About Gas Springs

Gas springs are typically used to assist in opening lids, covers, windows, conveyors, and seats—similar to a hatchback opening on a car.

More

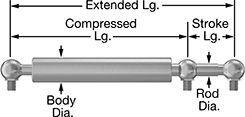

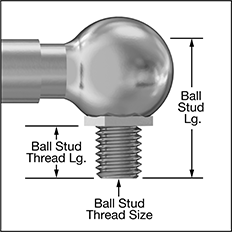

Corrosion-Resistant Long-Life Gas Spring Style Mechanical Springs

With no gas to leak out and a corrosion-resistant 316 stainless steel construction, these mechanical springs are built for long-term, maintenance-free use in wet environments. Unlike gas springs, mechanical springs don’t have seals that can dry out, so they’re a better choice when you need springs to stay in one position for a long time. They also handle vibration better than gas springs. To compensate for misalignment, ball socket end fittings rotate in any direction on the ball stud. The grease on these springs is FDA compliant for incidental food contact.

Rod | Ball Stud | ||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Extended Lg. | Compressed Lg. | Stroke Lg. | Extension Force, lbs. | Compression Force, lbs. | Body Dia. | Dia. | Thread Size | Removable End Fittings | Lg. | Thread Lg. | Thread Size | Temp. Range, °F | Specifications Met | Each | |

316 Stainless Steel Body and Rod | |||||||||||||||

| 9.58" | 7.58" | 2" | 10 | 30 | 1.1" | 0.55" | M10 | Yes | 1.7" | 0.78" | M10 | -50° to 200° | FDA Compliant 21 CFR 178.3570 | 0000000 | 0000000 |

| 15.58" | 11.58" | 4" | 25 | 75 | 1.1" | 0.55" | M10 | Yes | 1.7" | 0.78" | M10 | -50° to 200° | FDA Compliant 21 CFR 178.3570 | 0000000 | 000000 |

| 15.58" | 11.58" | 4" | 30 | 90 | 1.1" | 0.55" | M10 | Yes | 1.7" | 0.78" | M10 | -50° to 200° | FDA Compliant 21 CFR 178.3570 | 0000000 | 000000 |

| 21.58" | 15.58" | 6" | 30 | 90 | 1.1" | 0.55" | M10 | Yes | 1.7" | 0.78" | M10 | -50° to 200° | FDA Compliant 21 CFR 178.3570 | 0000000 | 000000 |

| 21.58" | 15.58" | 6" | 40 | 119 | 1.1" | 0.55" | M10 | Yes | 1.7" | 0.78" | M10 | -50° to 200° | FDA Compliant 21 CFR 178.3570 | 0000000 | 000000 |

| 21.58" | 15.58" | 6" | 60 | 182 | 1.1" | 0.55" | M10 | Yes | 1.7" | 0.78" | M10 | -50° to 200° | FDA Compliant 21 CFR 178.3570 | 0000000 | 000000 |

| 27.58" | 19.58" | 8" | 32 | 96 | 1.1" | 0.55" | M10 | Yes | 1.7" | 0.78" | M10 | -50° to 200° | FDA Compliant 21 CFR 178.3570 | 0000000 | 000000 |

| 27.58" | 21.58" | 6" | 75 | 338 | 1.1" | 0.55" | M10 | Yes | 1.7" | 0.78" | M10 | -50° to 200° | FDA Compliant 21 CFR 178.3570 | 0000000 | 000000 |

| 33.58" | 23.58" | 10" | 35 | 105 | 1.1" | 0.55" | M10 | Yes | 1.7" | 0.78" | M10 | -50° to 200° | FDA Compliant 21 CFR 178.3570 | 0000000 | 000000 |

| 39.58" | 27.58" | 12" | 35 | 105 | 1.1" | 0.55" | M10 | Yes | 1.7" | 0.78" | M10 | -50° to 200° | FDA Compliant 21 CFR 178.3570 | 0000000 | 000000 |

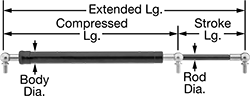

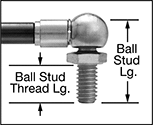

Long-Life Gas Spring Style Mechanical Springs

Mechanical operation means these springs have no seals to fail or gas to leak.

Ball Stud | ||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Extended Lg. | Compressed Lg. | Stroke Lg. | Extension Force, lbs. | Compression Force, lbs. | Body Dia. | Rod Dia. | Rod Thread Size | Removable End Fittings | Lg. | Thread Lg. | Thread Size | Temperature Range, ° F | Each | |

Painted Steel Body and Black Nitride Steel Rod | ||||||||||||||

| 9.58" | 7.58" | 2" | 10 | 30 | 1.1" | 0.55" | M10 | Yes | 1.7" | 0.78" | M10 | -30° to 180° | 0000000 | 0000000 |

| 15.58" | 11.58" | 4" | 25 | 75 | 1.1" | 0.55" | M10 | Yes | 1.7" | 0.78" | M10 | -30° to 180° | 0000000 | 000000 |

| 15.58" | 11.58" | 4" | 30 | 90 | 1.1" | 0.55" | M10 | Yes | 1.7" | 0.78" | M10 | -30° to 180° | 0000000 | 000000 |

| 21.58" | 15.58" | 6" | 30 | 90 | 1.1" | 0.55" | M10 | Yes | 1.7" | 0.78" | M10 | -30° to 180° | 0000000 | 000000 |

| 21.58" | 15.58" | 6" | 40 | 119 | 1.1" | 0.55" | M10 | Yes | 1.7" | 0.78" | M10 | -30° to 180° | 0000000 | 000000 |

| 21.58" | 15.58" | 6" | 60 | 182 | 1.1" | 0.55" | M10 | Yes | 1.7" | 0.78" | M10 | -30° to 180° | 0000000 | 000000 |

| 27.58" | 19.58" | 8" | 32 | 96 | 1.1" | 0.55" | M10 | Yes | 1.7" | 0.78" | M10 | -30° to 180° | 0000000 | 000000 |

| 27.58" | 21.58" | 6" | 75 | 338 | 1.1" | 0.55" | M10 | Yes | 1.7" | 0.78" | M10 | -30° to 180° | 0000000 | 000000 |

| 33.58" | 23.58" | 10" | 5 | 278 | 1.1" | 0.55" | M10 | Yes | 1.7" | 0.78" | M10 | -30° to 180° | 0000000 | 000000 |

| 33.58" | 23.58" | 10" | 35 | 105 | 1.1" | 0.55" | M10 | Yes | 1.7" | 0.78" | M10 | -30° to 180° | 0000000 | 000000 |

| 39.58" | 27.58" | 12" | 35 | 105 | 1.1" | 0.55" | M10 | Yes | 1.7" | 0.78" | M10 | -30° to 180° | 0000000 | 000000 |