About Composites

More

About Plastic

More

Marine-Grade Moisture-Resistant Polyethylene (HDPE) Sheets and Bars

- Color: See Table

- Maximum Temperature: 180° F

- Tensile Strength: 4,100 psi (Poor)

- Impact Strength: 1.1 ft.-lbs./in. (Poor)

- Hardness: Durometer 68D (Medium)

- For Use Outdoors: Yes

- Specifications Met: ASTM D4976, UL 94 HB

Also known as starboard, these sheets and bars won’t degrade when exposed to salt water, humidity, and UV light. They’re more rigid than standard HDPE sheets and bars, and have a coarse texture that masks scuffs and scratches.

| Thick. | Thickness Tolerance | Color | Each | |

6" × 6" | ||||

|---|---|---|---|---|

| 3/16" | -0.009" to 0.009" | 00000000 | 00000 | |

| 1/4" | -0.013" to 0.013" | 00000000 | 0000 | |

| 1/2" | -0.025" to 0.025" | 0000000 | 0000 | |

| 3/4" | -0.038" to 0.038" | 00000000 | 0000 | |

| 1" | -0.05" to 0.05" | 00000000 | 00000 | |

12" × 12" | ||||

| 3/16" | -0.009" to 0.009" | 00000000 | 0000 | |

| 1/4" | -0.013" to 0.013" | 00000000 | 00000 | |

| 1/2" | -0.025" to 0.025" | 00000000 | 00000 | |

| 3/4" | -0.038" to 0.038" | 00000000 | 00000 | |

| 1" | -0.05" to 0.05" | 00000000 | 00000 | |

24" × 24" | ||||

| 3/16" | -0.009" to 0.009" | 00000000 | 00000 | |

| 1/4" | -0.013" to 0.013" | 00000000 | 00000 | |

| 1/2" | -0.025" to 0.025" | 00000000 | 00000 | |

| 3/4" | -0.038" to 0.038" | 0000000 | 00000 | |

| 1" | -0.05" to 0.05" | 00000000 | 000000 | |

24" × 48" | ||||

| 3/16" | -0.009" to 0.009" | 00000000 | 00000 | |

| 1/4" | -0.013" to 0.013" | 00000000 | 00000 | |

| 1/2" | -0.025" to 0.025" | 00000000 | 000000 | |

| 3/4" | -0.038" to 0.038" | 00000000 | 000000 | |

| 1" | -0.05" to 0.05" | 00000000 | 000000 | |

36" × 36" | ||||

| 1/4" | -0.013" to 0.013" | 00000000 | 00000 | |

| 1/2" | -0.025" to 0.025" | 00000000 | 000000 | |

| 3/4" | -0.038" to 0.038" | 00000000 | 000000 | |

48" × 48" | ||||

| 3/16" | -0.009" to 0.009" | 00000000 | 00000 | |

| 1/4" | -0.013" to 0.013" | 00000000 | 000000 | |

| 1/2" | -0.025" to 0.025" | 0000000 | 000000 | |

| 3/4" | -0.038" to 0.038" | 00000000 | 000000 | |

| 1" | -0.05" to 0.05" | 00000000 | 000000 | |

48" × 96" | ||||

| 3/16" | -0.009" to 0.009" | 00000000 | 000000 | |

| 1/4" | -0.013" to 0.013" | 00000000 | 000000 | |

| 1/2" | -0.025" to 0.025" | 00000000 | 000000 | |

