Switch-Off Lifting Magnets

Also known as permanent lifting magnets, these magnets have an on/off handle to engage and release the magnet. They have a lifting eye for attaching a hook or sling. Style B magnet includes a detachable vertical lifting eye that mounts to the side of the magnet to lift plates vertically. Style C magnet has a pivoting lifting eye for both horizontal and vertical lifting.

Style A and B handles lock in both the on and off positions to prevent accidental release. Style C handle locks in the on position only.

Note: Capacities listed are based on lifting flat, rigid metal that has a clean, smooth surface. If used on dirty, oily, thin, or curved surfaces, the capacities will be reduced. Do not use on metal that flexes.

Warning: Never use to lift people or items over people.

For technical drawings and 3-D models, click on a part number.

Magnets | ||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

Lift Cap. @ Material Thick. | Replacement Handles | |||||||||||||

| Horizontal | Vertical | Cap. @ Dia. | Max. Material Lg. @ Material Thick. | Lg. | Wd. | Ht. | Lifting Eye Ht. | Handle Lg. | Max. Temp., °F | Specifications Met | Each | Each | ||

Style A— with Proof Test Certificate | ||||||||||||||

Steel | ||||||||||||||

| 180 lbs. @ 1/4" 250 lbs. @ 1/2" 250 lbs. @ 1" 250 lbs. @ 2" | __ | 125 lbs. @ 2" | 6 ft. @ 1/4" 8 ft. @ 1/2" 10 ft. @ 1" 10 ft. @ 2" | 4 1/2" | 2 1/2" | 5" | 1 3/8" | 4" | 180° | ASME B30.20 | 0000000 | 0000000 | 0000000 | 000000 |

| 270 lbs. @ 1/4" 600 lbs. @ 1/2" 800 lbs. @ 1" 800 lbs. @ 2" | __ | 400 lbs. @ 3" | 6 ft. @ 1/4" 8 ft. @ 1/2" 10 ft. @ 1" 10 ft. @ 2" | 7 3/4" | 3 1/2" | 8 3/4" | 2 3/8" | 8" | 180° | ASME B30.20 | 0000000 | 000000 | 0000000 | 000000 |

| 800 lbs. @ 1/2" 1,600 lbs. @ 1" 1,600 lbs. @ 2" | __ | 800 lbs. @ 4" | 8 ft. @ 1/2" 10 ft. @ 1" 10 ft. @ 2" | 10 3/4" | 4 3/4" | 8 3/4" | 3 1/2" | 9" | 180° | ASME B30.20 | 0000000 | 000000 | 0000000 | 000000 |

| 1,450 lbs. @ 1" 2,500 lbs. @ 2" | __ | 1,250 lbs. @ 5" | 10 ft. @ 1" 10 ft. @ 2" | 12 1/2" | 7" | 8 3/4" | 4 3/4" | 10 3/4" | 180° | ASME B30.20 | 0000000 | 00000000 | 0000000 | 000000 |

| 2,620 lbs. @ 2” 5,000 lbs. @ 3” | __ | 2,500 lbs. @ 14" | 10 ft. @ 2" 10 ft. @ 3” | 16 3/4" | 9 1/4" | 16 3/4" | 6" | 14 3/4" | 180° | ASME B30.20 | 0000000 | 00000000 | 0000000 | 000000 |

Style B— with Proof Test Certificate | ||||||||||||||

Steel | ||||||||||||||

| 670 lbs. @ 1/2" 1,000 lbs. @ 1" 1,000 lbs. @ 2" | 250 lbs. @ 1" | 1,000 lbs. @ 2" | 8 ft. @ 1/2" 10 ft. @ 1" 10 ft. @ 2" | 16 9/16" | 5 7/16" | 8" | 1 13/16" | 10 1/8" | 180° | ASME B30.20 | 0000000 | 00000000 | 0000000 | 000000 |

Style C— with Proof Test Certificate | ||||||||||||||

Steel | ||||||||||||||

| 150 lbs. @ 1/4" 150 lbs. @ 1/2" 150 lbs. @ 1" 150 lbs. @ 2" | 40 lbs. @ 1/4" | 75 lbs. @ 2" | 6 ft. @ 1/4" 8 ft. @ 1/2" 10 ft. @ 1" 10 ft. @ 2" | 5" | 2 1/2" | 10" | 2 1/4" | 2 1/2" | 180° | ASME B30.20 | 0000000 | 000000 | 0000000 | 00000 |

| 270 lbs. @ 1/4" 334 lbs. @ 1/2" 334 lbs. @ 1" 334 lbs. @ 2" | 75 lbs. @ 3/8" | 165 lbs. @ 4" | 6 ft. @ 1/4" 8 ft. @ 1/2" 10 ft. @ 1" 10 ft. @ 2" | 6 1/2" | 4" | 9 1/4" | 2 1/4" | 2 1/2" | 180° | ASME B30.20 | 0000000 | 000000 | 0000000 | 00000 |

| Each | ||

| 0000000 | 0000000 |

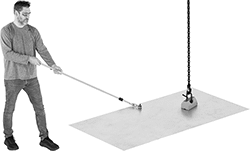

Battery-Powered Magnetic Lifters

Keep a safe distance from heavy loads—these lifters automatically engage when set down, so you don’t have to secure the magnet to the load yourself. When these lifters sense they’ve been set down again, they’ll automatically release the load. Alternatively, use the push buttons on these lifters to manually turn the magnet on and off. As a fail-safe, the magnet stays engaged even if the battery dies, preventing your load from dropping. Pair these lifters with a crane or hoist. They’re often used to move large metal sheets and pipes but can also be used to position loads when grinding or fixturing metal parts together.

