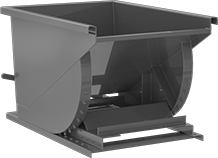

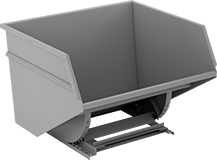

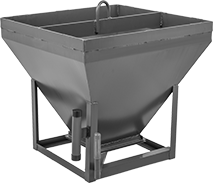

Hoppers

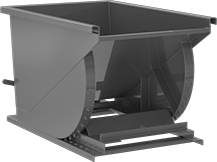

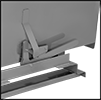

Use a forklift to move these perfectly balanced hoppers, then release the locking latch to dump the load. They automatically return to an upright, locked position. A smooth, formed edge around the top provides durability and the interior seams are welded for strength.

Lids (sold separately) fold open for loading or unloading.

Hoppers | ||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|

Volume Cap. | O'all | Max. Fork | Lids | |||||||||

| O'all Cap., lbs. | cu. ft. | cu. yds. | Lg. | Wd. | Ht. | Wd. | Ht. | Weight, lbs. | Each | Each | ||

Steel | ||||||||||||

| 4,000 | 6 3/4 | 0.25 | 45" | 34" | 22" | 23" | 3" | 270 | 00000000 | 0000000 | 0000000 | 0000000 |

| 4,000 | 9 | 0.33 | 53" | 32" | 33" | 21" | 3" | 340 | 00000000 | 000000 | 0000000 | 000000 |

| 4,000 | 13 1/2 | 0.5 | 53" | 38" | 33" | 27" | 3" | 370 | 0000000 | 000000 | 0000000 | 000000 |

| 4,000 | 20 1/4 | 0.75 | 59" | 40" | 37" | 29" | 3" | 440 | 00000000 | 00000000 | 0000000 | 000000 |

| 4,000 | 27 | 1 | 64" | 40" | 40" | 29" | 3" | 450 | 0000000 | 00000000 | 0000000 | 000000 |

| 4,000 | 40 1/2 | 1.5 | 64" | 58" | 40" | 29" | 3" | 540 | 0000000 | 00000000 | 0000000 | 000000 |

| 4,000 | 54 | 2 | 64" | 58" | 46" | 29" | 3" | 600 | 0000000 | 00000000 | 0000000 | 000000 |

| 4,000 | 67 1/2 | 2.5 | 64" | 70" | 46" | 29" | 3" | 700 | 00000000 | 00000000 | 0000000 | 000000 |

Extra-Durable Hoppers

Built to withstand the heaviest use, these hoppers have thick walls and a 40% thicker frame than other hoppers. Use a forklift to move these perfectly balanced hoppers, then release the locking latch to dump the load. They automatically return to an upright, locked position. A smooth, formed edge around the top provides durability and the interior seams are welded for strength.

Lids (sold separately) fold open for loading or unloading.

Hoppers | ||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|

Volume Cap. | O'all | Max. Fork | Lids | |||||||||

| O'all Cap., lbs. | cu. ft. | cu. yds. | Lg. | Wd. | Ht. | Wd. | Ht. | Weight, lbs. | Each | Each | ||

Steel | ||||||||||||

| 5,000 | 9 | 0.33 | 53" | 32" | 33" | 21" | 3" | 410 | 0000000 | 000000000 | 0000000 | 0000000 |

| 5,000 | 13 1/2 | 0.5 | 53" | 38" | 33" | 27" | 3" | 445 | 0000000 | 00000000 | 0000000 | 000000 |

| 6,000 | 20 1/4 | 0.75 | 59" | 40" | 37" | 29" | 3" | 555 | 0000000 | 00000000 | 0000000 | 000000 |

| 6,000 | 81 | 3 | 71" | 58" | 55" | 29" | 3" | 975 | 0000000 | 00000000 | 0000000 | 000000 |

| 6,000 | 108 | 4 | 71" | 80" | 55" | 43" | 3" | 1,205 | 0000000 | 00000000 | 0000000 | 00000000 |

| 6,000 | 135 | 5 | 71" | 100" | 55" | 43" | 3" | 1,425 | 0000000 | 00000000 | 0000000 | 00000000 |

| 7,000 | 27 | 1 | 64" | 40" | 40" | 29" | 3" | 605 | 0000000 | 00000000 | 0000000 | 000000 |

| 7,000 | 54 | 2 | 64" | 58" | 46" | 29" | 3" | 805 | 0000000 | 00000000 | 0000000 | 000000 |

| 7,000 | 67 1/2 | 2.5 | 71" | 47" | 55" | 29" | 3" | 860 | 0000000 | 00000000 | 0000000 | 000000 |

Strong-Wall Hoppers

These hoppers have thicker walls than standard hoppers for more strength. Use a forklift to move these perfectly balanced hoppers, then release the locking latch to dump the load. They automatically return to an upright, locked position. A smooth, formed edge around the top provides durability and the interior seams are welded for strength.