| 3/4" | -0.038" to 0.038" | 00000000 | 000000 | |

| 1" | -0.05" to 0.05" | 00000000 | 000000 | |

| Wd. | Lg., ft. | Color | Each | |

3/16" Thick. (-0.009" to 0.009") | ||||

|---|---|---|---|---|

| 1" | 4 | 0000000 | 00000 | |

| 2" | 4 | 0000000 | 0000 | |

| 3" | 4 | 0000000 | 0000 | |

| 4" | 4 | 0000000 | 00000 | |

1/4" Thick. (-0.013" to 0.013") | ||||

| 1" | 4 | 0000000 | 0000 | |

| 2" | 4 | 0000000 | 0000 | |

| 3" | 4 | 0000000 | 00000 | |

| 4" | 4 | 0000000 | 00000 | |

1/2" Thick. (-0.025" to 0.025") | ||||

| 1" | 4 | 0000000 | 0000 | |

| 2" | 4 | 0000000 | 00000 | |

| 3" | 4 | 0000000 | 00000 | |

| 4" | 4 | 0000000 | 00000 | |

3/4" Thick. (-0.038" to 0.038") | ||||

| 1" | 1 | 0000000 | 0000 | |

| 1" | 2 | 0000000 | 0000 | |

| 1" | 4 | 0000000 | 00000 | |

| 2" | 1 | 0000000 | 0000 | |

| 2" | 2 | 0000000 | 00000 | |

| 2" | 4 | 0000000 | 00000 | |

| 3" | 1 | 0000000 | 00000 | |

| 3" | 2 | 0000000 | 00000 | |

| 3" | 4 | 0000000 | 00000 | |

| 4" | 1 | 0000000 | 00000 | |

| 4" | 2 | 0000000 | 00000 | |

| 4" | 4 | 0000000 | 00000 | |

1" Thick. (-0.05" to 0.05") | ||||

| 1" | 1 | 0000000 | 0000 | |

| 1" | 2 | 0000000 | 0000 | |

| 1" | 4 | 0000000 | 00000 | |

| 2" | 1 | 0000000 | 0000 | |

| 2" | 2 | 0000000 | 00000 | |

| 2" | 4 | 0000000 | 00000 | |

| 3" | 1 | 0000000 | 00000 | |

| 3" | 2 | 0000000 | 00000 | |

| 3" | 4 | 0000000 | 00000 | |

| 4" | 1 | 0000000 | 00000 | |

| 4" | 2 | 0000000 | 00000 | |

| 4" | 4 | 0000000 | 00000 | |

Recycled Marine-Grade Moisture-Resistant Polyethylene (HDPE) Sheets

- Color: Black

- Maximum Temperature: 180° F

- Tensile Strength: 2,100 psi (Poor)

- Impact Strength: 0.7 ft-lbs./in. (Poor)

- Hardness: Durometer 68D (Medium)

- For Use Outdoors: Yes

Made of recycled HDPE plastic, these sheets are more sustainable and economical than standard marine-grade moisture-resistant HDPE sheets. They won’t absorb moisture or swell when exposed to humidity. They also won’t degrade in salt water. However, their properties have more variance and broader ranges than material that is not recycled. Because these sheets have a low carbon footprint, they can help you meet criteria for sustainability certifications, such as LEED and Envision, or comply with company environmental initiatives.

Coarse sheets are textured to hide scuffs and scratches.

