | Female | 9/32" | No | 220 | 0000000 | 000000 |

| 4 | 0-0.007 | 1,080 | NPT | 1/8 | Female | NPT | 1/8 | Female | 4" | 5 3/4" | 40-120 | NPT | 1/8 | Female | 9/32" | No | 220 | 0000000 | 000000 |

| 6 | 0-0.007 | 1,080 | NPT | 1/8 | Female | NPT | 1/8 | Female | 4" | 8 1/4" | 40-120 | NPT | 1/8 | Female | 9/32" | No | 220 | 0000000 | 000000 |

Pumps with Spray Nozzle | |||||||||||||||||||

| 1 | 0-0.007 | 1,080 | NPT | 1/8 | Female | NPT | 1/8 | Female | 4" | 2" | 40-120 | NPT | 1/8 | Female | 9/32" | No | 220 | 0000000 | 000000 |

| 2 | 0-0.007 | 1,080 | NPT | 1/8 | Female | NPT | 1/8 | Female | 4" | 3 1/4" | 40-120 | NPT | 1/8 | Female | 9/32" | No | 220 | 0000000 | 000000 |

| 4 | 0-0.007 | 1,080 | NPT | 1/8 | Female | NPT | 1/8 | Female | 4" | 5 3/4" | 40-120 | NPT | 1/8 | Female | 9/32" | No | 220 | 0000000 | 000000 |

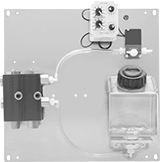

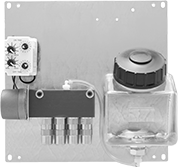

Air-Powered Oil-Dispensing Pump Systems

Ready to connect to your air system, these complete systems include a timer and a reservoir. Turn the dials to set the cycle interval. Each pump has a separate flow adjustment; use a screwdriver to turn the flow-adjustment screw. Pumps and their components come mounted on a panel.

Panel | |||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| No. of Pumps | Cap. | Oz. per Cycle | Dispensing Interval | Max. Oil Outlet Pressure, psi | Ht. | Wd. | Reservoir Material | Air Inlet Pressure, psi | For Air Inlet Tube OD | Voltage | Current, A | Temp. Range, °F | For Max. ISO Viscosity Grade | Each | |

1/8 NPT Female Outlets | |||||||||||||||

| 2 | 16 fl. oz. | 0-0.007 | 0.6 sec.-24 hrs. | 1,080 | 10 3/4" | 10 7/8" | Plastic | 40-120 | 1/4" | 120V AC | 0.06 | -15° to 180° | 220 | 000000 | 0000000 |

| 4 | 1 qt. | 0-0.007 | 0.6 sec.-24 hrs. | 1,080 | 10 3/4" | 10 7/8" | Plastic | 40-120 | 1/4" | 120V AC | 0.06 | -15° to 180° | 220 | 000000 | 000000 |

Oil Outlet | Overall | Mounting | ||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Cap. | No. of | Thread Type | Pipe Size | Gender | Ht. | Wd. | Dp. | Reservoir Material | Temp. Range, °F | Thread Size | Hole Dia. | Fasteners Included | Each | |

| 16 fl. oz. | 1 | NPT | 1/8 | Female | 5 9/16" | 3 1/4" | 3 1/4" | Plastic | 0° to 225° | 5/8"-18 | __ | __ | 0000000 | 000000 |

| 1 qt. | 1 | NPT | 1/8 | Female | 6 13/16" | 4 3/8" | 4 3/8" | Plastic | 0° to 225° | 5/8"-18 | 13/64" | No | 0000000 | 00000 |

Metering Valves for Oil-Dispensing Pumps

Use these valves with manual and electric pumps to dispense different amounts of oil from multiple lubrication points. They have a check valve to prevent backward flow. To connect to tubing, use a compression nut and sleeve (sold separately).