Lids (sold separately) fold open for loading or unloading.

Hoppers | ||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|

Volume Cap. | O'all | Max. Fork | Lids | |||||||||

| O'all Cap., lbs. | cu. ft. | cu. yds. | Lg. | Wd. | Ht. | Wd. | Ht. | Weight, lbs. | Each | Each | ||

Steel | ||||||||||||

| 4,000 | 6 3/4 | 0.25 | 45" | 34" | 23" | 23" | 3" | 310 | 0000000 | 0000000 | 0000000 | 0000000 |

| 4,000 | 9 | 0.33 | 53" | 32" | 33" | 21" | 3" | 370 | 0000000 | 000000 | 0000000 | 000000 |

| 4,000 | 13 1/2 | 0.5 | 53" | 38" | 33" | 27" | 3" | 405 | 0000000 | 000000 | 0000000 | 000000 |

| 5,000 | 20 1/4 | 0.75 | 59" | 40" | 37" | 29" | 3" | 515 | 0000000 | 00000000 | 0000000 | 000000 |

| 5,000 | 67 1/2 | 2.5 | 64" | 70" | 46" | 29" | 3" | 820 | 0000000 | 00000000 | 0000000 | 000000 |

| 6,000 | 27 | 1 | 64" | 40" | 40" | 29" | 3" | 565 | 0000000 | 00000000 | 0000000 | 000000 |

| 6,000 | 40 1/2 | 1.5 | 64" | 58" | 40" | 29" | 3" | 675 | 0000000 | 00000000 | 0000000 | 000000 |

| 6,000 | 54 | 2 | 64" | 58" | 46" | 29" | 3" | 750 | 0000000 | 00000000 | 0000000 | 000000 |

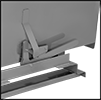

Strong-Wall Mobile Hoppers

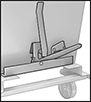

These hoppers have thicker walls than standard hoppers for more strength. Wheel them around or transport with a forklift. Release the locking latch and these perfectly balanced hoppers dump their load then automatically return to an upright, locked position. A smooth, formed edge around the top provides durability and the interior seams are welded for strength. Two swivel and two rigid casters make these hoppers easy to steer.

Iron wheels combine strength and durability with heat resistance. Use on smooth floors. Polyurethane wheels are nonmarking and work well on both smooth and rough floors.

Lids (sold separately) fold open for loading or unloading.

Hoppers | ||||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

Volume Cap. | O'all | Max. Fork | Wheel | Lids | ||||||||||||

| O'all Cap., lbs. | cu. ft. | cu. yds. | Lg. | Wd. | Ht. | Wd. | Ht. | Wheel Configuration | Caster Mount Type | Dia. | Type | Weight, lbs. | Each | Each | ||

Steel | ||||||||||||||||

Iron Wheels | ||||||||||||||||

| 4,000 | 6 3/4 | 0.25 | 45" | 34" | 32" | 23" | 3" | Two Swivel and Two Rigid Casters | Replaceable | 8" | Solid | 370 | 0000000 | 000000000 | 0000000 | 0000000 |

| 4,000 | 9 | 0.33 | 53" | 32" | 42" | 21" | 3" | Two Swivel and Two Rigid Casters | Replaceable | 8" | Solid | 425 | 0000000 | 00000000 | 0000000 | 000000 |

| 4,000 | 13 1/2 | 0.5 | 53" | 38" | 42" | 27" | 3" | Two Swivel and Two Rigid Casters | Replaceable | 8" | Solid | 460 | 0000000 | 00000000 | 0000000 | 000000 |

| 5,000 | 20 1/4 | 0.75 | 59" | 40" | 46" | 29" | 3" | Two Swivel and Two Rigid Casters | Replaceable | 8" | Solid | 585 | 0000000 | 00000000 | 0000000 | 000000 |

| 5,000 | 27 | 1 | 64" | 40" | 49" | 29" | 3" | Two Swivel and Two Rigid Casters | Replaceable | 8" | Solid | 610 | 0000000 | 00000000 | 0000000 | 000000 |

| 5,000 | 40 1/2 | 1.5 | 64" | 58" | 49" | 29" | 3" | Two Swivel and Two Rigid Casters | Replaceable | 8" | Solid | 725 | 0000000 | 00000000 | 0000000 | 000000 |

| 5,000 | 54 | 2 | 64" | 58" | 55" | 29" | 3" | Two Swivel and Two Rigid Casters | Replaceable | 8" | Solid | 780 | 0000000 | 00000000 | 0000000 | 000000 |

| 5,000 | 67 1/2 | 2.5 | 64" | 70" | 55" | 29" | 3" | Two Swivel and Two Rigid Casters | Replaceable | 8" | Solid | 875 | 0000000 | 00000000 | 0000000 | 000000 |