You can adjust the magnet’s strength on these lifters to protect thin materials from damage. Fine-tuning the strength is also useful for lifting just one sheet off a stack at a time.

Lifters with a remote control give you a way to manually turn the magnet on or off from a distance.

Warning: Never use to lift people or items over people.

For technical drawings and 3-D models, click on a part number.

| Horizontal Lift Cap. @ Material Thick. | Cap. @ Dia. | Max. Material Lg. @ Material Thick. | Lg. | Wd. | Ht. | Lifting Eye Ht. | Material | Material Orientation | Max. Temp., °F | Batteries Included | Battery Charger Included | Includes | Specifications Met | Each | |

| 154 lbs. @ 1/4" 297 lbs. @ 1/2" 440 lbs. @ 1" | 110 lbs. @ 5.906" | 5 ft. @ 1" | 5 15/16" | 5 5/16" | 11 3/4" | 2 7/8" | Steel | Horizontal | 175° | Yes | Yes | __ | ASME B30.20 | 0000000 | 000000000 |

| 231 lbs. @ 1/4" 518 lbs. @ 1/2" 981 lbs. @ 1" 1,102 lbs. @ 2" | 440 lbs. @ 7.874" | 8 ft. @ 2" | 7 7/8" | 10 3/8" | 15" | 3 3/4" | Steel | Horizontal | 175° | Yes | Yes | Remote Control | ASME B30.20 | 0000000 | 00000000 |

| 418 lbs. @ 1/4" 837 lbs. @ 1/2" 2,017 lbs. @ 1" 2,094 lbs. @ 2" | 880 lbs. @ 7.874" | 8 ft. @ 2" | 14" | 10 9/16" | 15" | 3 3/4" | Steel | Horizontal | 175° | Yes | Yes | Remote Control | ASME B30.20 | 0000000 | 00000000 |

Pry-Off Lifting Magnets

Also known as permanent lifting magnets, these magnets hold a load until you pull the handle and pry the magnet off. They have a lifting eye for attaching a hook or sling.

Style B magnets have a nonmarring roller release that prevents scraping and gouging the load as it is released.

Note: Capacities listed are based on lifting flat metal that has a clean, smooth surface. If used on dirty, oily, thin, or curved surfaces, the capacities will be reduced.

Warning: Never use to lift people or items over people.

For technical drawings and 3-D models, click on a part number.

| Style | Horizontal Lift Cap. @ Material Thick. | Max. Material Lg. @ Material Thick. | Lg. | Wd. | Ht. | Lifting Eye Ht. | Handle Lg. | Material | Max. Temp., °F | Includes | Specifications Met | Each | |

| A | 100 lbs. @ 1/16" 500 lbs. @ 1/4" 1,000 lbs. @ 1" | 3 ft. @ 1/16" 4 ft. @ 1/4" 6 ft. @ 1" | 9 1/2" | 6 1/2" | 3 1/4" | 1 3/4" | 9" | Stainless Steel | 260° | Proof Test Certificate | __ | 0000000 | 0000000 |

| A | 150 lbs. @ 1/16" 750 lbs. @ 1/4" 1,500 lbs. @ 1" | 4 ft. @ 1/16" 6 ft. @ 1/4" 8 ft. @ 1" | 13 3/4" | 6 1/4" | 5" | 3 3/8" | 12" | Stainless Steel | 260° | Proof Test Certificate | __ | 0000000 | 000000 |

| A | 250 lbs. @ 1/16" 1,250 lbs. @ 1/4" 2,500 lbs. @ 1" | 5 ft. @ 1/16" 8 ft. @ 1/4" 12 ft. @ 1" | 16 1/4" | 6 1/4" | 6 1/4" | 3 3/4" | 14 1/2" | Stainless Steel | 260° | Proof Test Certificate | __ | 0000000 | 00000000 |

| B | 400 lbs. @ 1/4" 400 lbs. @ 1" 400 lbs. @ 2" | 6 ft. @ 1/4" 10 ft. @ 1" 10 ft. @ 2" | 7 3/4" | 7 1/4" | 6 3/4" | 2 7/8" | 16" | Stainless Steel | 300° | Proof Test Certificate | ASME B30.20 | 0000000 | 000000 |

| B | 900 lbs. @ 1/4" 1,000 lbs. @ 1" 1,000 lbs. @ 2" | 6 ft. @ 1/4" 10 ft. @ 1" 10 ft. @ 2" | 10 3/4" | 7 1/4" | 6 3/4" | 2 7/8" | 16" | Stainless Steel | 300° | Proof Test Certificate | ASME B30.20 | 0000000 | 000000 |