Flow rate trade number indicates the relative amount of oil each valve delivers. For each increase in trade size, the amount of oil delivered approximately doubles. For example, 0 delivers twice the amount of oil that 00 delivers. In a system with two lubrication points, the lubrication point connected to 0 will receive 2/3 of the oil dispensed, and the lubrication point connected to 00 will receive 1/3 of the oil dispensed. In general, valves with lower relative flow rates are better for cycling systems; valves with higher relative flow rates are better for continuous recirculation systems.

Oil Outlet | Oil Inlet | ||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Thread Type | Pipe Size | Thread Size | Gender | Thread Type | Pipe Size | Thread Size | Gender | Max. Oil Outlet Pressure, psi | Lg. | Hex Wd., mm | Material | Temp. Range, °F | Choose a Flow Rate Trade Number | Each | |

| NPT | 1/8 | __ | Male | NPT | 1/8 | __ | Male | 200 | 1" | 10 | Brass | 32° to 120° | 0000000 | 000000 | |

| NPT | 1/8 | __ | Male | UNF | __ | 5/16"-24 | Male | 200 | 1" | 10 | Brass | 32° to 120° | 0000000 | 00000 | |

| UNF | __ | 5/16"-24 | Male | UNF | __ | 5/16"-24 | Male | 200 | 1" | 10 | Brass | 32° to 120° | 0000000 | 00000 | |

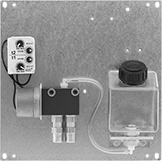

Fixed-Interval Electric Oil-Dispensing Pumps

Choose from pumps that dispense with a set interval. Turn the dial to adjust the flow from 0.1 oz. to 0.2 oz. per cycle. Pumps have a low-level switch that triggers an audible alarm and can be wired to additional, external alarms.

Use metering valves (sold separately) to adjust the flow of oil to multiple lubrication points.

Overall | ||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| No. of Pumps | Cap., qt. | Oz. per Cycle | Max. Oil Outlet Pressure, psi | Ht. | Wd. | Dp. | Reservoir Material | Voltage | Current, A | Temp. Range, °F | For Max. ISO Viscosity Grade | Choose a Dispensing Interval, min. | Each | |

5/16"-24 UNF Female Outlet | ||||||||||||||

| 1 | 2 1/8 | 0.1-0.2 | 40 | 8 7/8" | 7 7/8" | 5 1/8" | Plastic | 120V AC | 0.03 | 32° to 120° | 150 | 000000 | 0000000 | |

Overall | ||||||

|---|---|---|---|---|---|---|

| Ht. | Wd. | Dp. | Reservoir Material | Temp. Range, °F | Each | |

| 6" | 6 1/2" | 4 1/2" | Plastic | 32° to 120° | 0000000 | 0000000 |

Adjustable-Interval Electric Oil-Dispensing Pumps

Set the cycle interval as well as the dispensing duration. This pump has a maximum flow of 0.1 oz. per second. It has a low-level switch that triggers an audible alarm and can be wired to additional, external alarms.

Use metering valves (sold separately) to adjust the flow of oil to multiple lubrication points.

Overall | ||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Cap., qt. | Flow Duration, sec. | Flow Rate, oz./sec. | Dispensing Interval, min. | Max. Oil Outlet Pressure, psi | Ht. | Wd. | Dp. | Reservoir Material | Voltage | Current, A | Temp. Range, °F | For Max. ISO Viscosity Grade | Each | |

5/16"-24 UNF Female Outlet | ||||||||||||||

| 3 1/8 | 1-180 | 0.1 | 3-999 | 100 | 10 1/16" | 8 7/8" | 6 11/16" | Plastic | 120V AC | 0.03 | 32° to 120° | 150 | 000000 | 000000000 |

Overall | ||||||

|---|---|---|---|---|---|---|

| Ht. | Wd. | Dp. | Reservoir Material | Temp. Range, °F | Each | |

| 6 7/16" | 7 7/8" | 5 1/8" | Plastic | 32° to 120° | 0000000 | 0000000 |

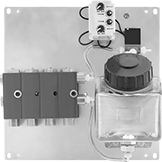

Precision Adjustable-Interval Electric Oil-Dispensing Pumps

With a maximum flow of 0.005 oz. per cycle, these pumps deliver small, precise amounts of oil. Turn the dials to set the cycle interval. Each pump has a separate flow adjustment; use retaining ring pliers to turn the flow-adjustment nut. Pumps and their components come mounted on a panel.