Polyurethane Rubber Wheels | ||||||||||||||||

| 4,000 | 6 3/4 | 0.25 | 45" | 34" | 32" | 23" | 3" | Two Swivel and Two Rigid Casters | Replaceable | 8" | Tread on Core | 355 | 0000000 | 00000000 | 0000000 | 000000 |

| 4,000 | 9 | 0.33 | 53" | 32" | 42" | 21" | 3" | Two Swivel and Two Rigid Casters | Replaceable | 8" | Tread on Core | 470 | 0000000 | 00000000 | 0000000 | 000000 |

| 4,000 | 13 1/2 | 0.5 | 53" | 38" | 42" | 27" | 3" | Two Swivel and Two Rigid Casters | Replaceable | 8" | Tread on Core | 485 | 0000000 | 00000000 | 0000000 | 000000 |

| 5,000 | 20 1/4 | 0.75 | 59" | 40" | 46" | 29" | 3" | Two Swivel and Two Rigid Casters | Replaceable | 8" | Tread on Core | 595 | 0000000 | 00000000 | 0000000 | 000000 |

| 5,000 | 27 | 1 | 64" | 40" | 49" | 29" | 3" | Two Swivel and Two Rigid Casters | Replaceable | 8" | Tread on Core | 630 | 0000000 | 00000000 | 0000000 | 000000 |

| 5,000 | 40 1/2 | 1.5 | 64" | 58" | 49" | 29" | 3" | Two Swivel and Two Rigid Casters | Replaceable | 8" | Tread on Core | 725 | 0000000 | 00000000 | 0000000 | 000000 |

| 5,000 | 54 | 2 | 64" | 58" | 55" | 29" | 3" | Two Swivel and Two Rigid Casters | Replaceable | 8" | Tread on Core | 820 | 0000000 | 00000000 | 0000000 | 000000 |

| 5,000 | 67 1/2 | 2.5 | 64" | 70" | 55" | 29" | 3" | Two Swivel and Two Rigid Casters | Replaceable | 8" | Tread on Core | 915 | 0000000 | 00000000 | 0000000 | 000000 |

Extra-Durable Mobile Hoppers

Built to withstand the heaviest use, these hoppers have thick walls and a 40% thicker frame than other hoppers. Wheel them around or transport with a forklift. Release the locking latch and these perfectly balanced hoppers dump their load then automatically return to an upright, locked position. A smooth, formed edge around the top provides durability and the interior seams are welded for strength. Two swivel and two rigid casters make these hoppers easy to steer.

Iron wheels combine strength and durability with heat resistance. Use on smooth floors. Polyurethane wheels are nonmarking and work well on both smooth and rough floors.

Lids (sold separately) fold open for loading or unloading.

Hoppers | ||||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

Volume Cap. | O'all | Max. Fork | Wheel | Lids | ||||||||||||

| O'all Cap., lbs. | cu. ft. | cu. yds. | Lg. | Wd. | Ht. | Wd. | Ht. | Wheel Configuration | Caster Mount Type | Dia. | Type | Weight, lbs. | Each | Each | ||

Steel | ||||||||||||||||

Iron Wheels | ||||||||||||||||

| 5,000 | 9 | 0.33 | 53" | 32" | 42" | 21" | 3" | Two Swivel and Two Rigid Casters | Replaceable | 8" | Solid | 465 | 0000000 | 000000000 | 0000000 | 0000000 |

| 5,000 | 13 1/2 | 0.5 | 53" | 38" | 42" | 27" | 3" | Two Swivel and Two Rigid Casters | Replaceable | 8" | Solid | 510 | 0000000 | 00000000 | 0000000 | 000000 |

| 5,000 | 20 1/4 | 0.75 | 59" | 40" | 46" | 29" | 3" | Two Swivel and Two Rigid Casters | Replaceable | 8" | Solid | 600 | 0000000 | 00000000 | 0000000 | 000000 |

| 5,000 | 27 | 1 | 64" | 40" | 49" | 29" | 3" | Two Swivel and Two Rigid Casters | Replaceable | 8" | Solid | 660 | 0000000 | 00000000 | 0000000 | 000000 |