| B | 1,000 lbs. @ 1/4" 1,500 lbs. @ 1" 1,500 lbs. @ 2" | 6 ft. @ 1/4" 10 ft. @ 1" 10 ft. @ 2" | 14 3/4" | 7 1/4" | 6 3/4" | 2 7/8" | 16" | Stainless Steel | 300° | Proof Test Certificate | ASME B30.20 | 0000000 | 000000 |

| B | 1,100 lbs. @ 1/4" 3,000 lbs. @ 1" 3,000 lbs. @ 2" | 6 ft. @ 1/4" 10 ft. @ 1" 10 ft. @ 2" | 19 1/4" | 10 1/2" | 7" | 2 7/8" | 16" | Stainless Steel | 300° | Proof Test Certificate | ASME B30.20 | 0000000 | 00000000 |

Switch-Off Hand-Held Magnetic Lifters

For heavy loads, these lifters have a stronger magnet than pull-release lifters and a lock to prevent accidental drops. To switch the magnet on and off, turn a handle or push a button. All lifters have a groove for grabbing round materials, such as pipe, in addition to flat materials.

Use push-button lifters one-handed, smoothly switching between lifting and dropping materials without changing your grip. To keep your hand safely away from hot or sharp objects, the buttons on these lifters are on the top of the handle. Since these lifters are battery powered, they’re quicker to turn on and off than lifters with an on/off handle. If the battery dies, the magnet stays on, keeping heavy loads secure.

Style C lifters have a handle that pivots for a comfortable position if you’re pulling sideways or straight up.

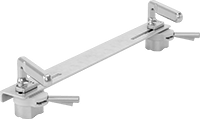

Style D lifters have two magnets to safely move large, heavy objects with either one or two people. You can adjust the distance between the handles.

Warning: Never use to lift people or items over people.

Lift Cap. @ Material Thick. | Overall | |||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Style | Horizontal | Vertical | Lg. | Wd. | Ht. | Material | Material Orientation | Batteries Included | Battery Charger Included | Includes | Each | |

On/Off Handle | ||||||||||||

| A | 60 lbs. @ 3/16" | __ | 6" | 2" | 5" | Steel | Horizontal | __ | __ | __ | 0000000 | 0000000 |

| A | 100 lbs. @ 3/16" | __ | 7 1/2" | 3 3/8" | 7 3/4" | Steel | Horizontal | __ | __ | __ | 0000000 | 000000 |

| B | 70 lbs. @ 2" | 45 lbs. @ 2" | 4 3/4" | 3 3/4" | 4 1/4" | Steel | Horizontal, Vertical | __ | __ | __ | 0000000 | 000000 |

| B | 125 lbs. @ 2" | 75 lbs. @ 2" | 4 3/4" | 3 3/4" | 5" | Steel | Horizontal, Vertical | __ | __ | __ | 0000000 | 000000 |

| C | 60 lbs. @ 2" | 40 lbs. @ 2" | 5 1/4" | 2 1/2" | 5 1/2" | Steel | Horizontal, Vertical | __ | __ | __ | 0000000 | 000000 |

| D | 140 lbs. @ 2" | 90 lbs. @ 2" | 22 1/2" | 5 1/4" | 4 1/2" | Steel | Horizontal, Vertical | __ | __ | __ | 0000000 | 000000 |

Push Button | ||||||||||||

| E | 65 lbs. @ 2" | 35 lbs. @ 2" | 6 3/4" | 3" | 8 1/4" | Steel | Horizontal, Vertical | Yes | Yes | Holster | 0000000 | 000000 |

Pry-Off Hand-Held Magnetic Lifters

A |  B |  C |  D |

E |  F |  G |

A no-frills solution to safely grab machined parts, scrap metal, and other magnetic items. These lifters are often used to move items that are too hot or sharp to handle directly.

Attach lifters with a lifting eye to a hook, rope, or chain to lower them into hard-to-reach places, such as deep bins or waterways. Alternatively, stick them to a magnetic surface and use the lifting eye to route hose, wiring, and other nonmagnetic items. Style E lifters have two different holes for the lifting eye, so you can thread it into different sides.

Lifters with a knob are often found holding documents up against machines.

Lifters with slide-on shields come with covers for the magnet to protect it from damage and wear when not in use.

Warning: Never use to lift people or items over people.