Panel | ||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| No. of Pumps | Cap. | Oz. per Cycle | Dispensing Interval | Max. Oil Outlet Pressure, psi | Ht. | Wd. | Reservoir Material | Pump Material | Voltage | Current, A | Temp. Range, °F | For Max. ISO Viscosity Grade | Each | |

1/8 NPT Female Outlets | ||||||||||||||

| 2 | 16 fl. oz. | 0-0.005 | 1 min.-24 hrs. | 250 | 10 3/4" | 10 7/8" | Plastic | Aluminum | 120V AC | 0.06 | -15° to 120° | 220 | 000000 | 0000000 |

| 4 | 1 qt. | 0-0.005 | 1 min.-24 hrs. | 100 | 10 3/4" | 10 7/8" | Plastic | Aluminum | 120V AC | 0.06 | -15° to 120° | 220 | 000000 | 000000 |

Oil Outlet | Overall | Mounting | ||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Cap. | No. of | Thread Type | Pipe Size | Gender | Ht. | Wd. | Dp. | Reservoir Material | Temp. Range, °F | Thread Size | Hole Dia. | Fasteners Included | Each | |

| 16 fl. oz. | 1 | NPT | 1/8 | Female | 5 9/16" | 3 1/4" | 3 1/4" | Plastic | 0° to 225° | 5/8"-18 | __ | __ | 0000000 | 000000 |

| 1 qt. | 1 | NPT | 1/8 | Female | 6 13/16" | 4 3/8" | 4 3/8" | Plastic | 0° to 225° | 5/8"-18 | 13/64" | No | 0000000 | 00000 |

Manual Oil-Dispensing Pumps

Dispense a fixed amount of oil by pumping the handle. To control flow to multiple lubrication points, use metering valves (sold separately).

Vertical pump dispenses oil when you pull the handle. Horizontal pumps dispense oil when you release the handle.

Oil Outlet | Overall | Mounting | For Max. Viscosity | |||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Cap., fl. oz. | Oz. per Cycle | Max. Oil Outlet Pressure, psi | Thread Type | Thread Size | Gender | Ht. | Wd. | Dp. | Reservoir Material | Temp. Range, °F | Hole Dia. | Fasteners Included | ISO Grade | SAE Grade | SSU Grade | AGMA Grade | Each | |

Vertical with Bottom Handle | ||||||||||||||||||

| 15 | 0.27 | 200 | UNF | 5/16"-24 | Female | 7 7/8" | 3 15/16" | 5 15/16" | Aluminum | 32° to 120° | 1/4" | No | 150 | 40 | 700 | 4 | 000000 | 0000000 |

Horizontal with Left Side Handle | ||||||||||||||||||

| 19 | 0.27 | 50 | UNF | 5/16"-24 | Female | 5" | 3 3/16" | 9 1/4" | Aluminum | 32° to 120° | 1/4" | No | 150 | 40 | 700 | 4 | 000000 | 000000 |

Horizontal with Right Side Handle | ||||||||||||||||||

| 19 | 0.27 | 50 | UNF | 5/16"-24 | Female | 5" | 3 3/16" | 9 1/4" | Aluminum | 32° to 120° | 1/4" | No | 150 | 40 | 700 | 4 | 000000 | 000000 |

Oil-Dispensing Stations

Connect these dispensing stations to your bulk oil container to easily fill hand-held dispensers. They include one faucet and can fit up to three, so you can access different types of oil at a single centralized point.