| 5,000 | 40 1/2 | 1.5 | 64" | 58" | 49" | 29" | 3" | Two Swivel and Two Rigid Casters | Replaceable | 8" | Solid | 775 | 000000 | 00000000 | 0000000 | 000000 |

| 5,000 | 54 | 2 | 64" | 58" | 55" | 29" | 3" | Two Swivel and Two Rigid Casters | Replaceable | 8" | Solid | 825 | 0000000 | 00000000 | 0000000 | 000000 |

| 5,000 | 67 1/2 | 2.5 | 71" | 47" | 64" | 29" | 3" | Two Swivel and Two Rigid Casters | Replaceable | 8" | Solid | 945 | 0000000 | 00000000 | 0000000 | 000000 |

| 5,000 | 81 | 3 | 71" | 58" | 64" | 29" | 3" | Two Swivel and Two Rigid Casters | Replaceable | 8" | Solid | 1,025 | 0000000 | 00000000 | 0000000 | 000000 |

| 5,000 | 108 | 4 | 71" | 80" | 64" | 43" | 3" | Two Swivel and Two Rigid Casters | Replaceable | 8" | Solid | 1,260 | 0000000 | 00000000 | 0000000 | 00000000 |

| 5,000 | 135 | 5 | 71" | 100" | 64" | 43" | 3" | Two Swivel and Two Rigid Casters | Replaceable | 8" | Solid | 1,465 | 0000000 | 00000000 | 0000000 | 00000000 |

Polyurethane Rubber Wheels | ||||||||||||||||

| 5,000 | 9 | 0.33 | 53" | 32" | 42" | 21" | 3" | Two Swivel and Two Rigid Casters | Replaceable | 8" | Tread on Core | 465 | 0000000 | 00000000 | 0000000 | 000000 |

| 5,000 | 13 1/2 | 0.5 | 53" | 38" | 42" | 27" | 3" | Two Swivel and Two Rigid Casters | Replaceable | 8" | Tread on Core | 510 | 0000000 | 00000000 | 0000000 | 000000 |

| 5,000 | 20 1/4 | 0.75 | 59" | 40" | 46" | 29" | 3" | Two Swivel and Two Rigid Casters | Replaceable | 8" | Tread on Core | 600 | 0000000 | 00000000 | 0000000 | 000000 |

| 5,000 | 27 | 1 | 64" | 40" | 49" | 29" | 3" | Two Swivel and Two Rigid Casters | Replaceable | 8" | Tread on Core | 660 | 0000000 | 00000000 | 0000000 | 000000 |

| 5,000 | 54 | 2 | 64" | 58" | 55" | 29" | 3" | Two Swivel and Two Rigid Casters | Replaceable | 8" | Tread on Core | 860 | 0000000 | 00000000 | 0000000 | 000000 |

| 5,000 | 67 1/2 | 2.5 | 71" | 47" | 64" | 29" | 3" | Two Swivel and Two Rigid Casters | Replaceable | 8" | Tread on Core | 945 | 0000000 | 00000000 | 0000000 | 000000 |

| 5,000 | 81 | 3 | 71" | 58" | 64" | 29" | 3" | Two Swivel and Two Rigid Casters | Replaceable | 8" | Tread on Core | 1,045 | 0000000 | 00000000 | 0000000 | 000000 |

| 5,000 | 108 | 4 | 71" | 80" | 64" | 43" | 3" | Two Swivel and Two Rigid Casters | Replaceable | 8" | Tread on Core | 1,260 | 0000000 | 00000000 | 0000000 | 00000000 |

| 5,000 | 135 | 5 | 71" | 100" | 64" | 43" | 3" | Two Swivel and Two Rigid Casters | Replaceable | 8" | Tread on Core | 1,465 | 0000000 | 00000000 | 0000000 | 00000000 |

Mobile Hoppers

Wheel around these hoppers or transport with a forklift. Two swivel and two rigid casters make these hoppers easy to steer.

Steel hoppers are stronger than polyethylene hoppers. They have a smooth, formed edge around the top for durability and the interior seams are welded for strength. Release the locking latch and these perfectly balanced hoppers dump their load. They automatically return to an upright, locked position.

Iron wheels combine strength and durability with heat resistance. Use on smooth floors. Polyurethane wheels are nonmarking and work well on both smooth and rough floors.

Lids (sold separately) fold open for loading or unloading.