Overall | |||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|

| Style | Capacity, lbs. | Dia. | Lg. | Wd. | Ht. | Eye Dia. | Material | Material Orientation | Includes | Each | |

Pry-Off Handle | |||||||||||

| A | 25 | __ | 1" | 3/4" | 2 1/2" | __ | Steel | Horizontal, Vertical | __ | 0000000 | 00000 |

| A | 50 | __ | 2" | 3/4" | 2" | __ | Steel | Horizontal, Vertical | __ | 0000000 | 00000 |

| A | 100 | __ | 4" | 3/4" | 2 1/2" | __ | Steel | Horizontal, Vertical | __ | 0000000 | 00000 |

| A | 150 | __ | 5" | 2" | 5" | __ | Steel | Horizontal, Vertical | __ | 0000000 | 00000 |

| A | 225 | __ | 5 1/4" | 2" | 5" | __ | Steel | Horizontal, Vertical | __ | 0000000 | 00000 |

| B | 100 | __ | 5 1/4" | 1" | 3 1/2" | __ | Plastic | Horizontal, Vertical | Slide-On Shields | 00000000 | 00000 |

Pry-Off Lifting Eye | |||||||||||

| C | 100 | __ | 2" | 2" | 1" | 1/2" | Steel | Horizontal, Vertical | Slide-On Shields | 0000000 | 00000 |

| C | 150 | __ | 5" | 2" | 2 1/2" | 1/2" | Steel | Horizontal, Vertical | Slide-On Shields | 0000000 | 00000 |

| C | 225 | __ | 5" | 2" | 3 1/2" | 5/8" | Steel | Horizontal, Vertical | __ | 00000000 | 00000 |

| D | 100 | __ | 6" | 3/4" | 2 1/4" | 1/2" | Steel | Horizontal, Vertical | __ | 00000000 | 00000 |

| E | 100 | __ | 2 1/2" | 2 1/2" | 1" | 1/2" | Steel | Horizontal, Vertical | Slide-On Shields | 0000000 | 00000 |

Pry-Off Knob | |||||||||||

| F | 20 | __ | 2 1/2" | 1 1/2" | 1 1/4" | __ | Steel | Horizontal, Vertical | __ | 00000000 | 00000 |

| F | 35 | __ | 2" | 1 3/4" | 1 1/2" | __ | Steel | Horizontal, Vertical | __ | 00000000 | 0000 |

| F | 40 | __ | 2 1/2" | 1 3/4" | 1 1/2" | __ | Steel | Horizontal, Vertical | __ | 00000000 | 0000 |

| F | 45 | __ | 3" | 2 1/2" | 1 1/2" | __ | Steel | Horizontal, Vertical | __ | 00000000 | 0000 |

| G | 16 | 1 1/2" | __ | __ | 1" | __ | Steel | Horizontal, Vertical | __ | 00000000 | 0000 |

| G | 65 | 2 3/4" | __ | __ | 1 1/2" | __ | Steel | Horizontal, Vertical | __ | 00000000 | 0000 |

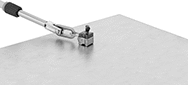

Magnetic Load Positioning Poles

Positioning

Pole

Guide suspended steel sheets, iron pipe, and other magnetic loads by pushing and pulling them from a safe distance. These poles have an on/off magnet at the end—release them by turning a switch on the magnet. Made of fiberglass, these poles are lightweight to reduce arm fatigue. They telescope for extra reach.

For technical drawings and 3-D models, click on a part number.

Pull-Release Hand-Held Magnetic Lifters

Quickly switch between grabbing and dropping items—the magnet on these lifters releases when you squeeze the lever and reengages as soon as you let go. Great for repeat jobs, they’re often used to move large amounts of small magnetic items, such as metal fasteners, from one place to another. They also work well for metal items that are too hot or sharp to handle directly.

Style A-D lifters pick up and release small objects more quickly and easily than Style E lifters.

Style E lifters are best for heavy steel sheets and blocks—they have a larger contact surface area and stronger magnet than Styles A-D.

Stainless steel and steel lifters resist cracking, breaking, and deforming better than plastic lifters.

Warning: Never use to lift people or items over people.

Overall | |||||||||

|---|---|---|---|---|---|---|---|---|---|

| Capacity, lbs. | Dia. | Lg. | Wd. | Ht. | Material | Material Orientation | Each | ||

Pull Lever | |||||||||

| A | 4 | 3 1/2" | __ | __ | 8" | Plastic | Horizontal, Vertical | 0000000 | 000000 |

| B | 2 | __ | 4 3/4" | 1 3/4" | 9 1/4" | Plastic | Horizontal, Vertical | 0000000 | 00000 |

| B | 2 | __ | 4 3/4" | 1 3/4" | 9 1/4" | Stainless Steel | Horizontal, Vertical | 0000000 | 000000 |

| B | 4 | __ | 4 3/4" | 3 1/4" | 9 1/4" | Plastic | Horizontal, Vertical | 0000000 | 00000 |

| B | 6 | __ | 6 1/4" | 4 3/4" | 9 1/4" | Plastic | Horizontal, Vertical | 0000000 | 000000 |

| B | 13 | __ | 11 1/4" | 4 3/4" | 9 3/4" | Steel | Horizontal, Vertical | 00000000 | 000000 |

| C | 9 | 4 1/2" | __ | __ | 9" | Plastic | Horizontal, Vertical | 00000000 | 00000 |

| D | 16 | 3 1/2" | __ | __ | 8 1/2" | Aluminum | Horizontal, Vertical | 0000000 | 00000 |

| D | 25 | 5" | __ | __ | 9 1/4" | Aluminum | Horizontal, Vertical | 0000000 | 00000 |

| E | 150 | __ | 5" | 2 1/4" | 6" | Stainless Steel | Horizontal, Vertical | 00000000 | 00000 |

Long-Reach Hand-Held Magnetic Lifters

Avoid bending down to grab magnetic objects off the ground and out of deep containers. With their long reach, these lifters also keep you at a safe distance from sharp metals.