Overall | For Max. Viscosity | |||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| For Max. Container Ht. | Flow Rate, gpm | Ht. | Wd. | Dp. | No. of Faucet Knockouts | Faucet Mounting Hardware Included | Material | ISO Grade | SAE Grade | SSU Grade | AGMA Grade | Features | Each | |

Station with Faucet | ||||||||||||||

| 14 7/8" | 1.5 | 32 5/8" | 19 3/4" | 10 3/4" | 3 | Yes | Steel | 460 | 140 | 7,750 | 7 | Knockouts for Digital Meters, Removable Drip Tray | 0000000 | 0000000 |

Oil Inlet | |||||||||

|---|---|---|---|---|---|---|---|---|---|

| Flow Rate, gpm | Thread Type | Pipe Size | Gender | Overall Ht. | Projection | Material | Mounting Hardware Included | Each | |

| 1.5 | NPTF | 1/2 | Male | 5 5/8" | 5 5/8" | Stainless Steel, Steel | Yes | 0000000 | 0000000 |

Precision Air-Powered Grease Dispensers

Powered by your air system, these dispensers release a precise amount of grease in timed intervals, so your machine will never have too much or too little. They’ll dispense the right amount even if changing temperatures affect the grease consistency. Back pressure doesn’t impact these dispensers either. But compared to motor-driven dispensers, they’re more complicated to set up. Besides your air system, you’ll need to attach a three-port solenoid valve and either a timer or programmable logic controller (PLC) to control the valve (all not included). If you use a PLC, they’ll prevent over-lubrication when your machine is down by only greasing when it’s running. This is useful for machines with intermittent downtime. Even without a PLC, you can manually cut off the flow without uninstalling the dispenser.

They’re modular, so install or remove pumps as your lubrication needs change. Each pump has mounting holes drilled through their body. Use a screwdriver to turn each pump’s flow-adjustment screw.

These dispensers don’t come with grease, so use the grease that’s best for your machine.

Grease Outlet | Overall | Air Inlet | ||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| No. of Grease Outlets | Cap., fl. oz. | Ounces per Cycle, oz. | For NLGI Viscosity Grade | Max. Grease Outlet Pressure, psi | Thread Type | Pipe Size | Gender | Ht. | Wd. | Max. Distance from Lubrication Point, ft. | Loading Method | Thread Type | Pipe Size | Gender | Each | |

| 1 | 1 1/2 | 0-0.007 | 00, 0, 1, 2 | 1,080 | NPT | 1/8 | Female | 8 5/16" | 3 1/4" | 3 | Grease Gun | NPT | 1/8 | Female | 0000000 | 0000000 |

| 2 | 1 1/2 | 0-0.007 | 00, 0, 1, 2 | 1,080 | NPT | 1/8 | Female | 8 5/16" | 4 1/2" | 3 | Grease Gun | NPT | 1/8 | Female | 0000000 | 000000 |

| 4 | 1 1/2 | 0-0.007 | 00, 0, 1, 2 | 1,080 | NPT | 1/8 | Female | 8 5/16" | 7" | 3 | Grease Gun | NPT | 1/8 | Female | 0000000 | 000000 |

| 6 | 1 1/2 | 0-0.007 | 00, 0, 1, 2 | 1,080 | NPT | 1/8 | Female | 8 5/16" | 9 1/2" | 3 | Grease Gun | NPT | 1/8 | Female | 0000000 | 000000 |

| Add-On Dispenser, 1 1/4" Wd. | 0000000 | Each | 0000000 |

Grease Fitting Manifolds

Save time by sending grease from one fitting to multiple points. These manifolds come with everything you need to set up a remote lubrication system. They deliver the same amount of grease to each lubrication point, so you’ll sometimes see them used to grease an entire machine. All lubrication points connected to the manifold must use the same type of grease.

The tubing attaches to the compression fittings on the manifold’s outlets. To connect the other end of the tubing to your lubrication point, use a compression fitting, an adapter, or both. Adapters come in a variety of shapes and sizes to reach tight or hard-to-reach areas.