Hoppers | |||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

Volume Cap. | O'all | Max. Fork | Wheel | Lids | |||||||||||

| O'all Cap., lbs. | cu. ft. | cu. yds. | Lg. | Wd. | Ht. | Wd. | Ht. | Caster Mount Type | Dia. | Type | Weight, lbs. | Each | Each | ||

Steel | |||||||||||||||

Iron Wheels | |||||||||||||||

| 3,000 | 13 1/2 | 0.5 | 53" | 38" | 42" | 27" | 3" | Replaceable | 8" | Solid | 435 | 0000000 | 000000000 | 0000000 | 0000000 |

| 4,000 | 27 | 1 | 64" | 40" | 49" | 29" | 3" | Replaceable | 8" | Solid | 480 | 0000000 | 00000000 | 0000000 | 000000 |

| 4,000 | 40 1/2 | 1.5 | 64" | 58" | 49" | 29" | 3" | Replaceable | 8" | Solid | 605 | 0000000 | 00000000 | 0000000 | 000000 |

| 4,000 | 54 | 2 | 64" | 58" | 55" | 29" | 3" | Replaceable | 8" | Solid | 660 | 0000000 | 00000000 | 0000000 | 000000 |

Polyurethane Rubber Wheels | |||||||||||||||

| 3,000 | 13 1/2 | 0.5 | 53" | 38" | 42" | 27" | 3" | Replaceable | 8" | Tread on Core | 415 | 0000000 | 00000000 | 0000000 | 000000 |

| 4,000 | 27 | 1 | 64" | 40" | 49" | 29" | 3" | Replaceable | 8" | Tread on Core | 505 | 0000000 | 00000000 | 0000000 | 000000 |

| 4,000 | 40 1/2 | 1.5 | 64" | 58" | 49" | 29" | 3" | Replaceable | 8" | Tread on Core | 595 | 0000000 | 00000000 | 0000000 | 000000 |

| 4,000 | 54 | 2 | 64" | 58" | 55" | 29" | 3" | Replaceable | 8" | Tread on Core | 635 | 0000000 | 00000000 | 0000000 | 000000 |

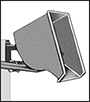

Hook-Mount Hoppers

Hoist these hoppers to move them to your work locations, then open the trapdoor on the bottom to empty.

Style A hoppers have a handle on each side of the trap door. Style B hoppers have one handle for the trapdoor and a shutoff to stop the discharge flow between loads.

Note: Not recommended for fine material such as sand or powder.

Gravity-Feed Bin Boxes

The sloped bottom of the picking bin allows parts to flow forward while the shallow-angle lip makes them easily accessible.

Add up to two feeding bins on top. They have an adjustable front panel and adjustment screw to control the amount of material that flows into the picking box.

Trailer Movers

Make moving and positioning trailers an easier job. The long handle on these movers gives you the leverage you need to roll the trailer. It has a removable hitch ball for connecting to a trailer. The wheels are flat free for easy rolling. Vertical capacity (also known as tongue weight) represents the weight of the load on the drawbar ring or hitch ball.

Hitch Ball | Wheel | |||||||||

|---|---|---|---|---|---|---|---|---|---|---|

| Vertical Capacity, lbs. | Overall Wd. | Dia. | Ht. | Dia. | Construction | Handle Lg. | Material | Color | Each | |

| 600 | 21" | 2" | 17 1/4" | 10" | Flat Free | 37 1/4" | Powder-Coated Steel | Yellow | 00000000 | 0000000 |

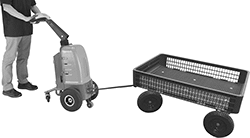

Electric Tuggers

Ease the strain and reduce the risk of injury when pulling heavy carts, trailers, and hoppers—these tuggers are powered by batteries. The handles on these tuggers have a comfortable grip and simple controls: there’s forward, reverse, and a horn. To prevent accidents, these tuggers will stop automatically if you take one of your hands off the handle. The wheels are filled with solid foam, so they won’t go flat.

Use the included pin hitch to attach these tuggers to any pin-compatible connector. You can connect equipment of different hitch heights or ball sizes with the adjustable-height ball-mount hitch (sold separately). To attach these tuggers to equipment without a hitch, use the spring-loaded channel lift (sold separately). Adjust the channel width to grab onto the bottom of trailers and carts.

Body | O'all | Wheel | |||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Cap., lbs. | Material | Color | Lg. | Wd. | Ht. | Handle Lg. | Dia. | Material | Construction | Battery Type | Voltage | Each | |

| 2,000 | Powder-Coated Steel | Yellow | 34" | 25 1/2" | 51" | 11 3/4" | 12" (Load) 4" (Steer) | Rubber | Flat Free | Rechargeable | 24V DC | 00000000 | 000000000 |