Lifters with a pull lever or pull bar have a mechanism to engage and release objects, making it easy to drop them into a bin. For pry-off lifters, you’ll need to manually remove your objects from the magnet.

Style E lifters have a narrow end that makes them good for collecting fine materials, such as metallic fillings, turnings, and shavings in tight spots. Made with a stainless steel housing, they resist corrosion, so they’re often used to grab material at the bottom of a water tank.

Thread a handle into Style F lifters to create their long reach. They have a wing nut to adjust the angle of the handle.

Warning: Never use to lift people or items over people.

Overall | |||||||||

|---|---|---|---|---|---|---|---|---|---|

| Style | Capacity, lbs. | Dia. | Lg. | Wd. | Ht. | Material | Material Orientation | Each | |

Pull Lever | |||||||||

| A | 2 | __ | 4 3/4" | 1 3/4" | 32 1/2" | Plastic | Horizontal, Vertical | 0000000 | 000000 |

| B | 4 | 3 1/2" | __ | __ | 28" | Plastic | Horizontal, Vertical | 0000000 | 00000 |

| C | 9 | 4 1/2" | __ | __ | 19 3/4" | Plastic | Horizontal, Vertical | 00000000 | 000000 |

| D | 16 | 3 1/2" | __ | __ | 36 1/2" | Aluminum | Horizontal, Vertical | 0000000 | 000000 |

Pull Bar | |||||||||

| E | 8 | 1" | __ | __ | 16" | Plastic, Stainless Steel | Horizontal, Vertical | 0000000 | 00000 |

| E | 8 | 1" | __ | __ | 41" | Plastic, Stainless Steel | Horizontal, Vertical | 0000000 | 000000 |

Pry Off | |||||||||

| F | 65 | 3 1/4" | __ | __ | 3 1/4" | Plastic | Horizontal, Vertical | 0000000 | 00000 |

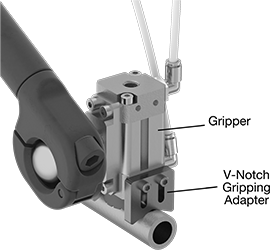

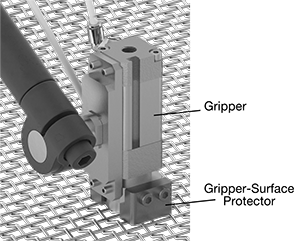

Air-Powered Magnetic Grippers

Connect these magnetic grippers to an air system to lift odd-shaped and perforated metal parts that often cause traditional vacuum cups to lose hold. Designed to work in any position, they only require one flat surface to securely grip parts. All have durable rare earth magnets that stay engaged, so they won’t drop parts in the event of air loss. Plus, unlike electromagnetic grippers, they do not need electric power to create a magnetic hold. Use these grippers in a variety of automated production lines and robotic pick-and-place systems.

Standard and heavy-load grippers have two air connections, one at each end, and a magnetic piston. One connection uses air to extend the piston and grip your part, while the other uses air to retract the piston and release the magnetic hold. All of these grippers have top and side mounting threads for attaching an optional mounting adapter that fits in tool arms commonly found in automation applications. Standard grippers with a stainless steel gripping surface withstand scrapes from parts with rough edges better than those with an aluminum gripping surface. Those with a proximity sensor signal when the magnetic piston is gripping or releasing a part, and uses that information to trigger other actions in your system. The sensors have a standard 4-pole micro M12 plug for electrical connections. Use heavy-load grippers for high temperatures when working near furnaces or near welding jobs.

Grippers with PNP sensors communicate proximity with a positive signal, while those with NPN sensors send a negative signal.

CE-marked grippers meet stringent European Union safety standards.

Friction rings absorb impact as grippers take hold to protect your parts from damage.

Note: Capacities listed are based on lifting flat metal that has a clean, smooth surface. If used on dirty, oily, thin, or curved surfaces, the capacities will be reduced.

Warning: Never use to lift people or items over people.

For technical drawings and 3-D models, click on a part number.

Grippers | ||||||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

O'all | Port | Temp., °F | Top Mount. Location | Side Mount. Location | Replacement Friction Rings | |||||||||||||

| Max. Gripping Cap. | Lg., mm | Wd., mm | Dp., mm | Pressure Range, psi | Pipe Size | Thread Type | Min. | Max. | Plug Type | Pipe Size | Thread Type | Thread Size | Thread Type | Specifications Met | Each | Each | ||