Female Compression Tube Outlet | Female NPT Grease Fitting Inlet | Overall | ||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Number of Outlets | For Tube OD | Number of Inlets | Shape | Pipe Size | Wd. | Dp. | Ht. | Max. Pressure, psi | Includes | For NLGI Viscosity Grade | Each | |

Aluminum | ||||||||||||

| 4 | 1/4" | 1 | 65° Elbow | 1/4 | 2 7/8" | 2" | 4" | 2,000 | 25 ft. Lg. 1/4" OD Tubing with NLGI 1 Grease 4 Each 1/8 NPT Male × 1/4" Female Straight Compression Tube Fittings 2 Each 1/8 NPT Female × 1/4"-28 UNF Male Straight Adapters 2 Each 1/8 NPT Female × 1/4"-28 SAE-LT Male 90° Elbow Adapters 2 Each 1/8 NPT Female × 1/8 NPT Male 45° Elbow Adapters 2 Each 1/8 NPT Female × 1/8 NPT Male 90° Elbow Adapters 1 Each Plastic Grease Fitting Dust Cap 8 Each Tubing Inserts 8 Each Cable Ties | 0, 00, 1, 2 | 0000000 | 0000000 |

| 6 | 1/4" | 1 | 65° Elbow | 1/4 | 2 7/8" | 2" | 4" | 2,000 | 50 ft. Lg. 1/4" OD Tubing with NLGI 1 Grease 6 Each 1/8 NPT Male × 1/4" Female Straight Compression Tube Fittings 2 Each 1/8 NPT Female × 1/4"-28 UNF Male Straight Adapters 3 Each 1/8 NPT Female × 1/4"-28 SAE-LT Male 90° Elbow Adapters 2 Each 1/8 NPT Female × 1/8 NPT Male 45° Elbow Adapters 3 Each 1/8 NPT Female × 1/8 NPT Male 90° Elbow Adapters 1 Each Plastic Grease Fitting Dust Cap 12 Each Tubing Inserts 12 Each Cable Ties | 0, 00, 1, 2 | 0000000 | 000000 |

| 12 | 1/4" | 1 | 65° Elbow | 1/4 | 2 7/8" | 2 5/8" | 4" | 2,000 | 100 ft. Lg. 1/4" OD Tubing with NLGI 1 Grease 12 Each 1/8 NPT Male × 1/4" Female Straight Compression Tube Fittings 4 Each 1/8 NPT Female × 1/4"-28 UNF Male Straight Adapters 6 Each 1/8 NPT Female × 1/4"-28 SAE-LT Male 90° Elbow Adapters 4 Each 1/8 NPT Female × 1/8 NPT Male 45° Elbow Adapters 6 Each 1/8 NPT Female × 1/8 NPT Male 90° Elbow Adapters 1 Each Plastic Grease Fitting Dust Cap 24 Each Tubing Inserts 24 Each Cable Ties | 0, 00, 1, 2 | 0000000 | 000000 |

High-Pressure Threaded Precision Flow-Adjustment Manifolds

- Valve Type: Needle

- For Use With: See table

- Seal Material: Fluoroelastomer Rubber

Often attached to differential pressure gauges to measure liquid level in tanks, these manifolds have two isolation valves with a pressure-equalizing valve between them. To isolate your differential pressure gauge for maintenance or calibration, shut off flow on both sides and equalize pressure in the manifold. All manifolds have a 316 stainless steel body for excellent corrosion resistance.

Metal-to-metal seats resist temperature fluctuations.

Flow coefficient (Cv) is the amount of water (in gallons per minute) at 60° F that will flow through a fully open manifold with a difference of 1 psi between the inlet and the outlet.

| Pipe Size | Flow Coefficient (Cv) | Max. Pressure | End-to-End Lg. | For Use With | Each | |

Nickel-Plated and Zinc-Plated 316 Stainless Steel Body—Metal-to-Metal Seat | ||||||

|---|---|---|---|---|---|---|

NPT Female × NPT Female | ||||||

| 1/2 | 0.44 | 10000 psi @ 200° F | 2 7/8" | Water, Oil, Air, Argon, Helium, Krypton, Neon, Xenon | 0000000 | 0000000 |