| Thickness | Thickness Tolerance | Each | |

6" × 6" | |||

|---|---|---|---|

Coarse | |||

| 3/4" | -0.038" to 0.038" | 00000000 | 000000 |

Smooth | |||

| 1" | -0.05" to 0.05" | 00000000 | 00000 |

12" × 12" | |||

Coarse | |||

| 3/4" | -0.038" to 0.038" | 00000000 | 00000 |

Smooth | |||

| 1" | -0.05" to 0.05" | 00000000 | 00000 |

24" × 24" | |||

Coarse | |||

| 3/16" | -0.009" to 0.009" | 00000000 | 00000 |

| 1/4" | -0.013" to 0.013" | 00000000 | 00000 |

| 1/2" | -0.025" to 0.025" | 00000000 | 00000 |

| 3/4" | -0.038" to 0.038" | 00000000 | 00000 |

Smooth | |||

| 1" | -0.05" to 0.05" | 00000000 | 000000 |

36" × 36" | |||

Coarse | |||

| 3/16" | -0.009" to 0.009" | 00000000 | 00000 |

| 1/4" | -0.013" to 0.013" | 00000000 | 00000 |

| 1/2" | -0.025" to 0.025" | 00000000 | 000000 |

| 3/4" | -0.038" to 0.038" | 00000000 | 000000 |

Smooth | |||

| 1" | -0.05" to 0.05" | 00000000 | 000000 |

48" × 24" | |||

Coarse | |||

| 3/16" | -0.009" to 0.009" | 00000000 | 00000 |

| 1/4" | -0.013" to 0.013" | 00000000 | 00000 |

| 1/2" | -0.025" to 0.025" | 00000000 | 00000 |

| 3/4" | -0.038" to 0.038" | 00000000 | 000000 |

Smooth | |||

| 1" | -0.05" to 0.05" | 00000000 | 000000 |

48" × 48" | |||

Coarse | |||

| 3/16" | -0.009" to 0.009" | 00000000 | 00000 |

| 1/4" | -0.013" to 0.013" | 00000000 | 00000 |

| 1/2" | -0.025" to 0.025" | 00000000 | 000000 |

| 3/4" | -0.038" to 0.038" | 00000000 | 000000 |

Smooth | |||

| 1" | -0.05" to 0.05" | 00000000 | 000000 |

96" × 48" | |||

Coarse | |||

| 3/16" | -0.009" to 0.009" | 00000000 | 00000 |

| 1/4" | -0.013" to 0.013" | 00000000 | 000000 |

| 1/2" | -0.025" to 0.025" | 00000000 | 000000 |

| 3/4" | -0.038" to 0.038" | 00000000 | 000000 |

Smooth | |||

| 1" | -0.05" to 0.05" | 00000000 | 000000 |

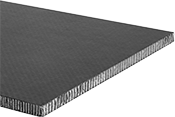

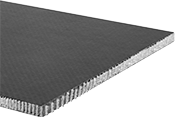

Composite Fiber Aramid Honeycomb Panels

- Face Color: Black

- Temperature Range: -100° to 250° F

- Yield Strength: Not Rated

- For Use Outdoors: No

With an aramid honeycomb core sandwiched between carbon fiber or fiberglass for rigidity, these panels are strong, but lightweight, and won’t conduct heat. Often used as wall panels in structural and insulating applications, they’re a lightweight alternative to solid composite and aluminum honeycomb panels.

Carbon-fiber-faced panels are stronger and more rigid than fiberglass-faced panels, so they resist deforming from bending, twisting, or buckling. They will, however, splinter from high-impact blows. These panels are lighter than fiberglass-faced panels. However, they conduct electricity, so don’t use them around electrical components.

Fiberglass-faced panels are often used around electrical components because they are good electrical insulators. They resist cracks from bumps and hits better than carbon-fiber-faced panels, but are not as strong or lightweight.

| Thickness | Thickness Tolerance | Honeycomb Cell Size | Each | |

12" × 12" | ||||

|---|---|---|---|---|

Carbon Fiber Face | ||||

| 1/8" | -0.03" to 0.03" | 0.125" | 00000000 | 0000000 |

| 1/4" | -0.03" to 0.03" | 0.125" | 00000000 | 000000 |

| 1/2" | -0.06" to 0.06" | 0.125" | 00000000 | 000000 |

Fiberglass Face | ||||

| 1/8" | -0.03" to 0.03" | 0.125" | 00000000 | 000000 |

| 1/4" | -0.03" to 0.03" | 0.125" | 00000000 | 000000 |

| 1/2" | -0.06" to 0.06" | 0.125" | 00000000 | 000000 |

Flexible Aramid Honeycomb Cores

- Color: Orange

- Temperature Range: -100° to 350° F

- Yield Strength: Not Rated

- For Use Outdoors: No

As a strong, lightweight, and buoyant alternative to solid panels, these aramid honeycomb cores are used to make interior wall panels and floor boards in marine, structural, and industrial applications. Compared to aluminum honeycomb cores, they're lightweight and more flexible, so you'll often find them lining boats and high-speed cars. However, they’re not as strong as aluminum cores. Aramid cores also resist flames, self-extinguish without melting or dripping, and are thermal and electrical insulators. Aramid is commonly known as Nomex.