Aluminum Housing with Aluminum Gripping Surface | ||||||||||||||||||

With Friction Ring | ||||||||||||||||||

| 2.6 lbs. / 1.1 kg | 70 | 30 | 30 | 55-85 | 1/8 | BSPP | 45° | 155° | __ | 1/8 | BSPP | M4 × 0.7 mm | Metric | CE Marked | 0000000 | 0000000 | 0000000 | 000000 |

| 7.4 lbs. / 3.3 kg | 70 | 40 | 40 | 55-85 | 1/8 | BSPP | 45° | 155° | __ | 1/4 | BSPP | M4 × 0.7 mm | Metric | CE Marked | 0000000 | 000000 | 0000000 | 00000 |

| 13.4 lbs. / 6.1 kg | 80 | 50 | 50 | 55-85 | 1/8 | BSPP | 45° | 155° | __ | 1/4 | BSPP | M5 × 0.8 mm | Metric | CE Marked | 0000000 | 000000 | 0000000 | 00000 |

| 21.7 lbs. / 9.8 kg | 80 | 70 | 70 | 55-85 | 1/8 | BSPP | 45° | 155° | __ | 1/4 | BSPP | M5 × 0.8 mm | Metric | CE Marked | 0000000 | 000000 | 0000000 | 00000 |

With Friction Ring and PNP Proximity Sensor | ||||||||||||||||||

| 2.6 lbs. / 1.1 kg | 70 | 30 | 30 | 55-85 | 1/8 | BSPP | 45° | 155° | 4-Pole Micro M12 | 1/8 | BSPP | M4 × 0.7 mm | Metric | CE Marked | 0000000 | 000000 | 0000000 | 00000 |

| 7.4 lbs. / 3.3 kg | 70 | 40 | 40 | 55-85 | 1/8 | BSPP | 45° | 155° | 4-Pole Micro M12 | 1/4 | BSPP | M4 × 0.7 mm | Metric | CE Marked | 0000000 | 000000 | 0000000 | 00000 |

| 13.4 lbs. / 6.1 kg | 80 | 50 | 50 | 55-85 | 1/8 | BSPP | 45° | 155° | 4-Pole Micro M12 | 1/4 | BSPP | M5 × 0.8 mm | Metric | CE Marked | 0000000 | 000000 | 0000000 | 00000 |

| 21.7 lbs. / 9.8 kg | 80 | 70 | 70 | 55-85 | 1/8 | BSPP | 45° | 155° | 4-Pole Micro M12 | 1/4 | BSPP | M5 × 0.8 mm | Metric | CE Marked | 0000000 | 000000 | 0000000 | 00000 |

With Friction Ring and NPN Proximity Sensor | ||||||||||||||||||

| 2.6 lbs. / 1.1 kg | 70 | 30 | 30 | 55-85 | 1/8 | BSPP | 45° | 155° | 4-Pole Micro M12 | 1/8 | BSPP | M4 × 0.7 mm | Metric | CE Marked | 0000000 | 000000 | 0000000 | 00000 |

| 7.4 lbs. / 3.3 kg | 70 | 40 | 40 | 55-85 | 1/8 | BSPP | 45° | 155° | 4-Pole Micro M12 | 1/4 | BSPP | M4 × 0.7 mm | Metric | CE Marked | 0000000 | 000000 | 0000000 | 00000 |

| 13.4 lbs. / 6.1 kg | 80 | 50 | 50 | 55-85 | 1/8 | BSPP | 45° | 155° | 4-Pole Micro M12 | 1/4 | BSPP | M5 × 0.8 mm | Metric | CE Marked | 0000000 | 000000 | 0000000 | 00000 |

| 21.7 lbs. / 9.8 kg | 80 | 70 | 70 | 55-85 | 1/8 | BSPP | 45° | 155° | 4-Pole Micro M12 | 1/4 | BSPP | M5 × 0.8 mm | Metric | CE Marked | 0000000 | 000000 | 0000000 | 00000 |

Aluminum Housing with Stainless Steel Gripping Surface | ||||||||||||||||||

With Friction Ring | ||||||||||||||||||

| 2.6 lbs. / 1.1 kg | 70 | 30 | 30 | 55-85 | 1/8 | BSPP | 45° | 155° | __ | 1/8 | BSPP | M4 × 0.7 mm | Metric | CE Marked | 0000000 | 000000 | 0000000 | 00000 |

| 7.4 lbs. / 3.3 kg | 70 | 40 | 40 | 55-85 | 1/8 | BSPP | 45° | 155° | __ | 1/4 | BSPP | M4 × 0.7 mm | Metric | CE Marked | 0000000 | 000000 | 0000000 | 00000 |

| 13.4 lbs. / 6.1 kg | 80 | 50 | 50 | 55-85 | 1/8 | BSPP | 45° | 155° | __ | 1/4 | BSPP | M5 × 0.8 mm | Metric | CE Marked | 0000000 | 000000 | 0000000 | 00000 |

| 21.7 lbs. / 9.8 kg | 80 | 70 | 70 | 55-85 | 1/8 | BSPP | 45° | 155° | __ | 1/4 | BSPP | M5 × 0.8 mm | Metric | CE Marked | 0000000 | 000000 | 0000000 | 00000 |

Grippers | ||||||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

O'all | Port | Temp., °F | Top Mount. Location | Side Mount. Location | Replacement Friction Rings | |||||||||||||

| Max. Gripping Cap. | Lg., mm | Wd., mm | Dp., mm | Pressure Range, psi | Pipe Size | Thread Size | Thread Type | Min. | Max. | Pipe Size | Thread Type | Thread Size | Thread Type | Specifications Met | Each | Each | ||

Aluminum Housing with Aluminum Gripping Surface | ||||||||||||||||||

With Friction Ring | ||||||||||||||||||

| 1.1 lbs. / 0.5 kg | 78 | 20 | 20 | 40-85 | __ | M5 × 0.8 mm | Metric | 45° | 155° | 1/8 | BSPP | M3 × 0.5 mm | Metric | CE Marked | 0000000 | 0000000 | 0000000 | 000000 |

| 6.7 lbs. / 3 kg | 99 | 30 | 30 | 40-85 | 1/8 | __ | BSPP | 45° | 155° | 1/8 | BSPP | M4 × 0.7 mm | Metric | CE Marked | 0000000 | 000000 | 0000000 | 00000 |

| 15.7 lbs. / 7.1 kg | 99 | 40 | 40 | 40-85 | 1/8 | __ | BSPP | 45° | 155° | 1/4 | BSPP | M4 × 0.7 mm | Metric | CE Marked | 0000000 | 000000 | 0000000 | 00000 |

| 21.7 lbs. / 9.8 kg | 123 | 50 | 50 | 40-85 | 1/8 | __ | BSPP | 45° | 155° | 1/4 | BSPP | M5 × 0.8 mm | Metric | CE Marked | 0000000 | 000000 | 0000000 | 00000 |

Gripper (Shown with

Optional Friction Ring)

Grippers | |||||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

O'all | Port | Temp., °F | Top Mount. Location | Side Mount. Location | Optional Friction Rings | ||||||||||||

| Max. Gripping Cap. | Lg., mm | Wd., mm | Dp., mm | Pressure Range, psi | Pipe Size | Thread Type | Min. | Max. | Pipe Size | Thread Type | Thread Size | Thread Type | Specifications Met | Each | Each | ||

Aluminum Housing with Steel Gripping Surface | |||||||||||||||||

| 8.9 lbs. / 4 kg | 99 | 30 | 30 | 40-85 | 1/8 | BSPP | 45° | 300° | 1/8 | BSPP | M4 × 0.7 mm | Metric | CE Marked | 0000000 | 0000000 | 0000000 | 000000 |

| 19.4 lbs. / 8.8 kg | 99 | 40 | 40 | 40-85 | 1/8 | BSPP | 45° | 300° | 1/4 | BSPP | M4 × 0.7 mm | Metric | CE Marked | 0000000 | 000000 | 0000000 | 00000 |

| 27.7 lbs. / 12.5 kg | 123 | 50 | 50 | 40-85 | 1/8 | BSPP | 45° | 300° | 1/4 | BSPP | M5 × 0.8 mm | Metric | CE Marked | 0000000 | 00000000 | 0000000 | 00000 |

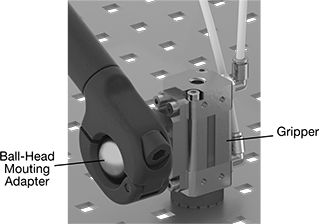

Use mounting adapters for attaching grippers to tool positioning arms. Those for two grippers have more holding strength for heavier parts. They’re also good for handling longer parts.

| For Gripper Width, mm | For Number of Grippers | Bolt Diameter, mm | Ball Diameter, mm | Wt. | Material | Mounting Fasteners Included | Each | |

For Standard Grippers | ||||||||

|---|---|---|---|---|---|---|---|---|

Ball-Head Mounting Adapter | ||||||||

| 30, 40 | 1 | __ | 28.5 | 0.17 lbs./ 0.08 kg | Aluminum | Yes | 0000000 | 0000000 |

| 30, 40 | 2 | __ | 28.5 | 0.25 lbs./ 0.12 kg | Aluminum | Yes | 0000000 | 000000 |

| 50, 70 | 1 | __ | 28.5 | 0.23 lbs./ 0.1 kg | Aluminum | Yes | 0000000 | 000000 |

| 50, 70 | 2 | __ | 28.5 | 0.39 lbs./ 0.18 kg | Aluminum | Yes | 0000000 | 000000 |

Bolt-Head Mounting Adapter | ||||||||

| 30, 40 | 1 | 19 | __ | 0.14 lbs./ 0.06 kg | Aluminum | Yes | 0000000 | 000000 |

| 30, 40 | 2 | 19 | __ | 0.23 lbs./ 0.1 kg | Aluminum | Yes | 0000000 | 000000 |

| 50, 70 | 1 | 19 | __ | 0.18 lbs./ 0.09 kg | Aluminum | Yes | 0000000 | 000000 |

| 50, 70 | 2 | 19 | __ | 0.36 lbs./ 0.16 kg | Aluminum | Yes | 0000000 | 000000 |

For Heavy-Load Grippers and Heavy-Load Grippers for High Temperatures | ||||||||

Ball-Head Mounting Adapter | ||||||||

| 30, 40 | 1 | __ | 28.5 | 0.39 lbs./ 0.18 kg | Aluminum | Yes | 0000000 | 000000 |

| 50 | 1 | __ | 28.5 | 0.47 lbs./ 0.21 kg | Aluminum | Yes | 0000000 | 000000 |

Use robot tool mounts with threaded connections to mount grippers to robot arms with ISO 31.5, 40, 50, or 63 mounting patterns. If you don't see your robot model number listed, measure the bolt circle diameter to determine mounting compatibility.

Robot Tool | End of Robot Arm (Bolt On) | |||||||||

|---|---|---|---|---|---|---|---|---|---|---|

| Pipe Size | Gender | Mounting Fasteners Included | Bolt Circle Dia. (Mounting Hole Pattern Compatibility) | Mounting Fasteners Included | Max. Load Cap. | Includes | For Robot Arm Manufacturer (Series/Model Number) | Each | ||

Threaded | ||||||||||

| For Grippers with 1/8 BSPP Top Mount | 3/8 | Female | Yes | 31.5 mm (ISO 31.5) 40 mm (ISO 40) 50 mm (ISO 50) 63 mm (ISO 63) | Yes | 110 lbs. / 50 kg | Universal 1/8 Male Thread Adapter | ABB (IRB 360 6/1600, 8/1130; IRB 120; IRB 140; IRB 1200; IRB 1410; IRB 1520ID; IRB 1600; IRB 2400; IRB 2600) FANUC (CR 4iA, 7iA; CRX 5iA, 10iA, 10iA/L, 20iA/L, 25iA; LR Mate 200iD/7L; M-20 iA) KUKA Robotics (KR 10 R1100-2) Omron (TM 5, 12, 14) Precise Automation (PAVP6; PF3400; PP100) Productive Robotics (OB7) Staubli (TX2 90) Universal Robots (UR3; UR3e; UR5; UR5e; UR10; UR10e; UR16; UR16e) Yaskawa/Motoman (GP 7, 8; MH 3BM, 3F, 5LS II, 5S II; MPP 3H, 3S; HC 10T; SIA 10D, 10F) | 00000000 | 0000000 |

| For Grippers with 1/4 BSPP Top Mount | 3/8 | Female | Yes | 31.5 mm (ISO 31.5) 40 mm (ISO 40) 50 mm (ISO 50) 63 mm (ISO 63) | Yes | 110 lbs. / 50 kg | Universal 1/4 Male Thread Adapter | ABB (IRB 360 6/1600, 8/1130; IRB 120; IRB 140; IRB 1200; IRB 1410; IRB 1520ID; IRB 1600; IRB 2400; IRB 2600) FANUC (CR 4iA, 7iA; CRX 5iA, 10iA, 10iA/L, 20iA/L, 25iA; LR Mate 200iD/7L; M-20 iA) KUKA Robotics (KR 10 R1100-2) Omron (TM 5, 12, 14) Precise Automation (PAVP6; PF3400; PP100) Productive Robotics (OB7) Staubli (TX2 90) Universal Robots (UR3; UR3e; UR5; UR5e; UR10; UR10e; UR16; UR16e) Yaskawa/Motoman (GP 7, 8; MH 3BM, 3F, 5LS II, 5S II; MPP 3H, 3S; HC 10T; SIA 10D, 10F) | 00000000 | 000000 |

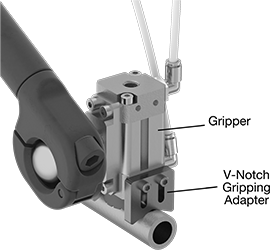

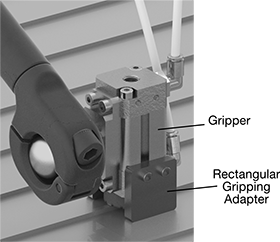

Add V-notch gripping adapters to grippers when you need a better hold on round parts, such as bars and tubes. Use rectangular gripping adapters with grippers for grasping uneven or curved parts that don’t have one flat surface that’s large enough to secure a hold—they’re designed to contact two separate flat surfaces.

| For Gripper Width, mm | For Workpiece Diameter, mm | Wt. | Material | Mounting Fasteners Included | Pair | |

For Heavy-Load Grippers and Heavy-Load Grippers for High Temperatures | ||||||

|---|---|---|---|---|---|---|

V-Notch Gripping Adapter | ||||||

| 20 | 3-10 | 0.03 lbs./0.01 kg | Aluminum | Yes | 0000000 | 0000000 |

| 30, 40 | 10-20 | 0.09 lbs./0.04 kg | Aluminum | Yes | 0000000 | 000000 |

| 50 | 20-30 | 0.11 lbs./0.05 kg | Aluminum | Yes | 0000000 | 000000 |

Rectangular Gripping Adapter | ||||||

| 20 | __ | 0.03 lbs./0.02 kg | Aluminum | Yes | 0000000 | 00000 |

| 30, 40 | __ | 0.09 lbs./0.04 kg | Aluminum | Yes | 0000000 | 00000 |

| 50 | __ | 0.14 lbs./0.06 kg | Aluminum | Yes | 0000000 | 00000 |

Gripper-surface protectors guard gripper surfaces from damage. Use them when handling hard or rough parts, such as metal sheets in hot-forming processes. If your gripper has friction rings, they are usually removed when using these protectors.